How To Measure Lithium Hydroxide Moisture Content Accurately

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Lithium Hydroxide Moisture Analysis Background and Objectives

Lithium hydroxide (LiOH) has emerged as a critical material in the global energy transition, particularly in the production of high-performance lithium-ion batteries for electric vehicles and renewable energy storage systems. The accurate measurement of moisture content in lithium hydroxide is of paramount importance as it directly impacts the quality, performance, and safety of the final battery products. This technical research aims to comprehensively examine the methodologies for precise moisture content determination in lithium hydroxide.

The evolution of lithium hydroxide analysis techniques has progressed significantly over the past decades, from basic gravimetric methods to sophisticated spectroscopic approaches. Initially, moisture content was primarily determined through loss-on-drying techniques, which provided limited accuracy and were highly susceptible to environmental variables. As battery technology advanced and specifications became more stringent, the need for more precise measurement methodologies grew proportionally.

Current industry standards typically require lithium hydroxide moisture content to be maintained below 0.5% for battery-grade applications, with some high-performance applications demanding even lower thresholds of 0.2% or less. This precision requirement has driven continuous innovation in measurement technologies and protocols, creating a dynamic technical landscape that merits thorough investigation.

The primary objective of this research is to evaluate existing moisture measurement techniques for lithium hydroxide, identifying their respective strengths, limitations, and applicability across different industrial contexts. Additionally, we aim to explore emerging technologies that promise enhanced accuracy, reliability, and efficiency in moisture determination, potentially establishing new industry benchmarks.

A secondary but equally important goal is to understand how moisture content variations affect downstream processes in battery manufacturing, quantifying the relationship between measurement precision and final product performance. This understanding will inform the development of optimized quality control protocols and potentially reveal opportunities for process improvements that could yield significant competitive advantages.

The technical trajectory indicates a shift toward non-destructive, real-time monitoring systems that can be integrated directly into production lines, allowing for continuous quality assurance rather than batch sampling. This research will assess the feasibility of such systems for lithium hydroxide processing, considering factors such as implementation costs, calibration requirements, and long-term reliability.

By establishing a comprehensive understanding of moisture measurement methodologies for lithium hydroxide, this research aims to contribute to the advancement of battery technology, supporting the broader transition to sustainable energy systems through improved material quality control and processing efficiency.

The evolution of lithium hydroxide analysis techniques has progressed significantly over the past decades, from basic gravimetric methods to sophisticated spectroscopic approaches. Initially, moisture content was primarily determined through loss-on-drying techniques, which provided limited accuracy and were highly susceptible to environmental variables. As battery technology advanced and specifications became more stringent, the need for more precise measurement methodologies grew proportionally.

Current industry standards typically require lithium hydroxide moisture content to be maintained below 0.5% for battery-grade applications, with some high-performance applications demanding even lower thresholds of 0.2% or less. This precision requirement has driven continuous innovation in measurement technologies and protocols, creating a dynamic technical landscape that merits thorough investigation.

The primary objective of this research is to evaluate existing moisture measurement techniques for lithium hydroxide, identifying their respective strengths, limitations, and applicability across different industrial contexts. Additionally, we aim to explore emerging technologies that promise enhanced accuracy, reliability, and efficiency in moisture determination, potentially establishing new industry benchmarks.

A secondary but equally important goal is to understand how moisture content variations affect downstream processes in battery manufacturing, quantifying the relationship between measurement precision and final product performance. This understanding will inform the development of optimized quality control protocols and potentially reveal opportunities for process improvements that could yield significant competitive advantages.

The technical trajectory indicates a shift toward non-destructive, real-time monitoring systems that can be integrated directly into production lines, allowing for continuous quality assurance rather than batch sampling. This research will assess the feasibility of such systems for lithium hydroxide processing, considering factors such as implementation costs, calibration requirements, and long-term reliability.

By establishing a comprehensive understanding of moisture measurement methodologies for lithium hydroxide, this research aims to contribute to the advancement of battery technology, supporting the broader transition to sustainable energy systems through improved material quality control and processing efficiency.

Market Demand for Precise Moisture Content Measurement

The global lithium-ion battery market has witnessed unprecedented growth, projected to reach $182.53 billion by 2030, with a CAGR of 15.3% from 2023. This explosive expansion directly correlates with increasing demand for precise moisture content measurement in lithium hydroxide, a critical component in high-performance battery cathodes. Accurate moisture measurement has transitioned from a manufacturing preference to an absolute necessity as battery manufacturers face mounting pressure to enhance energy density, extend cycle life, and improve safety profiles.

Battery-grade lithium hydroxide requires moisture content typically below 0.5%, with premium applications demanding even stricter tolerances of 0.2% or less. This precision requirement stems from moisture's detrimental effects on battery performance, including reduced capacity, accelerated degradation, and potential safety hazards. Each 0.1% deviation in moisture content can impact battery capacity by up to 2-3%, representing significant performance and economic implications in high-volume production environments.

The electric vehicle sector drives the most urgent demand for precise moisture measurement, with major manufacturers implementing increasingly stringent quality control protocols. Tesla, for instance, has reportedly tightened its moisture specifications for lithium materials by 30% in recent years. Similarly, battery giants like CATL, LG Energy Solution, and Samsung SDI have all upgraded their incoming material inspection protocols to include advanced moisture analysis techniques.

Beyond automotive applications, consumer electronics and grid-scale energy storage systems are similarly driving demand for precision. The consumer electronics segment, valued at $545 billion globally, increasingly specifies tighter moisture tolerances to support higher energy density batteries in smaller form factors. Meanwhile, the energy storage market, growing at 20% annually, requires consistent material properties for large-scale battery installations where performance variability can have magnified consequences.

Geographically, demand for precise moisture measurement technologies is most pronounced in Asia-Pacific, particularly China, Japan, and South Korea, which collectively represent over 65% of global lithium battery production. However, emerging battery manufacturing hubs in Europe and North America are rapidly adopting advanced quality control standards, expanding the market for sophisticated moisture analysis equipment.

Regulatory factors further amplify market demand, with transportation safety regulations increasingly focusing on battery material quality. The UN Model Regulations for the Transport of Dangerous Goods and similar frameworks have established stricter guidelines for battery materials, indirectly creating compliance requirements that necessitate precise moisture measurement capabilities throughout the supply chain.

Battery-grade lithium hydroxide requires moisture content typically below 0.5%, with premium applications demanding even stricter tolerances of 0.2% or less. This precision requirement stems from moisture's detrimental effects on battery performance, including reduced capacity, accelerated degradation, and potential safety hazards. Each 0.1% deviation in moisture content can impact battery capacity by up to 2-3%, representing significant performance and economic implications in high-volume production environments.

The electric vehicle sector drives the most urgent demand for precise moisture measurement, with major manufacturers implementing increasingly stringent quality control protocols. Tesla, for instance, has reportedly tightened its moisture specifications for lithium materials by 30% in recent years. Similarly, battery giants like CATL, LG Energy Solution, and Samsung SDI have all upgraded their incoming material inspection protocols to include advanced moisture analysis techniques.

Beyond automotive applications, consumer electronics and grid-scale energy storage systems are similarly driving demand for precision. The consumer electronics segment, valued at $545 billion globally, increasingly specifies tighter moisture tolerances to support higher energy density batteries in smaller form factors. Meanwhile, the energy storage market, growing at 20% annually, requires consistent material properties for large-scale battery installations where performance variability can have magnified consequences.

Geographically, demand for precise moisture measurement technologies is most pronounced in Asia-Pacific, particularly China, Japan, and South Korea, which collectively represent over 65% of global lithium battery production. However, emerging battery manufacturing hubs in Europe and North America are rapidly adopting advanced quality control standards, expanding the market for sophisticated moisture analysis equipment.

Regulatory factors further amplify market demand, with transportation safety regulations increasingly focusing on battery material quality. The UN Model Regulations for the Transport of Dangerous Goods and similar frameworks have established stricter guidelines for battery materials, indirectly creating compliance requirements that necessitate precise moisture measurement capabilities throughout the supply chain.

Current Challenges in Lithium Hydroxide Moisture Detection

The accurate measurement of moisture content in lithium hydroxide presents significant technical challenges that impact both quality control and production efficiency in the battery materials industry. Current detection methods exhibit several limitations that hinder precise quantification, particularly as industry standards become increasingly stringent with the expansion of electric vehicle and energy storage markets.

Traditional loss-on-drying (LOD) methods, while widely adopted, suffer from inherent variability due to inconsistent heating parameters and environmental influences. The standard procedure requires heating samples at 105-110°C, but this temperature range can lead to partial decomposition of lithium hydroxide, resulting in measurement errors typically ranging from 0.2-0.5% absolute. This margin of error becomes problematic when specifications demand moisture levels below 0.5%.

Karl Fischer titration, another common technique, faces challenges with lithium hydroxide's high alkalinity, which interferes with reagent reactions and endpoint detection. Modified Karl Fischer methods have been developed but require complex sample preparation and specialized equipment, limiting their application in routine quality control environments. Calibration drift remains a persistent issue, necessitating frequent recalibration procedures that interrupt production workflows.

Near-infrared (NIR) and infrared spectroscopic methods offer non-destructive alternatives but struggle with signal interference from hydroxide groups that overlap with water molecule signatures. Current calibration models require extensive reference datasets and frequent updates to maintain accuracy across varying production batches. The detection limit of approximately 0.1% moisture content falls short of the 0.05% precision increasingly demanded by high-performance battery manufacturers.

Online continuous monitoring systems represent an emerging approach but face integration challenges with existing production lines. Current sensor technologies exhibit drift under the highly alkaline conditions of lithium hydroxide processing environments, requiring frequent maintenance and recalibration. The trade-off between measurement speed and accuracy remains unresolved, with faster systems typically sacrificing precision.

Sample handling introduces additional variability, as lithium hydroxide's hygroscopic nature means it rapidly absorbs atmospheric moisture during measurement procedures. Even brief exposure to ambient air can increase moisture content by 0.1-0.3% within minutes, compromising measurement accuracy. Current sampling protocols struggle to maintain sample integrity throughout the testing process.

Standardization across the industry presents another significant challenge, with different manufacturers employing varied methodologies that yield inconsistent results. This hampers quality assurance efforts and complicates supplier qualification processes, particularly as global supply chains expand to meet growing demand for battery materials.

Traditional loss-on-drying (LOD) methods, while widely adopted, suffer from inherent variability due to inconsistent heating parameters and environmental influences. The standard procedure requires heating samples at 105-110°C, but this temperature range can lead to partial decomposition of lithium hydroxide, resulting in measurement errors typically ranging from 0.2-0.5% absolute. This margin of error becomes problematic when specifications demand moisture levels below 0.5%.

Karl Fischer titration, another common technique, faces challenges with lithium hydroxide's high alkalinity, which interferes with reagent reactions and endpoint detection. Modified Karl Fischer methods have been developed but require complex sample preparation and specialized equipment, limiting their application in routine quality control environments. Calibration drift remains a persistent issue, necessitating frequent recalibration procedures that interrupt production workflows.

Near-infrared (NIR) and infrared spectroscopic methods offer non-destructive alternatives but struggle with signal interference from hydroxide groups that overlap with water molecule signatures. Current calibration models require extensive reference datasets and frequent updates to maintain accuracy across varying production batches. The detection limit of approximately 0.1% moisture content falls short of the 0.05% precision increasingly demanded by high-performance battery manufacturers.

Online continuous monitoring systems represent an emerging approach but face integration challenges with existing production lines. Current sensor technologies exhibit drift under the highly alkaline conditions of lithium hydroxide processing environments, requiring frequent maintenance and recalibration. The trade-off between measurement speed and accuracy remains unresolved, with faster systems typically sacrificing precision.

Sample handling introduces additional variability, as lithium hydroxide's hygroscopic nature means it rapidly absorbs atmospheric moisture during measurement procedures. Even brief exposure to ambient air can increase moisture content by 0.1-0.3% within minutes, compromising measurement accuracy. Current sampling protocols struggle to maintain sample integrity throughout the testing process.

Standardization across the industry presents another significant challenge, with different manufacturers employing varied methodologies that yield inconsistent results. This hampers quality assurance efforts and complicates supplier qualification processes, particularly as global supply chains expand to meet growing demand for battery materials.

Existing Moisture Measurement Methodologies

01 Measurement and control of moisture content in lithium hydroxide

Various methods and devices are used to measure and control the moisture content in lithium hydroxide, which is critical for its quality and performance in applications. These methods include specialized moisture analyzers, infrared detection systems, and real-time monitoring equipment. Controlling moisture content is essential as it affects the reactivity, stability, and efficiency of lithium hydroxide in various industrial processes, particularly in battery manufacturing.- Measurement and control of moisture content in lithium hydroxide: Various methods and devices are used to measure and control the moisture content in lithium hydroxide, which is critical for its quality and performance in industrial applications. These methods include specialized moisture analyzers, infrared detection systems, and automated monitoring equipment that can provide accurate measurements of water content. Controlling moisture levels is essential as excess moisture can affect the reactivity and stability of lithium hydroxide in battery production and other applications.

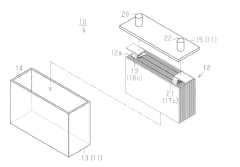

- Drying processes for lithium hydroxide: Different drying processes are employed to reduce the moisture content in lithium hydroxide to desired levels. These include vacuum drying, heat treatment at controlled temperatures, fluidized bed drying, and microwave drying techniques. The drying conditions such as temperature, pressure, and duration are carefully optimized to ensure effective moisture removal without degrading the lithium hydroxide quality. Proper drying is essential for applications requiring high-purity lithium hydroxide with specific moisture specifications.

- Moisture content specifications for battery applications: For lithium-ion battery manufacturing, lithium hydroxide must meet strict moisture content specifications. Typically, moisture levels need to be below certain thresholds (often less than 1%) to prevent adverse reactions during battery production. The moisture content directly impacts the electrochemical performance, shelf life, and safety of batteries. Manufacturers have developed specific testing protocols and quality control measures to ensure that lithium hydroxide meets these moisture specifications before use in battery production.

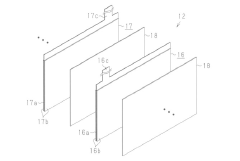

- Storage and packaging to maintain low moisture content: Special storage and packaging methods are used to maintain the low moisture content of lithium hydroxide during transportation and storage. These include moisture-resistant containers, desiccant packaging, controlled atmosphere storage, and hermetically sealed containers. The packaging materials are selected to prevent moisture absorption from the environment, as lithium hydroxide is hygroscopic and can rapidly absorb moisture from the air, which would compromise its quality and usability in various applications.

- Impact of moisture content on lithium hydroxide processing and performance: The moisture content of lithium hydroxide significantly affects its processing characteristics and performance in various applications. High moisture content can lead to agglomeration, reduced flowability, and processing difficulties. It can also impact chemical reactions, reduce purity, and affect the efficiency of lithium hydroxide in industrial processes. Research has focused on understanding the relationship between moisture content and performance parameters to establish optimal moisture levels for different applications and develop methods to mitigate negative effects of moisture variation.

02 Drying processes for lithium hydroxide

Different drying techniques are employed to reduce and control the moisture content in lithium hydroxide. These include vacuum drying, spray drying, fluidized bed drying, and microwave drying. The drying processes are carefully designed to achieve specific moisture content levels without degrading the chemical properties of lithium hydroxide. Parameters such as temperature, pressure, and drying time are optimized to ensure efficient moisture removal while maintaining product quality.Expand Specific Solutions03 Moisture specifications for battery-grade lithium hydroxide

Battery-grade lithium hydroxide requires specific moisture content specifications to ensure optimal performance in lithium-ion battery production. The moisture content typically needs to be below certain thresholds (often less than 1%) to prevent adverse reactions during battery manufacturing. These specifications are critical for ensuring battery safety, longevity, and performance. Standardized testing methods are used to verify compliance with these moisture specifications before the lithium hydroxide is used in battery production.Expand Specific Solutions04 Impact of moisture on lithium hydroxide storage and handling

Moisture content significantly affects the storage stability and handling properties of lithium hydroxide. High moisture content can lead to agglomeration, reduced flowability, and potential chemical reactions with packaging materials or other chemicals. Proper packaging methods, storage conditions, and handling protocols are implemented to maintain the desired moisture levels throughout the supply chain. Controlled humidity environments and moisture-resistant packaging are commonly used to protect lithium hydroxide from ambient moisture absorption.Expand Specific Solutions05 Moisture control in lithium hydroxide production processes

Various production processes incorporate specific steps to control the moisture content of lithium hydroxide during manufacturing. These include precise reaction conditions, controlled precipitation methods, and specialized filtration techniques. The moisture content is monitored throughout the production process, from raw material handling to final product packaging. Advanced process control systems are implemented to maintain consistent moisture levels, ensuring product quality and meeting customer specifications for different applications.Expand Specific Solutions

Key Industry Players in Moisture Analysis Instrumentation

The lithium hydroxide moisture content measurement market is in a growth phase, driven by increasing demand for high-quality lithium compounds in battery production. The global market is expanding rapidly alongside the electric vehicle boom, with significant investments in measurement technology development. Leading battery manufacturers like BYD, LG Chem, and SVOLT Energy Technology are advancing moisture measurement capabilities to ensure product quality and safety. Analytical instrument companies such as Shimadzu Corporation provide specialized equipment for precise moisture determination. The technology is maturing with innovations from both battery material producers (Hefei Guoxuan, Tianjin Lishen) and analytical equipment manufacturers, focusing on improving accuracy, reliability, and automation of moisture content measurements to meet stringent battery-grade lithium hydroxide specifications.

BYD Co., Ltd.

Technical Solution: BYD has engineered an advanced moisture analysis system specifically for lithium hydroxide quality control in battery production. Their technology utilizes near-infrared (NIR) spectroscopy combined with machine learning algorithms to provide rapid, non-destructive moisture content measurements. The system features specialized sample holders that minimize exposure to ambient conditions during measurement. BYD's approach incorporates reference standards with precisely known moisture content for regular calibration, ensuring measurement accuracy within ±0.02% across the critical range of 0.1-1.0% moisture content. The technology employs multiple wavelength analysis to differentiate between surface moisture and crystal water, providing more accurate total moisture determination. Their system includes automated sampling mechanisms that collect representative samples from production batches, reducing human error and contamination risks. The data management system tracks moisture trends over time, enabling process optimization and early detection of production issues.

Strengths: Rapid analysis time (under 60 seconds per sample); non-destructive testing preserves samples; machine learning algorithms improve accuracy over time with accumulated data. Weaknesses: Requires regular recalibration with reference standards; performance may be affected by particle size variations; initial calibration process is time-consuming.

Shimadzu Corp.

Technical Solution: Shimadzu has developed a comprehensive moisture analysis platform for lithium hydroxide that combines multiple measurement technologies. Their system integrates coulometric Karl Fischer titration with thermal desorption analysis, providing both total moisture content and information about moisture binding states. The technology features temperature-controlled sample introduction systems that prevent moisture absorption during handling. Shimadzu's approach includes specialized reagents optimized for alkaline materials like lithium hydroxide, overcoming traditional challenges with standard Karl Fischer reagents. Their instruments incorporate drift compensation algorithms that account for background moisture in carrier gases and system components, improving measurement accuracy to ±0.005% for samples in the 0.1-1.0% moisture range. The system includes automated data analysis software that identifies outliers and measurement anomalies, ensuring reliable quality control. Shimadzu's technology also features sealed sample preparation environments with controlled humidity, minimizing environmental contamination during the measurement process.

Strengths: Dual-technology approach provides comprehensive moisture profile; specialized reagents overcome alkaline sample challenges; high accuracy with drift compensation. Weaknesses: More complex operation compared to single-method systems; higher reagent consumption; requires more frequent calibration for optimal performance.

Critical Technologies for Accurate Moisture Determination

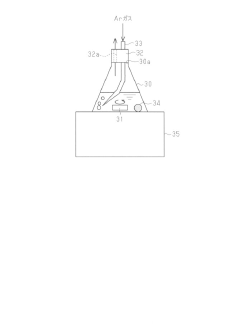

Method for measuring lithium component of positive electrode active material

PatentInactiveJP2016205862A

Innovation

- A method involving immersing the positive electrode active material sample in pure water, stirring it while bubbling inert gas through a communicating port to remove lithium components, followed by suction filtration and titration to measure the amounts accurately.

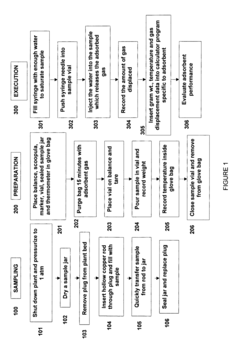

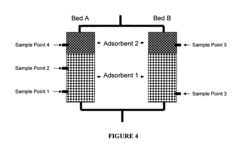

Method and kit for adsorbent performance evaluation

PatentInactiveUS7827855B2

Innovation

- A method and kit for on-site testing of adsorbent degradation that involves sampling, purging with a dry gas, measuring gas capacity, and using a displacing agent to assess adsorbent performance, allowing for early detection of contamination and other damage.

Regulatory Standards for Battery-Grade Materials

The regulatory landscape for battery-grade materials has become increasingly stringent as the electric vehicle and energy storage markets expand globally. For lithium hydroxide, a critical component in high-performance lithium-ion batteries, moisture content specifications are particularly important as they directly impact battery safety, performance, and longevity. The International Electrotechnical Commission (IEC) has established standard IEC 62660, which specifies moisture content in battery-grade lithium hydroxide should not exceed 0.5% by weight, with premium grades requiring levels below 0.2%.

In the United States, the American National Standards Institute (ANSI) and the Society of Automotive Engineers (SAE) have jointly developed SAE J2380, which includes specifications for moisture determination methods and acceptable limits. Similarly, the European Union has implemented EN 62660-1:2019, which aligns with international standards but adds additional requirements for materials used in European-manufactured batteries.

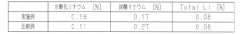

China, as the world's largest producer of lithium-ion batteries, has established GB/T 26580 standards, which specify moisture content limits of 0.3% for battery-grade lithium hydroxide. These standards also detail the approved measurement methodologies, including Karl Fischer titration and loss-on-drying techniques.

The Japanese Industrial Standards Committee (JISC) has published JIS C8715, which provides comprehensive specifications for lithium battery materials, including moisture content requirements of 0.4% maximum for lithium hydroxide used in high-energy density applications.

Regulatory compliance verification typically requires accredited laboratory testing using validated methods. The International Organization for Standardization (ISO) has developed ISO 18451-1, which standardizes the sampling and testing procedures for battery materials, ensuring consistency across global supply chains.

Recent regulatory trends indicate a move toward more stringent moisture specifications, with several jurisdictions considering reducing maximum allowable moisture content to 0.1% for next-generation battery applications. This shift is driven by the increasing energy density requirements of modern batteries and the corresponding safety considerations.

Manufacturers must also comply with documentation and traceability requirements, maintaining detailed records of moisture content measurements throughout the production process. Many jurisdictions now require Certificate of Analysis (CoA) documentation that specifically includes moisture content data for each batch of lithium hydroxide produced or imported for battery applications.

In the United States, the American National Standards Institute (ANSI) and the Society of Automotive Engineers (SAE) have jointly developed SAE J2380, which includes specifications for moisture determination methods and acceptable limits. Similarly, the European Union has implemented EN 62660-1:2019, which aligns with international standards but adds additional requirements for materials used in European-manufactured batteries.

China, as the world's largest producer of lithium-ion batteries, has established GB/T 26580 standards, which specify moisture content limits of 0.3% for battery-grade lithium hydroxide. These standards also detail the approved measurement methodologies, including Karl Fischer titration and loss-on-drying techniques.

The Japanese Industrial Standards Committee (JISC) has published JIS C8715, which provides comprehensive specifications for lithium battery materials, including moisture content requirements of 0.4% maximum for lithium hydroxide used in high-energy density applications.

Regulatory compliance verification typically requires accredited laboratory testing using validated methods. The International Organization for Standardization (ISO) has developed ISO 18451-1, which standardizes the sampling and testing procedures for battery materials, ensuring consistency across global supply chains.

Recent regulatory trends indicate a move toward more stringent moisture specifications, with several jurisdictions considering reducing maximum allowable moisture content to 0.1% for next-generation battery applications. This shift is driven by the increasing energy density requirements of modern batteries and the corresponding safety considerations.

Manufacturers must also comply with documentation and traceability requirements, maintaining detailed records of moisture content measurements throughout the production process. Many jurisdictions now require Certificate of Analysis (CoA) documentation that specifically includes moisture content data for each batch of lithium hydroxide produced or imported for battery applications.

Environmental Impact of Moisture Testing Procedures

The environmental implications of moisture testing procedures for lithium hydroxide are significant yet often overlooked in industrial settings. Traditional moisture determination methods such as Karl Fischer titration and loss-on-drying techniques utilize chemical reagents and solvents that may pose environmental hazards when improperly managed. These chemicals, including methanol, pyridine derivatives, and iodine-containing compounds, require specialized disposal protocols to prevent contamination of water systems and soil.

Energy consumption represents another critical environmental consideration. Conventional oven-drying methods operate at elevated temperatures for extended periods, resulting in substantial energy expenditure and associated carbon emissions. Modern automated moisture analyzers, while more efficient, still contribute to the industrial carbon footprint, particularly in large-scale lithium processing facilities where continuous testing is required.

Waste generation from moisture testing extends beyond chemical reagents to include single-use sample containers, calibration materials, and testing equipment components. The lithium industry's rapid expansion has multiplied these waste streams, creating disposal challenges that intersect with broader electronic waste management issues. Particularly concerning are the mercury-containing components in some specialized moisture determination equipment.

Recent advancements in green analytical chemistry have introduced more environmentally sustainable testing alternatives. Near-infrared spectroscopy and microwave resonance technology offer non-destructive, reagent-free moisture determination methods that significantly reduce environmental impact. These technologies minimize waste generation while maintaining or even improving measurement accuracy for lithium hydroxide moisture content.

Regulatory frameworks increasingly address the environmental aspects of analytical procedures in battery material production. The European Union's REACH regulations and similar initiatives in North America and Asia have established stricter guidelines for chemical usage in testing protocols. Forward-thinking lithium producers are adopting lifecycle assessment approaches to evaluate the environmental footprint of their quality control procedures, including moisture testing.

Water conservation presents another dimension of environmental concern, particularly relevant in arid regions where many lithium operations are located. Traditional moisture testing methods may consume significant quantities of purified water for sample preparation and equipment cleaning. Implementing closed-loop water systems and waterless testing technologies can substantially reduce this impact while maintaining testing integrity.

Energy consumption represents another critical environmental consideration. Conventional oven-drying methods operate at elevated temperatures for extended periods, resulting in substantial energy expenditure and associated carbon emissions. Modern automated moisture analyzers, while more efficient, still contribute to the industrial carbon footprint, particularly in large-scale lithium processing facilities where continuous testing is required.

Waste generation from moisture testing extends beyond chemical reagents to include single-use sample containers, calibration materials, and testing equipment components. The lithium industry's rapid expansion has multiplied these waste streams, creating disposal challenges that intersect with broader electronic waste management issues. Particularly concerning are the mercury-containing components in some specialized moisture determination equipment.

Recent advancements in green analytical chemistry have introduced more environmentally sustainable testing alternatives. Near-infrared spectroscopy and microwave resonance technology offer non-destructive, reagent-free moisture determination methods that significantly reduce environmental impact. These technologies minimize waste generation while maintaining or even improving measurement accuracy for lithium hydroxide moisture content.

Regulatory frameworks increasingly address the environmental aspects of analytical procedures in battery material production. The European Union's REACH regulations and similar initiatives in North America and Asia have established stricter guidelines for chemical usage in testing protocols. Forward-thinking lithium producers are adopting lifecycle assessment approaches to evaluate the environmental footprint of their quality control procedures, including moisture testing.

Water conservation presents another dimension of environmental concern, particularly relevant in arid regions where many lithium operations are located. Traditional moisture testing methods may consume significant quantities of purified water for sample preparation and equipment cleaning. Implementing closed-loop water systems and waterless testing technologies can substantially reduce this impact while maintaining testing integrity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!