Benchmarking OLED Material Integrity Under Mechanical Strain

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

OLED Flexibility Evolution and Research Objectives

The evolution of OLED (Organic Light Emitting Diode) technology has undergone significant transformation since its inception in the late 1980s. Initially developed as rigid display components, OLEDs have progressively evolved toward flexible applications, marking a revolutionary shift in display technology. The journey from rigid to flexible OLEDs represents one of the most significant technological advancements in modern electronics, enabling new form factors and applications previously unimaginable with conventional display technologies.

Early OLED implementations focused primarily on performance metrics such as luminance efficiency, color accuracy, and operational lifetime. However, as consumer electronics began trending toward more ergonomic and versatile form factors, the demand for flexible display solutions accelerated dramatically. This market-driven evolution pushed researchers to address fundamental challenges in material science, particularly regarding the mechanical properties of organic semiconductors and their supporting substrates.

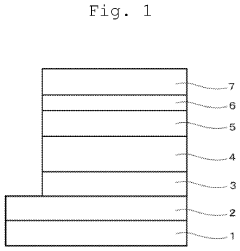

The transition toward flexible OLEDs has necessitated comprehensive redesign of material compositions, layer structures, and encapsulation techniques. Traditional glass substrates have been replaced with specialized polymers and ultra-thin glass, while rigid encapsulation methods have given way to thin-film barrier technologies. These advancements have enabled OLEDs to withstand increasingly demanding mechanical conditions, from simple curved displays to fully foldable and rollable implementations.

Current research objectives in OLED flexibility center on establishing standardized methodologies for evaluating material integrity under various mechanical strain conditions. The primary goal is to develop comprehensive benchmarking protocols that accurately predict OLED performance degradation resulting from repeated mechanical stress. This includes quantifying critical parameters such as crack initiation thresholds, delamination resistance, and conductivity changes under dynamic bending conditions.

Additionally, research aims to correlate mechanical strain patterns with specific failure modes in different OLED material systems. By understanding these relationships, researchers can develop more resilient material compositions and structural designs that maintain optimal electro-optical performance even after thousands of folding cycles. This knowledge is crucial for advancing next-generation flexible display technologies that can withstand daily use in consumer applications.

The ultimate objective of current benchmarking efforts is to establish industry-standard testing protocols that enable meaningful comparison between different material systems and structural approaches. These standardized methods will accelerate innovation by providing clear metrics for improvement and facilitating more efficient knowledge transfer between research institutions and commercial manufacturers. Such benchmarks will serve as essential tools for guiding future OLED material development toward increasingly robust flexible display solutions.

Early OLED implementations focused primarily on performance metrics such as luminance efficiency, color accuracy, and operational lifetime. However, as consumer electronics began trending toward more ergonomic and versatile form factors, the demand for flexible display solutions accelerated dramatically. This market-driven evolution pushed researchers to address fundamental challenges in material science, particularly regarding the mechanical properties of organic semiconductors and their supporting substrates.

The transition toward flexible OLEDs has necessitated comprehensive redesign of material compositions, layer structures, and encapsulation techniques. Traditional glass substrates have been replaced with specialized polymers and ultra-thin glass, while rigid encapsulation methods have given way to thin-film barrier technologies. These advancements have enabled OLEDs to withstand increasingly demanding mechanical conditions, from simple curved displays to fully foldable and rollable implementations.

Current research objectives in OLED flexibility center on establishing standardized methodologies for evaluating material integrity under various mechanical strain conditions. The primary goal is to develop comprehensive benchmarking protocols that accurately predict OLED performance degradation resulting from repeated mechanical stress. This includes quantifying critical parameters such as crack initiation thresholds, delamination resistance, and conductivity changes under dynamic bending conditions.

Additionally, research aims to correlate mechanical strain patterns with specific failure modes in different OLED material systems. By understanding these relationships, researchers can develop more resilient material compositions and structural designs that maintain optimal electro-optical performance even after thousands of folding cycles. This knowledge is crucial for advancing next-generation flexible display technologies that can withstand daily use in consumer applications.

The ultimate objective of current benchmarking efforts is to establish industry-standard testing protocols that enable meaningful comparison between different material systems and structural approaches. These standardized methods will accelerate innovation by providing clear metrics for improvement and facilitating more efficient knowledge transfer between research institutions and commercial manufacturers. Such benchmarks will serve as essential tools for guiding future OLED material development toward increasingly robust flexible display solutions.

Market Analysis for Flexible Display Technologies

The flexible display market has witnessed remarkable growth in recent years, driven by increasing consumer demand for portable, lightweight, and durable electronic devices. As of 2023, the global flexible display market is valued at approximately 15.1 billion USD, with projections indicating a compound annual growth rate (CAGR) of 33.4% through 2028. This exponential growth trajectory underscores the significant market potential for technologies that enhance the mechanical integrity of OLED materials under strain conditions.

Smartphone manufacturers represent the largest segment of flexible display technology adopters, accounting for nearly 62% of the current market share. Samsung and Apple lead this segment, with their flagship devices incorporating flexible OLED panels that offer enhanced user experiences through curved edges and foldable designs. The foldable smartphone sub-segment alone has grown by 126% year-over-year, indicating strong consumer acceptance despite premium pricing.

Beyond smartphones, wearable technology constitutes the second-largest application segment at 18% market share, with smartwatches and fitness trackers driving demand. Emerging applications in automotive dashboards (8%), smart home devices (7%), and medical equipment (5%) represent rapidly growing sectors that will further expand the market for strain-resistant OLED materials.

Regional analysis reveals Asia-Pacific as the dominant market, controlling 68% of global production capacity, with South Korea and China as manufacturing hubs. North America and Europe follow with 17% and 12% respectively, primarily as consumption markets rather than production centers.

Consumer preference surveys indicate that durability and longevity rank among the top three purchasing considerations for devices with flexible displays. Specifically, 78% of consumers express concern about screen damage in foldable devices, highlighting the critical importance of mechanical strain resistance in OLED materials.

The competitive landscape features display manufacturers like Samsung Display, LG Display, and BOE Technology leading in production capacity, while materials science companies including Universal Display Corporation, DuPont, and Merck focus on developing advanced OLED compounds with enhanced mechanical properties. Strategic partnerships between these entities have increased by 35% in the past two years, indicating industry recognition of the importance of material integrity under mechanical strain.

Market forecasts suggest that improvements in OLED material integrity could potentially reduce manufacturing costs by 14-18% through decreased rejection rates, while extending device lifespans by 30-40%, creating significant value for both manufacturers and consumers. This economic incentive drives continued investment in benchmarking and improving OLED performance under mechanical strain conditions.

Smartphone manufacturers represent the largest segment of flexible display technology adopters, accounting for nearly 62% of the current market share. Samsung and Apple lead this segment, with their flagship devices incorporating flexible OLED panels that offer enhanced user experiences through curved edges and foldable designs. The foldable smartphone sub-segment alone has grown by 126% year-over-year, indicating strong consumer acceptance despite premium pricing.

Beyond smartphones, wearable technology constitutes the second-largest application segment at 18% market share, with smartwatches and fitness trackers driving demand. Emerging applications in automotive dashboards (8%), smart home devices (7%), and medical equipment (5%) represent rapidly growing sectors that will further expand the market for strain-resistant OLED materials.

Regional analysis reveals Asia-Pacific as the dominant market, controlling 68% of global production capacity, with South Korea and China as manufacturing hubs. North America and Europe follow with 17% and 12% respectively, primarily as consumption markets rather than production centers.

Consumer preference surveys indicate that durability and longevity rank among the top three purchasing considerations for devices with flexible displays. Specifically, 78% of consumers express concern about screen damage in foldable devices, highlighting the critical importance of mechanical strain resistance in OLED materials.

The competitive landscape features display manufacturers like Samsung Display, LG Display, and BOE Technology leading in production capacity, while materials science companies including Universal Display Corporation, DuPont, and Merck focus on developing advanced OLED compounds with enhanced mechanical properties. Strategic partnerships between these entities have increased by 35% in the past two years, indicating industry recognition of the importance of material integrity under mechanical strain.

Market forecasts suggest that improvements in OLED material integrity could potentially reduce manufacturing costs by 14-18% through decreased rejection rates, while extending device lifespans by 30-40%, creating significant value for both manufacturers and consumers. This economic incentive drives continued investment in benchmarking and improving OLED performance under mechanical strain conditions.

Current Limitations in OLED Material Durability

Despite significant advancements in OLED technology, current materials face substantial durability challenges when subjected to mechanical strain. The organic layers in OLED displays typically exhibit brittle characteristics, with fracture thresholds occurring at strain levels between 1-3%. This limitation severely restricts their application in flexible and foldable devices where repeated bending and folding actions are essential operational requirements.

Material degradation under mechanical stress manifests through several failure mechanisms. Crack propagation represents the most visible form of damage, where tensile strain exceeds the elastic limit of the organic semiconductor materials, creating microscopic fractures that expand with continued stress. These cracks disrupt electron transport pathways, leading to visible dark spots and non-functional pixel areas.

Interfacial delamination presents another critical limitation, occurring at the boundaries between different material layers. The varying mechanical properties of electrode materials (typically ITO or metal films) and organic layers create stress concentration points during bending. When strain is applied, these interfaces experience shear forces that can cause separation, resulting in catastrophic device failure even before the individual materials reach their breaking points.

Crystallization under strain further compromises OLED durability. Many organic semiconductors exist in amorphous states for optimal charge transport properties. However, mechanical strain can induce molecular reorganization and crystallization, altering the electronic properties and reducing luminescence efficiency. This strain-induced crystallization is particularly problematic in phosphorescent materials commonly used for green and red emission layers.

Environmental factors compound these mechanical limitations. Oxygen and moisture ingress through microcracks formed during bending accelerates degradation through oxidation of the emissive materials. Current encapsulation technologies provide insufficient protection when the barrier layers themselves are compromised by mechanical deformation.

The temperature-dependent behavior of OLED materials adds another layer of complexity. Materials that demonstrate reasonable flexibility at room temperature often become significantly more brittle at lower temperatures, while elevated temperatures can induce plastic deformation and permanent structural changes. This temperature sensitivity narrows the operational window for flexible OLED applications.

Standardized testing methodologies for evaluating mechanical durability remain inconsistent across the industry, complicating comparative analysis between different material solutions. Current bend radius tests, folding endurance measurements, and tensile strain evaluations lack uniformity in testing conditions, making it difficult to establish reliable benchmarks for material performance under real-world usage scenarios.

Material degradation under mechanical stress manifests through several failure mechanisms. Crack propagation represents the most visible form of damage, where tensile strain exceeds the elastic limit of the organic semiconductor materials, creating microscopic fractures that expand with continued stress. These cracks disrupt electron transport pathways, leading to visible dark spots and non-functional pixel areas.

Interfacial delamination presents another critical limitation, occurring at the boundaries between different material layers. The varying mechanical properties of electrode materials (typically ITO or metal films) and organic layers create stress concentration points during bending. When strain is applied, these interfaces experience shear forces that can cause separation, resulting in catastrophic device failure even before the individual materials reach their breaking points.

Crystallization under strain further compromises OLED durability. Many organic semiconductors exist in amorphous states for optimal charge transport properties. However, mechanical strain can induce molecular reorganization and crystallization, altering the electronic properties and reducing luminescence efficiency. This strain-induced crystallization is particularly problematic in phosphorescent materials commonly used for green and red emission layers.

Environmental factors compound these mechanical limitations. Oxygen and moisture ingress through microcracks formed during bending accelerates degradation through oxidation of the emissive materials. Current encapsulation technologies provide insufficient protection when the barrier layers themselves are compromised by mechanical deformation.

The temperature-dependent behavior of OLED materials adds another layer of complexity. Materials that demonstrate reasonable flexibility at room temperature often become significantly more brittle at lower temperatures, while elevated temperatures can induce plastic deformation and permanent structural changes. This temperature sensitivity narrows the operational window for flexible OLED applications.

Standardized testing methodologies for evaluating mechanical durability remain inconsistent across the industry, complicating comparative analysis between different material solutions. Current bend radius tests, folding endurance measurements, and tensile strain evaluations lack uniformity in testing conditions, making it difficult to establish reliable benchmarks for material performance under real-world usage scenarios.

Benchmark Methodologies for OLED Material Integrity

01 Material stability and degradation prevention in OLED devices

Various techniques are employed to enhance the stability of OLED materials and prevent degradation during operation. These include specialized encapsulation methods, use of stabilizing additives, and structural modifications to the organic compounds. These approaches help maintain material integrity over time, extending device lifetime and preserving performance characteristics under operational conditions.- Material stability and degradation prevention in OLED devices: Various approaches are employed to enhance the stability of OLED materials and prevent degradation, which is crucial for maintaining device performance over time. These include specialized encapsulation techniques, use of stabilizing additives, and structural modifications of organic materials to improve their resistance to environmental factors such as moisture, oxygen, and heat. These methods help preserve the integrity of the emissive materials and extend the operational lifetime of OLED devices.

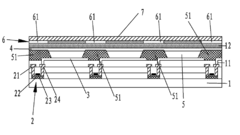

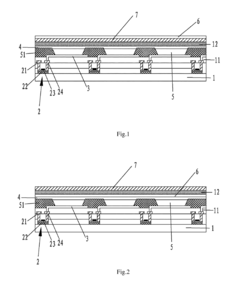

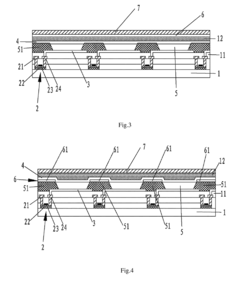

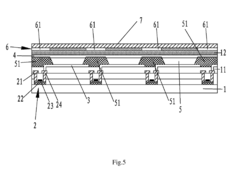

- Encapsulation technologies for OLED material protection: Advanced encapsulation technologies are developed to protect sensitive OLED materials from environmental contaminants. These include multi-layer barrier films, inorganic/organic hybrid encapsulation structures, and edge sealing techniques that effectively prevent moisture and oxygen ingress. Some approaches utilize thin-film encapsulation with alternating organic and inorganic layers to create tortuous paths for contaminants while maintaining flexibility and transparency required for display applications.

- Novel OLED material compositions for enhanced durability: Innovative material compositions are designed to enhance the inherent durability of OLED components. These include modified host materials, dopants with improved thermal stability, and charge transport materials resistant to electrochemical degradation. By engineering molecular structures with stronger bonds, incorporating stabilizing functional groups, and optimizing energy level alignment between layers, these compositions maintain their integrity under operational stress, resulting in more robust OLED devices with extended lifespans.

- Manufacturing processes to preserve OLED material integrity: Specialized manufacturing processes are developed to preserve the integrity of OLED materials during device fabrication. These include controlled deposition environments, optimized annealing protocols, and contamination-free handling procedures. Advanced techniques such as vacuum thermal evaporation under ultra-high purity conditions, solution processing in inert atmospheres, and laser-assisted patterning methods help minimize material degradation during manufacturing, ensuring that the intrinsic properties of the organic materials are maintained in the final device.

- Testing and quality control methods for OLED material integrity: Comprehensive testing and quality control methods are implemented to evaluate and ensure OLED material integrity throughout the development and production processes. These include accelerated aging tests, spectroscopic analysis techniques, and in-situ monitoring systems that can detect early signs of material degradation. Advanced analytical methods such as time-resolved photoluminescence, thermal desorption spectroscopy, and high-resolution imaging allow for precise assessment of material properties and identification of potential failure mechanisms before they affect device performance.

02 Encapsulation technologies for moisture and oxygen protection

Advanced encapsulation technologies are critical for protecting sensitive OLED materials from environmental factors like moisture and oxygen. These technologies include multi-layer barrier films, inorganic/organic hybrid structures, and hermetic sealing methods. Effective encapsulation significantly improves material integrity by preventing the ingress of contaminants that would otherwise cause rapid degradation of the organic materials.Expand Specific Solutions03 Novel material compositions for enhanced durability

Innovative material compositions are developed to enhance the durability of OLED devices. These include specially designed host-dopant systems, cross-linkable materials, and thermally stable compounds. By engineering materials at the molecular level, researchers can create OLED components that maintain structural and functional integrity under electrical stress, heat, and prolonged operation.Expand Specific Solutions04 Manufacturing processes to preserve material integrity

Specialized manufacturing processes are implemented to preserve the integrity of OLED materials during device fabrication. These include controlled deposition techniques, low-temperature processing, and contamination-free handling protocols. By optimizing manufacturing conditions, degradation of sensitive organic materials can be minimized, resulting in devices with superior performance and longevity.Expand Specific Solutions05 Testing and quality control methods for material integrity

Comprehensive testing and quality control methods are essential for ensuring OLED material integrity. These include accelerated aging tests, spectroscopic analysis techniques, and in-situ monitoring systems. These methods allow manufacturers to identify potential material degradation issues early in the development process and implement appropriate countermeasures to maintain material integrity throughout the device lifecycle.Expand Specific Solutions

Leading Companies in Flexible OLED Development

The OLED material integrity under mechanical strain market is currently in a growth phase, characterized by increasing adoption of flexible displays in consumer electronics. The global market size for flexible OLED displays is expanding rapidly, projected to reach significant value as manufacturers seek durable materials that maintain performance under bending and folding conditions. From a technical maturity perspective, industry leaders like Samsung Display, LG Display, and BOE Technology have made substantial advancements in flexible OLED technology, while companies such as LG Chem and INNOX Advanced Materials focus on developing strain-resistant materials. Japanese players including Japan Display and Sakai Display Products are contributing specialized solutions, while research organizations like CEA and emerging players such as Visionox and TCL CSOT are working to overcome remaining technical challenges in maintaining OLED integrity under various mechanical stress conditions.

LG Chem Ltd.

Technical Solution: LG Chem has developed an advanced materials-focused benchmarking system for evaluating OLED material integrity under mechanical strain, with particular emphasis on polymer substrates and encapsulation materials. Their methodology centers on molecular-level analysis of how mechanical deformation affects the chemical and physical properties of OLED materials over time. LG Chem employs specialized analytical techniques including in-situ Raman spectroscopy and dynamic mechanical analysis to characterize material changes during bending. Their benchmarking process evaluates critical parameters including glass transition temperature shifts, polymer chain alignment, and interfacial adhesion strength under various strain conditions. The company has pioneered accelerated testing protocols that correlate molecular-level changes with macroscopic device performance, allowing for prediction of long-term reliability from short-term tests. Their benchmarking system includes comparative analysis of different material formulations under identical strain conditions, enabling direct comparison of material candidates. LG Chem's approach incorporates environmental factors including UV exposure, temperature cycling, and humidity to evaluate how these variables interact with mechanical strain to affect material degradation pathways.

Strengths: LG Chem's benchmarking methodology provides exceptional insight into fundamental material behavior under strain, with particular strength in polymer substrate and encapsulation materials where they have extensive expertise. Their molecular-level analysis capabilities allow for early identification of degradation mechanisms before they manifest as device failures. Weaknesses: Their approach may emphasize materials characterization over complete device performance metrics, potentially requiring integration with other testing methodologies for comprehensive evaluation. The specialized analytical equipment required may limit accessibility of their full methodology.

LG Display Co., Ltd.

Technical Solution: LG Display has established a sophisticated benchmarking framework for evaluating OLED material integrity under mechanical strain, particularly focused on their rollable and flexible OLED technologies. Their methodology incorporates multi-dimensional stress testing that examines both compressive and tensile strain effects on OLED performance. LG's approach includes specialized equipment that can apply precise mechanical deformation while simultaneously measuring electrical characteristics, optical performance, and material integrity. Their benchmarking process evaluates critical parameters including threshold voltage shifts, luminance uniformity, and color stability under various bending radii and repeated cycling conditions. LG Display has developed proprietary testing fixtures that can simulate complex deformation patterns beyond simple folding, including rolling and twisting motions that represent potential real-world use cases. Their system incorporates environmental testing chambers that allow for strain testing under varying temperature and humidity conditions to evaluate environmental factors' impact on mechanical durability. Additionally, LG employs advanced surface analysis techniques to characterize microscopic changes in material interfaces during mechanical deformation.

Strengths: LG's benchmarking methodology excels in evaluating rollable OLED technologies where they have significant commercial experience. Their testing protocols are particularly strong in identifying failure mechanisms at material interfaces and encapsulation boundaries. Weaknesses: Their benchmarking approach may emphasize certain mechanical deformation modes (rolling) over others (folding), potentially limiting applicability to all flexible display form factors. Their testing methodology may require specialized equipment not readily available to smaller research organizations.

Critical Patents in Strain-Resistant OLED Materials

Organic light-emitting diode (OLED) device and display device

PatentActiveUS9905625B2

Innovation

- Incorporating a light-blocking layer, made of materials like ZnO, IGZO, TiO2, or TiO2, between the organic light-emitting layer and the cathode, or at the light-exiting side of the OLED device to block UV light, thereby preventing performance degradation.

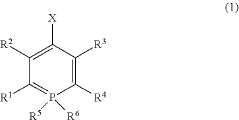

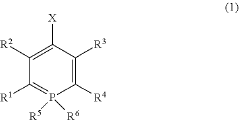

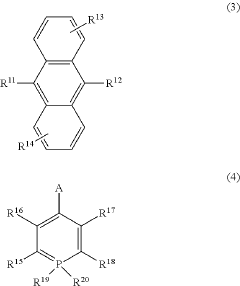

Light-emitting material for organic light-emitting diode, blue light-emitting material for organic light-emitting diode, and organic light-emitting diode

PatentInactiveUS20220181555A1

Innovation

- A phosphinine derivative with specific electron-withdrawing substituents is used as a dopant in combination with an anthracene derivative in the organic light-emitting layer, enhancing quantum yield and emission wavelength for pure blue light emission.

Manufacturing Challenges in Flexible OLED Production

The manufacturing of flexible OLED displays presents significant technical challenges that impact production yield, cost efficiency, and product reliability. One of the most critical hurdles is maintaining material integrity during the fabrication process, where OLEDs must withstand various mechanical stresses while preserving their electroluminescent properties.

The production of flexible OLEDs requires ultra-thin substrates, typically polyimide films, which are inherently difficult to handle during manufacturing. These substrates must undergo multiple deposition processes while maintaining dimensional stability. Current manufacturing lines experience up to 15% yield loss due to substrate warping and misalignment during thermal cycling processes.

Encapsulation represents another major manufacturing challenge. Traditional rigid glass encapsulation methods are incompatible with flexible displays, necessitating the development of thin-film encapsulation (TFE) technologies. These multi-layer barrier films must achieve water vapor transmission rates below 10^-6 g/m²/day to prevent OLED degradation, while simultaneously maintaining flexibility. Industry data indicates that encapsulation defects account for approximately 22% of flexible OLED failures in production environments.

The deposition of organic materials presents unique challenges in flexible OLED manufacturing. Vacuum thermal evaporation, the predominant deposition method, must be precisely controlled to ensure uniform layer thickness across flexible substrates that may exhibit topographical variations. Thickness variations exceeding ±5% can lead to visible non-uniformities in display performance and accelerated degradation under mechanical strain.

Integration of the thin-film transistor (TFT) backplane with flexible substrates introduces additional complexity. Low-temperature polysilicon (LTPS) or oxide TFT processes must be modified to accommodate the thermal limitations of polymer substrates, which typically cannot withstand temperatures above 350°C without degradation. This thermal constraint limits the selection of available semiconductor materials and processing techniques.

Roll-to-roll (R2R) manufacturing, while promising for cost reduction, introduces unique challenges in maintaining registration accuracy across large-area flexible substrates. Current R2R systems struggle to maintain alignment precision better than ±10μm, whereas high-resolution displays require alignment accuracy of ±5μm or better. This misalignment can create stress concentration points that become failure initiation sites when the display is flexed.

The production of flexible OLEDs requires ultra-thin substrates, typically polyimide films, which are inherently difficult to handle during manufacturing. These substrates must undergo multiple deposition processes while maintaining dimensional stability. Current manufacturing lines experience up to 15% yield loss due to substrate warping and misalignment during thermal cycling processes.

Encapsulation represents another major manufacturing challenge. Traditional rigid glass encapsulation methods are incompatible with flexible displays, necessitating the development of thin-film encapsulation (TFE) technologies. These multi-layer barrier films must achieve water vapor transmission rates below 10^-6 g/m²/day to prevent OLED degradation, while simultaneously maintaining flexibility. Industry data indicates that encapsulation defects account for approximately 22% of flexible OLED failures in production environments.

The deposition of organic materials presents unique challenges in flexible OLED manufacturing. Vacuum thermal evaporation, the predominant deposition method, must be precisely controlled to ensure uniform layer thickness across flexible substrates that may exhibit topographical variations. Thickness variations exceeding ±5% can lead to visible non-uniformities in display performance and accelerated degradation under mechanical strain.

Integration of the thin-film transistor (TFT) backplane with flexible substrates introduces additional complexity. Low-temperature polysilicon (LTPS) or oxide TFT processes must be modified to accommodate the thermal limitations of polymer substrates, which typically cannot withstand temperatures above 350°C without degradation. This thermal constraint limits the selection of available semiconductor materials and processing techniques.

Roll-to-roll (R2R) manufacturing, while promising for cost reduction, introduces unique challenges in maintaining registration accuracy across large-area flexible substrates. Current R2R systems struggle to maintain alignment precision better than ±10μm, whereas high-resolution displays require alignment accuracy of ±5μm or better. This misalignment can create stress concentration points that become failure initiation sites when the display is flexed.

Reliability Standards for Foldable Display Technologies

The reliability standards for foldable display technologies have evolved significantly in response to the unique challenges posed by flexible OLED screens. These standards address the critical aspects of durability, performance consistency, and longevity under repeated mechanical stress conditions that are inherent to foldable devices.

Industry organizations such as the International Electrotechnical Commission (IEC) and JEDEC have developed specialized testing protocols specifically for foldable displays. These include standardized folding cycle tests that typically require devices to withstand between 100,000 to 200,000 folding operations without significant degradation in display quality or functionality.

Material integrity standards focus on several key parameters including bend radius limitations, which typically specify minimum safe folding radii between 1.5mm to 3mm depending on the display technology. Stress distribution requirements ensure that mechanical strain is evenly distributed across the folding area to prevent localized damage points that could lead to premature failure.

Temperature variation resistance standards are particularly important for foldable displays, as thermal expansion and contraction can exacerbate mechanical stress. Current standards require devices to maintain integrity across operating temperature ranges of -20°C to 60°C while undergoing folding operations.

Optical performance standards for foldable displays mandate maximum allowable changes in brightness, color accuracy, and contrast ratio after specified numbers of folding cycles. Typically, these standards permit no more than 10-15% degradation in these parameters after the full lifecycle testing.

Delamination resistance standards address the unique multi-layer construction of OLED displays, requiring adhesion strength between layers to withstand specified shear forces during repeated folding. These standards typically specify maximum allowable separation between layers measured in micrometers.

Crease visibility metrics have been established to quantify the visual impact of the fold line, with standards typically specifying maximum allowable crease depth and width measurements. Advanced standards now include requirements for crease recovery time – how quickly the visible fold mark diminishes when the display is unfolded.

Emerging reliability standards are beginning to incorporate accelerated aging protocols that combine mechanical folding with environmental stressors such as humidity, UV exposure, and temperature cycling to better simulate real-world usage conditions and provide more accurate lifetime predictions for foldable display technologies.

Industry organizations such as the International Electrotechnical Commission (IEC) and JEDEC have developed specialized testing protocols specifically for foldable displays. These include standardized folding cycle tests that typically require devices to withstand between 100,000 to 200,000 folding operations without significant degradation in display quality or functionality.

Material integrity standards focus on several key parameters including bend radius limitations, which typically specify minimum safe folding radii between 1.5mm to 3mm depending on the display technology. Stress distribution requirements ensure that mechanical strain is evenly distributed across the folding area to prevent localized damage points that could lead to premature failure.

Temperature variation resistance standards are particularly important for foldable displays, as thermal expansion and contraction can exacerbate mechanical stress. Current standards require devices to maintain integrity across operating temperature ranges of -20°C to 60°C while undergoing folding operations.

Optical performance standards for foldable displays mandate maximum allowable changes in brightness, color accuracy, and contrast ratio after specified numbers of folding cycles. Typically, these standards permit no more than 10-15% degradation in these parameters after the full lifecycle testing.

Delamination resistance standards address the unique multi-layer construction of OLED displays, requiring adhesion strength between layers to withstand specified shear forces during repeated folding. These standards typically specify maximum allowable separation between layers measured in micrometers.

Crease visibility metrics have been established to quantify the visual impact of the fold line, with standards typically specifying maximum allowable crease depth and width measurements. Advanced standards now include requirements for crease recovery time – how quickly the visible fold mark diminishes when the display is unfolded.

Emerging reliability standards are beginning to incorporate accelerated aging protocols that combine mechanical folding with environmental stressors such as humidity, UV exposure, and temperature cycling to better simulate real-world usage conditions and provide more accurate lifetime predictions for foldable display technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!