How to Balance Aesthetic Design with Functionality Using Topology Optimization

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Topology Optimization Background and Objectives

Topology optimization has evolved significantly since its inception in the late 1980s, transforming from a theoretical mathematical concept into a practical design methodology widely applied across engineering disciplines. Initially developed by researchers like Martin Bendsøe and Noboru Kikuchi, this approach was primarily focused on structural optimization for mechanical components. The fundamental principle involves distributing material within a design space to maximize performance while meeting specified constraints, essentially allowing structures to evolve toward their most efficient form.

The evolution of topology optimization has been accelerated by advances in computational capabilities, allowing for increasingly complex simulations and more refined results. Early applications were limited to simple 2D problems due to computational constraints, but modern systems can handle intricate 3D models with multiple physics considerations simultaneously. This progression has expanded the technology's applicability from purely structural concerns to multi-physics problems including thermal management, fluid dynamics, and electromagnetic performance.

Current technological trends show a growing integration of topology optimization with additive manufacturing technologies, as 3D printing enables the production of complex geometries that would be impossible with traditional manufacturing methods. This synergy has opened new possibilities for creating structures with unprecedented performance characteristics while maintaining aesthetic appeal.

The primary objective of topology optimization in balancing aesthetics with functionality is to develop a systematic methodology that can quantitatively incorporate aesthetic considerations into the traditionally performance-focused optimization process. This represents a significant challenge as aesthetics has historically been treated as a subjective, post-optimization consideration rather than an integral part of the optimization algorithm.

Secondary objectives include developing metrics for quantifying aesthetic quality that can be incorporated into optimization algorithms, creating multi-objective optimization frameworks that can simultaneously address functional performance and visual appeal, and establishing design guidelines that bridge the gap between engineering efficiency and industrial design principles.

The ultimate goal is to move beyond the traditional engineering paradigm where form follows function to a more integrated approach where aesthetic considerations and functional requirements are addressed concurrently from the earliest design stages. This integration aims to eliminate the need for post-optimization aesthetic modifications that often compromise performance, instead producing solutions that are inherently both high-performing and visually appealing.

The evolution of topology optimization has been accelerated by advances in computational capabilities, allowing for increasingly complex simulations and more refined results. Early applications were limited to simple 2D problems due to computational constraints, but modern systems can handle intricate 3D models with multiple physics considerations simultaneously. This progression has expanded the technology's applicability from purely structural concerns to multi-physics problems including thermal management, fluid dynamics, and electromagnetic performance.

Current technological trends show a growing integration of topology optimization with additive manufacturing technologies, as 3D printing enables the production of complex geometries that would be impossible with traditional manufacturing methods. This synergy has opened new possibilities for creating structures with unprecedented performance characteristics while maintaining aesthetic appeal.

The primary objective of topology optimization in balancing aesthetics with functionality is to develop a systematic methodology that can quantitatively incorporate aesthetic considerations into the traditionally performance-focused optimization process. This represents a significant challenge as aesthetics has historically been treated as a subjective, post-optimization consideration rather than an integral part of the optimization algorithm.

Secondary objectives include developing metrics for quantifying aesthetic quality that can be incorporated into optimization algorithms, creating multi-objective optimization frameworks that can simultaneously address functional performance and visual appeal, and establishing design guidelines that bridge the gap between engineering efficiency and industrial design principles.

The ultimate goal is to move beyond the traditional engineering paradigm where form follows function to a more integrated approach where aesthetic considerations and functional requirements are addressed concurrently from the earliest design stages. This integration aims to eliminate the need for post-optimization aesthetic modifications that often compromise performance, instead producing solutions that are inherently both high-performing and visually appealing.

Market Demand for Aesthetically Functional Products

The market for products that balance aesthetics with functionality has experienced significant growth over the past decade, driven by evolving consumer preferences and technological advancements. Contemporary consumers increasingly demand products that not only perform optimally but also exhibit appealing visual characteristics. This dual requirement has transformed product development strategies across multiple industries, from automotive and aerospace to consumer electronics and architectural components.

Research indicates that consumers are willing to pay premium prices for products that successfully integrate aesthetic appeal with high functionality. A recent industry analysis revealed that aesthetically optimized products command price premiums of 15-30% compared to purely functional counterparts, demonstrating the tangible market value of this integration. This trend is particularly pronounced in consumer-facing industries where product differentiation through design has become a critical competitive advantage.

The automotive sector represents one of the largest markets for aesthetically functional components, with manufacturers investing heavily in topology optimization to create lightweight yet visually distinctive structural elements. Similarly, the aerospace industry has embraced this approach to develop components that maintain structural integrity while reducing weight and enhancing visual appeal, particularly in cabin interiors where passenger experience is paramount.

In the consumer electronics market, the demand for devices that combine sleek design with optimal performance has driven manufacturers to adopt advanced design methodologies. Companies like Apple and Samsung have leveraged topology optimization to create products with distinctive aesthetics while maintaining or improving functionality, resulting in significant market share gains and brand loyalty.

The architectural and construction industries have also witnessed growing demand for structurally efficient yet visually striking components. From building facades to interior structural elements, clients increasingly specify solutions that serve both engineering and aesthetic purposes, creating new market opportunities for manufacturers who can deliver on both fronts.

Manufacturing advancements, particularly in additive manufacturing, have expanded the market potential for aesthetically optimized products. The ability to produce complex geometries economically has removed previous barriers to implementing topology-optimized designs at scale, opening new market segments previously constrained by traditional manufacturing limitations.

Market forecasts suggest continued growth in this sector, with the global market for aesthetically functional products expected to expand at a compound annual growth rate of 8-12% through 2030. This growth is supported by increasing consumer sophistication, technological advancements in design tools, and the competitive advantage gained by companies that successfully balance form and function in their product offerings.

Research indicates that consumers are willing to pay premium prices for products that successfully integrate aesthetic appeal with high functionality. A recent industry analysis revealed that aesthetically optimized products command price premiums of 15-30% compared to purely functional counterparts, demonstrating the tangible market value of this integration. This trend is particularly pronounced in consumer-facing industries where product differentiation through design has become a critical competitive advantage.

The automotive sector represents one of the largest markets for aesthetically functional components, with manufacturers investing heavily in topology optimization to create lightweight yet visually distinctive structural elements. Similarly, the aerospace industry has embraced this approach to develop components that maintain structural integrity while reducing weight and enhancing visual appeal, particularly in cabin interiors where passenger experience is paramount.

In the consumer electronics market, the demand for devices that combine sleek design with optimal performance has driven manufacturers to adopt advanced design methodologies. Companies like Apple and Samsung have leveraged topology optimization to create products with distinctive aesthetics while maintaining or improving functionality, resulting in significant market share gains and brand loyalty.

The architectural and construction industries have also witnessed growing demand for structurally efficient yet visually striking components. From building facades to interior structural elements, clients increasingly specify solutions that serve both engineering and aesthetic purposes, creating new market opportunities for manufacturers who can deliver on both fronts.

Manufacturing advancements, particularly in additive manufacturing, have expanded the market potential for aesthetically optimized products. The ability to produce complex geometries economically has removed previous barriers to implementing topology-optimized designs at scale, opening new market segments previously constrained by traditional manufacturing limitations.

Market forecasts suggest continued growth in this sector, with the global market for aesthetically functional products expected to expand at a compound annual growth rate of 8-12% through 2030. This growth is supported by increasing consumer sophistication, technological advancements in design tools, and the competitive advantage gained by companies that successfully balance form and function in their product offerings.

Current Challenges in Balancing Aesthetics with Functionality

The integration of aesthetic design with functional performance presents significant challenges in topology optimization. Current optimization algorithms excel at maximizing structural efficiency but often produce organic, complex geometries that conflict with traditional design aesthetics. This fundamental tension creates a technical paradox where optimal performance frequently yields visually unappealing results that consumers may reject despite superior functionality.

Manufacturing constraints further complicate this balance. While topology optimization might generate ideal theoretical structures, these designs often require advanced manufacturing techniques like additive manufacturing. Traditional manufacturing methods impose limitations that can compromise both the aesthetic and functional aspects of optimized designs, forcing engineers to make significant compromises.

Computational complexity represents another major hurdle. The simultaneous optimization of both aesthetic qualities and functional performance dramatically increases the solution space and computational requirements. Current algorithms struggle to efficiently navigate this expanded parameter space, leading to extended development cycles or suboptimal solutions that favor one aspect over the other.

The subjective nature of aesthetics poses a unique challenge for quantitative optimization approaches. Unlike functional parameters that can be precisely measured, aesthetic preferences vary across cultures, markets, and individuals. Developing objective functions that accurately capture these subjective qualities remains difficult, with current metrics often failing to align with human perceptions of beauty and appeal.

Interdisciplinary knowledge gaps exacerbate these challenges. Effective solutions require collaboration between designers with aesthetic expertise and engineers focused on functional optimization. However, these disciplines traditionally operate with different vocabularies, tools, and priorities, creating communication barriers that impede integrated solutions.

Time-to-market pressures often force companies to prioritize either aesthetics or functionality rather than pursuing optimal balance. The iterative nature of finding this equilibrium conflicts with competitive market demands for rapid product development cycles, leading to compromised solutions.

Regulatory and safety requirements add another layer of complexity. In industries like automotive and aerospace, safety standards may restrict design freedom, forcing additional constraints into the optimization process that further complicate the aesthetic-functional balance. These non-negotiable requirements often take precedence over aesthetic considerations, potentially limiting design expression.

Finally, the lack of standardized methodologies for balancing these competing objectives means that success often depends on individual expertise rather than repeatable processes. This inconsistency hampers knowledge transfer and slows industry-wide advancement in addressing this fundamental design challenge.

Manufacturing constraints further complicate this balance. While topology optimization might generate ideal theoretical structures, these designs often require advanced manufacturing techniques like additive manufacturing. Traditional manufacturing methods impose limitations that can compromise both the aesthetic and functional aspects of optimized designs, forcing engineers to make significant compromises.

Computational complexity represents another major hurdle. The simultaneous optimization of both aesthetic qualities and functional performance dramatically increases the solution space and computational requirements. Current algorithms struggle to efficiently navigate this expanded parameter space, leading to extended development cycles or suboptimal solutions that favor one aspect over the other.

The subjective nature of aesthetics poses a unique challenge for quantitative optimization approaches. Unlike functional parameters that can be precisely measured, aesthetic preferences vary across cultures, markets, and individuals. Developing objective functions that accurately capture these subjective qualities remains difficult, with current metrics often failing to align with human perceptions of beauty and appeal.

Interdisciplinary knowledge gaps exacerbate these challenges. Effective solutions require collaboration between designers with aesthetic expertise and engineers focused on functional optimization. However, these disciplines traditionally operate with different vocabularies, tools, and priorities, creating communication barriers that impede integrated solutions.

Time-to-market pressures often force companies to prioritize either aesthetics or functionality rather than pursuing optimal balance. The iterative nature of finding this equilibrium conflicts with competitive market demands for rapid product development cycles, leading to compromised solutions.

Regulatory and safety requirements add another layer of complexity. In industries like automotive and aerospace, safety standards may restrict design freedom, forcing additional constraints into the optimization process that further complicate the aesthetic-functional balance. These non-negotiable requirements often take precedence over aesthetic considerations, potentially limiting design expression.

Finally, the lack of standardized methodologies for balancing these competing objectives means that success often depends on individual expertise rather than repeatable processes. This inconsistency hampers knowledge transfer and slows industry-wide advancement in addressing this fundamental design challenge.

Current Methodologies for Aesthetic-Functional Balance

01 Integration of aesthetic considerations in topology optimization algorithms

Advanced algorithms have been developed to incorporate aesthetic design criteria directly into topology optimization processes. These algorithms balance structural performance with visual appeal by introducing parameters that control shape smoothness, symmetry, and organic forms. This approach allows designers to achieve both functional efficiency and aesthetic quality simultaneously, rather than treating them as separate concerns. The integration helps in creating products that are not only structurally sound but also visually appealing to consumers.- Integration of aesthetic considerations in topology optimization algorithms: Advanced algorithms have been developed that incorporate aesthetic design parameters into traditional topology optimization processes. These algorithms balance structural efficiency with visual appeal by introducing design constraints that consider aesthetic factors such as smoothness, symmetry, and visual harmony. This approach enables designers to generate optimized structures that not only meet functional requirements but also satisfy aesthetic preferences, creating products that are both efficient and visually appealing.

- Multi-objective optimization frameworks for balancing functionality and aesthetics: Multi-objective optimization frameworks have been developed to simultaneously address both functional performance and aesthetic design requirements. These frameworks use weighted objective functions that consider structural integrity, material usage, manufacturing constraints, and aesthetic qualities. By employing Pareto optimization techniques, designers can explore trade-offs between competing objectives and select solutions that best balance engineering performance with visual design considerations, allowing for more holistic product development.

- User-interactive topology optimization systems: Interactive systems allow designers to guide the topology optimization process in real-time, incorporating their aesthetic preferences while maintaining functional requirements. These systems provide intuitive interfaces where users can specify design preferences, adjust parameters, and evaluate different design iterations. By combining computational optimization with human creativity and judgment, these interactive systems enable the creation of designs that balance mathematical optimization with artistic expression and brand identity considerations.

- Manufacturing-aware topology optimization for aesthetic products: Manufacturing-aware topology optimization techniques consider both the aesthetic requirements and manufacturing constraints simultaneously. These methods incorporate manufacturing process limitations such as minimum feature size, build orientation, and support structure requirements into the optimization process. By accounting for these constraints early in the design phase, the resulting optimized structures maintain their aesthetic qualities while ensuring manufacturability, reducing the need for post-optimization modifications that might compromise the design intent.

- Machine learning approaches for aesthetic topology optimization: Machine learning techniques are being applied to topology optimization to better capture and incorporate aesthetic preferences. These approaches use neural networks trained on databases of aesthetically pleasing designs to guide the optimization process toward solutions that maintain visual appeal while meeting functional requirements. Some systems employ generative adversarial networks to create designs that mimic specific aesthetic styles or design languages, enabling the creation of optimized structures that align with particular brand identities or design philosophies.

02 Multi-objective optimization frameworks for balancing functionality and aesthetics

Multi-objective optimization frameworks enable designers to simultaneously consider both functional requirements and aesthetic preferences. These frameworks use weighted objective functions that combine structural performance metrics with aesthetic design parameters. By adjusting the weights, designers can explore different trade-offs between functionality and visual appeal. Some implementations incorporate machine learning techniques to predict aesthetic preferences based on user feedback, allowing for more personalized design solutions that maintain structural integrity while meeting subjective design goals.Expand Specific Solutions03 User-interactive topology optimization systems

Interactive systems have been developed that allow designers to guide the topology optimization process in real-time. These systems provide intuitive interfaces where users can specify aesthetic preferences while the algorithm handles functional constraints. By enabling direct manipulation of design parameters during optimization, designers can inject their creative vision while maintaining performance requirements. Some systems incorporate virtual reality or augmented reality interfaces to enhance the spatial understanding of complex designs, facilitating better aesthetic decisions without compromising structural performance.Expand Specific Solutions04 Manufacturing-aware topology optimization for aesthetic designs

Manufacturing constraints are integrated into topology optimization processes to ensure that aesthetically pleasing designs remain producible. These approaches consider fabrication limitations such as minimum feature size, build orientation, and material constraints while optimizing for both functionality and visual appeal. By incorporating manufacturing awareness early in the design process, the resulting optimized structures maintain their aesthetic qualities when physically produced. This integration helps bridge the gap between idealized computer models and real-world manufacturing capabilities.Expand Specific Solutions05 Biomimetic approaches to topology optimization

Biomimetic design principles are applied to topology optimization to achieve structures that are both functionally efficient and aesthetically pleasing. By emulating patterns and forms found in nature, these approaches create organic-looking designs that often appeal to human aesthetic preferences while maintaining optimal mechanical performance. The resulting structures frequently exhibit flowing curves, hierarchical patterns, and natural proportions that are visually appealing while efficiently distributing forces. This approach leverages millions of years of natural evolution to inform both the functional and aesthetic aspects of design.Expand Specific Solutions

Leading Companies and Research Institutions in Topology Optimization

Topology optimization for balancing aesthetic design with functionality is currently in a growth phase, with the market expanding as industries recognize its value in creating efficient, visually appealing products. The global market is estimated to reach significant scale as manufacturing sectors increasingly adopt these techniques. Technologically, the field shows varying maturity levels across players. Companies like Dassault Systèmes, Siemens AG, and ANSYS lead with comprehensive commercial solutions, while Altair Engineering and Autodesk offer specialized tools gaining market traction. Academic institutions including Zhejiang University, Georgia Tech, and University of Michigan contribute significant research advancements. Automotive manufacturers such as Honda and Toyota are implementing these techniques for lightweight, efficient component design, demonstrating the technology's cross-industry applicability.

Dassault Systèmes SE

Technical Solution: Dassault Systèmes has developed TOSCA, an advanced topology optimization solution integrated within their 3DEXPERIENCE platform that specifically addresses the challenge of balancing aesthetics with functionality. Their approach combines traditional topology optimization with advanced surface smoothing and shape control algorithms to produce designs that are both structurally efficient and visually appealing. Dassault's technology incorporates design intent preservation features that allow designers to specify regions or features that should maintain certain aesthetic characteristics while other areas are optimized for performance[1]. Their platform includes advanced manufacturing constraints such as symmetry controls, minimum/maximum thickness requirements, and draft angle considerations that ensure optimized designs can be manufactured while maintaining their aesthetic qualities. Dassault has pioneered the concept of "functional aesthetics" where visual appeal emerges naturally from optimized functionality rather than being imposed artificially. Their solution includes real-time visualization tools that allow designers to see how changes to optimization parameters affect both structural performance and aesthetic qualities simultaneously[2]. The company has also developed specialized algorithms for preserving brand identity elements and design language within topology optimization, acknowledging that aesthetics often needs to align with established visual brand guidelines.

Strengths: Excellent integration with CATIA and other Dassault design tools; powerful surface smoothing capabilities produce highly refined results; comprehensive manufacturing constraint options. Weaknesses: Complex ecosystem requires significant investment in training and implementation; sometimes produces results that favor mathematical optimization over aesthetic considerations; high computational requirements for complex models.

Siemens AG

Technical Solution: Siemens has developed NX Topology Optimization, an integrated solution within their NX software suite that specifically addresses the balance between aesthetics and functionality. Their approach combines traditional topology optimization with advanced smoothing algorithms and design interpretation tools to create structures that are both visually appealing and highly functional. Siemens' technology incorporates design space controls that allow designers to specify regions where aesthetic considerations should take precedence over pure structural optimization[1]. Their platform includes advanced manufacturing constraint options such as symmetry controls, minimum/maximum member size requirements, and draw direction constraints that ensure optimized designs can be manufactured while maintaining their aesthetic qualities. Siemens has pioneered the integration of topology optimization with convergent modeling, allowing designers to seamlessly work with both faceted and B-rep geometry during the optimization process. Their solution includes real-time performance feedback tools that allow designers to understand the functional impact of aesthetic design decisions, facilitating better tradeoff decisions[2]. The company has also developed specialized algorithms for preserving design intent and brand identity elements within topology optimization, acknowledging that aesthetics often needs to align with established visual brand guidelines.

Strengths: Seamless integration with NX CAD environment; excellent manufacturing constraint options; powerful smoothing algorithms produce refined results. Weaknesses: Complex user interface with steep learning curve; sometimes produces results that still require significant manual refinement; high computational requirements for complex models with multiple load cases.

Key Algorithms and Mathematical Models Analysis

Optimum design support device, optimum setting support method, and optimum design support program

PatentWO2006009026A1

Innovation

- The use of a topology optimization technique to create an organically connected structure of different functional elements, combined with shape optimization, to design a compliant mechanism that outputs desired loads or displacements, allowing for practical implementation of previously unmanufacturable hinge elements by setting an initial actual shape and modifying it to achieve target values within elastic deformation ranges.

Topology optimization with design-dependent loads and boundary conditions for multi-physics applications

PatentInactiveUS20210004512A1

Innovation

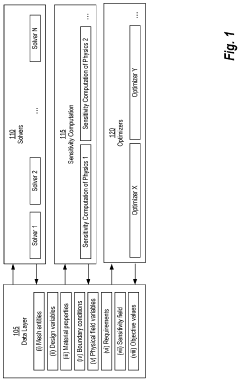

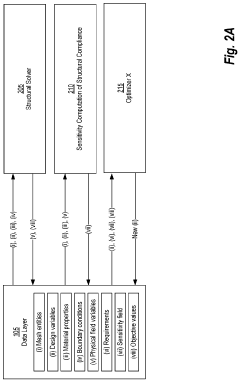

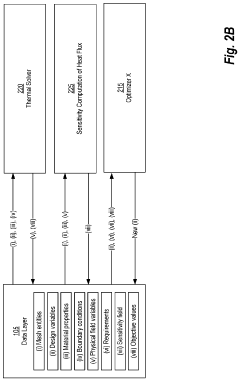

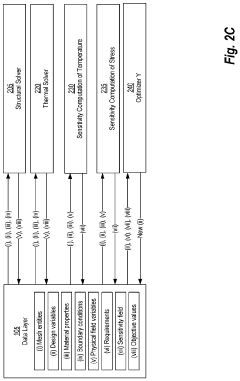

- A framework comprising a meshing module, physics solvers, sensitivity computation modules, and optimizer modules that iteratively generate and update design variables to handle changing boundary conditions and loads, using flood-filling techniques and material interpolation schemes to manage complexity and ensure convergence.

Material Science Considerations for Optimized Designs

Material selection plays a pivotal role in topology optimization processes, directly influencing both the aesthetic qualities and functional performance of the final design. When implementing topology optimization techniques, engineers must carefully consider material properties such as elasticity, strength-to-weight ratio, and thermal conductivity, as these characteristics fundamentally determine how structures respond to applied loads and environmental conditions.

Different materials exhibit varying degrees of anisotropy, which affects how forces are distributed throughout an optimized structure. For instance, fiber-reinforced composites display directional strength properties that can be strategically aligned with load paths identified through topology optimization, enhancing both structural integrity and visual appeal. This synergy between material science and optimization algorithms enables designers to achieve more elegant solutions that maintain or exceed performance requirements.

Manufacturing constraints also significantly impact material selection decisions. While certain materials may offer superior theoretical performance, their processability through available manufacturing methods must be evaluated. Advanced manufacturing techniques such as additive manufacturing have expanded the range of feasible materials for complex topology-optimized structures, allowing for previously impossible geometries while maintaining aesthetic coherence.

Surface finish and texture considerations represent another critical intersection between material science and design aesthetics. Materials that can achieve high-quality surface finishes without extensive post-processing are increasingly valuable in topology optimization applications where organic, complex geometries are common. The visual and tactile qualities of different materials contribute significantly to the perceived value and aesthetic appeal of the final product.

Sustainability factors have emerged as essential considerations in material selection for optimized designs. Bio-based polymers, recycled metals, and other environmentally responsible materials are being incorporated into topology optimization workflows, adding another dimension to the balance between aesthetics and functionality. These materials often present unique visual characteristics that can be leveraged as design features rather than limitations.

Multi-material optimization represents the frontier of material science applications in topology optimization. By strategically combining materials with complementary properties within a single component, designers can achieve unprecedented performance-to-weight ratios while creating visually distinctive elements. Gradient materials and functionally graded structures enable smooth transitions between different material properties, eliminating sharp interfaces that may compromise structural integrity or aesthetic continuity.

Different materials exhibit varying degrees of anisotropy, which affects how forces are distributed throughout an optimized structure. For instance, fiber-reinforced composites display directional strength properties that can be strategically aligned with load paths identified through topology optimization, enhancing both structural integrity and visual appeal. This synergy between material science and optimization algorithms enables designers to achieve more elegant solutions that maintain or exceed performance requirements.

Manufacturing constraints also significantly impact material selection decisions. While certain materials may offer superior theoretical performance, their processability through available manufacturing methods must be evaluated. Advanced manufacturing techniques such as additive manufacturing have expanded the range of feasible materials for complex topology-optimized structures, allowing for previously impossible geometries while maintaining aesthetic coherence.

Surface finish and texture considerations represent another critical intersection between material science and design aesthetics. Materials that can achieve high-quality surface finishes without extensive post-processing are increasingly valuable in topology optimization applications where organic, complex geometries are common. The visual and tactile qualities of different materials contribute significantly to the perceived value and aesthetic appeal of the final product.

Sustainability factors have emerged as essential considerations in material selection for optimized designs. Bio-based polymers, recycled metals, and other environmentally responsible materials are being incorporated into topology optimization workflows, adding another dimension to the balance between aesthetics and functionality. These materials often present unique visual characteristics that can be leveraged as design features rather than limitations.

Multi-material optimization represents the frontier of material science applications in topology optimization. By strategically combining materials with complementary properties within a single component, designers can achieve unprecedented performance-to-weight ratios while creating visually distinctive elements. Gradient materials and functionally graded structures enable smooth transitions between different material properties, eliminating sharp interfaces that may compromise structural integrity or aesthetic continuity.

Industry-Specific Implementation Case Studies

The automotive industry has pioneered topology optimization implementation, with BMW's 2018 i8 Roadster featuring a 3D-printed aluminum component that reduced weight by 44% while maintaining structural integrity. This breakthrough demonstrated how aesthetic considerations could be integrated with functional requirements through careful constraint definition in the optimization algorithm, allowing designers to preserve brand-specific visual elements while achieving performance targets.

In aerospace, Airbus utilized topology optimization for the A320neo wing brackets, resulting in a 40% weight reduction. Their approach incorporated manufacturing constraints directly into the optimization process, ensuring the components maintained a clean, visually coherent appearance while meeting strict safety standards. The success of this implementation has led to expanded use across multiple aircraft programs, with designers now able to specify aesthetic boundary conditions alongside mechanical requirements.

The medical device sector presents unique challenges where patient comfort and perception significantly impact product success. Zimmer Biomet's knee implant designs leverage topology optimization to create organic-looking structures that patients perceive as more natural while improving functional outcomes. Their methodology includes specific aesthetic parameters in the optimization algorithm, ensuring the final products maintain visual coherence while optimizing weight distribution and stress management.

Consumer electronics manufacturers like Apple have integrated topology optimization into their design workflow, particularly for internal structural components. Their approach balances the invisible functional elements with visible design features by establishing clear boundaries between optimization zones. This selective application allows for maximum weight and material reduction in non-visible areas while preserving the brand's distinctive aesthetic in customer-facing elements.

Architecture firms including Zaha Hadid Architects have applied topology optimization to create structurally efficient yet visually striking building components. Their methodology involves a two-stage process where initial optimization focuses purely on structural performance, followed by a refinement phase where designers manually modify the solution to enhance visual appeal while maintaining structural integrity. This collaborative approach between computational systems and human designers has produced landmark structures that balance engineering efficiency with architectural expression.

The furniture industry demonstrates how topology optimization can directly enhance aesthetic value, with companies like Kartell producing chairs that showcase the optimization process itself as a design feature. By carefully controlling the optimization parameters and incorporating manufacturing constraints specific to injection molding, they've created products where the structural optimization pattern becomes the primary visual identity of the product.

In aerospace, Airbus utilized topology optimization for the A320neo wing brackets, resulting in a 40% weight reduction. Their approach incorporated manufacturing constraints directly into the optimization process, ensuring the components maintained a clean, visually coherent appearance while meeting strict safety standards. The success of this implementation has led to expanded use across multiple aircraft programs, with designers now able to specify aesthetic boundary conditions alongside mechanical requirements.

The medical device sector presents unique challenges where patient comfort and perception significantly impact product success. Zimmer Biomet's knee implant designs leverage topology optimization to create organic-looking structures that patients perceive as more natural while improving functional outcomes. Their methodology includes specific aesthetic parameters in the optimization algorithm, ensuring the final products maintain visual coherence while optimizing weight distribution and stress management.

Consumer electronics manufacturers like Apple have integrated topology optimization into their design workflow, particularly for internal structural components. Their approach balances the invisible functional elements with visible design features by establishing clear boundaries between optimization zones. This selective application allows for maximum weight and material reduction in non-visible areas while preserving the brand's distinctive aesthetic in customer-facing elements.

Architecture firms including Zaha Hadid Architects have applied topology optimization to create structurally efficient yet visually striking building components. Their methodology involves a two-stage process where initial optimization focuses purely on structural performance, followed by a refinement phase where designers manually modify the solution to enhance visual appeal while maintaining structural integrity. This collaborative approach between computational systems and human designers has produced landmark structures that balance engineering efficiency with architectural expression.

The furniture industry demonstrates how topology optimization can directly enhance aesthetic value, with companies like Kartell producing chairs that showcase the optimization process itself as a design feature. By carefully controlling the optimization parameters and incorporating manufacturing constraints specific to injection molding, they've created products where the structural optimization pattern becomes the primary visual identity of the product.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!