Topology Optimization in Spacecraft: Weight Reduction Strategies

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Spacecraft Topology Optimization Background and Objectives

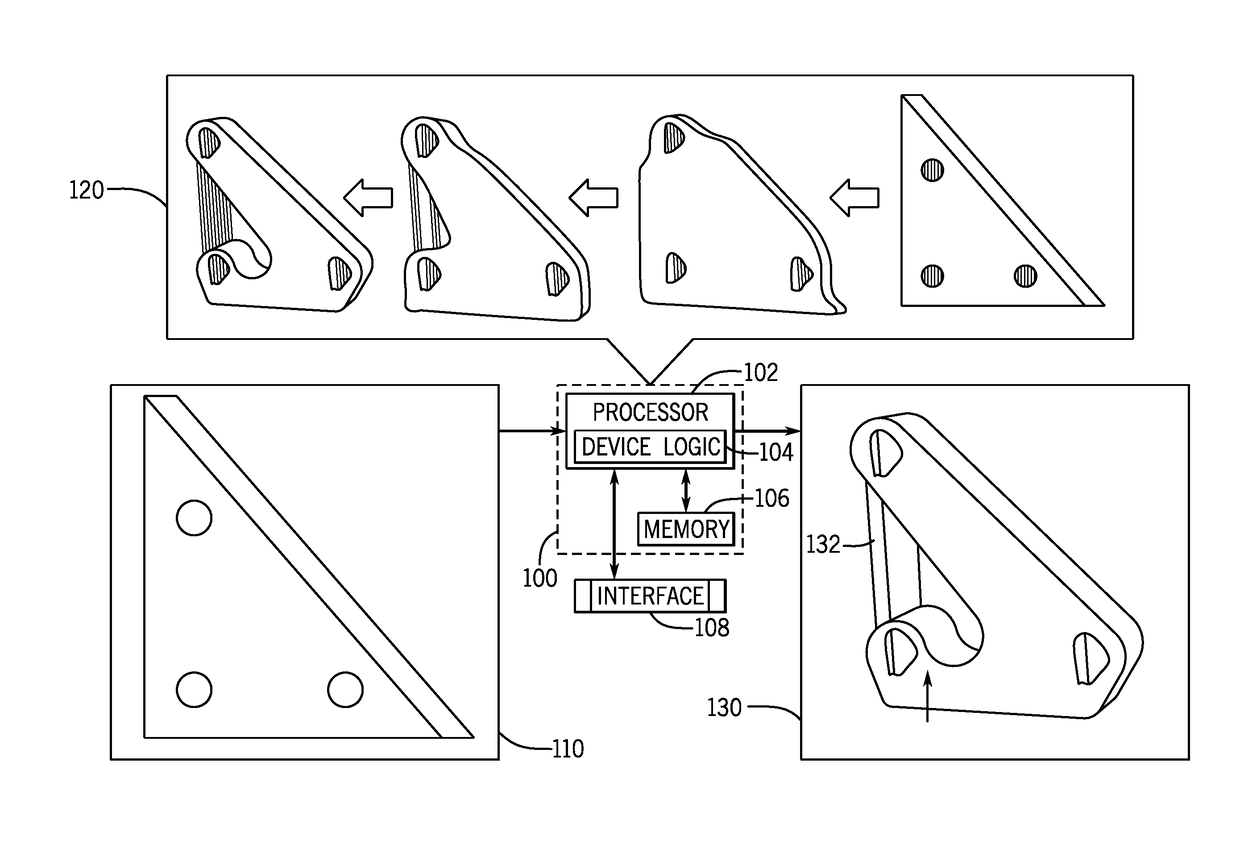

Topology optimization has emerged as a revolutionary approach in spacecraft design, evolving from its origins in structural engineering during the 1980s. This mathematical method determines the optimal material distribution within a given design space, subject to specific constraints and performance criteria. In spacecraft applications, topology optimization has transformed from an academic concept to an essential industrial tool over the past three decades, with significant acceleration in practical implementation since the 2010s due to advances in computational capabilities and additive manufacturing technologies.

The primary objective of topology optimization in spacecraft design is to achieve substantial weight reduction while maintaining or enhancing structural performance. This goal is particularly critical in the aerospace industry, where each kilogram of payload represents approximately $20,000 in launch costs. By optimizing material distribution, engineers can create spacecraft components that are 30-50% lighter than conventional designs while meeting or exceeding strength and stiffness requirements.

Current technological trends indicate a convergence of topology optimization with multi-physics analysis, allowing simultaneous consideration of structural, thermal, and vibrational performance. This holistic approach addresses the complex operational environment of spacecraft, where components must withstand extreme temperature fluctuations, vacuum conditions, and launch vibrations. The evolution of these techniques has been driven by both academic research and industrial applications, with notable contributions from space agencies like NASA and ESA, as well as private companies such as SpaceX and Blue Origin.

The trajectory of topology optimization development shows a clear progression from simple structural problems to complex multi-disciplinary optimization scenarios. Early applications focused primarily on static load cases, while contemporary approaches incorporate dynamic loading, thermal management, and even radiation shielding considerations. This evolution reflects the increasing sophistication of both the mathematical models and the computational tools available to engineers.

Looking forward, the field aims to develop more integrated optimization frameworks that can simultaneously address multiple performance criteria while considering manufacturing constraints specific to space applications. The ultimate technical goal is to create a seamless workflow from conceptual design through optimization to manufacturing validation, enabling rapid iteration and deployment of optimized spacecraft components that significantly reduce mass while enhancing mission capabilities and reliability.

The primary objective of topology optimization in spacecraft design is to achieve substantial weight reduction while maintaining or enhancing structural performance. This goal is particularly critical in the aerospace industry, where each kilogram of payload represents approximately $20,000 in launch costs. By optimizing material distribution, engineers can create spacecraft components that are 30-50% lighter than conventional designs while meeting or exceeding strength and stiffness requirements.

Current technological trends indicate a convergence of topology optimization with multi-physics analysis, allowing simultaneous consideration of structural, thermal, and vibrational performance. This holistic approach addresses the complex operational environment of spacecraft, where components must withstand extreme temperature fluctuations, vacuum conditions, and launch vibrations. The evolution of these techniques has been driven by both academic research and industrial applications, with notable contributions from space agencies like NASA and ESA, as well as private companies such as SpaceX and Blue Origin.

The trajectory of topology optimization development shows a clear progression from simple structural problems to complex multi-disciplinary optimization scenarios. Early applications focused primarily on static load cases, while contemporary approaches incorporate dynamic loading, thermal management, and even radiation shielding considerations. This evolution reflects the increasing sophistication of both the mathematical models and the computational tools available to engineers.

Looking forward, the field aims to develop more integrated optimization frameworks that can simultaneously address multiple performance criteria while considering manufacturing constraints specific to space applications. The ultimate technical goal is to create a seamless workflow from conceptual design through optimization to manufacturing validation, enabling rapid iteration and deployment of optimized spacecraft components that significantly reduce mass while enhancing mission capabilities and reliability.

Market Analysis for Lightweight Spacecraft Structures

The spacecraft structural components market is experiencing robust growth, driven by increasing satellite deployments and space exploration missions. Currently valued at approximately $3.2 billion, this market segment is projected to reach $5.7 billion by 2028, representing a compound annual growth rate of 12.3%. Lightweight structures specifically account for nearly 40% of this market, with topology optimization solutions emerging as a high-growth subsegment.

Demand for lightweight spacecraft structures is primarily fueled by commercial satellite operators seeking to maximize payload capacity while minimizing launch costs. With launch expenses ranging from $2,500 to $10,000 per kilogram depending on orbit requirements, weight reduction directly translates to significant cost savings. Industry analysis indicates that a 10% reduction in structural weight can yield 7-15% savings in overall mission costs.

The small satellite market represents the fastest-growing segment, with over 1,700 small satellites launched in 2022 alone. This segment is particularly sensitive to weight considerations, creating substantial market opportunities for advanced topology optimization solutions. Constellation projects by companies like SpaceX, OneWeb, and Amazon's Project Kuiper collectively plan to deploy over 20,000 satellites in the coming decade, establishing a sustained demand pipeline.

Geographically, North America dominates the market with 42% share, followed by Europe (28%) and Asia-Pacific (21%). However, the Asia-Pacific region is demonstrating the highest growth rate at 16.8% annually, driven by expanding space programs in China, India, and Japan.

Customer segmentation reveals three primary markets: government space agencies (35%), commercial satellite operators (48%), and defense contractors (17%). Government agencies typically prioritize performance and reliability over cost, while commercial operators are highly cost-sensitive and increasingly receptive to innovative lightweight solutions.

Market research indicates that customers are willing to pay premium prices for topology-optimized components that deliver weight reductions exceeding 25% compared to conventional designs. The average price premium for such components ranges between 30-45%, yet still delivers positive ROI through launch cost savings.

Key market trends include increasing integration of additive manufacturing with topology optimization, growing demand for multifunctional structures that combine structural and thermal management properties, and rising interest in in-orbit manufacturing to bypass launch constraints entirely. Additionally, sustainability considerations are gaining importance, with customers seeking designs that minimize space debris and enable end-of-life deorbiting.

Demand for lightweight spacecraft structures is primarily fueled by commercial satellite operators seeking to maximize payload capacity while minimizing launch costs. With launch expenses ranging from $2,500 to $10,000 per kilogram depending on orbit requirements, weight reduction directly translates to significant cost savings. Industry analysis indicates that a 10% reduction in structural weight can yield 7-15% savings in overall mission costs.

The small satellite market represents the fastest-growing segment, with over 1,700 small satellites launched in 2022 alone. This segment is particularly sensitive to weight considerations, creating substantial market opportunities for advanced topology optimization solutions. Constellation projects by companies like SpaceX, OneWeb, and Amazon's Project Kuiper collectively plan to deploy over 20,000 satellites in the coming decade, establishing a sustained demand pipeline.

Geographically, North America dominates the market with 42% share, followed by Europe (28%) and Asia-Pacific (21%). However, the Asia-Pacific region is demonstrating the highest growth rate at 16.8% annually, driven by expanding space programs in China, India, and Japan.

Customer segmentation reveals three primary markets: government space agencies (35%), commercial satellite operators (48%), and defense contractors (17%). Government agencies typically prioritize performance and reliability over cost, while commercial operators are highly cost-sensitive and increasingly receptive to innovative lightweight solutions.

Market research indicates that customers are willing to pay premium prices for topology-optimized components that deliver weight reductions exceeding 25% compared to conventional designs. The average price premium for such components ranges between 30-45%, yet still delivers positive ROI through launch cost savings.

Key market trends include increasing integration of additive manufacturing with topology optimization, growing demand for multifunctional structures that combine structural and thermal management properties, and rising interest in in-orbit manufacturing to bypass launch constraints entirely. Additionally, sustainability considerations are gaining importance, with customers seeking designs that minimize space debris and enable end-of-life deorbiting.

Current State and Challenges in Spacecraft Weight Reduction

Topology optimization for spacecraft weight reduction has reached significant maturity in recent years, with aerospace manufacturers globally adopting these techniques to achieve substantial mass savings while maintaining structural integrity. Current implementation typically involves finite element analysis coupled with optimization algorithms that redistribute material within a design space according to load paths. Leading aerospace entities like NASA, ESA, SpaceX, and Boeing have reported weight reductions of 30-45% for specific components through topology optimization.

Despite these advances, several technical challenges persist in the spacecraft application domain. The extreme operating conditions of space environments—including vacuum, radiation, and extreme temperature fluctuations (ranging from -150°C to +150°C)—create unique constraints that complicate optimization processes. Traditional topology optimization algorithms often struggle to account for these multi-physics considerations simultaneously.

Manufacturing limitations represent another significant hurdle. While topology optimization frequently generates complex organic geometries that are theoretically optimal, these designs may prove impractical to manufacture using conventional techniques. Additive manufacturing has partially addressed this issue, but material options for 3D printing in aerospace applications remain limited compared to traditional manufacturing materials, particularly regarding space-grade certification requirements.

Multi-objective optimization presents additional complexity. Spacecraft components must simultaneously satisfy competing requirements beyond mere weight reduction, including thermal management, vibration damping, and radiation shielding. Current algorithms often struggle to balance these diverse performance metrics within a single optimization framework.

Computational efficiency remains problematic for large-scale spacecraft applications. Full-vehicle topology optimization demands enormous computational resources, with some analyses requiring weeks on high-performance computing clusters. This timeline conflicts with increasingly compressed spacecraft development schedules in the competitive commercial space sector.

Verification and certification pathways for topology-optimized components represent perhaps the most significant barrier to widespread adoption. Regulatory frameworks and testing protocols were largely developed for conventionally designed components, creating uncertainty in the qualification process for topology-optimized structures. The non-intuitive nature of algorithmically generated designs sometimes creates resistance among certification authorities accustomed to more traditional design approaches.

Geographic distribution of topology optimization expertise shows concentration in North America and Europe, with growing capabilities in China and Japan. This uneven distribution creates potential competitive advantages for aerospace entities with access to advanced optimization capabilities and the manufacturing infrastructure to realize complex designs.

Despite these advances, several technical challenges persist in the spacecraft application domain. The extreme operating conditions of space environments—including vacuum, radiation, and extreme temperature fluctuations (ranging from -150°C to +150°C)—create unique constraints that complicate optimization processes. Traditional topology optimization algorithms often struggle to account for these multi-physics considerations simultaneously.

Manufacturing limitations represent another significant hurdle. While topology optimization frequently generates complex organic geometries that are theoretically optimal, these designs may prove impractical to manufacture using conventional techniques. Additive manufacturing has partially addressed this issue, but material options for 3D printing in aerospace applications remain limited compared to traditional manufacturing materials, particularly regarding space-grade certification requirements.

Multi-objective optimization presents additional complexity. Spacecraft components must simultaneously satisfy competing requirements beyond mere weight reduction, including thermal management, vibration damping, and radiation shielding. Current algorithms often struggle to balance these diverse performance metrics within a single optimization framework.

Computational efficiency remains problematic for large-scale spacecraft applications. Full-vehicle topology optimization demands enormous computational resources, with some analyses requiring weeks on high-performance computing clusters. This timeline conflicts with increasingly compressed spacecraft development schedules in the competitive commercial space sector.

Verification and certification pathways for topology-optimized components represent perhaps the most significant barrier to widespread adoption. Regulatory frameworks and testing protocols were largely developed for conventionally designed components, creating uncertainty in the qualification process for topology-optimized structures. The non-intuitive nature of algorithmically generated designs sometimes creates resistance among certification authorities accustomed to more traditional design approaches.

Geographic distribution of topology optimization expertise shows concentration in North America and Europe, with growing capabilities in China and Japan. This uneven distribution creates potential competitive advantages for aerospace entities with access to advanced optimization capabilities and the manufacturing infrastructure to realize complex designs.

Current Topology Optimization Methods for Weight Reduction

01 Computational methods for topology optimization

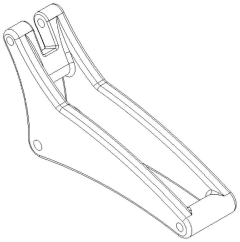

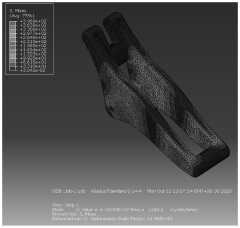

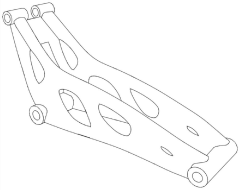

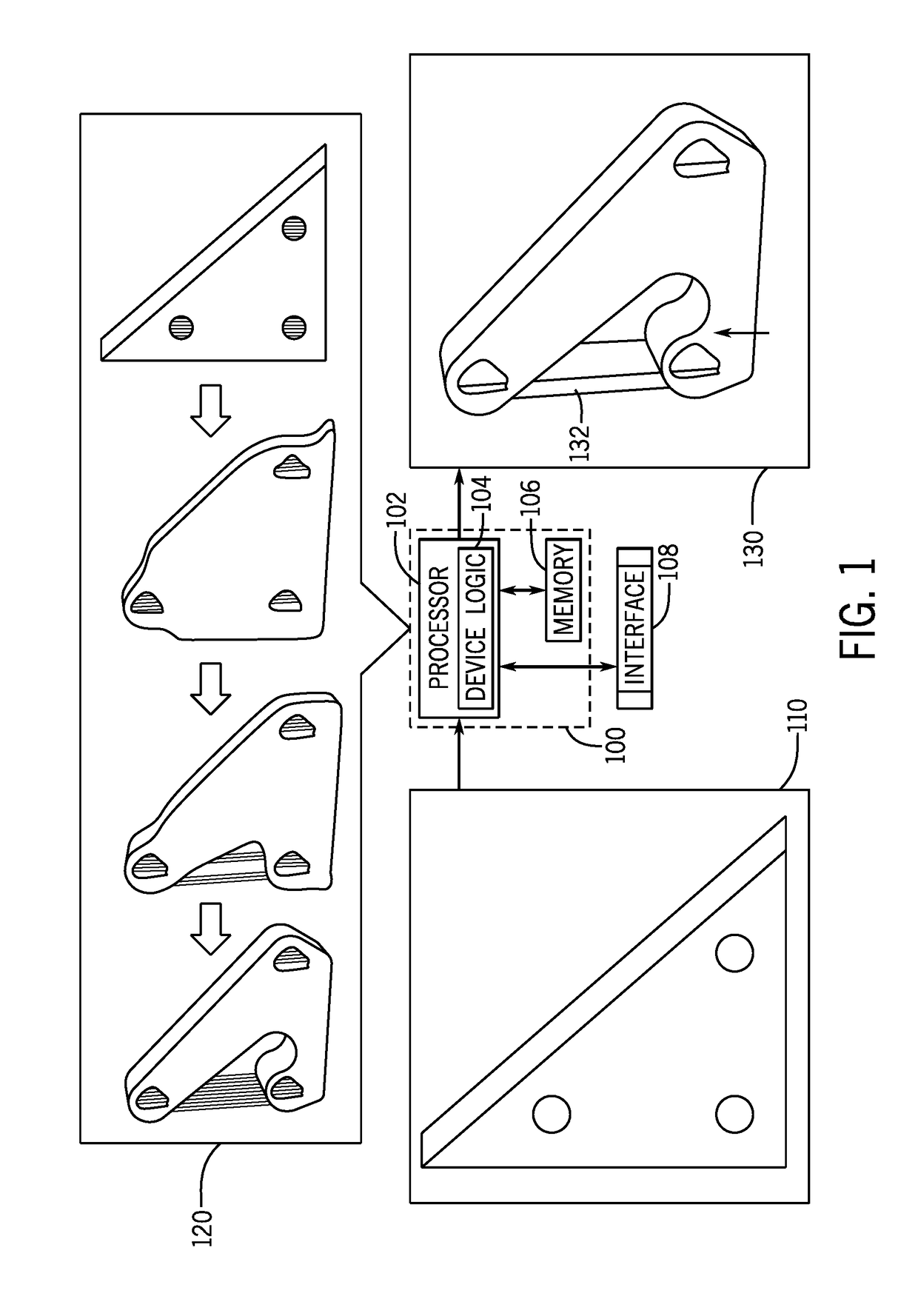

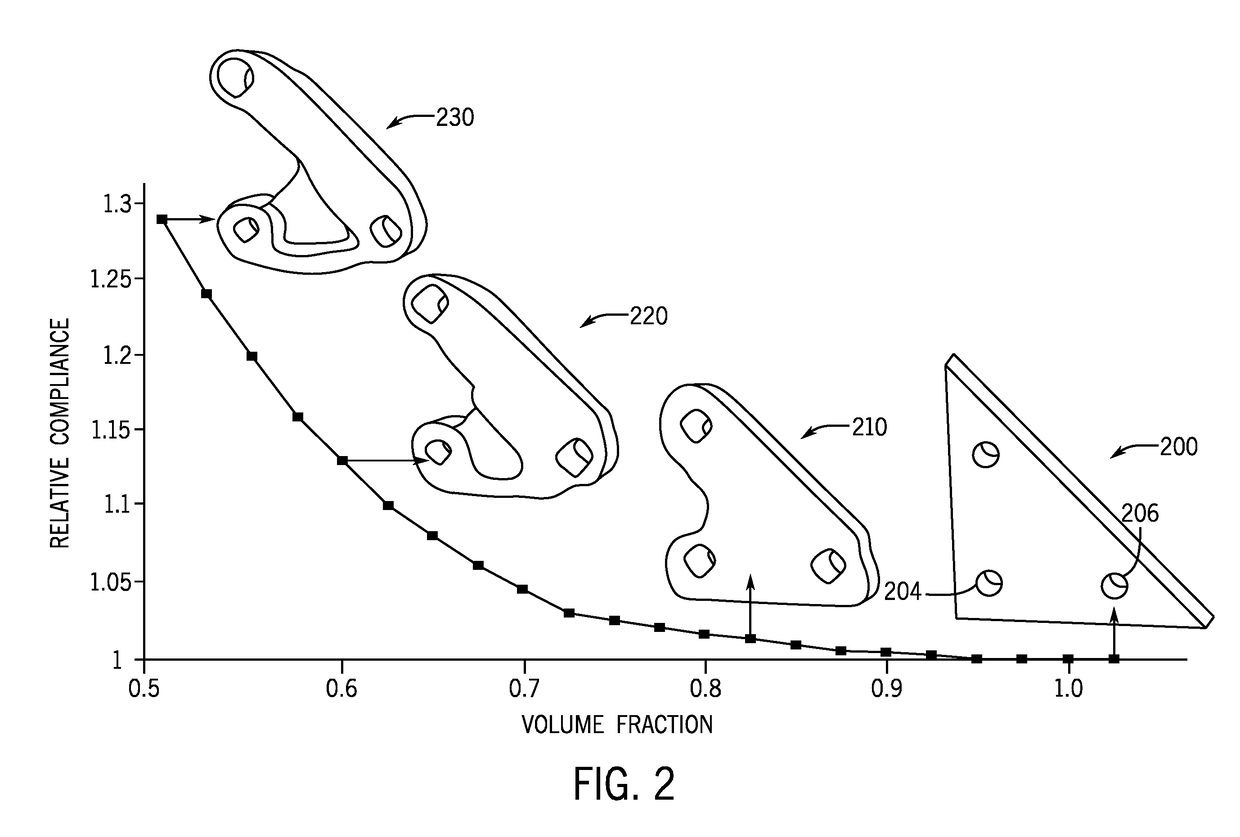

Various computational methods are employed for topology optimization to achieve weight reduction. These include finite element analysis, mathematical algorithms, and simulation techniques that analyze structural performance under different loading conditions. These methods help identify optimal material distribution patterns that maintain structural integrity while minimizing weight, leading to efficient designs with reduced material usage.- Topology optimization algorithms for structural weight reduction: Advanced algorithms are employed in topology optimization to reduce the weight of structures while maintaining their mechanical performance. These algorithms identify optimal material distribution by iteratively analyzing stress patterns and removing unnecessary material from low-stress regions. The optimization process typically involves defining design constraints, objective functions for weight minimization, and performance criteria to ensure structural integrity despite material reduction.

- Lattice and cellular structures for lightweight design: Lattice and cellular structures provide an effective approach to weight reduction through topology optimization. These structures feature internal geometries with repeated patterns of voids that significantly reduce mass while maintaining strength. By strategically designing these internal architectures with variable density distributions, engineers can create components that have optimized strength-to-weight ratios for specific loading conditions, resulting in substantial weight savings compared to solid structures.

- Multi-objective optimization for weight reduction in automotive and aerospace applications: Multi-objective topology optimization techniques are particularly valuable in automotive and aerospace industries where weight reduction directly impacts fuel efficiency and performance. These approaches simultaneously consider multiple design objectives such as minimizing weight, maximizing stiffness, and optimizing thermal performance. The optimization process balances these competing requirements to create lightweight components that meet strict industry standards for safety, durability, and functionality.

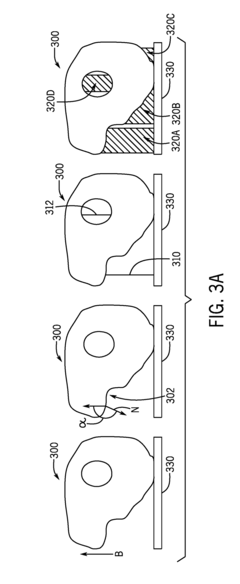

- Additive manufacturing integration with topology optimization: Additive manufacturing technologies enable the production of complex geometries generated through topology optimization that would be impossible to create using traditional manufacturing methods. This integration allows for the fabrication of highly optimized lightweight structures with internal features, conformal cooling channels, and variable density regions. The design freedom provided by additive manufacturing removes many conventional manufacturing constraints, allowing topology optimization algorithms to explore more radical weight-saving solutions.

- Machine learning approaches for enhanced topology optimization: Machine learning techniques are increasingly being applied to topology optimization to accelerate the design process and discover novel lightweight structures. These approaches use neural networks and other AI methods to predict optimal material distributions based on training data from previous optimization results. Machine learning can significantly reduce computational time while exploring more diverse design spaces, leading to more efficient weight reduction solutions that might not be discovered through traditional optimization methods.

02 Lattice and cellular structures for weight reduction

Topology optimization can generate lightweight structures through the implementation of lattice and cellular designs. These structures feature internal patterns with strategically placed voids that reduce material volume while maintaining mechanical properties. By optimizing the geometry and distribution of these cellular structures, significant weight reduction can be achieved without compromising structural performance or functionality.Expand Specific Solutions03 Multi-objective optimization approaches

Multi-objective optimization techniques balance weight reduction with other critical design requirements such as strength, stiffness, and manufacturability. These approaches use algorithms that simultaneously consider multiple performance criteria to find optimal solutions. By evaluating trade-offs between competing objectives, designers can achieve weight reduction while ensuring the final component meets all necessary functional requirements.Expand Specific Solutions04 Industry-specific topology optimization applications

Topology optimization for weight reduction has been adapted for specific industries such as automotive, aerospace, and medical devices. Each application area has unique requirements regarding load conditions, material properties, and manufacturing constraints. Specialized optimization techniques have been developed to address these industry-specific challenges, resulting in lightweight components that meet the particular performance standards of each sector.Expand Specific Solutions05 Manufacturing considerations in topology optimization

Effective topology optimization for weight reduction must account for manufacturing constraints and processes. This includes considerations for additive manufacturing, traditional machining limitations, and material properties. By incorporating manufacturability constraints directly into the optimization algorithm, designers can ensure that the lightweight structures generated can be practically produced while maintaining their weight-saving benefits.Expand Specific Solutions

Key Industry Players in Spacecraft Structural Design

Topology optimization in spacecraft weight reduction is currently in a growth phase, with the market expanding due to increasing demand for lightweight, fuel-efficient spacecraft designs. The global market for aerospace topology optimization solutions is estimated at $300-400 million annually, growing at 15-20%. Technologically, the field is maturing rapidly with Boeing, Siemens, and Thales leading commercial applications through advanced simulation software and manufacturing techniques. Academic institutions like Nanjing University of Aeronautics & Astronautics and Korea Advanced Institute of Science & Technology are driving fundamental research, while Autodesk and Siemens Industry Software provide sophisticated optimization platforms. The integration of AI and machine learning by companies like Boeing and Mitsubishi Electric Research Laboratories represents the cutting edge, enabling more efficient structural designs while maintaining critical performance requirements.

Siemens AG

Technical Solution: Siemens has pioneered comprehensive topology optimization solutions for spacecraft through their NX Nastran software suite. Their approach integrates multi-physics simulations with advanced optimization algorithms specifically calibrated for aerospace applications. Siemens' technology employs a combination of density-based and level-set methods to generate optimized structures that account for thermal loads, vibration, and launch stresses simultaneously[2]. Their platform enables engineers to define manufacturing constraints directly within the optimization workflow, ensuring that resulting designs are producible using available technologies. The company has developed specialized modules for composite material optimization, allowing for fiber orientation optimization alongside structural topology[4]. Siemens' solution incorporates automated design validation tools that verify optimized components against aerospace standards and requirements, streamlining the certification process for flight hardware. Recent implementations have demonstrated weight reductions of up to 35% for satellite structural components while maintaining all performance requirements.

Strengths: Comprehensive software ecosystem that integrates with manufacturing workflows; extensive validation capabilities against aerospace standards; ability to handle multi-physics optimization problems. Weaknesses: Significant computational resources required; steep learning curve for full platform utilization; higher licensing costs compared to some alternatives.

The Boeing Co.

Technical Solution: Boeing has developed advanced topology optimization methodologies specifically for spacecraft weight reduction. Their approach integrates multi-scale optimization techniques with manufacturing constraints to create lightweight structures that maintain structural integrity under extreme space conditions. Boeing's TAPAS (Topology And Physics-based Approach for Spacecraft) framework combines finite element analysis with machine learning algorithms to identify optimal material distribution patterns[1]. The company has implemented this technology in several satellite platforms and space vehicle components, achieving weight reductions of 25-40% compared to conventional designs while maintaining or improving structural performance[3]. Boeing's process incorporates additive manufacturing capabilities to produce complex geometries that would be impossible with traditional manufacturing methods, enabling lattice structures and variable density components that maximize strength-to-weight ratios for critical spacecraft parts.

Strengths: Industry-leading expertise in aerospace applications with proven implementation on actual spacecraft; integration with advanced manufacturing capabilities; comprehensive consideration of space-specific loading conditions. Weaknesses: Proprietary systems may limit collaboration opportunities; high computational requirements for complex optimization problems; solutions may require specialized manufacturing facilities.

Critical Patents and Research in Spacecraft Lightweighting

Spacecraft support topological lattice bionic design method based on inherent characteristic constraints

PatentActiveCN112329163A

Innovation

- The topological lattice bionic design method of the spacecraft bracket based on inherent characteristic constraints is adopted. Through topology optimization and three-dimensional lattice structure design to maximize the frequency, and combined with the stress cloud map, further weight reduction optimization is performed to ensure that the natural frequency of the bracket reaches above 100Hz.

Support structure constrained topology optimization for additive manufacturing

PatentActiveUS20180079149A1

Innovation

- A topology optimization framework that constrains the support structure volume by using a support volume-sensitive approach, incorporating topological sensitivity methods and augmented Lagrangian techniques to iteratively optimize designs, reducing the need for support structures while maintaining performance criteria.

Material Science Advancements for Topology Optimization

Recent advancements in material science have revolutionized topology optimization approaches for spacecraft design. The development of high-performance lightweight alloys, particularly aluminum-lithium alloys and titanium-based composites, has provided engineers with materials that offer superior strength-to-weight ratios while maintaining necessary structural integrity. These materials exhibit excellent fatigue resistance and thermal stability, critical properties for the extreme conditions encountered in space environments.

Metamaterials represent another breakthrough, offering unprecedented mechanical properties through engineered microstructures rather than chemical composition. These materials can be designed with negative Poisson's ratios or tailored anisotropic properties that enable more efficient load paths when incorporated into topology optimization algorithms. The ability to 3D print complex metamaterial lattices has removed many traditional manufacturing constraints, allowing for implementation of previously theoretical optimized structures.

Carbon fiber reinforced polymers (CFRPs) continue to evolve with improvements in fiber alignment techniques and matrix materials. Advanced CFRPs now offer up to 40% weight reduction compared to traditional aluminum structures while maintaining equivalent stiffness. Nano-enhanced variants incorporating graphene or carbon nanotubes provide additional performance improvements, with some experimental composites demonstrating strength increases of 30-45% over standard composites.

Functionally graded materials (FGMs) represent a paradigm shift in topology optimization by enabling continuous variation of material properties throughout a component. This approach eliminates abrupt transitions between different materials, reducing stress concentrations and improving overall structural performance. Recent developments in additive manufacturing have made production of FGMs increasingly viable for spacecraft applications.

Multi-material optimization techniques have advanced significantly, allowing algorithms to simultaneously determine optimal material selection and structural configuration. These approaches consider not only mechanical properties but also thermal expansion coefficients, radiation resistance, and other space-specific requirements. The integration of machine learning algorithms has accelerated this process, enabling rapid exploration of vast material-geometry solution spaces.

Ceramic matrix composites (CMCs) have emerged as promising candidates for high-temperature applications in spacecraft, offering exceptional thermal stability while maintaining low density. Silicon carbide-based CMCs can withstand temperatures exceeding 1400°C while providing significant weight savings over traditional superalloys. When incorporated into topology optimization frameworks, these materials enable more efficient thermal management systems and propulsion components.

Metamaterials represent another breakthrough, offering unprecedented mechanical properties through engineered microstructures rather than chemical composition. These materials can be designed with negative Poisson's ratios or tailored anisotropic properties that enable more efficient load paths when incorporated into topology optimization algorithms. The ability to 3D print complex metamaterial lattices has removed many traditional manufacturing constraints, allowing for implementation of previously theoretical optimized structures.

Carbon fiber reinforced polymers (CFRPs) continue to evolve with improvements in fiber alignment techniques and matrix materials. Advanced CFRPs now offer up to 40% weight reduction compared to traditional aluminum structures while maintaining equivalent stiffness. Nano-enhanced variants incorporating graphene or carbon nanotubes provide additional performance improvements, with some experimental composites demonstrating strength increases of 30-45% over standard composites.

Functionally graded materials (FGMs) represent a paradigm shift in topology optimization by enabling continuous variation of material properties throughout a component. This approach eliminates abrupt transitions between different materials, reducing stress concentrations and improving overall structural performance. Recent developments in additive manufacturing have made production of FGMs increasingly viable for spacecraft applications.

Multi-material optimization techniques have advanced significantly, allowing algorithms to simultaneously determine optimal material selection and structural configuration. These approaches consider not only mechanical properties but also thermal expansion coefficients, radiation resistance, and other space-specific requirements. The integration of machine learning algorithms has accelerated this process, enabling rapid exploration of vast material-geometry solution spaces.

Ceramic matrix composites (CMCs) have emerged as promising candidates for high-temperature applications in spacecraft, offering exceptional thermal stability while maintaining low density. Silicon carbide-based CMCs can withstand temperatures exceeding 1400°C while providing significant weight savings over traditional superalloys. When incorporated into topology optimization frameworks, these materials enable more efficient thermal management systems and propulsion components.

Launch Cost Economics and Weight Reduction ROI

The economics of spacecraft launches are fundamentally driven by the cost-to-weight ratio, with current industry standards ranging from $2,500 to $10,000 per kilogram to low Earth orbit, depending on the launch provider and mission parameters. This economic reality creates a compelling business case for topology optimization and weight reduction strategies in spacecraft design. Analysis of recent launch data indicates that for every kilogram reduced in spacecraft mass, companies can save between $3,000 and $12,000 in direct launch costs, accounting for variables such as orbit altitude and inclination.

Return on investment calculations for topology optimization implementation show promising results across the aerospace industry. Case studies from major satellite manufacturers demonstrate that investments in advanced optimization software and engineering expertise typically yield ROI ratios between 5:1 and 15:1 when measured against launch cost savings alone. The initial investment in topology optimization technology—including software licenses, computational resources, and specialized training—generally ranges from $100,000 to $500,000 for mid-sized aerospace companies, with payback periods as short as 6-18 months for production programs.

Beyond direct launch cost savings, secondary economic benefits further enhance the value proposition of weight reduction strategies. These include increased payload capacity, which can accommodate additional revenue-generating instruments or extended mission capabilities. Financial modeling suggests that each additional kilogram of payload capacity created through weight reduction can generate between $50,000 and $200,000 in mission value over the spacecraft's operational lifetime, depending on the application.

The economics of weight reduction become particularly compelling when viewed through the lens of constellation deployments. For large satellite constellations comprising dozens or hundreds of identical units, topology optimization applied during the design phase can produce exponential cost benefits. Analysis of recent constellation projects reveals that a 5% weight reduction across a 100-satellite constellation can translate to launch cost savings exceeding $25 million, fundamentally altering project economics.

Market trends indicate that launch costs are projected to decrease by 30-40% over the next decade due to reusable launch systems and increased competition. However, this reduction in per-kilogram launch costs is unlikely to diminish the importance of weight optimization, as the industry simultaneously moves toward smaller satellites and more complex missions that impose stricter mass constraints. Economic forecasting models suggest that the ROI for topology optimization will remain robust even in scenarios where launch costs decrease significantly.

Return on investment calculations for topology optimization implementation show promising results across the aerospace industry. Case studies from major satellite manufacturers demonstrate that investments in advanced optimization software and engineering expertise typically yield ROI ratios between 5:1 and 15:1 when measured against launch cost savings alone. The initial investment in topology optimization technology—including software licenses, computational resources, and specialized training—generally ranges from $100,000 to $500,000 for mid-sized aerospace companies, with payback periods as short as 6-18 months for production programs.

Beyond direct launch cost savings, secondary economic benefits further enhance the value proposition of weight reduction strategies. These include increased payload capacity, which can accommodate additional revenue-generating instruments or extended mission capabilities. Financial modeling suggests that each additional kilogram of payload capacity created through weight reduction can generate between $50,000 and $200,000 in mission value over the spacecraft's operational lifetime, depending on the application.

The economics of weight reduction become particularly compelling when viewed through the lens of constellation deployments. For large satellite constellations comprising dozens or hundreds of identical units, topology optimization applied during the design phase can produce exponential cost benefits. Analysis of recent constellation projects reveals that a 5% weight reduction across a 100-satellite constellation can translate to launch cost savings exceeding $25 million, fundamentally altering project economics.

Market trends indicate that launch costs are projected to decrease by 30-40% over the next decade due to reusable launch systems and increased competition. However, this reduction in per-kilogram launch costs is unlikely to diminish the importance of weight optimization, as the industry simultaneously moves toward smaller satellites and more complex missions that impose stricter mass constraints. Economic forecasting models suggest that the ROI for topology optimization will remain robust even in scenarios where launch costs decrease significantly.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!