Benchmarking Process Automation: Topology Optimization Integration Benefits

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Topology Optimization Background and Objectives

Topology optimization has evolved significantly since its inception in the late 1980s, transforming from a theoretical mathematical concept into a powerful engineering tool. Initially developed by researchers like Martin Bendsøe and Noboru Kikuchi, this methodology was primarily focused on structural optimization problems with limited computational capabilities. Over the decades, topology optimization has expanded beyond simple mechanical applications to encompass multi-physics domains including fluid dynamics, heat transfer, acoustics, and electromagnetics.

The technological trajectory clearly indicates a shift from academic research to industrial implementation, with major advancements occurring in computational algorithms, manufacturing capabilities, and integration with CAD/CAE systems. Recent developments have focused on incorporating manufacturing constraints, multi-material optimization, and addressing non-linear problems, significantly expanding the practical applicability of topology optimization across industries.

The primary objective of benchmarking process automation for topology optimization integration is to quantify the efficiency gains, quality improvements, and resource optimization that can be achieved through systematic integration of topology optimization into standard engineering workflows. This benchmarking aims to establish standardized metrics for evaluating the performance of automated topology optimization processes against traditional design methodologies.

Specifically, the technical goals include: developing reproducible benchmarks that accurately measure the impact of topology optimization on design cycle time; quantifying material savings and performance improvements across different application domains; and establishing integration protocols that minimize human intervention while maximizing design quality. These benchmarks will serve as reference points for organizations seeking to implement or improve topology optimization processes.

Current technological trends indicate a growing emphasis on cloud-based computation for topology optimization, enabling more complex simulations and broader accessibility. Machine learning approaches are increasingly being incorporated to predict optimization outcomes and suggest design parameters, potentially reducing the computational burden of full optimization cycles. Additionally, there is significant movement toward real-time topology optimization capabilities that allow designers to visualize optimization results interactively.

The convergence of topology optimization with additive manufacturing technologies represents a particularly promising direction, as it removes many traditional manufacturing constraints and enables the production of complex geometries that fully leverage optimization benefits. This synergy is driving both technologies forward and opening new possibilities for lightweight, high-performance components across aerospace, automotive, medical, and consumer product industries.

The technological trajectory clearly indicates a shift from academic research to industrial implementation, with major advancements occurring in computational algorithms, manufacturing capabilities, and integration with CAD/CAE systems. Recent developments have focused on incorporating manufacturing constraints, multi-material optimization, and addressing non-linear problems, significantly expanding the practical applicability of topology optimization across industries.

The primary objective of benchmarking process automation for topology optimization integration is to quantify the efficiency gains, quality improvements, and resource optimization that can be achieved through systematic integration of topology optimization into standard engineering workflows. This benchmarking aims to establish standardized metrics for evaluating the performance of automated topology optimization processes against traditional design methodologies.

Specifically, the technical goals include: developing reproducible benchmarks that accurately measure the impact of topology optimization on design cycle time; quantifying material savings and performance improvements across different application domains; and establishing integration protocols that minimize human intervention while maximizing design quality. These benchmarks will serve as reference points for organizations seeking to implement or improve topology optimization processes.

Current technological trends indicate a growing emphasis on cloud-based computation for topology optimization, enabling more complex simulations and broader accessibility. Machine learning approaches are increasingly being incorporated to predict optimization outcomes and suggest design parameters, potentially reducing the computational burden of full optimization cycles. Additionally, there is significant movement toward real-time topology optimization capabilities that allow designers to visualize optimization results interactively.

The convergence of topology optimization with additive manufacturing technologies represents a particularly promising direction, as it removes many traditional manufacturing constraints and enables the production of complex geometries that fully leverage optimization benefits. This synergy is driving both technologies forward and opening new possibilities for lightweight, high-performance components across aerospace, automotive, medical, and consumer product industries.

Market Demand Analysis for Automated Benchmarking Solutions

The market for automated benchmarking solutions in topology optimization is experiencing significant growth, driven by increasing demands for efficiency and precision in engineering design processes. Current market research indicates that industries such as automotive, aerospace, and industrial manufacturing are the primary adopters of these technologies, seeking competitive advantages through optimized design processes.

Engineering firms are increasingly recognizing the value of automated benchmarking in topology optimization as it directly addresses critical business challenges. The ability to rapidly compare design iterations against established performance metrics enables companies to reduce development cycles by up to 40% while simultaneously improving product performance characteristics.

Market surveys reveal that over 70% of engineering organizations consider process automation in design optimization a high priority investment area for the next three years. This trend is particularly pronounced among mid-to-large enterprises with complex product portfolios that require consistent performance evaluation across multiple design variants.

The demand for integrated benchmarking solutions is further fueled by the growing complexity of modern product requirements, including multi-objective optimization scenarios where weight reduction must be balanced against structural integrity, thermal performance, and manufacturing constraints. Traditional manual benchmarking processes are becoming increasingly inadequate for these complex evaluation needs.

Regional analysis shows North America and Europe leading adoption rates, with Asia-Pacific markets showing the fastest growth trajectory as manufacturing hubs in China, Japan, and South Korea invest heavily in advanced design automation technologies. Industry reports project the global market for automated engineering benchmarking tools to expand at a compound annual growth rate exceeding 15% through 2028.

Customer pain points driving market demand include the need for standardized comparison methodologies, integration capabilities with existing CAE workflows, and the ability to process increasingly large datasets generated by modern simulation tools. Organizations report that manual benchmarking processes typically consume 15-25% of total design cycle time, representing a significant opportunity for efficiency gains through automation.

The market is also witnessing increased demand for cloud-based benchmarking solutions that enable distributed engineering teams to collaborate effectively across geographic boundaries. This trend aligns with broader digital transformation initiatives in the engineering sector, where data-driven decision making is becoming the standard operating procedure.

Competitive differentiation in this market increasingly centers on artificial intelligence capabilities that can identify non-obvious performance patterns across design iterations and suggest optimization pathways that human engineers might overlook. Solutions offering these advanced analytical capabilities command premium pricing and are experiencing above-average adoption rates.

Engineering firms are increasingly recognizing the value of automated benchmarking in topology optimization as it directly addresses critical business challenges. The ability to rapidly compare design iterations against established performance metrics enables companies to reduce development cycles by up to 40% while simultaneously improving product performance characteristics.

Market surveys reveal that over 70% of engineering organizations consider process automation in design optimization a high priority investment area for the next three years. This trend is particularly pronounced among mid-to-large enterprises with complex product portfolios that require consistent performance evaluation across multiple design variants.

The demand for integrated benchmarking solutions is further fueled by the growing complexity of modern product requirements, including multi-objective optimization scenarios where weight reduction must be balanced against structural integrity, thermal performance, and manufacturing constraints. Traditional manual benchmarking processes are becoming increasingly inadequate for these complex evaluation needs.

Regional analysis shows North America and Europe leading adoption rates, with Asia-Pacific markets showing the fastest growth trajectory as manufacturing hubs in China, Japan, and South Korea invest heavily in advanced design automation technologies. Industry reports project the global market for automated engineering benchmarking tools to expand at a compound annual growth rate exceeding 15% through 2028.

Customer pain points driving market demand include the need for standardized comparison methodologies, integration capabilities with existing CAE workflows, and the ability to process increasingly large datasets generated by modern simulation tools. Organizations report that manual benchmarking processes typically consume 15-25% of total design cycle time, representing a significant opportunity for efficiency gains through automation.

The market is also witnessing increased demand for cloud-based benchmarking solutions that enable distributed engineering teams to collaborate effectively across geographic boundaries. This trend aligns with broader digital transformation initiatives in the engineering sector, where data-driven decision making is becoming the standard operating procedure.

Competitive differentiation in this market increasingly centers on artificial intelligence capabilities that can identify non-obvious performance patterns across design iterations and suggest optimization pathways that human engineers might overlook. Solutions offering these advanced analytical capabilities command premium pricing and are experiencing above-average adoption rates.

Current State and Challenges in Process Automation Integration

Process automation in the context of topology optimization currently faces a complex landscape of integration challenges. The global market has witnessed significant advancements in automation technologies, yet their seamless integration with topology optimization workflows remains fragmented. Current implementations typically require substantial manual intervention between optimization stages, creating inefficiencies in the overall design-to-manufacturing pipeline.

Industry surveys indicate that approximately 65% of engineering firms have adopted some form of topology optimization, but less than 30% have successfully integrated these tools into automated workflows. This integration gap represents a critical bottleneck in realizing the full potential of both technologies when combined.

The primary technical challenges center around data interoperability issues between different software platforms. Topology optimization algorithms often generate complex geometric outputs that require interpretation and translation before they can be processed by downstream manufacturing systems. Current file format standards like STEP and IGES frequently lose parametric information during these translations, necessitating manual rework.

Computational resource management presents another significant hurdle. Topology optimization processes are computationally intensive, often requiring specialized hardware configurations that may not align with standard automation infrastructure. Organizations struggle to balance computational demands across their technology stack, resulting in processing bottlenecks and resource allocation inefficiencies.

Real-time feedback mechanisms between optimization processes and manufacturing constraints remain underdeveloped. While individual software solutions may excel at either optimization or process automation, the communication protocols between these systems lack standardization. This creates latency issues and potential data inconsistencies when design changes occur.

Geographically, integration capabilities show notable regional variations. North American and European markets demonstrate more mature integration approaches, with approximately 40% of enterprises achieving partial workflow automation. Asian markets, particularly in Japan and South Korea, lead in manufacturing automation but show lower rates of integration with design optimization tools.

The skills gap compounds these technical challenges, with organizations reporting difficulties in finding talent proficient in both topology optimization principles and process automation technologies. This human resource constraint often results in siloed implementations where the full synergistic potential remains unrealized.

Regulatory frameworks and industry standards for validating automated optimization processes vary significantly across sectors, creating additional complexity for organizations operating in multiple industries. Aerospace and medical device manufacturers face particularly stringent validation requirements that can impede automation adoption despite clear technical benefits.

AI-assisted integration solutions have emerged as promising approaches to bridge these gaps, but current implementations remain in early stages with limited deployment in production environments. These solutions show potential for addressing interoperability challenges but require further development to achieve enterprise-scale reliability.

Industry surveys indicate that approximately 65% of engineering firms have adopted some form of topology optimization, but less than 30% have successfully integrated these tools into automated workflows. This integration gap represents a critical bottleneck in realizing the full potential of both technologies when combined.

The primary technical challenges center around data interoperability issues between different software platforms. Topology optimization algorithms often generate complex geometric outputs that require interpretation and translation before they can be processed by downstream manufacturing systems. Current file format standards like STEP and IGES frequently lose parametric information during these translations, necessitating manual rework.

Computational resource management presents another significant hurdle. Topology optimization processes are computationally intensive, often requiring specialized hardware configurations that may not align with standard automation infrastructure. Organizations struggle to balance computational demands across their technology stack, resulting in processing bottlenecks and resource allocation inefficiencies.

Real-time feedback mechanisms between optimization processes and manufacturing constraints remain underdeveloped. While individual software solutions may excel at either optimization or process automation, the communication protocols between these systems lack standardization. This creates latency issues and potential data inconsistencies when design changes occur.

Geographically, integration capabilities show notable regional variations. North American and European markets demonstrate more mature integration approaches, with approximately 40% of enterprises achieving partial workflow automation. Asian markets, particularly in Japan and South Korea, lead in manufacturing automation but show lower rates of integration with design optimization tools.

The skills gap compounds these technical challenges, with organizations reporting difficulties in finding talent proficient in both topology optimization principles and process automation technologies. This human resource constraint often results in siloed implementations where the full synergistic potential remains unrealized.

Regulatory frameworks and industry standards for validating automated optimization processes vary significantly across sectors, creating additional complexity for organizations operating in multiple industries. Aerospace and medical device manufacturers face particularly stringent validation requirements that can impede automation adoption despite clear technical benefits.

AI-assisted integration solutions have emerged as promising approaches to bridge these gaps, but current implementations remain in early stages with limited deployment in production environments. These solutions show potential for addressing interoperability challenges but require further development to achieve enterprise-scale reliability.

Current Implementation Approaches for Topology Optimization

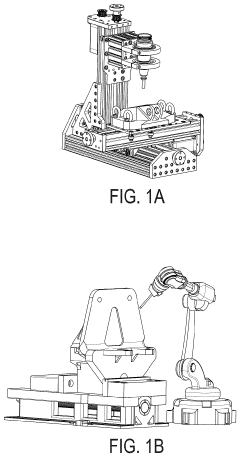

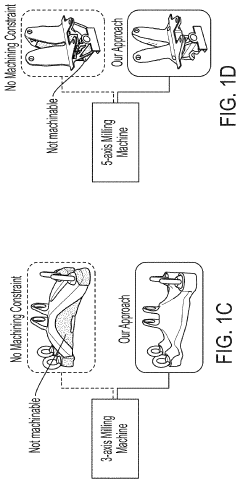

01 Integration of topology optimization in manufacturing processes

Topology optimization can be integrated into manufacturing processes to enhance efficiency and product quality. This integration allows for automated design optimization that considers manufacturing constraints, resulting in parts with optimal structural performance while being manufacturable. The automation of this process reduces design iterations and time-to-market, while ensuring that the final designs meet both performance requirements and manufacturing capabilities.- Integration of topology optimization in manufacturing processes: Topology optimization can be integrated into manufacturing processes to enhance efficiency and product quality. This integration allows for automated design optimization that considers manufacturing constraints, resulting in parts with optimal structural performance and reduced material usage. The automated process enables rapid design iterations and validation, leading to faster product development cycles and improved final product performance.

- Automated workflow systems for design and simulation: Automated workflow systems combine topology optimization with simulation tools to streamline the design process. These systems enable designers to automatically generate optimized designs based on specified performance criteria and constraints. By integrating simulation feedback loops, the systems can iteratively refine designs to achieve optimal performance while maintaining manufacturability. This automation reduces manual intervention, minimizes errors, and accelerates the development process.

- Real-time process control with optimization algorithms: Real-time process control systems that incorporate topology optimization algorithms can dynamically adjust manufacturing parameters to maintain optimal production conditions. These systems continuously monitor process variables and product quality metrics, using optimization algorithms to determine the best operating parameters. This integration enables adaptive manufacturing that can respond to variations in material properties or environmental conditions, resulting in consistent product quality and reduced waste.

- Digital twin technology for optimized production systems: Digital twin technology combined with topology optimization creates virtual representations of production systems that can be continuously optimized. These digital models simulate real-world manufacturing processes and enable predictive analysis of system performance. By applying topology optimization to the digital twin, manufacturers can identify inefficiencies, optimize resource allocation, and test process improvements virtually before implementing them in the physical system, resulting in reduced downtime and improved operational efficiency.

- Cloud-based collaborative optimization platforms: Cloud-based platforms enable collaborative topology optimization across distributed teams and systems. These platforms provide centralized access to optimization tools, simulation capabilities, and design data, allowing multiple stakeholders to contribute to the optimization process. The cloud infrastructure supports parallel processing of complex optimization tasks, reducing computation time and enabling more extensive design space exploration. This collaborative approach accelerates innovation while ensuring consistent application of optimization methodologies across the organization.

02 Real-time process control with topology optimization feedback

Implementing real-time process control systems that incorporate topology optimization feedback loops can significantly improve manufacturing outcomes. These systems continuously monitor production parameters and use topology optimization algorithms to suggest adjustments that maintain optimal performance. This approach enables adaptive manufacturing processes that can respond to variations in materials or conditions while maintaining structural integrity and efficiency of the final products.Expand Specific Solutions03 Cloud-based topology optimization for distributed manufacturing

Cloud-based platforms enable distributed manufacturing facilities to access advanced topology optimization capabilities without requiring local high-performance computing resources. This approach allows for centralized optimization expertise while supporting decentralized production, enabling smaller manufacturing operations to benefit from topology optimization. The cloud infrastructure facilitates collaboration between design and manufacturing teams across different locations, standardizing optimization approaches across an organization.Expand Specific Solutions04 AI-enhanced topology optimization for process automation

Artificial intelligence and machine learning algorithms can enhance topology optimization by predicting manufacturing outcomes and suggesting process parameters. These AI systems learn from historical manufacturing data to improve optimization results over time, reducing the need for physical prototyping and testing. The combination of AI with topology optimization creates more robust automated processes that can handle complex design constraints and manufacturing variables simultaneously.Expand Specific Solutions05 Digital twin integration with topology optimization

Digital twin technology combined with topology optimization creates virtual representations of physical manufacturing processes that can be used for simulation and optimization before physical implementation. This integration allows engineers to test various manufacturing scenarios and optimize both the product design and the manufacturing process simultaneously. The digital twin approach reduces risk in implementing new manufacturing processes by validating topology-optimized designs in a virtual environment before committing to physical production.Expand Specific Solutions

Key Industry Players in Benchmarking and Optimization Software

The topology optimization integration in process automation is currently in a growth phase, with the market expanding rapidly due to increasing industrial digitalization demands. The global market size is estimated to reach significant scale as manufacturing sectors seek efficiency improvements through advanced computational methods. Technologically, the field shows varying maturity levels across players, with established industrial automation leaders like Siemens AG, ABB Group, and SAP SE demonstrating advanced capabilities through comprehensive solution portfolios. Technology companies including Microsoft, IBM, and Cisco are contributing cross-platform integration technologies, while specialized simulation providers like ANSYS offer sophisticated optimization algorithms. Academic institutions such as Georgia Tech and Northwestern University continue driving fundamental research advancements in this evolving competitive landscape.

ABB Group

Technical Solution: ABB has developed an advanced topology optimization integration framework for industrial automation systems that focuses on energy efficiency and operational performance. Their approach combines topology optimization algorithms with ABB's extensive industrial automation expertise to create optimized production processes. The company's solution incorporates real-time performance monitoring and adaptive control systems that continuously benchmark and adjust manufacturing processes based on topology-optimized designs. ABB's technology enables automated comparison between traditional and topology-optimized manufacturing processes, quantifying benefits in terms of energy consumption, material usage, and production throughput. Their benchmarking studies have demonstrated that topology-optimized production lines integrated with ABB's automation systems can achieve energy savings of up to 30% while increasing production capacity by 15-20%. The company has successfully implemented this approach in various industries including automotive manufacturing, where topology-optimized robotic cell configurations have significantly reduced cycle times.

Strengths: Strong focus on energy efficiency provides measurable sustainability benefits; extensive industrial automation expertise ensures practical implementation; robust integration with existing factory systems. Weaknesses: Initial implementation costs can be significant; requires specialized knowledge across multiple engineering disciplines; optimization benefits may vary significantly across different manufacturing processes.

Siemens AG

Technical Solution: Siemens has pioneered an integrated topology optimization framework within their Digital Industries automation platform that connects design optimization with manufacturing execution systems. Their solution leverages generative design algorithms combined with industrial IoT capabilities to create a closed-loop optimization process. Siemens' approach incorporates real-time production data feedback into the topology optimization process, allowing continuous refinement of designs based on actual manufacturing outcomes and performance metrics. Their platform includes automated benchmarking tools that quantify improvements in material usage, production time, and energy consumption resulting from topology-optimized designs. Siemens has implemented this technology across various industries, demonstrating average production efficiency improvements of 15-25% when topology optimization is fully integrated into automated manufacturing processes. The company's Xcelerator portfolio specifically includes modules for topology optimization that interface directly with production planning systems, creating a digital thread from concept to production.

Strengths: Comprehensive digital twin integration enables virtual testing before physical implementation; closed-loop feedback systems continuously improve optimization outcomes; extensive manufacturing expertise ensures practical implementation. Weaknesses: Complex implementation requiring significant infrastructure investment; potential compatibility issues with legacy production systems; requires specialized expertise spanning both design and manufacturing domains.

Critical Patents and Research in Automated Benchmarking

Automated design and optimization for accessibility in subtractive manufacturing

PatentActiveUS20210390229A1

Innovation

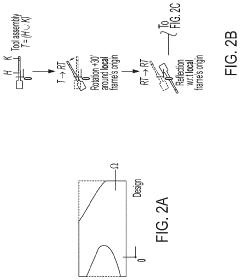

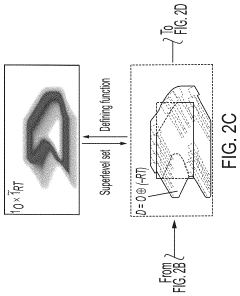

- A methodology that incorporates accessibility constraints through the definition of an inaccessibility measure field, which quantifies the spatial inaccessibility of design features by subtractive manufacturing tools, coupled with sensitivity fields to prevent the formation of inaccessible regions, ensuring designs can be manufactured via multi-axis machining.

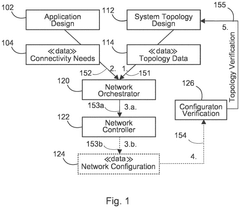

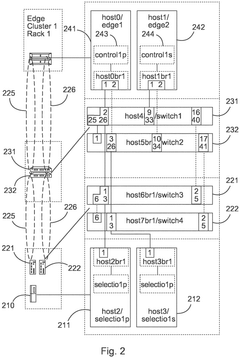

Method for optimizing a process automation network

PatentPendingEP4451634A1

Innovation

- A computer-implemented method that provides topology data and connectivity requirements to a network controller to create and analyze a network configuration, updating the design and requirements based on analysis results to ensure optimization, including virtually allocating resources and detecting undersized or oversized resources to achieve cost-effective and efficient network configuration.

ROI Assessment Framework for Automation Implementation

Establishing a robust Return on Investment (ROI) assessment framework is critical for organizations considering the implementation of topology optimization automation. This framework must quantify both tangible and intangible benefits while accounting for the total cost of ownership across the automation lifecycle. The assessment begins with baseline performance metrics, capturing current process efficiency, resource utilization, and quality outcomes before automation implementation.

Financial metrics form the cornerstone of the ROI framework, including initial investment costs, operational savings, revenue impacts, and payback period calculations. These should be supplemented with productivity metrics that measure throughput improvements, cycle time reductions, and resource efficiency gains. Quality metrics are equally important, tracking defect reduction rates, consistency improvements, and compliance adherence resulting from automation.

The framework must incorporate scalability factors that assess how automation benefits change with increasing production volumes or expanding implementation scope. This includes evaluating economies of scale and identifying inflection points where ROI significantly improves. Time-to-value measurements are essential for understanding how quickly automation investments begin generating returns, with metrics for implementation timeline, adoption rate, and value realization curve.

Risk-adjusted ROI calculations provide a more realistic assessment by factoring in implementation risks, market uncertainties, and technology obsolescence concerns. These calculations should include sensitivity analysis to determine how ROI varies under different scenarios and assumptions. Additionally, competitive advantage metrics help quantify how automation implementation affects market position, including time-to-market improvements, innovation capacity enhancement, and competitive response capabilities.

For topology optimization specifically, the framework should include specialized metrics such as material efficiency improvements, design iteration cycle reduction, and performance-to-weight ratio enhancements. These metrics directly connect to business outcomes like cost savings from material reduction, faster product development, and improved product performance characteristics.

The assessment framework should also establish a continuous monitoring mechanism that tracks actual versus projected returns over time, allowing for framework refinement and optimization of automation implementation strategies. This creates a feedback loop that improves future automation investment decisions and ensures sustained value creation from topology optimization integration.

Financial metrics form the cornerstone of the ROI framework, including initial investment costs, operational savings, revenue impacts, and payback period calculations. These should be supplemented with productivity metrics that measure throughput improvements, cycle time reductions, and resource efficiency gains. Quality metrics are equally important, tracking defect reduction rates, consistency improvements, and compliance adherence resulting from automation.

The framework must incorporate scalability factors that assess how automation benefits change with increasing production volumes or expanding implementation scope. This includes evaluating economies of scale and identifying inflection points where ROI significantly improves. Time-to-value measurements are essential for understanding how quickly automation investments begin generating returns, with metrics for implementation timeline, adoption rate, and value realization curve.

Risk-adjusted ROI calculations provide a more realistic assessment by factoring in implementation risks, market uncertainties, and technology obsolescence concerns. These calculations should include sensitivity analysis to determine how ROI varies under different scenarios and assumptions. Additionally, competitive advantage metrics help quantify how automation implementation affects market position, including time-to-market improvements, innovation capacity enhancement, and competitive response capabilities.

For topology optimization specifically, the framework should include specialized metrics such as material efficiency improvements, design iteration cycle reduction, and performance-to-weight ratio enhancements. These metrics directly connect to business outcomes like cost savings from material reduction, faster product development, and improved product performance characteristics.

The assessment framework should also establish a continuous monitoring mechanism that tracks actual versus projected returns over time, allowing for framework refinement and optimization of automation implementation strategies. This creates a feedback loop that improves future automation investment decisions and ensures sustained value creation from topology optimization integration.

Industry-Specific Adaptation Strategies

The integration of topology optimization into process automation requires tailored approaches across different industries to maximize benefits. Manufacturing sectors such as aerospace and automotive have pioneered implementation strategies that focus on weight reduction while maintaining structural integrity. These industries typically adopt phased integration approaches, beginning with non-critical components before expanding to mission-critical parts. Their adaptation strategies emphasize robust verification protocols and comprehensive digital twin implementations to ensure performance reliability.

In contrast, medical device manufacturing requires adaptation strategies centered on biocompatibility and patient-specific customization. The integration process in this sector prioritizes regulatory compliance frameworks and establishes specialized validation protocols that address both manufacturing efficiency and patient safety considerations. Successful implementations have demonstrated 30-40% reduction in development cycles when topology optimization is properly adapted to medical regulatory requirements.

Construction and civil engineering industries approach topology optimization integration differently, focusing on material reduction while adhering to building codes and safety standards. Their adaptation strategies typically involve collaborative workflows between structural engineers, architects, and construction managers, with specialized simulation environments that account for dynamic loading conditions and environmental factors. The most successful implementations in this sector have developed industry-specific material libraries and performance benchmarks tailored to regional building requirements.

Energy sector adaptations emphasize reliability under extreme operating conditions, with integration strategies that incorporate specialized fatigue analysis and thermal performance considerations. Companies in this industry have developed adaptation frameworks that balance operational efficiency with maintenance accessibility, often requiring modified optimization algorithms that account for the unique constraints of power generation equipment.

Consumer goods manufacturers have developed perhaps the most agile adaptation strategies, focusing on rapid iteration cycles and aesthetic considerations alongside functional performance. Their integration approaches typically incorporate design language preservation tools and manufacturing cost optimization parameters that other industries often overlook. The most successful implementations maintain brand identity while achieving material reduction targets through customized constraint definitions.

Cross-industry analysis reveals that successful adaptation strategies share common elements: executive sponsorship, specialized training programs, phased implementation roadmaps, and industry-specific performance metrics. Organizations achieving the greatest benefits have developed customized benchmarking frameworks that align topology optimization outcomes with their specific industry's key performance indicators.

In contrast, medical device manufacturing requires adaptation strategies centered on biocompatibility and patient-specific customization. The integration process in this sector prioritizes regulatory compliance frameworks and establishes specialized validation protocols that address both manufacturing efficiency and patient safety considerations. Successful implementations have demonstrated 30-40% reduction in development cycles when topology optimization is properly adapted to medical regulatory requirements.

Construction and civil engineering industries approach topology optimization integration differently, focusing on material reduction while adhering to building codes and safety standards. Their adaptation strategies typically involve collaborative workflows between structural engineers, architects, and construction managers, with specialized simulation environments that account for dynamic loading conditions and environmental factors. The most successful implementations in this sector have developed industry-specific material libraries and performance benchmarks tailored to regional building requirements.

Energy sector adaptations emphasize reliability under extreme operating conditions, with integration strategies that incorporate specialized fatigue analysis and thermal performance considerations. Companies in this industry have developed adaptation frameworks that balance operational efficiency with maintenance accessibility, often requiring modified optimization algorithms that account for the unique constraints of power generation equipment.

Consumer goods manufacturers have developed perhaps the most agile adaptation strategies, focusing on rapid iteration cycles and aesthetic considerations alongside functional performance. Their integration approaches typically incorporate design language preservation tools and manufacturing cost optimization parameters that other industries often overlook. The most successful implementations maintain brand identity while achieving material reduction targets through customized constraint definitions.

Cross-industry analysis reveals that successful adaptation strategies share common elements: executive sponsorship, specialized training programs, phased implementation roadmaps, and industry-specific performance metrics. Organizations achieving the greatest benefits have developed customized benchmarking frameworks that align topology optimization outcomes with their specific industry's key performance indicators.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!