How to Achieve Enhanced Scaffolding Structures Using Topology Optimization

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Topology Optimization Background and Objectives

Topology optimization has emerged as a revolutionary computational design methodology in structural engineering over the past three decades. Originally developed in the 1980s by researchers seeking to maximize structural performance while minimizing material usage, this approach has evolved from academic theory to practical implementation across multiple industries. The fundamental principle involves distributing material within a design space to achieve optimal performance under specified constraints, effectively allowing structures to "grow" organically in response to applied loads and boundary conditions.

The evolution of topology optimization has been accelerated by advances in computational power, mathematical algorithms, and manufacturing capabilities. Early implementations were limited by computational constraints and manufacturing feasibility, but modern approaches can handle complex multi-physics problems while considering manufacturability constraints. The field has progressed from simple compliance minimization problems to addressing complex objectives including thermal management, fluid flow, and multi-material designs.

Recent technological developments in additive manufacturing have dramatically expanded the practical applications of topology optimization. The layer-by-layer construction process of 3D printing enables the fabrication of complex geometries that would be impossible with traditional manufacturing methods, allowing designers to fully leverage the organic, often biomimetic structures that emerge from topology optimization processes.

In the context of scaffolding structures, topology optimization presents unique opportunities and challenges. Scaffolding requires specific mechanical properties including high strength-to-weight ratios, controlled porosity, and directional stiffness characteristics. The primary objective of applying topology optimization to scaffolding is to develop structures that can provide superior load-bearing capacity while minimizing material usage and manufacturing complexity.

Current research aims to overcome several key challenges in this domain. These include developing multi-scale optimization approaches that can address both macro-structural performance and micro-structural features simultaneously, incorporating anisotropic material properties into optimization algorithms, and ensuring manufacturability of the resulting designs. Additionally, there is growing interest in time-dependent optimization that can account for dynamic loading conditions typical in scaffolding applications.

The ultimate goal of this technical investigation is to establish a comprehensive framework for topology optimization specifically tailored to scaffolding structures. This includes identifying appropriate mathematical formulations, developing efficient computational methods, and establishing design guidelines that bridge theoretical optimization with practical implementation. By addressing these objectives, we aim to enable the next generation of scaffolding systems that offer enhanced structural performance, improved safety margins, and reduced material consumption.

The evolution of topology optimization has been accelerated by advances in computational power, mathematical algorithms, and manufacturing capabilities. Early implementations were limited by computational constraints and manufacturing feasibility, but modern approaches can handle complex multi-physics problems while considering manufacturability constraints. The field has progressed from simple compliance minimization problems to addressing complex objectives including thermal management, fluid flow, and multi-material designs.

Recent technological developments in additive manufacturing have dramatically expanded the practical applications of topology optimization. The layer-by-layer construction process of 3D printing enables the fabrication of complex geometries that would be impossible with traditional manufacturing methods, allowing designers to fully leverage the organic, often biomimetic structures that emerge from topology optimization processes.

In the context of scaffolding structures, topology optimization presents unique opportunities and challenges. Scaffolding requires specific mechanical properties including high strength-to-weight ratios, controlled porosity, and directional stiffness characteristics. The primary objective of applying topology optimization to scaffolding is to develop structures that can provide superior load-bearing capacity while minimizing material usage and manufacturing complexity.

Current research aims to overcome several key challenges in this domain. These include developing multi-scale optimization approaches that can address both macro-structural performance and micro-structural features simultaneously, incorporating anisotropic material properties into optimization algorithms, and ensuring manufacturability of the resulting designs. Additionally, there is growing interest in time-dependent optimization that can account for dynamic loading conditions typical in scaffolding applications.

The ultimate goal of this technical investigation is to establish a comprehensive framework for topology optimization specifically tailored to scaffolding structures. This includes identifying appropriate mathematical formulations, developing efficient computational methods, and establishing design guidelines that bridge theoretical optimization with practical implementation. By addressing these objectives, we aim to enable the next generation of scaffolding systems that offer enhanced structural performance, improved safety margins, and reduced material consumption.

Market Analysis for Optimized Scaffolding Solutions

The global market for optimized scaffolding solutions is experiencing significant growth, driven by increasing demands in construction, aerospace, medical implants, and additive manufacturing sectors. The scaffolding industry, traditionally characterized by conventional designs and materials, is undergoing a transformation as topology optimization techniques enable structures that are simultaneously lighter, stronger, and more resource-efficient.

Current market valuation for advanced scaffolding solutions stands at approximately $12.5 billion, with projections indicating a compound annual growth rate of 7.8% over the next five years. This growth trajectory is particularly pronounced in regions with extensive infrastructure development initiatives, including East Asia, North America, and parts of Europe where construction activities remain robust despite economic fluctuations.

The construction sector represents the largest market segment, accounting for nearly 65% of demand for optimized scaffolding solutions. Within this segment, high-rise building projects and complex architectural designs are driving adoption of topology-optimized structures that can support greater loads while reducing material usage by up to 30% compared to traditional designs.

Medical applications constitute the fastest-growing segment, expanding at 12.3% annually. The demand for patient-specific implants and tissue engineering scaffolds has created a specialized market niche where topology optimization delivers critical performance advantages in terms of biocompatibility, mechanical properties, and cellular integration.

Market analysis reveals significant regional variations in adoption rates. European markets show the highest penetration of topology-optimized scaffolding solutions, supported by stringent safety regulations and sustainability initiatives. The Asia-Pacific region demonstrates the most rapid growth, fueled by urbanization trends and massive infrastructure investments in countries like China and India.

Customer demand patterns indicate a shift toward integrated solutions that combine optimized structural designs with smart monitoring capabilities. This trend is creating new market opportunities for technology providers who can deliver comprehensive scaffolding systems with embedded sensors and real-time performance analytics.

Pricing models in the market are evolving from traditional material-plus-labor calculations toward value-based approaches that account for the performance improvements and material savings enabled by topology optimization. Premium pricing of 15-25% above conventional solutions is becoming standard, justified by demonstrable lifecycle cost reductions.

Market barriers include high initial investment costs for design software and manufacturing equipment, knowledge gaps among traditional contractors, and regulatory frameworks that have not fully adapted to novel structural designs. These factors have created a segmented market where early adopters gain significant competitive advantages while mainstream adoption progresses at a measured pace.

Current market valuation for advanced scaffolding solutions stands at approximately $12.5 billion, with projections indicating a compound annual growth rate of 7.8% over the next five years. This growth trajectory is particularly pronounced in regions with extensive infrastructure development initiatives, including East Asia, North America, and parts of Europe where construction activities remain robust despite economic fluctuations.

The construction sector represents the largest market segment, accounting for nearly 65% of demand for optimized scaffolding solutions. Within this segment, high-rise building projects and complex architectural designs are driving adoption of topology-optimized structures that can support greater loads while reducing material usage by up to 30% compared to traditional designs.

Medical applications constitute the fastest-growing segment, expanding at 12.3% annually. The demand for patient-specific implants and tissue engineering scaffolds has created a specialized market niche where topology optimization delivers critical performance advantages in terms of biocompatibility, mechanical properties, and cellular integration.

Market analysis reveals significant regional variations in adoption rates. European markets show the highest penetration of topology-optimized scaffolding solutions, supported by stringent safety regulations and sustainability initiatives. The Asia-Pacific region demonstrates the most rapid growth, fueled by urbanization trends and massive infrastructure investments in countries like China and India.

Customer demand patterns indicate a shift toward integrated solutions that combine optimized structural designs with smart monitoring capabilities. This trend is creating new market opportunities for technology providers who can deliver comprehensive scaffolding systems with embedded sensors and real-time performance analytics.

Pricing models in the market are evolving from traditional material-plus-labor calculations toward value-based approaches that account for the performance improvements and material savings enabled by topology optimization. Premium pricing of 15-25% above conventional solutions is becoming standard, justified by demonstrable lifecycle cost reductions.

Market barriers include high initial investment costs for design software and manufacturing equipment, knowledge gaps among traditional contractors, and regulatory frameworks that have not fully adapted to novel structural designs. These factors have created a segmented market where early adopters gain significant competitive advantages while mainstream adoption progresses at a measured pace.

Current Challenges in Scaffolding Structural Design

Despite significant advancements in scaffolding design methodologies, the field continues to face several critical challenges that impede optimal structural performance. Traditional scaffolding design approaches often rely on standardized components and conventional geometries, resulting in structures that are either overdesigned (wasting material and increasing costs) or underdesigned (compromising safety margins). This fundamental inefficiency stems from the inability to precisely distribute material according to actual load paths and stress distributions.

The complexity of load conditions presents another significant challenge. Scaffolding structures must withstand various load combinations including dead loads, live loads, wind loads, and sometimes seismic forces. Current design methodologies struggle to simultaneously optimize for these multiple load cases, particularly when they act in different directions or with varying magnitudes throughout the structure's lifecycle.

Material heterogeneity and anisotropy further complicate scaffolding design. Most design approaches assume homogeneous material properties, whereas actual construction materials exhibit varying degrees of anisotropy and property variations. This discrepancy leads to suboptimal designs that fail to leverage the full potential of modern construction materials.

Computational limitations remain a persistent obstacle in advanced scaffolding design. While topology optimization algorithms offer promising solutions, they typically require substantial computational resources, especially for large-scale scaffolding systems. The high computational cost often forces designers to simplify models or reduce resolution, compromising the quality of optimization results.

Manufacturing constraints represent another critical challenge. Theoretically optimal designs generated through topology optimization may prove difficult or impossible to fabricate using conventional construction methods. The gap between mathematically optimal solutions and practically manufacturable structures continues to limit the implementation of advanced design methodologies.

Regulatory frameworks and safety standards also impose significant constraints on scaffolding design innovation. Current codes and standards were largely developed for conventional designs and may not adequately accommodate novel topologically optimized structures, creating regulatory barriers to implementation.

Finally, the industry faces a knowledge gap in translating theoretical topology optimization techniques into practical scaffolding applications. Many practitioners lack familiarity with advanced computational design tools, while academic researchers may not fully appreciate practical construction constraints, creating a disconnect between theoretical possibilities and practical implementation.

The complexity of load conditions presents another significant challenge. Scaffolding structures must withstand various load combinations including dead loads, live loads, wind loads, and sometimes seismic forces. Current design methodologies struggle to simultaneously optimize for these multiple load cases, particularly when they act in different directions or with varying magnitudes throughout the structure's lifecycle.

Material heterogeneity and anisotropy further complicate scaffolding design. Most design approaches assume homogeneous material properties, whereas actual construction materials exhibit varying degrees of anisotropy and property variations. This discrepancy leads to suboptimal designs that fail to leverage the full potential of modern construction materials.

Computational limitations remain a persistent obstacle in advanced scaffolding design. While topology optimization algorithms offer promising solutions, they typically require substantial computational resources, especially for large-scale scaffolding systems. The high computational cost often forces designers to simplify models or reduce resolution, compromising the quality of optimization results.

Manufacturing constraints represent another critical challenge. Theoretically optimal designs generated through topology optimization may prove difficult or impossible to fabricate using conventional construction methods. The gap between mathematically optimal solutions and practically manufacturable structures continues to limit the implementation of advanced design methodologies.

Regulatory frameworks and safety standards also impose significant constraints on scaffolding design innovation. Current codes and standards were largely developed for conventional designs and may not adequately accommodate novel topologically optimized structures, creating regulatory barriers to implementation.

Finally, the industry faces a knowledge gap in translating theoretical topology optimization techniques into practical scaffolding applications. Many practitioners lack familiarity with advanced computational design tools, while academic researchers may not fully appreciate practical construction constraints, creating a disconnect between theoretical possibilities and practical implementation.

Current Methodologies for Scaffold Topology Optimization

01 Modular scaffolding systems

Modular scaffolding systems provide enhanced structural integrity through interconnectable components that can be assembled in various configurations. These systems feature standardized connection points, adjustable heights, and quick-lock mechanisms that allow for rapid deployment and reconfiguration. The modular design enables customization for different project requirements while maintaining structural stability and safety compliance.- Modular scaffolding systems: Modular scaffolding systems provide enhanced structural integrity through interconnectable components that can be assembled in various configurations. These systems feature standardized connection points, allowing for quick assembly and disassembly while maintaining structural stability. The modular design enables customization for different project requirements and can include features such as adjustable heights, load-bearing capabilities, and safety mechanisms.

- Reinforced scaffolding materials: Enhanced scaffolding structures utilize advanced materials and reinforcement techniques to improve strength-to-weight ratios. These innovations include composite materials, high-tensile steel alloys, and specialized coatings that provide corrosion resistance and extended service life. The reinforced materials allow for higher load capacities while maintaining or reducing the overall weight of the scaffolding structure, improving both safety and efficiency.

- Advanced connection and locking mechanisms: Innovative connection and locking mechanisms enhance the stability and safety of scaffolding structures. These include quick-release systems, self-locking joints, and fail-safe connectors that prevent accidental disassembly. The advanced mechanisms reduce assembly time while ensuring secure connections between components, minimizing the risk of structural failure and improving overall scaffold integrity under various load conditions.

- Adjustable and adaptable scaffolding designs: Adaptable scaffolding designs incorporate features that allow for adjustment to irregular surfaces, varying heights, and complex architectural elements. These systems include telescopic components, articulating joints, and variable-angle connectors that can conform to non-standard building shapes. The adjustability enables scaffolding to be deployed in challenging environments while maintaining structural integrity and providing safe working platforms.

- Integrated safety features: Enhanced scaffolding structures incorporate integrated safety features designed to protect workers and improve operational efficiency. These include built-in guardrails, toe boards, access ladders, and anchor points for personal fall protection systems. Some advanced designs also feature load monitoring systems, wind resistance improvements, and stabilizing outriggers that automatically deploy when needed, significantly reducing workplace accidents and improving compliance with safety regulations.

02 Reinforced scaffolding materials

Advanced materials are used to enhance the strength-to-weight ratio of scaffolding structures. These include high-tensile steel alloys, composite materials, and reinforced polymers that provide superior load-bearing capacity while reducing overall weight. The materials are engineered to resist corrosion, weathering, and structural fatigue, extending the service life of scaffolding systems while improving safety and performance in demanding environments.Expand Specific Solutions03 Safety enhancement mechanisms

Innovative safety features are integrated into scaffolding structures to protect workers and improve operational efficiency. These include automatic locking systems, anti-slip platforms, integrated fall protection anchors, and safety nets. Some designs incorporate electronic monitoring systems that detect structural stress, improper assembly, or excessive loading, providing real-time alerts to prevent accidents and structural failures.Expand Specific Solutions04 Adaptable scaffolding for complex geometries

Specialized scaffolding systems are designed to accommodate complex architectural shapes and challenging construction environments. These systems feature adjustable angles, curved components, and flexible connection points that can conform to irregular surfaces and non-standard geometries. The adaptability allows for scaffolding installation on historical buildings, modern curved structures, and in confined spaces where conventional scaffolding would be impractical.Expand Specific Solutions05 Automated and mechanized scaffolding systems

Advanced scaffolding incorporates automation and mechanization to improve efficiency and reduce labor requirements. These systems feature hydraulic or electric lifting mechanisms, self-climbing capabilities, and remote-controlled adjustment functions. Some designs include integrated hoisting systems, motorized platforms, and automated assembly/disassembly sequences that significantly reduce setup time and improve worker productivity while maintaining structural integrity.Expand Specific Solutions

Leading Companies in Advanced Structural Engineering

The topology optimization market for enhanced scaffolding structures is currently in a growth phase, with increasing adoption across manufacturing, aerospace, and biomedical sectors. The global market size is expanding rapidly, driven by demand for lightweight, high-performance structures. Technology maturity varies across applications, with companies like Siemens AG and Dassault Systèmes leading commercial software development, while academic institutions such as MIT, Georgia Tech, and Zhejiang University advance fundamental research. Industrial players including Boeing, Toyota, and Caterpillar are implementing topology optimization in product development. The competitive landscape features collaboration between software providers (Siemens Industry Software), research institutions, and end-users, with emerging competition from specialized engineering firms and university spin-offs developing novel algorithms and application-specific solutions.

Siemens AG

Technical Solution: Siemens AG has developed an advanced topology optimization platform called NX Topology Optimizer that integrates with their CAD/CAM/CAE software suite. Their approach combines traditional topology optimization algorithms with manufacturing constraints to create scaffolding structures that are both optimized for performance and manufacturable. The technology employs multi-objective optimization techniques that simultaneously consider structural performance, material usage, and manufacturing limitations. Siemens' solution incorporates lattice structure generation capabilities that allow for the creation of complex internal scaffolding with variable density distributions based on stress analysis results. Their platform also features advanced smoothing algorithms that refine the typically rough surfaces produced by topology optimization, making the results more suitable for direct manufacturing. Siemens has implemented machine learning techniques to accelerate the optimization process by predicting optimal starting points based on similar previous designs, reducing computation time by up to 40%.

Strengths: Seamless integration with existing CAD/CAM workflows enables efficient design-to-manufacturing processes. The comprehensive approach considering both performance and manufacturability results in practical, implementable designs. Weaknesses: The system requires significant computational resources for complex optimization problems, and the proprietary nature of their software ecosystem can create vendor lock-in for customers.

Intel Corp.

Technical Solution: Intel has developed advanced topology optimization techniques focused on thermal management and structural integrity for microelectronic packaging and semiconductor manufacturing equipment. Their approach combines traditional topology optimization with thermal-mechanical coupled analysis to create optimized scaffolding structures that address both structural and thermal requirements. Intel's technology employs specialized algorithms that account for the unique constraints of semiconductor manufacturing, including cleanroom compatibility, thermal expansion matching, and vibration isolation. Their methodology incorporates multi-material optimization capabilities that allow for the strategic placement of different materials within a single component to achieve optimal performance. Intel has implemented high-performance computing techniques that leverage their own processor technologies to accelerate the optimization process, enabling the exploration of larger design spaces. Their platform includes specialized manufacturing constraints tailored to the precision requirements of semiconductor equipment, ensuring that optimized designs can be manufactured to the required tolerances. Intel has also developed techniques for optimizing structures at multiple scales, from chip-level features to equipment support structures.

Strengths: Specialized expertise in thermal-mechanical optimization creates structures that excel in the demanding environment of semiconductor manufacturing. Their high-performance computing approach enables optimization of extremely complex structures within practical timeframes. Weaknesses: Their techniques are highly specialized for microelectronics applications and may not translate well to other industries, and their solutions typically require access to substantial computing resources.

Key Algorithms and Computational Methods Analysis

Topology optimization with bidirectional mesh adaptation

PatentWO2023133734A1

Innovation

- Bidirectional mesh adaptation technique that dynamically adjusts mesh resolution during topology optimization, allowing for both refinement and coarsening based on optimization progress.

- Multi-physics topology optimization approach that balances computational efficiency with design detail preservation, particularly beneficial for thermal-flow applications like gas turbine components.

- Sensitivity analysis methodology that identifies critical regions requiring higher mesh resolution while allowing coarser meshes in less critical areas, optimizing computational resource allocation.

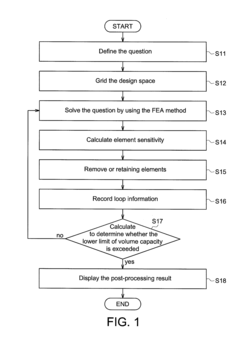

Structural topology optimization design method

PatentInactiveUS20160140269A1

Innovation

- A modified BESO method that omits the iteration process until the target volume capacity is reached, directly using structural profiles after each loop as optimization results, and utilizes a display interface to show the relationship between volume capacity and stiffness, allowing for easier determination of processing feasibility.

Material Science Considerations for Enhanced Scaffolds

The selection of appropriate materials is fundamental to the success of topology-optimized scaffolding structures. Material properties directly influence the mechanical behavior, biocompatibility, and overall performance of scaffolds. Recent advances in material science have expanded the range of available options, from traditional metals and polymers to innovative composites and biomaterials specifically designed for scaffold applications.

Mechanical properties such as elastic modulus, yield strength, and fatigue resistance must be carefully considered when designing scaffolds through topology optimization. These properties determine how the structure will respond to applied loads and environmental conditions. Materials with tunable mechanical properties offer significant advantages, allowing designers to create scaffolds with spatially varying characteristics that better mimic natural tissues or adapt to specific structural requirements.

Biodegradability represents another critical consideration for many scaffold applications, particularly in biomedical fields. Materials that degrade at controlled rates can provide temporary support while allowing natural tissue to gradually assume load-bearing responsibilities. The degradation kinetics must be synchronized with the tissue regeneration process, requiring precise material selection and design optimization.

Surface properties of materials significantly impact cell adhesion, proliferation, and differentiation in biomedical scaffolds. Topology optimization must account for these surface-dependent biological interactions, potentially incorporating different materials or surface treatments in specific regions of the scaffold to promote desired cellular responses.

Manufacturing constraints also influence material selection for topology-optimized scaffolds. Additive manufacturing techniques like selective laser melting, stereolithography, and fused deposition modeling each have specific material compatibility requirements. The resolution, accuracy, and surface finish achievable with different material-process combinations must be evaluated when implementing topology optimization solutions.

Multi-material approaches represent a frontier in scaffold design, enabling structures with spatially varying properties. Advanced topology optimization algorithms can now handle multiple materials simultaneously, creating functionally graded structures that transition smoothly between different material properties. This capability is particularly valuable for interfaces between tissues with different mechanical requirements or for creating scaffolds with integrated sensing or actuation capabilities.

Environmental stability must also be considered, as scaffolds may be exposed to corrosive environments, temperature fluctuations, or sterilization processes. Materials must maintain their designed properties throughout the intended service life of the scaffold, which requires thorough testing under relevant conditions.

Mechanical properties such as elastic modulus, yield strength, and fatigue resistance must be carefully considered when designing scaffolds through topology optimization. These properties determine how the structure will respond to applied loads and environmental conditions. Materials with tunable mechanical properties offer significant advantages, allowing designers to create scaffolds with spatially varying characteristics that better mimic natural tissues or adapt to specific structural requirements.

Biodegradability represents another critical consideration for many scaffold applications, particularly in biomedical fields. Materials that degrade at controlled rates can provide temporary support while allowing natural tissue to gradually assume load-bearing responsibilities. The degradation kinetics must be synchronized with the tissue regeneration process, requiring precise material selection and design optimization.

Surface properties of materials significantly impact cell adhesion, proliferation, and differentiation in biomedical scaffolds. Topology optimization must account for these surface-dependent biological interactions, potentially incorporating different materials or surface treatments in specific regions of the scaffold to promote desired cellular responses.

Manufacturing constraints also influence material selection for topology-optimized scaffolds. Additive manufacturing techniques like selective laser melting, stereolithography, and fused deposition modeling each have specific material compatibility requirements. The resolution, accuracy, and surface finish achievable with different material-process combinations must be evaluated when implementing topology optimization solutions.

Multi-material approaches represent a frontier in scaffold design, enabling structures with spatially varying properties. Advanced topology optimization algorithms can now handle multiple materials simultaneously, creating functionally graded structures that transition smoothly between different material properties. This capability is particularly valuable for interfaces between tissues with different mechanical requirements or for creating scaffolds with integrated sensing or actuation capabilities.

Environmental stability must also be considered, as scaffolds may be exposed to corrosive environments, temperature fluctuations, or sterilization processes. Materials must maintain their designed properties throughout the intended service life of the scaffold, which requires thorough testing under relevant conditions.

Safety Standards and Compliance Requirements

Scaffolding safety standards and compliance requirements represent a critical framework governing the implementation of topology-optimized scaffolding structures in construction and industrial applications. The International Scaffolding Association (ISA) and Occupational Safety and Health Administration (OSHA) have established comprehensive guidelines that specifically address load-bearing capacity requirements, which must be rigorously considered when implementing topology optimization techniques.

These standards typically mandate that scaffolding structures must withstand at least four times their intended load capacity, creating a significant safety margin that topology optimization algorithms must incorporate as constraint parameters. Recent updates to ISO 22915-2:2018 have introduced specific provisions for non-conventional scaffolding geometries, directly impacting how topology optimization can be applied while maintaining regulatory compliance.

Material certification requirements present another crucial compliance consideration. Materials used in topology-optimized scaffolding must meet specific strength-to-weight ratios and durability standards as outlined in ASTM A500/A500M for steel structural tubing and ASTM B221 for aluminum alloys. The European Committee for Standardization (CEN) has also established EN 12810 and EN 12811 standards that provide detailed specifications for prefabricated scaffolding components, including those with optimized geometries.

Structural integrity verification protocols have evolved significantly to accommodate advanced computational design methods. The American Society of Civil Engineers (ASCE) now recognizes finite element analysis (FEA) validation as an acceptable compliance pathway for topology-optimized structures, provided that physical testing validates computational models for critical load cases. This represents a significant regulatory advancement enabling broader adoption of topology optimization techniques.

Regional variations in compliance requirements create additional complexity. While European standards (Eurocode 3) permit greater design flexibility through performance-based approaches, many Asian countries maintain more prescriptive requirements that can limit the implementation of highly optimized geometries. Australia and New Zealand have pioneered risk-based assessment frameworks specifically addressing novel structural configurations resulting from topology optimization.

Periodic inspection and maintenance requirements must also be integrated into topology-optimized designs. The unique geometries resulting from optimization algorithms often necessitate specialized inspection protocols to ensure continued compliance throughout the scaffolding lifecycle. The Construction Industry Research and Information Association (CIRIA) has developed specific guidance for inspecting non-standard structural configurations that should be incorporated into maintenance planning for topology-optimized scaffolding systems.

These standards typically mandate that scaffolding structures must withstand at least four times their intended load capacity, creating a significant safety margin that topology optimization algorithms must incorporate as constraint parameters. Recent updates to ISO 22915-2:2018 have introduced specific provisions for non-conventional scaffolding geometries, directly impacting how topology optimization can be applied while maintaining regulatory compliance.

Material certification requirements present another crucial compliance consideration. Materials used in topology-optimized scaffolding must meet specific strength-to-weight ratios and durability standards as outlined in ASTM A500/A500M for steel structural tubing and ASTM B221 for aluminum alloys. The European Committee for Standardization (CEN) has also established EN 12810 and EN 12811 standards that provide detailed specifications for prefabricated scaffolding components, including those with optimized geometries.

Structural integrity verification protocols have evolved significantly to accommodate advanced computational design methods. The American Society of Civil Engineers (ASCE) now recognizes finite element analysis (FEA) validation as an acceptable compliance pathway for topology-optimized structures, provided that physical testing validates computational models for critical load cases. This represents a significant regulatory advancement enabling broader adoption of topology optimization techniques.

Regional variations in compliance requirements create additional complexity. While European standards (Eurocode 3) permit greater design flexibility through performance-based approaches, many Asian countries maintain more prescriptive requirements that can limit the implementation of highly optimized geometries. Australia and New Zealand have pioneered risk-based assessment frameworks specifically addressing novel structural configurations resulting from topology optimization.

Periodic inspection and maintenance requirements must also be integrated into topology-optimized designs. The unique geometries resulting from optimization algorithms often necessitate specialized inspection protocols to ensure continued compliance throughout the scaffolding lifecycle. The Construction Industry Research and Information Association (CIRIA) has developed specific guidance for inspecting non-standard structural configurations that should be incorporated into maintenance planning for topology-optimized scaffolding systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!