Lithium Hydroxide Safety: Protocols For Industrial Handling

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Hydroxide Safety Background and Objectives

Lithium hydroxide (LiOH) has emerged as a critical chemical compound in various industrial applications, particularly in the rapidly expanding lithium-ion battery sector. The historical development of lithium hydroxide usage can be traced back to the mid-20th century, with significant acceleration in the past two decades due to the electric vehicle revolution. This technical evolution has transformed lithium hydroxide from a specialty chemical to a strategic industrial material, with global production increasing tenfold since 2010.

The safety protocols for industrial handling of lithium hydroxide have evolved alongside its increased production volumes. Early handling procedures were often adapted from general caustic material guidelines, but the unique properties of lithium compounds necessitated more specialized approaches. The technical trajectory shows a clear progression from basic containment strategies to sophisticated engineering controls and monitoring systems designed specifically for lithium hydroxide processing environments.

Current technical objectives in lithium hydroxide safety management focus on several key areas: minimizing worker exposure through advanced personal protective equipment and automated handling systems; preventing environmental contamination through improved containment technologies; and developing real-time monitoring capabilities for early detection of potential safety incidents. These objectives align with the broader industry trend toward process intensification while maintaining rigorous safety standards.

The technological landscape for lithium hydroxide safety is characterized by increasing integration of digital monitoring tools, including IoT sensors for atmospheric lithium detection and automated emergency response systems. This represents a significant advancement from the manual monitoring procedures that dominated the industry until approximately 2015. The trend indicates a move toward predictive safety systems rather than reactive protocols.

Research objectives in this field include developing more effective neutralization techniques for lithium hydroxide spills, creating advanced filtration systems for production facilities, and establishing standardized safety protocols that can be implemented across various industrial settings. These objectives are driven by both regulatory requirements and industry recognition of safety as a competitive advantage.

The ultimate technical goal is to establish a comprehensive safety framework that enables the scaling of lithium hydroxide production to meet growing global demand while simultaneously reducing incident rates and severity. This requires addressing the fundamental chemical properties of lithium hydroxide—its high alkalinity (pH >14), water reactivity, and potential for exothermic reactions—through engineered solutions that can be implemented at industrial scale.

The safety protocols for industrial handling of lithium hydroxide have evolved alongside its increased production volumes. Early handling procedures were often adapted from general caustic material guidelines, but the unique properties of lithium compounds necessitated more specialized approaches. The technical trajectory shows a clear progression from basic containment strategies to sophisticated engineering controls and monitoring systems designed specifically for lithium hydroxide processing environments.

Current technical objectives in lithium hydroxide safety management focus on several key areas: minimizing worker exposure through advanced personal protective equipment and automated handling systems; preventing environmental contamination through improved containment technologies; and developing real-time monitoring capabilities for early detection of potential safety incidents. These objectives align with the broader industry trend toward process intensification while maintaining rigorous safety standards.

The technological landscape for lithium hydroxide safety is characterized by increasing integration of digital monitoring tools, including IoT sensors for atmospheric lithium detection and automated emergency response systems. This represents a significant advancement from the manual monitoring procedures that dominated the industry until approximately 2015. The trend indicates a move toward predictive safety systems rather than reactive protocols.

Research objectives in this field include developing more effective neutralization techniques for lithium hydroxide spills, creating advanced filtration systems for production facilities, and establishing standardized safety protocols that can be implemented across various industrial settings. These objectives are driven by both regulatory requirements and industry recognition of safety as a competitive advantage.

The ultimate technical goal is to establish a comprehensive safety framework that enables the scaling of lithium hydroxide production to meet growing global demand while simultaneously reducing incident rates and severity. This requires addressing the fundamental chemical properties of lithium hydroxide—its high alkalinity (pH >14), water reactivity, and potential for exothermic reactions—through engineered solutions that can be implemented at industrial scale.

Industrial Demand Analysis for Lithium Hydroxide

The global lithium hydroxide market has witnessed substantial growth in recent years, primarily driven by the expanding electric vehicle (EV) industry and renewable energy storage systems. As a critical component in the production of high-nickel content cathode materials for lithium-ion batteries, lithium hydroxide demand has surged significantly, with the market value reaching approximately $1.7 billion in 2022 and projected to grow at a CAGR of 9.2% through 2030.

The automotive sector represents the largest consumer of lithium hydroxide, accounting for over 65% of global demand. This is attributed to the superior performance characteristics of lithium hydroxide-based cathodes, which enable higher energy density, improved thermal stability, and extended driving range in EVs. Major automakers have announced ambitious electrification targets, with companies like Volkswagen, GM, and Ford committing to invest billions in EV production capacity over the next decade.

Geographically, China dominates both production and consumption of lithium hydroxide, controlling roughly 60% of global processing capacity. However, significant investments are underway in North America, Europe, and Australia to diversify the supply chain and reduce dependency on Chinese production. The European market is experiencing particularly rapid growth, with demand expected to increase threefold by 2030 as the region accelerates its transition away from internal combustion engines.

The industrial lubricant sector represents another significant application area, albeit smaller than batteries, with lithium hydroxide serving as a key ingredient in lithium-based greases. These specialized lubricants offer exceptional performance under extreme temperatures and pressures, making them valuable in automotive, aerospace, and industrial machinery applications.

Supply constraints have created significant price volatility in recent years, with lithium hydroxide prices reaching historic highs in 2022 before moderating somewhat in 2023. This volatility has prompted end-users to pursue long-term supply agreements and vertical integration strategies to secure stable access to this critical material.

Safety considerations are increasingly influencing market dynamics, with manufacturers implementing more stringent handling protocols and investing in advanced containment systems. This trend is driving demand for specialized safety equipment, training programs, and engineering controls specifically designed for lithium hydroxide processing environments.

The pharmaceutical and consumer goods industries represent smaller but growing market segments, with lithium hydroxide utilized in the synthesis of certain medications and as a component in specialty ceramics and glass products. These applications typically require higher purity grades and more specialized handling procedures than battery applications.

The automotive sector represents the largest consumer of lithium hydroxide, accounting for over 65% of global demand. This is attributed to the superior performance characteristics of lithium hydroxide-based cathodes, which enable higher energy density, improved thermal stability, and extended driving range in EVs. Major automakers have announced ambitious electrification targets, with companies like Volkswagen, GM, and Ford committing to invest billions in EV production capacity over the next decade.

Geographically, China dominates both production and consumption of lithium hydroxide, controlling roughly 60% of global processing capacity. However, significant investments are underway in North America, Europe, and Australia to diversify the supply chain and reduce dependency on Chinese production. The European market is experiencing particularly rapid growth, with demand expected to increase threefold by 2030 as the region accelerates its transition away from internal combustion engines.

The industrial lubricant sector represents another significant application area, albeit smaller than batteries, with lithium hydroxide serving as a key ingredient in lithium-based greases. These specialized lubricants offer exceptional performance under extreme temperatures and pressures, making them valuable in automotive, aerospace, and industrial machinery applications.

Supply constraints have created significant price volatility in recent years, with lithium hydroxide prices reaching historic highs in 2022 before moderating somewhat in 2023. This volatility has prompted end-users to pursue long-term supply agreements and vertical integration strategies to secure stable access to this critical material.

Safety considerations are increasingly influencing market dynamics, with manufacturers implementing more stringent handling protocols and investing in advanced containment systems. This trend is driving demand for specialized safety equipment, training programs, and engineering controls specifically designed for lithium hydroxide processing environments.

The pharmaceutical and consumer goods industries represent smaller but growing market segments, with lithium hydroxide utilized in the synthesis of certain medications and as a component in specialty ceramics and glass products. These applications typically require higher purity grades and more specialized handling procedures than battery applications.

Current Safety Challenges in Lithium Hydroxide Handling

The industrial handling of lithium hydroxide presents significant safety challenges due to its corrosive nature and reactivity. Current industrial practices face multiple obstacles in ensuring worker safety while maintaining operational efficiency. The primary concern stems from lithium hydroxide's strong alkaline properties, with a pH exceeding 14, making it severely caustic to human tissue, particularly affecting the eyes, respiratory system, and skin upon contact.

Respiratory protection challenges remain prominent in industrial settings, as lithium hydroxide dust particles can become airborne during processing, packaging, and transfer operations. Conventional dust masks often prove inadequate for long-term exposure protection, while more sophisticated respiratory equipment may restrict worker mobility and communication, creating operational inefficiencies.

Storage stability represents another critical challenge, as lithium hydroxide readily absorbs carbon dioxide and moisture from the atmosphere, potentially leading to container pressurization and compromised product integrity. Current storage solutions frequently struggle to balance accessibility needs with hermetic sealing requirements, particularly in high-humidity environments or facilities with temperature fluctuations.

Emergency response protocols face implementation hurdles across diverse industrial settings. The rapid neutralization required for lithium hydroxide spills demands specialized training and equipment that many facilities have yet to fully integrate into their safety programs. Response time delays during incidents can significantly exacerbate exposure risks and environmental contamination.

Cross-contamination prevention remains problematic, especially in multi-product facilities where lithium hydroxide may interact with incompatible materials such as acids, certain metals, or organic compounds. Current segregation practices often rely heavily on procedural controls rather than engineered solutions, increasing the risk of human error.

Worker training consistency presents an ongoing challenge, with significant variations in safety protocol implementation observed across different regions and facility types. The technical complexity of lithium hydroxide's hazard profile requires specialized knowledge that exceeds standard hazardous material training programs, creating knowledge gaps among handling personnel.

Monitoring technologies for workplace exposure levels remain limited in their ability to provide real-time data on airborne lithium hydroxide concentrations. Most current detection methods involve delayed sampling and laboratory analysis, preventing immediate corrective actions when exposure thresholds are exceeded.

Transportation safety continues to challenge the industry, with incidents during material transfer between processing stages or facilities representing a significant risk factor. Current containment systems occasionally fail under impact or environmental stressors, highlighting the need for more robust packaging and handling protocols throughout the supply chain.

Respiratory protection challenges remain prominent in industrial settings, as lithium hydroxide dust particles can become airborne during processing, packaging, and transfer operations. Conventional dust masks often prove inadequate for long-term exposure protection, while more sophisticated respiratory equipment may restrict worker mobility and communication, creating operational inefficiencies.

Storage stability represents another critical challenge, as lithium hydroxide readily absorbs carbon dioxide and moisture from the atmosphere, potentially leading to container pressurization and compromised product integrity. Current storage solutions frequently struggle to balance accessibility needs with hermetic sealing requirements, particularly in high-humidity environments or facilities with temperature fluctuations.

Emergency response protocols face implementation hurdles across diverse industrial settings. The rapid neutralization required for lithium hydroxide spills demands specialized training and equipment that many facilities have yet to fully integrate into their safety programs. Response time delays during incidents can significantly exacerbate exposure risks and environmental contamination.

Cross-contamination prevention remains problematic, especially in multi-product facilities where lithium hydroxide may interact with incompatible materials such as acids, certain metals, or organic compounds. Current segregation practices often rely heavily on procedural controls rather than engineered solutions, increasing the risk of human error.

Worker training consistency presents an ongoing challenge, with significant variations in safety protocol implementation observed across different regions and facility types. The technical complexity of lithium hydroxide's hazard profile requires specialized knowledge that exceeds standard hazardous material training programs, creating knowledge gaps among handling personnel.

Monitoring technologies for workplace exposure levels remain limited in their ability to provide real-time data on airborne lithium hydroxide concentrations. Most current detection methods involve delayed sampling and laboratory analysis, preventing immediate corrective actions when exposure thresholds are exceeded.

Transportation safety continues to challenge the industry, with incidents during material transfer between processing stages or facilities representing a significant risk factor. Current containment systems occasionally fail under impact or environmental stressors, highlighting the need for more robust packaging and handling protocols throughout the supply chain.

Existing Industrial Safety Solutions and Protocols

01 Safe handling and storage of lithium hydroxide

Lithium hydroxide requires specific handling and storage protocols to ensure safety. These include using appropriate personal protective equipment, storing in cool, dry areas away from incompatible materials, and implementing proper ventilation systems. Safety measures should address its corrosive nature and potential health hazards from dust inhalation or skin contact. Proper containment systems and emergency response procedures are essential for preventing and managing accidental releases.- Handling and storage safety measures for lithium hydroxide: Proper handling and storage of lithium hydroxide is crucial for safety. This includes using appropriate personal protective equipment, maintaining controlled storage conditions, and implementing specific handling protocols to prevent exposure. Safety measures also involve proper labeling, segregation from incompatible materials, and maintaining appropriate ventilation in storage areas to minimize risks associated with this caustic material.

- Safety in lithium hydroxide production processes: Safety considerations in the production of lithium hydroxide include process controls, equipment design, and operational procedures that minimize risks. This involves monitoring reaction conditions, implementing emergency shutdown systems, and designing production facilities with safety features. Production safety also encompasses waste management protocols and emission controls to prevent environmental contamination and protect worker health.

- Transportation safety regulations for lithium hydroxide: Transportation of lithium hydroxide requires adherence to specific safety regulations and protocols. This includes proper packaging requirements, labeling according to hazardous material guidelines, and documentation for shipping. Safety measures during transport also involve route planning, emergency response procedures, and training for personnel handling the material during loading, transit, and unloading operations.

- Environmental safety and waste management: Environmental safety considerations for lithium hydroxide include proper waste disposal methods, spill containment procedures, and monitoring of environmental impact. This involves neutralization techniques for spills, wastewater treatment processes, and protocols to prevent contamination of soil and water sources. Comprehensive environmental management systems are implemented to ensure compliance with regulations and minimize ecological impact.

- Safety monitoring and emergency response protocols: Safety monitoring systems and emergency response protocols are essential for managing lithium hydroxide hazards. This includes detection equipment for monitoring exposure levels, alarm systems, and established procedures for responding to accidents or spills. Emergency response plans include first aid measures for exposure, evacuation procedures, and coordination with emergency services. Regular safety drills and training ensure preparedness for potential incidents.

02 Transportation safety regulations for lithium hydroxide

Transportation of lithium hydroxide is subject to strict safety regulations due to its classification as a hazardous material. These regulations specify requirements for packaging, labeling, documentation, and emergency response information. Special containers designed to prevent leakage or exposure during transit are required. Carriers must follow specific routes and handling procedures to minimize risks during transportation, with different requirements applying to various modes of transport including road, rail, sea, and air.Expand Specific Solutions03 Environmental impact and waste management

Managing the environmental impact of lithium hydroxide involves proper waste disposal procedures and preventing contamination of water sources. Neutralization techniques are employed before disposal to reduce alkalinity. Environmental monitoring systems track potential releases, while containment strategies prevent soil and groundwater contamination. Advanced treatment technologies help recover and recycle lithium hydroxide from waste streams, reducing environmental footprint and supporting sustainability goals in lithium processing operations.Expand Specific Solutions04 Occupational health and exposure controls

Protecting workers from lithium hydroxide exposure requires comprehensive occupational health measures. These include engineering controls like local exhaust ventilation, administrative controls such as training programs and exposure monitoring, and personal protective equipment including respiratory protection, chemical-resistant gloves, and eye protection. Medical surveillance programs monitor workers for potential health effects, while emergency eyewash stations and showers provide immediate response capabilities for accidental exposures.Expand Specific Solutions05 Fire and reactivity hazard management

Managing fire and reactivity hazards associated with lithium hydroxide involves understanding its incompatibilities with certain materials and implementing appropriate firefighting techniques. While lithium hydroxide itself is not flammable, it can react with water to generate heat and potentially ignite nearby combustible materials. Specialized fire suppression agents are required, as water-based methods may be ineffective or dangerous. Segregation from incompatible substances and proper facility design help prevent dangerous chemical reactions.Expand Specific Solutions

Major Industry Players and Safety Compliance

The lithium hydroxide safety market is currently in a growth phase, driven by increasing demand for lithium-ion batteries in electric vehicles and energy storage systems. The global market size is expanding rapidly, with projections exceeding $1.5 billion by 2027. Technical maturity varies across companies, with established players like POSCO Holdings, LG Energy Solution, and LG Chem demonstrating advanced safety protocols and handling technologies. Sumitomo Metal Mining and Air Products & Chemicals have developed sophisticated containment systems, while newer entrants like Guangdong Bangpu Recycling Technology and Pure Lithium Corp are innovating in safer processing methods. Companies such as Sion Power and Galaxy Lithium are focusing on integrating safety features directly into production processes, creating a competitive landscape where industrial safety expertise increasingly represents a significant market differentiator.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has developed a comprehensive lithium hydroxide safety management system tailored for battery manufacturing environments. Their approach centers on a "zero exposure" philosophy implemented through fully automated handling systems that eliminate direct worker contact with lithium hydroxide. The company utilizes sealed processing chambers with robotic material transfer mechanisms that maintain complete isolation between workers and lithium hydroxide throughout all manufacturing stages. Their facilities incorporate specialized ventilation systems with multi-stage filtration that achieves 99.995% removal efficiency for lithium hydroxide particulates down to 0.1 microns. LG Energy Solution's protocols include continuous environmental monitoring with distributed sensor networks that detect even trace amounts of lithium hydroxide in workplace air, triggering automated responses when concentrations exceed 10% of permissible exposure limits. Their emergency management system features integrated spill containment infrastructure with automated neutralization capabilities using proprietary buffer solutions that rapidly render lithium hydroxide inert while minimizing secondary reaction hazards. Additionally, the company has developed specialized training programs using augmented reality simulations that allow workers to practice emergency procedures in virtual environments before implementing them in actual facilities.

Strengths: Fully automated handling virtually eliminates worker exposure risk; integrated monitoring and response systems provide rapid intervention capabilities; specialized training enhances emergency preparedness. Weaknesses: High implementation and maintenance costs; significant technical expertise required for system operation; heavy reliance on automation creates potential vulnerabilities during power outages or system failures.

Air Products & Chemicals, Inc.

Technical Solution: Air Products & Chemicals has developed an integrated lithium hydroxide safety management system that combines engineering controls, administrative procedures, and specialized training. Their approach centers on a proprietary ventilation and containment system that maintains negative pressure in handling areas, preventing the escape of lithium hydroxide dust to adjacent work zones. The company employs advanced dust suppression technology that uses controlled humidity levels (maintained between 40-60%) to reduce airborne particulates by approximately 85% compared to uncontrolled environments. Their handling protocols include automated packaging systems that minimize direct worker contact with lithium hydroxide. Air Products has also developed specialized emergency response procedures for lithium hydroxide incidents, including proprietary neutralization formulations that rapidly render spills safe while minimizing secondary reaction hazards. Their comprehensive training program includes virtual reality simulations of emergency scenarios, allowing workers to practice response procedures in a risk-free environment before handling actual materials.

Strengths: Holistic approach integrating engineering, administrative, and personal protective measures; advanced dust suppression technology significantly reduces exposure risks; innovative training methods improve emergency response capabilities. Weaknesses: System requires precise environmental control that may be difficult to maintain in varied industrial settings; humidity-based dust suppression may introduce additional considerations for moisture-sensitive processes; comprehensive implementation requires significant initial investment.

Critical Safety Technologies and Standards Review

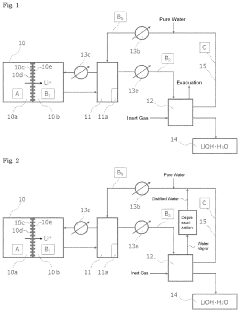

Method for producing lithium hydroxide

PatentPendingUS20230406718A1

Innovation

- A method involving the use of a Li permselective membrane to recover Li ions from a lithium ion extract in a lithium secondary battery, with temperature control at 50° C. or higher, followed by crystallization, either cooling or evaporative, to produce high-purity lithium hydroxide while minimizing energy consumption, and utilizing inert gases to suppress impurity formation.

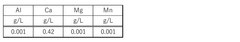

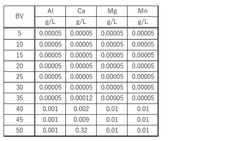

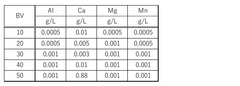

Lithium hydroxide production method

PatentWO2021166479A1

Innovation

- A method involving a neutralization step with an alkali, followed by an ion exchange step using an iminodiacetate type chelate resin, and subsequent electrodialysis to reduce the burden of removing divalent or higher ions, including the use of an oxidation step to precipitate manganese and an adsorption-elution process with lithium manganate to enhance purity and reduce resin load.

Regulatory Framework and Compliance Requirements

The regulatory landscape for lithium hydroxide handling is complex and multifaceted, spanning international, national, and local frameworks. At the international level, the Globally Harmonized System of Classification and Labelling of Chemicals (GHS) provides standardized hazard classification and communication requirements. Organizations handling lithium hydroxide must align their safety data sheets and labeling with GHS guidelines, ensuring consistent hazard communication across borders.

In the United States, the Occupational Safety and Health Administration (OSHA) enforces the Hazard Communication Standard (29 CFR 1910.1200), which mandates comprehensive hazard evaluation, proper labeling, and employee training for chemical handling. The Environmental Protection Agency (EPA) regulates lithium hydroxide under the Toxic Substances Control Act (TSCA) and the Resource Conservation and Recovery Act (RCRA), governing its production, use, and disposal.

European operations must comply with the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation and the Classification, Labelling and Packaging (CLP) regulation. These frameworks require thorough registration of chemical substances, safety assessments, and appropriate risk management measures. Companies must submit detailed dossiers containing physicochemical, toxicological, and ecotoxicological information.

Transportation of lithium hydroxide falls under various regulations including the International Maritime Dangerous Goods (IMDG) Code, International Air Transport Association (IATA) Dangerous Goods Regulations, and country-specific transportation rules. As a corrosive substance, lithium hydroxide requires specific packaging, labeling, and documentation during transport.

Compliance requirements extend to workplace safety standards, including exposure limits established by agencies such as the American Conference of Governmental Industrial Hygienists (ACGIH) and the National Institute for Occupational Safety and Health (NIOSH). These organizations set Threshold Limit Values (TLVs) and Recommended Exposure Limits (RELs) for lithium hydroxide exposure.

Facilities handling significant quantities of lithium hydroxide may be subject to emergency planning and community right-to-know regulations, such as the Emergency Planning and Community Right-to-Know Act (EPCRA) in the US. These regulations require reporting of chemical inventories and releases to local emergency planning committees.

Compliance documentation must be maintained, including safety data sheets, exposure monitoring records, employee training documentation, and incident reports. Regular audits and inspections are necessary to ensure ongoing compliance with evolving regulations. Companies must establish robust management systems to track regulatory changes and implement timely updates to their handling protocols.

In the United States, the Occupational Safety and Health Administration (OSHA) enforces the Hazard Communication Standard (29 CFR 1910.1200), which mandates comprehensive hazard evaluation, proper labeling, and employee training for chemical handling. The Environmental Protection Agency (EPA) regulates lithium hydroxide under the Toxic Substances Control Act (TSCA) and the Resource Conservation and Recovery Act (RCRA), governing its production, use, and disposal.

European operations must comply with the Registration, Evaluation, Authorization and Restriction of Chemicals (REACH) regulation and the Classification, Labelling and Packaging (CLP) regulation. These frameworks require thorough registration of chemical substances, safety assessments, and appropriate risk management measures. Companies must submit detailed dossiers containing physicochemical, toxicological, and ecotoxicological information.

Transportation of lithium hydroxide falls under various regulations including the International Maritime Dangerous Goods (IMDG) Code, International Air Transport Association (IATA) Dangerous Goods Regulations, and country-specific transportation rules. As a corrosive substance, lithium hydroxide requires specific packaging, labeling, and documentation during transport.

Compliance requirements extend to workplace safety standards, including exposure limits established by agencies such as the American Conference of Governmental Industrial Hygienists (ACGIH) and the National Institute for Occupational Safety and Health (NIOSH). These organizations set Threshold Limit Values (TLVs) and Recommended Exposure Limits (RELs) for lithium hydroxide exposure.

Facilities handling significant quantities of lithium hydroxide may be subject to emergency planning and community right-to-know regulations, such as the Emergency Planning and Community Right-to-Know Act (EPCRA) in the US. These regulations require reporting of chemical inventories and releases to local emergency planning committees.

Compliance documentation must be maintained, including safety data sheets, exposure monitoring records, employee training documentation, and incident reports. Regular audits and inspections are necessary to ensure ongoing compliance with evolving regulations. Companies must establish robust management systems to track regulatory changes and implement timely updates to their handling protocols.

Emergency Response and Incident Management Systems

Effective emergency response and incident management systems are critical components of industrial lithium hydroxide handling protocols. These systems must be designed to address the specific hazards associated with lithium hydroxide, including its corrosive nature, reactivity with water, and potential for generating hydrogen gas. A comprehensive emergency response framework begins with clear incident classification protocols that categorize events based on severity, scope, and required response level.

Industrial facilities handling lithium hydroxide should implement a tiered response system with defined roles and responsibilities for each team member. This includes designated emergency coordinators, hazardous materials specialists, medical responders, and communication officers. Regular training exercises and simulations are essential to ensure all personnel understand their roles during an emergency situation involving lithium hydroxide exposure or release.

Communication systems form the backbone of effective incident management. Facilities must establish redundant notification channels including alarm systems, public address announcements, emergency radios, and mobile alerts. These systems should be designed to function even during power outages or when standard communication infrastructure is compromised. Clear communication protocols must define who receives notifications, in what order, and through which channels.

Specialized equipment for lithium hydroxide incidents must be readily accessible in strategic locations throughout the facility. This includes appropriate personal protective equipment (PPE), neutralizing agents such as dilute acetic acid, dry chemical fire extinguishers, and spill containment materials that can handle alkaline corrosives. Decontamination stations should be established with proper drainage systems that prevent environmental contamination.

Coordination with external emergency services is another critical element. Facilities should develop memoranda of understanding with local fire departments, hazardous materials teams, and medical facilities, ensuring these organizations understand the specific challenges of lithium hydroxide incidents. Regular joint training exercises improve coordination and familiarize external responders with facility layouts and hazard locations.

Post-incident analysis procedures must be established to evaluate response effectiveness and identify improvement opportunities. This includes detailed documentation of the incident timeline, actions taken, resources deployed, and outcomes achieved. Root cause analysis should be conducted to prevent similar incidents, while response effectiveness metrics help quantify performance and guide future training and equipment investments.

Integration with business continuity planning ensures that emergency response systems consider not only immediate safety concerns but also the restoration of operations following an incident. Recovery procedures should address decontamination requirements, equipment inspection protocols, and verification steps before resuming normal operations involving lithium hydroxide handling.

Industrial facilities handling lithium hydroxide should implement a tiered response system with defined roles and responsibilities for each team member. This includes designated emergency coordinators, hazardous materials specialists, medical responders, and communication officers. Regular training exercises and simulations are essential to ensure all personnel understand their roles during an emergency situation involving lithium hydroxide exposure or release.

Communication systems form the backbone of effective incident management. Facilities must establish redundant notification channels including alarm systems, public address announcements, emergency radios, and mobile alerts. These systems should be designed to function even during power outages or when standard communication infrastructure is compromised. Clear communication protocols must define who receives notifications, in what order, and through which channels.

Specialized equipment for lithium hydroxide incidents must be readily accessible in strategic locations throughout the facility. This includes appropriate personal protective equipment (PPE), neutralizing agents such as dilute acetic acid, dry chemical fire extinguishers, and spill containment materials that can handle alkaline corrosives. Decontamination stations should be established with proper drainage systems that prevent environmental contamination.

Coordination with external emergency services is another critical element. Facilities should develop memoranda of understanding with local fire departments, hazardous materials teams, and medical facilities, ensuring these organizations understand the specific challenges of lithium hydroxide incidents. Regular joint training exercises improve coordination and familiarize external responders with facility layouts and hazard locations.

Post-incident analysis procedures must be established to evaluate response effectiveness and identify improvement opportunities. This includes detailed documentation of the incident timeline, actions taken, resources deployed, and outcomes achieved. Root cause analysis should be conducted to prevent similar incidents, while response effectiveness metrics help quantify performance and guide future training and equipment investments.

Integration with business continuity planning ensures that emergency response systems consider not only immediate safety concerns but also the restoration of operations following an incident. Recovery procedures should address decontamination requirements, equipment inspection protocols, and verification steps before resuming normal operations involving lithium hydroxide handling.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!