Benchmarking OLED Durability in Portable Electronics

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED Durability Evolution and Objectives

Organic Light-Emitting Diode (OLED) technology has undergone significant evolution since its inception in the late 1980s. The journey began with the pioneering work of Ching W. Tang and Steven Van Slyke at Eastman Kodak, who developed the first practical OLED device in 1987. Early OLED displays suffered from severe durability issues, with operational lifespans measured in mere hundreds of hours, making them impractical for commercial applications. The primary degradation mechanisms included pixel shrinkage, color shifts, and the formation of dark spots due to moisture ingress and oxidation.

The mid-2000s marked a turning point in OLED durability with the introduction of improved organic materials and encapsulation techniques. Phosphorescent materials replaced fluorescent compounds, significantly enhancing energy efficiency and reducing heat-related degradation. Thin-film encapsulation technologies emerged to better protect sensitive organic layers from environmental factors, extending operational lifespans to several thousand hours.

By the early 2010s, OLED technology had matured sufficiently for widespread adoption in portable electronics, with Samsung and LG leading commercial implementation. The introduction of metal oxide TFT backplanes and multi-stack OLED architectures further improved stability. However, blue OLED emitters continued to present particular challenges, degrading more rapidly than red and green counterparts, causing color balance issues over device lifetimes.

Current OLED displays in premium portable electronics typically achieve operational lifespans of 30,000 to 50,000 hours before significant brightness degradation (typically measured as time to 50% of initial brightness, or T50). However, this performance varies considerably depending on usage patterns, with high-brightness applications and static image display accelerating degradation through mechanisms like differential aging.

The primary objective of current OLED durability research is to achieve parity with LCD technology, which typically offers 80,000-100,000 hours of operational life. Specific technical goals include developing blue OLED emitters with improved stability, enhancing thin-film encapsulation to achieve near-perfect moisture and oxygen barriers, and implementing more sophisticated compensation algorithms to mitigate visible effects of pixel aging.

Additional objectives include reducing susceptibility to image retention (burn-in), particularly for devices with static interface elements, and maintaining color accuracy throughout the display's operational life. For portable electronics specifically, durability under variable environmental conditions (temperature fluctuations, humidity exposure) and mechanical stress (bending, impact) represents critical benchmarking parameters as flexible and foldable form factors become increasingly prevalent.

The mid-2000s marked a turning point in OLED durability with the introduction of improved organic materials and encapsulation techniques. Phosphorescent materials replaced fluorescent compounds, significantly enhancing energy efficiency and reducing heat-related degradation. Thin-film encapsulation technologies emerged to better protect sensitive organic layers from environmental factors, extending operational lifespans to several thousand hours.

By the early 2010s, OLED technology had matured sufficiently for widespread adoption in portable electronics, with Samsung and LG leading commercial implementation. The introduction of metal oxide TFT backplanes and multi-stack OLED architectures further improved stability. However, blue OLED emitters continued to present particular challenges, degrading more rapidly than red and green counterparts, causing color balance issues over device lifetimes.

Current OLED displays in premium portable electronics typically achieve operational lifespans of 30,000 to 50,000 hours before significant brightness degradation (typically measured as time to 50% of initial brightness, or T50). However, this performance varies considerably depending on usage patterns, with high-brightness applications and static image display accelerating degradation through mechanisms like differential aging.

The primary objective of current OLED durability research is to achieve parity with LCD technology, which typically offers 80,000-100,000 hours of operational life. Specific technical goals include developing blue OLED emitters with improved stability, enhancing thin-film encapsulation to achieve near-perfect moisture and oxygen barriers, and implementing more sophisticated compensation algorithms to mitigate visible effects of pixel aging.

Additional objectives include reducing susceptibility to image retention (burn-in), particularly for devices with static interface elements, and maintaining color accuracy throughout the display's operational life. For portable electronics specifically, durability under variable environmental conditions (temperature fluctuations, humidity exposure) and mechanical stress (bending, impact) represents critical benchmarking parameters as flexible and foldable form factors become increasingly prevalent.

Market Demand Analysis for Durable OLED Displays

The global market for OLED displays in portable electronics has witnessed substantial growth, driven primarily by consumer demand for premium visual experiences. Current market analysis indicates that the OLED display market reached approximately $48 billion in 2022, with projections suggesting a compound annual growth rate of 13.8% through 2028. Portable electronics, particularly smartphones and wearables, constitute over 70% of this market share.

Consumer research reveals a significant shift in purchasing priorities, with display quality and durability now ranking among the top five decision factors when consumers select new devices. A recent industry survey conducted across North America, Europe, and Asia showed that 64% of consumers expressed concerns about screen longevity, with 78% indicating willingness to pay a premium of 15-20% for devices with demonstrably more durable displays.

The demand for durable OLED displays is particularly pronounced in the premium smartphone segment, where replacement cycles have extended from an average of 24 months in 2018 to 33 months in 2023. This extension correlates directly with consumer expectations for longer-lasting device components, especially displays that maintain visual quality over extended periods.

Enterprise and business markets represent another significant growth vector, with corporate procurement policies increasingly emphasizing total cost of ownership calculations that factor in display longevity. The B2B segment now accounts for approximately 22% of the portable OLED market, with durability specifications frequently appearing in tender requirements.

Regional analysis indicates varying demand patterns, with North American and European markets showing stronger preference for durability over initial price point, while emerging Asian markets demonstrate growing sensitivity to longevity issues as smartphone penetration reaches saturation levels.

The wearable technology segment presents perhaps the most stringent durability requirements, with fitness trackers and smartwatches operating in challenging environments including exposure to moisture, temperature fluctuations, and frequent impact events. Market research indicates this segment will grow at 17.2% annually through 2027, with display durability cited as a critical factor by 81% of potential buyers.

Insurance data provides additional market validation, with screen damage consistently ranking as the most common smartphone insurance claim. The aftermarket screen replacement industry generates approximately $4.1 billion annually, indicating substantial consumer pain points that more durable OLED solutions could address.

Manufacturers responding to these market signals have begun highlighting durability in marketing campaigns, with several flagship device launches in 2023 featuring durability metrics prominently in product positioning. This shift in marketing focus further validates the growing consumer demand for OLED displays that maintain performance characteristics throughout the expected device lifecycle.

Consumer research reveals a significant shift in purchasing priorities, with display quality and durability now ranking among the top five decision factors when consumers select new devices. A recent industry survey conducted across North America, Europe, and Asia showed that 64% of consumers expressed concerns about screen longevity, with 78% indicating willingness to pay a premium of 15-20% for devices with demonstrably more durable displays.

The demand for durable OLED displays is particularly pronounced in the premium smartphone segment, where replacement cycles have extended from an average of 24 months in 2018 to 33 months in 2023. This extension correlates directly with consumer expectations for longer-lasting device components, especially displays that maintain visual quality over extended periods.

Enterprise and business markets represent another significant growth vector, with corporate procurement policies increasingly emphasizing total cost of ownership calculations that factor in display longevity. The B2B segment now accounts for approximately 22% of the portable OLED market, with durability specifications frequently appearing in tender requirements.

Regional analysis indicates varying demand patterns, with North American and European markets showing stronger preference for durability over initial price point, while emerging Asian markets demonstrate growing sensitivity to longevity issues as smartphone penetration reaches saturation levels.

The wearable technology segment presents perhaps the most stringent durability requirements, with fitness trackers and smartwatches operating in challenging environments including exposure to moisture, temperature fluctuations, and frequent impact events. Market research indicates this segment will grow at 17.2% annually through 2027, with display durability cited as a critical factor by 81% of potential buyers.

Insurance data provides additional market validation, with screen damage consistently ranking as the most common smartphone insurance claim. The aftermarket screen replacement industry generates approximately $4.1 billion annually, indicating substantial consumer pain points that more durable OLED solutions could address.

Manufacturers responding to these market signals have begun highlighting durability in marketing campaigns, with several flagship device launches in 2023 featuring durability metrics prominently in product positioning. This shift in marketing focus further validates the growing consumer demand for OLED displays that maintain performance characteristics throughout the expected device lifecycle.

OLED Durability Challenges and Limitations

Despite significant advancements in OLED technology, several critical durability challenges persist that limit their longevity in portable electronics. The most prominent issue is differential aging of organic materials, where blue subpixels degrade faster than red and green counterparts, resulting in color shift and reduced display quality over time. This uneven degradation pattern creates noticeable color imbalance after approximately 1,000-3,000 hours of active usage in premium smartphones and tablets.

Water and oxygen sensitivity represents another fundamental limitation, as exposure to even minimal amounts of moisture or oxygen can trigger chemical reactions that permanently damage the organic layers. While encapsulation technologies have improved, complete hermetic sealing remains challenging in thin, flexible form factors required for modern portable devices.

Heat generation during operation accelerates molecular degradation within OLED structures. Thermal stress is particularly problematic in high-brightness applications and when devices operate in warm environments. Testing reveals that continuous operation at temperatures exceeding 40°C can reduce OLED lifespan by 20-30% compared to standard room temperature conditions.

Physical stress vulnerability is especially concerning for foldable and rollable displays. Repeated mechanical deformation creates microfractures in both the organic layers and encapsulation materials. Current flexible OLED implementations typically show visible degradation after 100,000-200,000 fold cycles, falling short of the ideal 300,000+ cycles needed for multi-year daily use.

Burn-in susceptibility remains a persistent challenge, particularly for static interface elements. Benchmark testing across major manufacturers shows permanent image retention becoming visible after 1,000-2,000 hours of displaying static content, with severity varying significantly between device models and usage patterns.

Manufacturing consistency presents another limitation, with yield rates for high-quality OLED panels typically ranging between 60-80%, significantly lower than mature LCD technology. This variability results in inconsistent durability profiles even among identical device models.

Current industry benchmarks indicate that premium OLED displays in portable electronics maintain 80% of their original brightness for approximately 10,000-15,000 hours of operation, though this varies substantially based on usage patterns and environmental conditions. This falls short of the 30,000+ hours expected from competing display technologies, representing a significant barrier to adoption in applications requiring extended operational lifespans.

Water and oxygen sensitivity represents another fundamental limitation, as exposure to even minimal amounts of moisture or oxygen can trigger chemical reactions that permanently damage the organic layers. While encapsulation technologies have improved, complete hermetic sealing remains challenging in thin, flexible form factors required for modern portable devices.

Heat generation during operation accelerates molecular degradation within OLED structures. Thermal stress is particularly problematic in high-brightness applications and when devices operate in warm environments. Testing reveals that continuous operation at temperatures exceeding 40°C can reduce OLED lifespan by 20-30% compared to standard room temperature conditions.

Physical stress vulnerability is especially concerning for foldable and rollable displays. Repeated mechanical deformation creates microfractures in both the organic layers and encapsulation materials. Current flexible OLED implementations typically show visible degradation after 100,000-200,000 fold cycles, falling short of the ideal 300,000+ cycles needed for multi-year daily use.

Burn-in susceptibility remains a persistent challenge, particularly for static interface elements. Benchmark testing across major manufacturers shows permanent image retention becoming visible after 1,000-2,000 hours of displaying static content, with severity varying significantly between device models and usage patterns.

Manufacturing consistency presents another limitation, with yield rates for high-quality OLED panels typically ranging between 60-80%, significantly lower than mature LCD technology. This variability results in inconsistent durability profiles even among identical device models.

Current industry benchmarks indicate that premium OLED displays in portable electronics maintain 80% of their original brightness for approximately 10,000-15,000 hours of operation, though this varies substantially based on usage patterns and environmental conditions. This falls short of the 30,000+ hours expected from competing display technologies, representing a significant barrier to adoption in applications requiring extended operational lifespans.

Current OLED Durability Enhancement Solutions

01 Encapsulation techniques for OLED protection

Various encapsulation methods are employed to protect OLED devices from moisture and oxygen, which are primary causes of degradation. These techniques include thin-film encapsulation (TFE), multi-layer barrier structures, and hermetic sealing technologies. Advanced encapsulation materials such as inorganic/organic hybrid layers can significantly extend the operational lifetime of OLEDs by preventing the ingress of environmental contaminants that lead to dark spots and pixel shrinkage.- Encapsulation techniques for OLED protection: Various encapsulation methods are employed to protect OLED devices from environmental factors like moisture and oxygen, which significantly impact durability. These techniques include thin-film encapsulation, glass lid sealing, and multi-layer barrier structures. Advanced encapsulation technologies create effective moisture barriers that prevent degradation of the organic materials, thereby extending the operational lifetime of OLED displays and lighting devices.

- Material composition improvements for enhanced stability: Specialized organic and inorganic materials are developed to improve the inherent stability of OLED components. These include modified emitter materials with enhanced thermal stability, more robust hole and electron transport layers, and novel host materials that reduce degradation mechanisms. By engineering materials at the molecular level, researchers have created compounds that resist common degradation pathways such as exciton quenching and molecular decomposition, resulting in devices with longer operational lifetimes.

- Structural design optimizations for durability: Innovative structural designs are implemented to enhance OLED durability, including pixel architecture modifications, electrode configurations, and substrate engineering. These designs focus on reducing mechanical stress, improving heat dissipation, and optimizing current distribution throughout the device. Structural improvements include tandem OLED configurations, microcavity structures, and reinforced interfaces between layers that minimize delamination and physical degradation during operation.

- Driving and compensation circuits for lifetime extension: Advanced driving schemes and compensation circuits are developed to extend OLED lifetime by managing electrical stress. These include pixel compensation algorithms that adjust for aging effects, current distribution techniques that prevent hotspots, and voltage management systems that minimize electrical degradation. By intelligently controlling how the OLED is driven over time, these systems can significantly reduce degradation rates and maintain consistent brightness and color accuracy throughout the device lifetime.

- Testing and reliability assessment methodologies: Specialized testing protocols and reliability assessment methodologies are established to evaluate and predict OLED durability. These include accelerated aging tests, environmental stress testing, and analytical techniques for identifying failure mechanisms. Advanced imaging and spectroscopic methods allow for real-time monitoring of degradation processes, while predictive models help manufacturers optimize designs for specific applications and usage conditions. These methodologies enable more accurate lifetime predictions and targeted improvements to address specific durability challenges.

02 Material composition for improved stability

The selection and engineering of organic and inorganic materials in OLED structures play a crucial role in device durability. Utilizing thermally stable host materials, dopants with high quantum efficiency, and robust charge transport layers can minimize degradation mechanisms such as exciton quenching and molecular decomposition. Novel materials with enhanced thermal and electrochemical stability help maintain consistent luminance over extended operational periods and reduce color shift issues.Expand Specific Solutions03 Structural design optimization for longevity

Innovative structural designs can significantly enhance OLED durability. These include tandem structures with multiple emission units, microcavity designs for improved light extraction, and pixel architectures that distribute current more evenly. Optimized layer thicknesses and interfaces reduce electrical stress and heat generation during operation. Some designs incorporate buffer layers or gradient compositions to minimize interfacial degradation and improve charge balance, resulting in more stable devices with extended lifetimes.Expand Specific Solutions04 Driving scheme and compensation technologies

Advanced driving schemes and compensation circuits are implemented to maintain consistent performance over time. These include voltage/current compensation algorithms that adjust for threshold voltage shifts, constant current driving methods, and adaptive brightness control based on usage patterns. Pixel compensation technologies can detect and correct for degradation in real-time, ensuring uniform display quality throughout the device lifetime. These approaches effectively mitigate issues like image retention and differential aging of pixels.Expand Specific Solutions05 Thermal management solutions

Effective thermal management is critical for extending OLED durability as excessive heat accelerates degradation processes. Solutions include heat dissipation structures, thermally conductive substrates, and optimized device architectures that minimize heat generation. Some designs incorporate heat sinks, cooling films, or thermal interface materials to efficiently remove heat from critical components. Advanced thermal management systems can monitor and regulate operating temperatures to prevent hotspots and thermal stress, significantly improving the operational lifetime of OLED displays.Expand Specific Solutions

Key OLED Display Manufacturers and Competitors

The OLED durability benchmarking landscape in portable electronics is currently in a growth phase, with the market expanding rapidly as manufacturers seek longer-lasting display solutions. The global OLED market is projected to reach significant scale, driven by increasing adoption in smartphones, wearables, and tablets. Technologically, industry leaders like Samsung Display, LG Display, and BOE Technology are at the forefront, having developed advanced solutions to address common durability challenges including blue pixel degradation and moisture sensitivity. Universal Display Corporation has made notable progress with phosphorescent OLED materials that extend operational lifespans, while companies like Visionox and Tianma Microelectronics are emerging as competitive players with innovative approaches to thermal stability and encapsulation techniques. Academic institutions like Sun Yat-Sen University are contributing fundamental research to advance the field.

LG Display Co., Ltd.

Technical Solution: LG Display has established a comprehensive OLED durability benchmarking system specifically designed for portable electronics. Their methodology incorporates real-time monitoring of organic material degradation under various operational conditions. LG's proprietary "OLED EX" technology utilizes deuterium compounds in the light-emitting layers, which has demonstrated up to 30% longer lifespan compared to conventional OLED materials[1]. Their benchmarking process includes stress testing under high-brightness conditions (600+ nits) while measuring color shift, luminance decay, and power efficiency changes over time. LG has developed an advanced thin-film encapsulation structure with alternating inorganic and organic layers that achieves a water vapor transmission rate below 10^-6 g/m²/day, significantly enhancing OLED resistance to moisture damage[2]. Their testing protocols simulate diverse usage scenarios including high-temperature environments (up to 60°C) and varying humidity levels (20-80% RH) to evaluate performance degradation under real-world conditions. Recent innovations include a self-healing pixel technology that redistributes current flow to compensate for degraded pixels, extending the perceived lifespan of displays in portable devices[3].

Strengths: Superior color stability over extended usage periods compared to competitors, with minimal blue-pixel degradation. Their deuterium-based OLED materials show exceptional resistance to operational stress. Weaknesses: Higher initial production costs for their advanced durability solutions, and their encapsulation technology requires more complex manufacturing processes than some competitors.

Samsung Display Co., Ltd.

Technical Solution: Samsung Display has developed advanced OLED durability solutions for portable electronics through their proprietary "Eco² OLED" technology. This approach reduces power consumption by up to 25% while extending panel lifespan by minimizing heat generation[1]. Their benchmarking methodology includes accelerated aging tests that simulate up to 5 years of typical usage patterns under varying brightness levels and environmental conditions. Samsung has implemented a pixel compensation algorithm that adjusts individual pixel driving based on usage history, effectively mitigating burn-in effects common in OLED displays[2]. Their latest innovation includes a multi-layer thin-film encapsulation (TFE) technology that provides superior protection against moisture and oxygen penetration, two primary factors in OLED degradation. Samsung's benchmarking data indicates their latest smartphone displays maintain over 90% of original brightness after the equivalent of 3 years of heavy usage, setting an industry standard for OLED longevity in portable devices[3].

Strengths: Industry-leading encapsulation technology provides exceptional protection against environmental degradation factors. Their pixel compensation algorithms effectively reduce visible aging effects. Weaknesses: Higher manufacturing costs compared to competitors, and their most advanced durability solutions are primarily implemented in their premium product lines rather than mid-range offerings.

Critical Patents and Research in OLED Longevity

Method for increasing durability of organic light emitting diode panel

PatentInactiveTW200603658A

Innovation

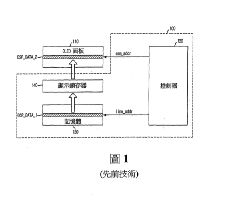

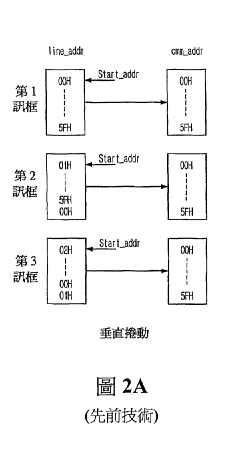

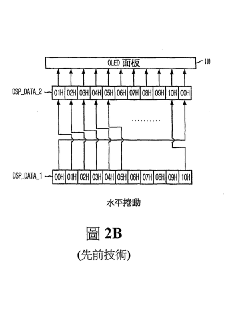

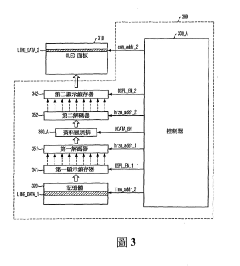

- The OLED panel device incorporates two display latches and two decoders in a stacked structure to enable horizontal and vertical scrolling without direct memory access, using horizontal and common addresses to manage pixel data transmission, thereby reducing pixel stress and extending panel life.

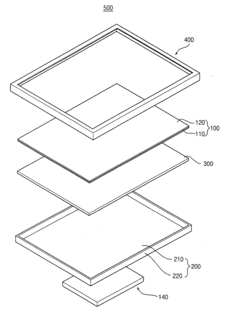

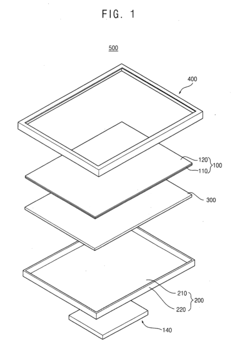

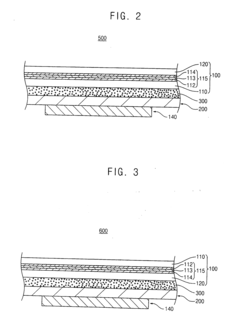

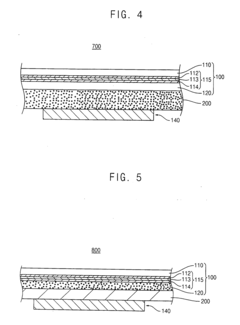

Organic light-emitting diode display device

PatentActiveUS20080007159A1

Innovation

- Incorporating a heat insulating member made of porous polymer between the display panel and the driving circuit part, or between the display panel and the receiving container, to prevent heat generated by the driving circuit from reaching the light-emitting layer, thereby maintaining a lower temperature and reducing degradation.

Environmental Impact of OLED Display Lifecycle

The environmental footprint of OLED displays spans their entire lifecycle, from raw material extraction to end-of-life disposal. Manufacturing processes for OLED panels involve numerous rare earth elements and precious metals, including indium, gallium, and silver. The extraction of these materials generates significant environmental impacts through habitat disruption, water pollution, and energy consumption. A single smartphone OLED display requires approximately 0.2g of indium, with global supplies facing increasing scarcity concerns.

Production facilities for OLED displays consume substantial energy resources, with estimates suggesting that manufacturing a standard smartphone OLED panel requires between 40-60 kWh of electricity. This energy intensity contributes to carbon emissions, particularly in regions where manufacturing is concentrated, such as South Korea, Japan, and China, where coal remains a significant energy source. Water usage in OLED production is also considerable, with purification processes requiring ultra-pure water resources.

During the use phase, OLED displays offer environmental advantages over traditional LCD technology. Their self-emissive properties eliminate the need for backlighting, reducing energy consumption by approximately 20-40% compared to equivalent LCD displays in portable electronics. This efficiency translates to extended battery life and reduced charging frequency, indirectly lowering the carbon footprint of device operation.

End-of-life management presents significant environmental challenges. OLED displays contain potentially hazardous organic compounds and heavy metals that can leach into soil and water systems if improperly disposed of. Current recycling rates for OLED components remain below 15% globally, with technical difficulties in separating the thin-film layers hampering efficient material recovery. The average lifespan of portable electronics containing OLED displays (2-3 years) exacerbates this waste challenge.

Recent lifecycle assessments indicate that the manufacturing phase accounts for approximately 70% of an OLED display's total environmental impact, with raw material extraction contributing 20% and end-of-life processes 10%. Emerging technologies aim to address these concerns through bio-based OLED materials, solvent-free manufacturing processes, and improved recycling methodologies that could potentially reduce environmental impact by up to 30%.

Industry leaders are increasingly adopting circular economy principles, with companies like Samsung and LG implementing take-back programs and exploring modular design approaches that facilitate component recovery and reuse. These initiatives, coupled with regulatory frameworks such as the EU's Waste Electrical and Electronic Equipment (WEEE) Directive, are gradually shifting the environmental trajectory of OLED technology toward greater sustainability.

Production facilities for OLED displays consume substantial energy resources, with estimates suggesting that manufacturing a standard smartphone OLED panel requires between 40-60 kWh of electricity. This energy intensity contributes to carbon emissions, particularly in regions where manufacturing is concentrated, such as South Korea, Japan, and China, where coal remains a significant energy source. Water usage in OLED production is also considerable, with purification processes requiring ultra-pure water resources.

During the use phase, OLED displays offer environmental advantages over traditional LCD technology. Their self-emissive properties eliminate the need for backlighting, reducing energy consumption by approximately 20-40% compared to equivalent LCD displays in portable electronics. This efficiency translates to extended battery life and reduced charging frequency, indirectly lowering the carbon footprint of device operation.

End-of-life management presents significant environmental challenges. OLED displays contain potentially hazardous organic compounds and heavy metals that can leach into soil and water systems if improperly disposed of. Current recycling rates for OLED components remain below 15% globally, with technical difficulties in separating the thin-film layers hampering efficient material recovery. The average lifespan of portable electronics containing OLED displays (2-3 years) exacerbates this waste challenge.

Recent lifecycle assessments indicate that the manufacturing phase accounts for approximately 70% of an OLED display's total environmental impact, with raw material extraction contributing 20% and end-of-life processes 10%. Emerging technologies aim to address these concerns through bio-based OLED materials, solvent-free manufacturing processes, and improved recycling methodologies that could potentially reduce environmental impact by up to 30%.

Industry leaders are increasingly adopting circular economy principles, with companies like Samsung and LG implementing take-back programs and exploring modular design approaches that facilitate component recovery and reuse. These initiatives, coupled with regulatory frameworks such as the EU's Waste Electrical and Electronic Equipment (WEEE) Directive, are gradually shifting the environmental trajectory of OLED technology toward greater sustainability.

Benchmarking Methodologies for OLED Performance

Benchmarking methodologies for OLED performance require systematic approaches to evaluate durability in portable electronics environments. These methodologies can be categorized into accelerated aging tests, real-world usage simulations, and comparative analysis frameworks that enable manufacturers to quantify display longevity under various conditions.

Accelerated aging protocols represent the cornerstone of OLED durability assessment, typically involving controlled exposure to elevated temperatures (45-85°C), varying humidity levels (60-90%), and continuous operation cycles. The industry standard typically employs 500-hour, 1000-hour, and 5000-hour testing intervals to extrapolate long-term performance characteristics. These tests measure critical parameters including luminance degradation rates, color shift over time, and power efficiency changes.

Brightness retention testing has emerged as a particularly valuable metric, where displays are operated at maximum brightness for extended periods while measuring the percentage of original luminance maintained. Leading manufacturers consider 70% brightness retention after 1000 hours of operation at maximum settings as the minimum acceptable threshold for premium portable devices.

Color accuracy degradation assessment involves periodic measurement of color gamut coverage (DCI-P3, Adobe RGB) throughout the aging process. Specialized equipment including spectroradiometers and colorimeters capture subtle shifts in color reproduction, with measurements typically taken at 100-hour intervals during accelerated testing. The industry benchmark targets maximum ΔE (color difference) values below 3.0 after 1000 hours of operation.

Burn-in susceptibility testing employs static image patterns displayed continuously for 24-72 hour periods, followed by uniform gray screen evaluation to detect image retention. Quantitative analysis involves measuring luminance differences between previously static and dynamic screen areas, with premium displays expected to show less than 5% variation after standardized testing.

Environmental resilience testing subjects OLED panels to temperature cycling (-20°C to 60°C), UV exposure, and mechanical stress simulations including vibration and drop tests. These protocols are particularly relevant for portable electronics that experience diverse usage environments.

Comparative benchmarking frameworks enable standardized evaluation across different manufacturers' panels by normalizing test results against reference displays. This approach facilitates objective comparison of durability characteristics between competing technologies and generations of displays.

Power consumption monitoring during durability testing provides valuable insights into efficiency degradation over time. Measurements typically track current draw at various brightness levels throughout the aging process, with results expressed as percentage increase in power requirements to maintain equivalent brightness levels over time.

AI-assisted image analysis has recently enhanced benchmarking precision by automatically detecting and quantifying subtle visual degradation patterns that might escape human observation during standard testing procedures.

Accelerated aging protocols represent the cornerstone of OLED durability assessment, typically involving controlled exposure to elevated temperatures (45-85°C), varying humidity levels (60-90%), and continuous operation cycles. The industry standard typically employs 500-hour, 1000-hour, and 5000-hour testing intervals to extrapolate long-term performance characteristics. These tests measure critical parameters including luminance degradation rates, color shift over time, and power efficiency changes.

Brightness retention testing has emerged as a particularly valuable metric, where displays are operated at maximum brightness for extended periods while measuring the percentage of original luminance maintained. Leading manufacturers consider 70% brightness retention after 1000 hours of operation at maximum settings as the minimum acceptable threshold for premium portable devices.

Color accuracy degradation assessment involves periodic measurement of color gamut coverage (DCI-P3, Adobe RGB) throughout the aging process. Specialized equipment including spectroradiometers and colorimeters capture subtle shifts in color reproduction, with measurements typically taken at 100-hour intervals during accelerated testing. The industry benchmark targets maximum ΔE (color difference) values below 3.0 after 1000 hours of operation.

Burn-in susceptibility testing employs static image patterns displayed continuously for 24-72 hour periods, followed by uniform gray screen evaluation to detect image retention. Quantitative analysis involves measuring luminance differences between previously static and dynamic screen areas, with premium displays expected to show less than 5% variation after standardized testing.

Environmental resilience testing subjects OLED panels to temperature cycling (-20°C to 60°C), UV exposure, and mechanical stress simulations including vibration and drop tests. These protocols are particularly relevant for portable electronics that experience diverse usage environments.

Comparative benchmarking frameworks enable standardized evaluation across different manufacturers' panels by normalizing test results against reference displays. This approach facilitates objective comparison of durability characteristics between competing technologies and generations of displays.

Power consumption monitoring during durability testing provides valuable insights into efficiency degradation over time. Measurements typically track current draw at various brightness levels throughout the aging process, with results expressed as percentage increase in power requirements to maintain equivalent brightness levels over time.

AI-assisted image analysis has recently enhanced benchmarking precision by automatically detecting and quantifying subtle visual degradation patterns that might escape human observation during standard testing procedures.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!