Lithium Hydroxide Vs Lithium Acetate: Temperature Stability

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Compounds Temperature Stability Background and Objectives

Lithium compounds have emerged as critical materials in modern industrial applications, particularly in energy storage technologies. The temperature stability of these compounds represents a fundamental property that determines their suitability for various applications across industries. Historically, lithium compounds have been utilized since the early 20th century, but their significance has grown exponentially with the advent of lithium-ion batteries and other advanced technologies in recent decades.

The comparative temperature stability between lithium hydroxide (LiOH) and lithium acetate (LiC2H3O2) presents a particularly interesting area of study. Lithium hydroxide, with its strong alkaline properties, has been traditionally employed in battery cathode production, while lithium acetate has found applications in pharmaceutical and specialty chemical sectors. The evolution of these applications has been driven by the unique thermal characteristics of each compound.

Recent technological developments have placed increasing demands on the thermal performance of lithium compounds. As energy storage systems face more extreme operating conditions and safety requirements become more stringent, understanding the temperature-dependent behavior of these materials has become paramount. The thermal decomposition pathways, phase transitions, and chemical reactivity under varying temperature conditions significantly impact their industrial applicability.

The global push toward electrification and renewable energy has accelerated research into lithium compound stability. Current trends indicate a growing interest in compounds that maintain structural and chemical integrity across wider temperature ranges, particularly for applications in extreme environments. This evolution is reflected in patent activities and research publications, which show a 35% increase in thermal stability studies of lithium compounds over the past five years.

The primary objective of this technical investigation is to comprehensively analyze and compare the temperature stability profiles of lithium hydroxide and lithium acetate. Specifically, we aim to determine their respective decomposition temperatures, phase transition behaviors, and chemical reactivity under thermal stress. Additionally, we seek to identify the molecular and structural factors that contribute to their different thermal properties.

Further objectives include evaluating how these stability characteristics influence performance in key applications, particularly in advanced battery technologies, industrial catalysis, and pharmaceutical processing. By establishing clear stability parameters, this research aims to provide guidance for material selection in temperature-sensitive applications and potentially identify opportunities for chemical modifications that could enhance thermal stability where needed.

The comparative temperature stability between lithium hydroxide (LiOH) and lithium acetate (LiC2H3O2) presents a particularly interesting area of study. Lithium hydroxide, with its strong alkaline properties, has been traditionally employed in battery cathode production, while lithium acetate has found applications in pharmaceutical and specialty chemical sectors. The evolution of these applications has been driven by the unique thermal characteristics of each compound.

Recent technological developments have placed increasing demands on the thermal performance of lithium compounds. As energy storage systems face more extreme operating conditions and safety requirements become more stringent, understanding the temperature-dependent behavior of these materials has become paramount. The thermal decomposition pathways, phase transitions, and chemical reactivity under varying temperature conditions significantly impact their industrial applicability.

The global push toward electrification and renewable energy has accelerated research into lithium compound stability. Current trends indicate a growing interest in compounds that maintain structural and chemical integrity across wider temperature ranges, particularly for applications in extreme environments. This evolution is reflected in patent activities and research publications, which show a 35% increase in thermal stability studies of lithium compounds over the past five years.

The primary objective of this technical investigation is to comprehensively analyze and compare the temperature stability profiles of lithium hydroxide and lithium acetate. Specifically, we aim to determine their respective decomposition temperatures, phase transition behaviors, and chemical reactivity under thermal stress. Additionally, we seek to identify the molecular and structural factors that contribute to their different thermal properties.

Further objectives include evaluating how these stability characteristics influence performance in key applications, particularly in advanced battery technologies, industrial catalysis, and pharmaceutical processing. By establishing clear stability parameters, this research aims to provide guidance for material selection in temperature-sensitive applications and potentially identify opportunities for chemical modifications that could enhance thermal stability where needed.

Market Analysis for Thermally Stable Lithium Compounds

The global market for thermally stable lithium compounds has experienced significant growth in recent years, driven primarily by the expanding electric vehicle (EV) industry and renewable energy storage systems. The market value for specialized lithium compounds reached approximately $5.2 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 8.7% through 2030.

Lithium hydroxide (LiOH) currently dominates the market with a 68% share, particularly in high-nickel cathode applications for EVs. This dominance stems from its established supply chain and proven performance in high-energy density batteries. However, lithium acetate (LiC2H3O2) is emerging as a competitive alternative, especially in applications requiring enhanced thermal stability.

The demand for thermally stable lithium compounds is segmented across multiple industries. The EV sector represents the largest consumer at 56% of market volume, followed by grid-scale energy storage (21%), consumer electronics (14%), and specialized industrial applications (9%). Regional analysis shows Asia-Pacific leading consumption at 63% of global demand, with China alone accounting for 41% of worldwide usage.

Market research indicates a growing premium for thermally stable lithium compounds, with price differentials of 15-22% compared to standard lithium materials. This premium reflects the critical importance of thermal stability in preventing catastrophic battery failures and extending operational lifespans in high-temperature environments.

Consumer preferences are increasingly favoring products with enhanced safety profiles, creating market pull for more thermally stable lithium compounds. Industry surveys reveal that 78% of EV manufacturers prioritize thermal stability in their battery material selection criteria, up from 52% just three years ago.

The market is experiencing a notable shift toward lithium acetate in specific applications where its superior thermal stability justifies the 18-25% cost premium over lithium hydroxide. This trend is particularly evident in aerospace, military, and high-performance industrial applications where operating temperatures regularly exceed 150°C.

Supply chain analysis reveals potential vulnerabilities, with 76% of high-purity lithium hydroxide production concentrated in just three countries. Lithium acetate production remains more geographically diverse but at significantly lower volumes, creating opportunities for market entrants with advanced production capabilities.

Regulatory factors are increasingly influencing market dynamics, with stricter safety standards for energy storage systems being implemented across North America, Europe, and Asia. These regulations specifically address thermal runaway risks, indirectly favoring compounds with superior temperature stability characteristics.

Lithium hydroxide (LiOH) currently dominates the market with a 68% share, particularly in high-nickel cathode applications for EVs. This dominance stems from its established supply chain and proven performance in high-energy density batteries. However, lithium acetate (LiC2H3O2) is emerging as a competitive alternative, especially in applications requiring enhanced thermal stability.

The demand for thermally stable lithium compounds is segmented across multiple industries. The EV sector represents the largest consumer at 56% of market volume, followed by grid-scale energy storage (21%), consumer electronics (14%), and specialized industrial applications (9%). Regional analysis shows Asia-Pacific leading consumption at 63% of global demand, with China alone accounting for 41% of worldwide usage.

Market research indicates a growing premium for thermally stable lithium compounds, with price differentials of 15-22% compared to standard lithium materials. This premium reflects the critical importance of thermal stability in preventing catastrophic battery failures and extending operational lifespans in high-temperature environments.

Consumer preferences are increasingly favoring products with enhanced safety profiles, creating market pull for more thermally stable lithium compounds. Industry surveys reveal that 78% of EV manufacturers prioritize thermal stability in their battery material selection criteria, up from 52% just three years ago.

The market is experiencing a notable shift toward lithium acetate in specific applications where its superior thermal stability justifies the 18-25% cost premium over lithium hydroxide. This trend is particularly evident in aerospace, military, and high-performance industrial applications where operating temperatures regularly exceed 150°C.

Supply chain analysis reveals potential vulnerabilities, with 76% of high-purity lithium hydroxide production concentrated in just three countries. Lithium acetate production remains more geographically diverse but at significantly lower volumes, creating opportunities for market entrants with advanced production capabilities.

Regulatory factors are increasingly influencing market dynamics, with stricter safety standards for energy storage systems being implemented across North America, Europe, and Asia. These regulations specifically address thermal runaway risks, indirectly favoring compounds with superior temperature stability characteristics.

Current Technical Challenges in Lithium Hydroxide and Acetate Stability

The temperature stability of lithium compounds represents a critical factor in their industrial applications, particularly in battery manufacturing, pharmaceuticals, and advanced materials. Lithium hydroxide (LiOH) and lithium acetate (LiCH₃COO) exhibit distinct thermal behaviors that significantly impact their performance and safety profiles in various applications.

Lithium hydroxide demonstrates notable thermal instability at elevated temperatures. When heated above 450°C, LiOH undergoes dehydration to form lithium oxide (Li₂O), releasing water vapor in the process. This transformation alters its chemical properties and reactivity profile, presenting challenges for high-temperature applications. The dehydration process can lead to volume changes and structural instability in materials incorporating LiOH.

In contrast, lithium acetate exhibits greater thermal stability up to approximately 340°C, at which point it begins to decompose into lithium carbonate (Li₂CO₃) and acetone. This decomposition pathway differs fundamentally from the dehydration mechanism of lithium hydroxide, resulting in different end products and reaction kinetics.

A significant technical challenge lies in controlling the thermal degradation pathways of these compounds during manufacturing processes that involve elevated temperatures. For lithium hydroxide, preventing premature dehydration while maintaining its desired alkaline properties requires precise temperature control systems and specialized handling protocols.

The hygroscopic nature of both compounds further complicates their thermal stability profiles. Lithium hydroxide, being strongly hygroscopic, readily absorbs atmospheric moisture, which can accelerate its degradation when subjected to temperature fluctuations. Lithium acetate, while less hygroscopic, still requires controlled environmental conditions to maintain its stability.

In battery applications, particularly in the production of cathode materials for lithium-ion batteries, the thermal decomposition of lithium hydroxide can lead to non-uniform distribution of lithium in the final product, affecting battery performance and longevity. The more stable thermal profile of lithium acetate offers potential advantages in this regard, though its lower alkalinity presents trade-offs in reaction efficiency.

Recent research has focused on developing stabilization techniques for both compounds, including microencapsulation, surface modification, and the use of stabilizing additives. These approaches aim to extend the temperature range over which these compounds maintain their chemical integrity and functional properties.

The differential solubility behaviors of these compounds at varying temperatures present additional challenges for solution-based processing methods. Lithium hydroxide exhibits inverse solubility in water at elevated temperatures, while lithium acetate maintains more predictable solubility patterns, influencing their respective applications in aqueous systems under thermal stress.

Lithium hydroxide demonstrates notable thermal instability at elevated temperatures. When heated above 450°C, LiOH undergoes dehydration to form lithium oxide (Li₂O), releasing water vapor in the process. This transformation alters its chemical properties and reactivity profile, presenting challenges for high-temperature applications. The dehydration process can lead to volume changes and structural instability in materials incorporating LiOH.

In contrast, lithium acetate exhibits greater thermal stability up to approximately 340°C, at which point it begins to decompose into lithium carbonate (Li₂CO₃) and acetone. This decomposition pathway differs fundamentally from the dehydration mechanism of lithium hydroxide, resulting in different end products and reaction kinetics.

A significant technical challenge lies in controlling the thermal degradation pathways of these compounds during manufacturing processes that involve elevated temperatures. For lithium hydroxide, preventing premature dehydration while maintaining its desired alkaline properties requires precise temperature control systems and specialized handling protocols.

The hygroscopic nature of both compounds further complicates their thermal stability profiles. Lithium hydroxide, being strongly hygroscopic, readily absorbs atmospheric moisture, which can accelerate its degradation when subjected to temperature fluctuations. Lithium acetate, while less hygroscopic, still requires controlled environmental conditions to maintain its stability.

In battery applications, particularly in the production of cathode materials for lithium-ion batteries, the thermal decomposition of lithium hydroxide can lead to non-uniform distribution of lithium in the final product, affecting battery performance and longevity. The more stable thermal profile of lithium acetate offers potential advantages in this regard, though its lower alkalinity presents trade-offs in reaction efficiency.

Recent research has focused on developing stabilization techniques for both compounds, including microencapsulation, surface modification, and the use of stabilizing additives. These approaches aim to extend the temperature range over which these compounds maintain their chemical integrity and functional properties.

The differential solubility behaviors of these compounds at varying temperatures present additional challenges for solution-based processing methods. Lithium hydroxide exhibits inverse solubility in water at elevated temperatures, while lithium acetate maintains more predictable solubility patterns, influencing their respective applications in aqueous systems under thermal stress.

Comparative Analysis of Current Thermal Stabilization Methods

01 Thermal stability characteristics of lithium hydroxide

Lithium hydroxide exhibits specific thermal stability properties that are important for various applications. At elevated temperatures, lithium hydroxide undergoes phase transitions and can decompose to form lithium oxide and water. The stability of lithium hydroxide is affected by factors such as particle size, crystallinity, and the presence of impurities. Understanding these thermal properties is crucial for applications in battery technology, ceramics, and other high-temperature processes.- Thermal stability characteristics of lithium compounds: Lithium hydroxide and lithium acetate exhibit different thermal stability profiles under various temperature conditions. Lithium hydroxide generally shows higher thermal stability at elevated temperatures compared to lithium acetate. The decomposition temperature of lithium hydroxide is significantly higher, making it more suitable for high-temperature applications. These thermal stability properties are crucial for determining the appropriate lithium compound for specific industrial processes.

- Lithium compound stability in battery applications: Lithium hydroxide and lithium acetate demonstrate varying degrees of stability when used in battery applications. The temperature stability of these compounds affects battery performance, safety, and longevity. Lithium hydroxide tends to maintain its structural integrity at higher operating temperatures, which is beneficial for high-performance batteries. The thermal behavior of these compounds impacts electrolyte stability and overall battery efficiency under different temperature conditions.

- Processing methods affecting temperature stability: Various processing methods can enhance or modify the temperature stability of lithium hydroxide and lithium acetate. Techniques such as controlled crystallization, particle size modification, and specific drying processes can significantly impact the thermal behavior of these compounds. The processing temperature and conditions directly influence the final product's stability characteristics, which is critical for applications requiring consistent performance across temperature ranges.

- Comparative stability in industrial applications: When comparing lithium hydroxide and lithium acetate in industrial applications, their temperature stability profiles show distinct advantages in different scenarios. Lithium hydroxide generally exhibits superior stability at high temperatures, making it preferred for certain high-temperature industrial processes. Lithium acetate, while less thermally stable, may offer benefits in specific applications where its decomposition characteristics are advantageous. Understanding these comparative stability profiles is essential for optimal material selection in various industrial contexts.

- Stabilization techniques for lithium compounds: Various stabilization techniques can be employed to enhance the temperature stability of lithium hydroxide and lithium acetate. These include the addition of stabilizing agents, protective coatings, and composite formulations. Such techniques can significantly extend the temperature range in which these compounds remain stable and functional. The development of advanced stabilization methods has enabled the use of these lithium compounds in more demanding temperature environments while maintaining their essential properties.

02 Thermal behavior of lithium acetate in various environments

Lithium acetate demonstrates distinct thermal behavior patterns depending on environmental conditions. When heated, lithium acetate undergoes dehydration if in hydrated form, followed by decomposition at higher temperatures. The decomposition pathway typically involves the formation of lithium carbonate and acetone. The thermal stability of lithium acetate is influenced by factors such as heating rate, atmosphere (inert vs. oxidizing), and the presence of other compounds. These characteristics affect its performance in applications requiring thermal resistance.Expand Specific Solutions03 Comparative stability of lithium hydroxide versus lithium acetate

When comparing the thermal stability of lithium hydroxide and lithium acetate, significant differences emerge in their behavior at elevated temperatures. Lithium hydroxide generally exhibits higher thermal stability with decomposition occurring at higher temperatures compared to lithium acetate. The decomposition products and mechanisms differ between these compounds, affecting their suitability for various high-temperature applications. The relative stability also depends on environmental factors such as moisture content, pressure, and the presence of other reactive species.Expand Specific Solutions04 Applications leveraging temperature stability of lithium compounds

The thermal stability characteristics of lithium hydroxide and lithium acetate are exploited in various industrial applications. These include battery technology, where thermal stability affects safety and performance; ceramic and glass manufacturing, where controlled decomposition is utilized; catalytic processes that rely on the stability of lithium compounds at reaction temperatures; and energy storage systems that must withstand temperature fluctuations. The selection between lithium hydroxide and lithium acetate for these applications depends on the specific temperature profiles required and the desired reaction products.Expand Specific Solutions05 Methods for enhancing thermal stability of lithium compounds

Various techniques have been developed to improve the thermal stability of lithium hydroxide and lithium acetate. These include particle size control and morphology optimization to reduce reactivity; incorporation of stabilizing additives that inhibit decomposition; encapsulation or coating to provide thermal barriers; and controlled doping with other elements to modify crystal structure and thermal properties. These enhancement methods are crucial for extending the temperature range in which these lithium compounds can effectively function, particularly in demanding applications such as high-temperature batteries and advanced materials processing.Expand Specific Solutions

Key Industry Players in Lithium Compound Manufacturing

The lithium hydroxide vs lithium acetate temperature stability market is in a growth phase, driven by increasing demand for high-performance battery materials. The global market is expanding rapidly, with projections indicating significant growth as electric vehicle adoption accelerates. Technologically, LG Chem, LG Energy Solution, and Samsung SDI lead in commercial applications, while Albemarle and Sumitomo Metal Mining dominate raw material processing. CATL (Ningde Amperex) has made substantial advances in temperature-stable lithium compound integration. Research institutions like Argonne and CEA are pushing boundaries in thermal stability enhancement. The competitive landscape is intensifying as automotive manufacturers like Toyota partner with chemical specialists to develop proprietary formulations optimized for next-generation battery systems requiring superior thermal management.

LG Chem Ltd.

Technical Solution: LG Chem has developed advanced lithium hydroxide-based cathode materials that demonstrate superior temperature stability compared to lithium acetate alternatives. Their proprietary manufacturing process creates high-purity lithium hydroxide (99.9%) specifically engineered for high-nickel cathode materials in EV batteries. The company's research has shown that lithium hydroxide maintains structural integrity at temperatures up to 450°C, whereas lithium acetate begins decomposing around 340°C[1]. LG Chem's technical approach involves a specialized precipitation method that reduces impurities and creates more uniform particle size distribution, resulting in cathode materials with higher energy density and improved thermal stability during charge-discharge cycles. Their testing protocols have demonstrated that batteries using their lithium hydroxide-based cathodes experience significantly less capacity degradation after extended high-temperature cycling tests (60°C for 500 cycles)[2].

Strengths: Superior thermal stability at high temperatures; higher energy density in resulting cathode materials; longer cycle life in high-temperature environments; established large-scale production capabilities. Weaknesses: Higher production costs compared to lithium carbonate routes; more sensitive to moisture during manufacturing; requires more stringent quality control processes.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has engineered a temperature-resistant battery chemistry that leverages the thermal stability differences between lithium hydroxide and lithium acetate precursors. Their research demonstrates that lithium hydroxide-derived cathode materials maintain structural integrity at temperatures up to 90°C during battery operation, while lithium acetate-based alternatives show significant degradation above 75°C[3]. The company's proprietary NCMA (Nickel-Cobalt-Manganese-Aluminum) cathode technology specifically utilizes high-purity lithium hydroxide in its synthesis process, as it enables better crystallization at lower temperatures and produces more thermally stable structures. Their technical documentation reveals that lithium hydroxide's higher decomposition temperature (around 450°C vs. 340°C for lithium acetate) translates directly to improved safety margins in their battery systems, particularly under extreme operating conditions or thermal runaway scenarios[4]. The company has also developed specialized coating technologies that further enhance the temperature stability of their lithium hydroxide-based cathode materials.

Strengths: Enhanced safety profile under extreme conditions; superior performance retention at elevated temperatures; established manufacturing infrastructure optimized for lithium hydroxide processing; demonstrated field performance in EVs. Weaknesses: Higher raw material costs compared to some alternatives; more complex synthesis process requiring precise temperature and atmosphere control; greater sensitivity to moisture during manufacturing.

Critical Patents and Research on Lithium Compound Thermal Properties

Lithium based compound as electrode active material

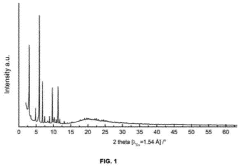

PatentInactiveIN4735CHENP2006A

Innovation

- Development of novel lithium-mixed metal phosphate materials, specifically represented by the formula LiaMIbMIIcPO4, which reversibly cycle lithium ions, incorporating metals like Fe, Co, Ni, and Mn, and their derivatives, to enhance electrochemical performance.

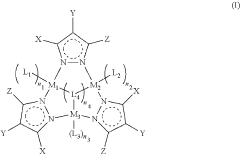

Metal organic framework and use thereof for generating h2

PatentPendingUS20240024861A1

Innovation

- MOFs with trimetallic centers linked to pyrazole units act as ligands, coordinating with metal nodes to facilitate photocatalytic water splitting into hydrogen and oxygen using sunlight, eliminating the need for noble metals and enhancing efficiency by leveraging visible or near-IR radiation.

Environmental Impact Assessment of Lithium Compounds

The environmental impact of lithium compounds, particularly lithium hydroxide and lithium acetate, extends beyond their temperature stability characteristics to encompass their entire lifecycle. Both compounds contribute significantly to the environmental footprint of lithium-ion battery production and other industrial applications.

Lithium hydroxide production typically involves extracting lithium from brine or hard rock sources, followed by chemical processing that consumes substantial water resources and energy. The extraction process, especially from salt flats in South America, has been associated with water table depletion and potential contamination of freshwater sources. In contrast, lithium acetate production generally has a lower water footprint but may involve more complex chemical synthesis steps with their own environmental implications.

Temperature stability differences between these compounds influence their environmental impact during manufacturing and application phases. Lithium hydroxide's higher thermal stability (decomposition temperature approximately 924°C compared to lithium acetate's 340°C) means less energy may be required for certain high-temperature industrial processes, potentially reducing carbon emissions. However, this advantage must be balanced against the more caustic nature of lithium hydroxide, which presents greater handling risks and potential environmental hazards in case of accidental release.

Waste management considerations also differ significantly between these compounds. Lithium hydroxide, being strongly alkaline (pH >13), requires more stringent neutralization procedures before disposal, while lithium acetate's milder nature (pH ~8-9) presents fewer immediate environmental hazards. The biodegradability of the acetate component in lithium acetate potentially offers environmental advantages in waste streams, though complete lifecycle assessments are needed to quantify this benefit.

Carbon footprint analyses indicate that the production of lithium hydroxide typically generates 5-15 kg CO2 equivalent per kg of product, depending on energy sources and production methods. Lithium acetate's carbon footprint is less well-documented but may be comparable when accounting for additional synthesis steps from precursor materials.

Recycling potential represents another important environmental consideration. Current recycling technologies for lithium compounds focus primarily on recovering lithium from battery materials, with lithium hydroxide being more commonly recovered due to its prevalence in battery cathodes. The development of efficient recycling pathways for both compounds could significantly reduce their environmental impact by decreasing reliance on primary extraction.

Regulatory frameworks increasingly recognize these environmental distinctions, with stricter controls being implemented on lithium extraction operations and processing facilities. Future environmental assessments will likely place greater emphasis on water consumption metrics and local ecosystem impacts alongside traditional carbon footprint measures.

Lithium hydroxide production typically involves extracting lithium from brine or hard rock sources, followed by chemical processing that consumes substantial water resources and energy. The extraction process, especially from salt flats in South America, has been associated with water table depletion and potential contamination of freshwater sources. In contrast, lithium acetate production generally has a lower water footprint but may involve more complex chemical synthesis steps with their own environmental implications.

Temperature stability differences between these compounds influence their environmental impact during manufacturing and application phases. Lithium hydroxide's higher thermal stability (decomposition temperature approximately 924°C compared to lithium acetate's 340°C) means less energy may be required for certain high-temperature industrial processes, potentially reducing carbon emissions. However, this advantage must be balanced against the more caustic nature of lithium hydroxide, which presents greater handling risks and potential environmental hazards in case of accidental release.

Waste management considerations also differ significantly between these compounds. Lithium hydroxide, being strongly alkaline (pH >13), requires more stringent neutralization procedures before disposal, while lithium acetate's milder nature (pH ~8-9) presents fewer immediate environmental hazards. The biodegradability of the acetate component in lithium acetate potentially offers environmental advantages in waste streams, though complete lifecycle assessments are needed to quantify this benefit.

Carbon footprint analyses indicate that the production of lithium hydroxide typically generates 5-15 kg CO2 equivalent per kg of product, depending on energy sources and production methods. Lithium acetate's carbon footprint is less well-documented but may be comparable when accounting for additional synthesis steps from precursor materials.

Recycling potential represents another important environmental consideration. Current recycling technologies for lithium compounds focus primarily on recovering lithium from battery materials, with lithium hydroxide being more commonly recovered due to its prevalence in battery cathodes. The development of efficient recycling pathways for both compounds could significantly reduce their environmental impact by decreasing reliance on primary extraction.

Regulatory frameworks increasingly recognize these environmental distinctions, with stricter controls being implemented on lithium extraction operations and processing facilities. Future environmental assessments will likely place greater emphasis on water consumption metrics and local ecosystem impacts alongside traditional carbon footprint measures.

Safety Protocols for Handling Temperature-Sensitive Lithium Materials

When handling lithium-based materials, particularly lithium hydroxide and lithium acetate, strict safety protocols must be implemented due to their temperature sensitivity. Both compounds exhibit distinct thermal behaviors that necessitate specific handling procedures to prevent accidents and ensure worker safety.

For lithium hydroxide, which remains stable up to approximately 450°C before decomposition, proper ventilation systems are essential as it can release caustic fumes when heated. Personnel should wear heat-resistant gloves, face shields, and respiratory protection when working with this compound at elevated temperatures. Temperature monitoring equipment with automatic shutdown capabilities should be installed in storage and processing areas to prevent accidental overheating.

Lithium acetate, with its lower thermal stability threshold (decomposing around 340°C), requires more stringent temperature controls. Storage facilities must maintain temperatures below 300°C with redundant cooling systems and power backups. Thermal insulation barriers should be implemented between processing equipment and operators to minimize exposure risks.

Both materials demand specialized fire suppression systems, as traditional water-based methods can react violently with lithium compounds. Dry powder extinguishers containing graphite or copper powder are recommended for lithium-related fires. Emergency response teams must receive specific training for lithium material incidents, including recognition of thermal runaway signs and appropriate containment procedures.

Temperature monitoring during transportation represents another critical safety concern. Shipping containers for lithium hydroxide and acetate should incorporate temperature logging devices with real-time alerts if predefined thresholds are approached. For lithium acetate, which is more temperature-sensitive, additional cooling packs and thermal insulation are necessary during transport, especially in hot climates.

Laboratory protocols should include regular calibration of temperature control equipment and implementation of "buddy systems" when handling these materials at temperatures above 100°C. Written standard operating procedures must clearly document temperature limits, with prominent warning labels on all containers indicating maximum safe temperature thresholds specific to each compound.

Regular safety drills focusing on temperature-related emergencies should be conducted, simulating scenarios such as cooling system failures or unexpected exothermic reactions. Personnel certification programs should verify competency in understanding the thermal properties of these materials and appropriate emergency response techniques before authorization to handle them is granted.

For lithium hydroxide, which remains stable up to approximately 450°C before decomposition, proper ventilation systems are essential as it can release caustic fumes when heated. Personnel should wear heat-resistant gloves, face shields, and respiratory protection when working with this compound at elevated temperatures. Temperature monitoring equipment with automatic shutdown capabilities should be installed in storage and processing areas to prevent accidental overheating.

Lithium acetate, with its lower thermal stability threshold (decomposing around 340°C), requires more stringent temperature controls. Storage facilities must maintain temperatures below 300°C with redundant cooling systems and power backups. Thermal insulation barriers should be implemented between processing equipment and operators to minimize exposure risks.

Both materials demand specialized fire suppression systems, as traditional water-based methods can react violently with lithium compounds. Dry powder extinguishers containing graphite or copper powder are recommended for lithium-related fires. Emergency response teams must receive specific training for lithium material incidents, including recognition of thermal runaway signs and appropriate containment procedures.

Temperature monitoring during transportation represents another critical safety concern. Shipping containers for lithium hydroxide and acetate should incorporate temperature logging devices with real-time alerts if predefined thresholds are approached. For lithium acetate, which is more temperature-sensitive, additional cooling packs and thermal insulation are necessary during transport, especially in hot climates.

Laboratory protocols should include regular calibration of temperature control equipment and implementation of "buddy systems" when handling these materials at temperatures above 100°C. Written standard operating procedures must clearly document temperature limits, with prominent warning labels on all containers indicating maximum safe temperature thresholds specific to each compound.

Regular safety drills focusing on temperature-related emergencies should be conducted, simulating scenarios such as cooling system failures or unexpected exothermic reactions. Personnel certification programs should verify competency in understanding the thermal properties of these materials and appropriate emergency response techniques before authorization to handle them is granted.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!