Evaluate Industrial Applicability of Topology Optimization in Large Equipment Design

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Topology Optimization Background and Objectives

Topology optimization has emerged as a revolutionary approach in engineering design, evolving from theoretical mathematical concepts in the 1980s to a practical design methodology widely adopted across industries today. This computational method determines the optimal material distribution within a given design space, subject to specified constraints and load conditions, to maximize performance criteria such as stiffness while minimizing material usage. The evolution of topology optimization has been closely linked with advancements in computational power, finite element analysis capabilities, and additive manufacturing technologies, creating a synergistic relationship that has accelerated its practical implementation.

The historical trajectory of topology optimization shows significant milestones, beginning with Bendsøe and Kikuchi's homogenization method in 1988, followed by the SIMP (Solid Isotropic Material with Penalization) method in the 1990s, and more recently, level-set and phase-field methods. Each advancement has expanded the applicability and efficiency of topology optimization techniques, gradually transitioning from academic research to industrial application.

In the context of large equipment design, topology optimization represents a paradigm shift from traditional design methodologies. Conventional approaches typically rely on experience-based iterative design, often resulting in over-engineered structures with excessive material usage. The objective of implementing topology optimization in large equipment design is multifaceted: to significantly reduce material consumption while maintaining or enhancing structural performance, to decrease manufacturing and operational costs, and to improve sustainability metrics through reduced resource utilization and enhanced energy efficiency.

Current technological trends indicate a growing integration of topology optimization with machine learning algorithms, multi-physics simulations, and cloud computing platforms, enabling more sophisticated analyses that account for complex real-world conditions. These developments are particularly relevant for large equipment design, where multiple physical phenomena, manufacturing constraints, and operational requirements must be simultaneously considered.

The primary technical goal of this investigation is to evaluate the industrial applicability of topology optimization specifically for large-scale equipment, addressing unique challenges such as scale-dependent manufacturing constraints, multi-functional requirements, and the economic feasibility of implementing optimized designs in production environments. This includes assessing the maturity of current topology optimization methodologies for large-scale applications, identifying technical gaps, and determining the potential return on investment for industrial adoption.

The historical trajectory of topology optimization shows significant milestones, beginning with Bendsøe and Kikuchi's homogenization method in 1988, followed by the SIMP (Solid Isotropic Material with Penalization) method in the 1990s, and more recently, level-set and phase-field methods. Each advancement has expanded the applicability and efficiency of topology optimization techniques, gradually transitioning from academic research to industrial application.

In the context of large equipment design, topology optimization represents a paradigm shift from traditional design methodologies. Conventional approaches typically rely on experience-based iterative design, often resulting in over-engineered structures with excessive material usage. The objective of implementing topology optimization in large equipment design is multifaceted: to significantly reduce material consumption while maintaining or enhancing structural performance, to decrease manufacturing and operational costs, and to improve sustainability metrics through reduced resource utilization and enhanced energy efficiency.

Current technological trends indicate a growing integration of topology optimization with machine learning algorithms, multi-physics simulations, and cloud computing platforms, enabling more sophisticated analyses that account for complex real-world conditions. These developments are particularly relevant for large equipment design, where multiple physical phenomena, manufacturing constraints, and operational requirements must be simultaneously considered.

The primary technical goal of this investigation is to evaluate the industrial applicability of topology optimization specifically for large-scale equipment, addressing unique challenges such as scale-dependent manufacturing constraints, multi-functional requirements, and the economic feasibility of implementing optimized designs in production environments. This includes assessing the maturity of current topology optimization methodologies for large-scale applications, identifying technical gaps, and determining the potential return on investment for industrial adoption.

Market Demand Analysis for Optimized Industrial Equipment

The global market for industrial equipment optimization is experiencing significant growth, driven by increasing pressure on manufacturers to reduce material costs while maintaining or improving equipment performance. According to recent industry analyses, the market for topology optimization software and services in industrial equipment design is projected to grow at a compound annual growth rate of 15% through 2028, reaching a market value of approximately 2.5 billion USD.

Heavy machinery and large equipment manufacturers face intensifying competition and tightening profit margins, creating strong demand for weight reduction solutions that don't compromise structural integrity. A survey of manufacturing executives revealed that 78% consider material cost reduction a high priority, while 65% specifically identified topology optimization as a key technology for achieving this goal.

The energy sector represents a particularly promising market segment, with wind turbine manufacturers reporting material savings of 20-30% through topology optimization of structural components. Similarly, the mining equipment industry has demonstrated keen interest, with major players investing substantially in optimization technologies to reduce operational costs associated with fuel consumption and maintenance of heavy machinery.

Aerospace and defense contractors constitute another significant market segment, where the demand for lightweight yet durable equipment has driven adoption of advanced optimization techniques. The market penetration in this sector has reached approximately 45%, with continued growth expected as computational capabilities advance.

Regional analysis indicates that North America and Europe currently lead in adoption rates, accounting for 65% of the global market share. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate at 22% annually, driven by rapid industrialization and government initiatives promoting advanced manufacturing technologies.

Customer requirements analysis reveals that ease of integration with existing CAD/CAM systems ranks as the top priority for potential adopters, followed by computational efficiency and result reliability. The ability to handle multi-material optimization and manufacturing constraints also features prominently in customer demand profiles.

Market barriers include the high initial investment required for implementation, shortage of skilled professionals familiar with the technology, and concerns about the manufacturability of optimized designs. These factors have limited adoption among small and medium enterprises, creating a market gap that could be addressed through more accessible solutions and training programs.

The service aspect of the market shows particular promise, with consulting services for topology optimization implementation growing at 18% annually, outpacing software sales alone. This indicates strong demand for expertise alongside technological solutions.

Heavy machinery and large equipment manufacturers face intensifying competition and tightening profit margins, creating strong demand for weight reduction solutions that don't compromise structural integrity. A survey of manufacturing executives revealed that 78% consider material cost reduction a high priority, while 65% specifically identified topology optimization as a key technology for achieving this goal.

The energy sector represents a particularly promising market segment, with wind turbine manufacturers reporting material savings of 20-30% through topology optimization of structural components. Similarly, the mining equipment industry has demonstrated keen interest, with major players investing substantially in optimization technologies to reduce operational costs associated with fuel consumption and maintenance of heavy machinery.

Aerospace and defense contractors constitute another significant market segment, where the demand for lightweight yet durable equipment has driven adoption of advanced optimization techniques. The market penetration in this sector has reached approximately 45%, with continued growth expected as computational capabilities advance.

Regional analysis indicates that North America and Europe currently lead in adoption rates, accounting for 65% of the global market share. However, the Asia-Pacific region, particularly China and India, is experiencing the fastest growth rate at 22% annually, driven by rapid industrialization and government initiatives promoting advanced manufacturing technologies.

Customer requirements analysis reveals that ease of integration with existing CAD/CAM systems ranks as the top priority for potential adopters, followed by computational efficiency and result reliability. The ability to handle multi-material optimization and manufacturing constraints also features prominently in customer demand profiles.

Market barriers include the high initial investment required for implementation, shortage of skilled professionals familiar with the technology, and concerns about the manufacturability of optimized designs. These factors have limited adoption among small and medium enterprises, creating a market gap that could be addressed through more accessible solutions and training programs.

The service aspect of the market shows particular promise, with consulting services for topology optimization implementation growing at 18% annually, outpacing software sales alone. This indicates strong demand for expertise alongside technological solutions.

Current State and Challenges in Large Equipment Design

Large equipment design currently faces significant challenges in balancing structural integrity with weight reduction and performance optimization. Traditional design methodologies rely heavily on experience-based approaches and iterative testing, which often result in over-engineered structures with excessive material usage. This conventional approach not only increases manufacturing costs but also leads to higher operational expenses due to increased weight and material consumption.

The global large equipment manufacturing industry is experiencing intensified competition, with increasing pressure to reduce production costs while enhancing equipment performance. Environmental regulations and sustainability requirements further complicate the design landscape, demanding more efficient use of materials and energy throughout the equipment lifecycle.

Current design processes for large industrial equipment typically involve computer-aided design (CAD) systems coupled with finite element analysis (FEA) for structural validation. However, these approaches generally start with a predefined geometry that undergoes iterative refinement rather than fundamentally questioning the optimal material distribution from first principles. This limitation results in designs that may be functionally adequate but far from optimal in terms of material efficiency and performance characteristics.

Technical challenges in large equipment design include managing complex load cases, addressing dynamic operating conditions, and ensuring manufacturability of optimized designs. The scale of large industrial equipment introduces unique difficulties in simulation accuracy, with computational requirements often becoming prohibitive for comprehensive analysis of complete structures at high resolution.

Material selection presents another significant challenge, as designers must balance mechanical properties, weight considerations, cost factors, and increasingly, environmental impact. Advanced materials offer potential solutions but introduce additional complexities in terms of modeling behavior, manufacturing processes, and long-term reliability prediction.

Geographically, leadership in large equipment design technology shows distinct patterns, with European manufacturers often emphasizing precision engineering and efficiency, North American companies focusing on innovation and performance optimization, and Asian manufacturers rapidly advancing in cost-effective production techniques while increasingly investing in advanced design methodologies.

The integration of digital twins and IoT capabilities into large equipment design creates additional layers of complexity, requiring interdisciplinary approaches that extend beyond traditional mechanical engineering. Designers must now consider not only physical structures but also sensor placement, data collection systems, and the integration of control systems that can respond to real-time operational data.

The global large equipment manufacturing industry is experiencing intensified competition, with increasing pressure to reduce production costs while enhancing equipment performance. Environmental regulations and sustainability requirements further complicate the design landscape, demanding more efficient use of materials and energy throughout the equipment lifecycle.

Current design processes for large industrial equipment typically involve computer-aided design (CAD) systems coupled with finite element analysis (FEA) for structural validation. However, these approaches generally start with a predefined geometry that undergoes iterative refinement rather than fundamentally questioning the optimal material distribution from first principles. This limitation results in designs that may be functionally adequate but far from optimal in terms of material efficiency and performance characteristics.

Technical challenges in large equipment design include managing complex load cases, addressing dynamic operating conditions, and ensuring manufacturability of optimized designs. The scale of large industrial equipment introduces unique difficulties in simulation accuracy, with computational requirements often becoming prohibitive for comprehensive analysis of complete structures at high resolution.

Material selection presents another significant challenge, as designers must balance mechanical properties, weight considerations, cost factors, and increasingly, environmental impact. Advanced materials offer potential solutions but introduce additional complexities in terms of modeling behavior, manufacturing processes, and long-term reliability prediction.

Geographically, leadership in large equipment design technology shows distinct patterns, with European manufacturers often emphasizing precision engineering and efficiency, North American companies focusing on innovation and performance optimization, and Asian manufacturers rapidly advancing in cost-effective production techniques while increasingly investing in advanced design methodologies.

The integration of digital twins and IoT capabilities into large equipment design creates additional layers of complexity, requiring interdisciplinary approaches that extend beyond traditional mechanical engineering. Designers must now consider not only physical structures but also sensor placement, data collection systems, and the integration of control systems that can respond to real-time operational data.

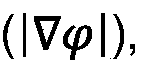

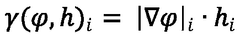

Current Implementation Approaches for Large-Scale Applications

01 Topology optimization in manufacturing and design

Topology optimization techniques are applied in manufacturing and design processes to create optimized structures with improved performance characteristics. These methods use mathematical algorithms to determine the optimal distribution of material within a design space, subject to specific constraints and objectives. The optimization process can lead to lightweight structures with enhanced strength-to-weight ratios, reduced material usage, and improved functional performance, making it valuable for industries such as automotive, aerospace, and consumer products manufacturing.- Topology optimization in manufacturing and design: Topology optimization techniques are applied in manufacturing and design processes to create optimized structures with improved performance characteristics. These methods involve mathematical algorithms that determine the optimal distribution of material within a design space, subject to specific constraints and objectives. The optimization process can lead to lightweight yet strong components, reduced material usage, and enhanced functional performance in industrial applications such as automotive, aerospace, and consumer products.

- Topology optimization for additive manufacturing: Topology optimization is particularly valuable in additive manufacturing (3D printing) processes, where complex geometries can be produced without traditional manufacturing constraints. The integration of topology optimization with additive manufacturing enables the creation of highly optimized parts with intricate internal structures, lattices, and organic shapes that would be impossible to produce using conventional manufacturing methods. This combination allows for weight reduction, improved thermal management, and enhanced mechanical properties in industrial components.

- Computational methods for topology optimization: Advanced computational methods are essential for implementing topology optimization in industrial applications. These include finite element analysis (FEA), machine learning algorithms, and specialized software tools that can handle complex optimization problems. The computational approaches enable engineers to simulate and analyze multiple design iterations quickly, considering various loading conditions, material properties, and manufacturing constraints to arrive at optimal solutions for industrial components and systems.

- Topology optimization in network and system design: Beyond physical components, topology optimization principles are applied to network and system design in industrial settings. This includes optimizing communication networks, power distribution systems, and industrial process flows. The optimization techniques help determine the most efficient arrangement of nodes, connections, and resources to maximize performance, reliability, and energy efficiency while minimizing costs and vulnerabilities in industrial infrastructure.

- Multi-objective topology optimization for industrial applications: Industrial applications often require balancing multiple competing objectives in the optimization process. Multi-objective topology optimization approaches allow engineers to simultaneously consider factors such as structural performance, thermal management, manufacturing constraints, and cost considerations. These methods provide a range of Pareto-optimal solutions that represent different trade-offs between objectives, enabling industrial decision-makers to select designs that best meet their specific requirements and constraints.

02 Topology optimization for additive manufacturing

Topology optimization is particularly well-suited for additive manufacturing (3D printing) applications, as it enables the creation of complex geometries that would be difficult or impossible to produce using traditional manufacturing methods. The integration of topology optimization with additive manufacturing allows for the production of highly optimized components with internal lattice structures, conformal cooling channels, and other features that maximize performance while minimizing material usage. This approach is being increasingly adopted in industries requiring customized, high-performance parts with complex geometries.Expand Specific Solutions03 Topology optimization in electronic and network systems

Topology optimization principles are being applied to electronic systems and network architectures to improve performance, efficiency, and reliability. This includes optimizing circuit layouts, network routing, thermal management systems, and electronic component placement. By applying topology optimization algorithms to these systems, engineers can achieve better signal integrity, reduced power consumption, improved heat dissipation, and enhanced overall system performance, which is particularly valuable in telecommunications, data centers, and consumer electronics industries.Expand Specific Solutions04 Software and computational methods for topology optimization

Advanced software tools and computational methods have been developed specifically for topology optimization applications across various industries. These tools incorporate finite element analysis, machine learning algorithms, and multi-physics simulations to solve complex optimization problems. The software enables engineers to define design spaces, constraints, and objectives, then automatically generate optimized structures that meet performance requirements. These computational approaches significantly reduce design iteration time and enable the exploration of innovative solutions that might not be discovered through traditional design methods.Expand Specific Solutions05 Topology optimization for energy and sustainability applications

Topology optimization is increasingly being applied to energy systems and sustainability-focused applications to improve efficiency and reduce environmental impact. This includes optimizing heat exchangers, fluid flow systems, structural components in renewable energy systems, and materials with specific thermal or acoustic properties. By applying topology optimization to these applications, engineers can develop more energy-efficient systems, reduce material usage, and create components with improved performance characteristics, contributing to sustainability goals across various industries.Expand Specific Solutions

Key Industry Players and Technology Providers

Topology optimization in large equipment design is currently in a growth phase, with the market expanding due to increasing demand for lightweight, efficient structures in industrial applications. The global market size is estimated to reach significant scale as industries adopt these advanced design methodologies. Technologically, the field shows varying maturity levels across different sectors. Leading companies like Siemens AG, ANSYS, Autodesk, and Dassault Systèmes have developed sophisticated software solutions, while industrial manufacturers such as Caterpillar, Honda, and RTX Corp are implementing these technologies in practical applications. Academic institutions including Georgia Tech, Zhejiang University, and Huazhong University of Science & Technology are advancing fundamental research, creating a robust ecosystem that bridges theoretical development with industrial implementation.

Siemens AG

Technical Solution: Siemens has developed a comprehensive topology optimization solution integrated within their Simcenter software suite, specifically designed for large equipment design challenges. Their approach combines parametric optimization with advanced manufacturing constraints to ensure designs are not only structurally optimal but also manufacturable. The company's NX Nastran Topology Optimization module employs mathematical algorithms that iteratively remove inefficient material while maintaining structural integrity under specified loading conditions[1]. Siemens' solution stands out for its ability to handle multi-physics optimization, considering thermal, fluid, and structural aspects simultaneously - critical for large industrial equipment. Their platform incorporates design interpretation tools that automatically convert optimized mesh structures into smooth CAD models ready for manufacturing[3]. Additionally, Siemens has pioneered integration with additive manufacturing workflows, allowing for the production of complex geometries that would be impossible with traditional manufacturing methods[5].

Strengths: Comprehensive integration across the entire product development lifecycle; robust multi-physics capabilities; strong manufacturing constraint handling. Weaknesses: Complex implementation requiring significant expertise; higher computational requirements compared to simpler solutions; potential challenges in optimization for extremely large structures with numerous load cases.

Autodesk, Inc.

Technical Solution: Autodesk has pioneered generative design approaches to topology optimization through their Fusion 360 platform, specifically tailored for large equipment applications. Their technology utilizes cloud-based computing resources to process complex optimization problems that would overwhelm traditional workstations[2]. Autodesk's solution employs machine learning algorithms that learn from previous optimization results to accelerate convergence for similar design problems. Their approach is distinctive in its ability to simultaneously evaluate thousands of design alternatives against multiple objectives including weight reduction, stress distribution, and manufacturing constraints[4]. For large equipment design, Autodesk has implemented specialized algorithms that can handle non-linear material behavior and contact conditions between components. The platform includes automated design validation tools that verify optimized structures against industry standards and regulations. Autodesk has also developed specific workflows for large-scale metal casting and fabrication processes that incorporate manufacturing constraints directly into the optimization process[7].

Strengths: Intuitive user interface accessible to non-specialists; cloud computing capabilities handling extremely large models; excellent integration with manufacturing workflows. Weaknesses: Subscription-based pricing model can be costly for smaller organizations; occasional connectivity issues with cloud-based processing; limited control over specific optimization parameters compared to more specialized tools.

Critical Patents and Research in Industrial Topology Optimization

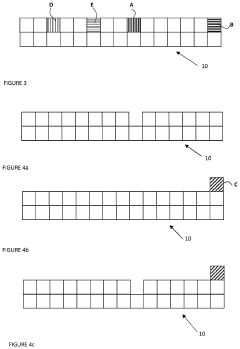

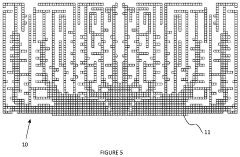

Topology optimization with bidirectional mesh adaptation

PatentWO2023133734A1

Innovation

- Bidirectional mesh adaptation technique that dynamically adjusts mesh resolution during topology optimization, allowing for both refinement and coarsening based on optimization progress.

- Integration of multi-physics simulation capabilities with adaptive meshing to efficiently handle complex industrial applications like gas turbine components where thermal-flow and structural objectives must be balanced.

- Methodology to maintain design feature fidelity while reducing computational resources through strategic mesh management, enabling practical application of topology optimization to large industrial equipment.

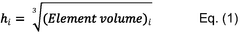

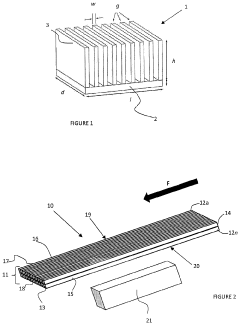

Heatsink configuration generation

PatentPendingUS20230169233A1

Innovation

- A method involving a computer-executed process that generates a heatsink configuration by iteratively removing and adding tessellated rods based on thermal evaluation parameters, allowing for the creation of non-parameterizable geometries that optimize thermal performance without relying on adjoint solutions or optimizers, using a combination of additive and subtractive techniques.

Cost-Benefit Analysis of Topology Optimization Implementation

Implementing topology optimization in large equipment design requires significant initial investment but offers substantial long-term returns. The upfront costs include specialized software licenses ranging from $10,000 to $50,000 annually, depending on capabilities and vendor support. Additional expenses arise from hardware upgrades to handle complex computational demands, typically requiring workstations with high-performance processors and substantial RAM, representing investments of $5,000-$15,000 per engineering workstation.

Personnel training constitutes another significant cost factor. Engineers require specialized training in topology optimization principles and software operation, with courses costing $2,000-$5,000 per engineer. Organizations must also account for productivity decreases during the learning curve period, estimated at 15-20% reduction over 2-3 months.

Against these investments, topology optimization delivers measurable benefits. Material savings typically range from 20-40% compared to traditional designs, translating to substantial cost reductions in large equipment manufacturing. A case study from the mining equipment sector demonstrated annual material cost savings of $1.2 million after implementing topology optimization across their product line.

Performance improvements represent another significant benefit. Optimized components show enhanced strength-to-weight ratios, with documented improvements of 15-30% in structural performance. This translates to extended equipment lifespan and reduced maintenance requirements, with maintenance cost reductions of 10-25% reported by early adopters.

Production efficiency gains emerge as topology-optimized components often consolidate multiple parts into single units. This simplification reduces assembly time by 15-40% and decreases associated labor costs. Manufacturing complexity may initially increase due to complex geometries, but this is increasingly mitigated by advances in additive manufacturing technologies.

Return on investment timelines vary by industry and application scale. Aerospace and defense manufacturers typically achieve ROI within 12-18 months, while heavy machinery manufacturers report breakeven periods of 18-24 months. The financial benefits accelerate as implementation matures and optimization expertise develops within the organization.

For maximum cost-effectiveness, companies should adopt phased implementation strategies, beginning with non-critical components before progressing to core structural elements. This approach minimizes disruption while allowing engineering teams to develop expertise progressively.

Personnel training constitutes another significant cost factor. Engineers require specialized training in topology optimization principles and software operation, with courses costing $2,000-$5,000 per engineer. Organizations must also account for productivity decreases during the learning curve period, estimated at 15-20% reduction over 2-3 months.

Against these investments, topology optimization delivers measurable benefits. Material savings typically range from 20-40% compared to traditional designs, translating to substantial cost reductions in large equipment manufacturing. A case study from the mining equipment sector demonstrated annual material cost savings of $1.2 million after implementing topology optimization across their product line.

Performance improvements represent another significant benefit. Optimized components show enhanced strength-to-weight ratios, with documented improvements of 15-30% in structural performance. This translates to extended equipment lifespan and reduced maintenance requirements, with maintenance cost reductions of 10-25% reported by early adopters.

Production efficiency gains emerge as topology-optimized components often consolidate multiple parts into single units. This simplification reduces assembly time by 15-40% and decreases associated labor costs. Manufacturing complexity may initially increase due to complex geometries, but this is increasingly mitigated by advances in additive manufacturing technologies.

Return on investment timelines vary by industry and application scale. Aerospace and defense manufacturers typically achieve ROI within 12-18 months, while heavy machinery manufacturers report breakeven periods of 18-24 months. The financial benefits accelerate as implementation matures and optimization expertise develops within the organization.

For maximum cost-effectiveness, companies should adopt phased implementation strategies, beginning with non-critical components before progressing to core structural elements. This approach minimizes disruption while allowing engineering teams to develop expertise progressively.

Manufacturing Constraints and Production Feasibility

The implementation of topology optimization in large equipment design faces significant manufacturing constraints that must be carefully evaluated to ensure production feasibility. Traditional manufacturing methods often struggle with the complex geometries generated by topology optimization algorithms. Subtractive manufacturing processes like CNC machining may be unable to access internal features or create certain organic shapes that topology optimization typically produces. This limitation necessitates design modifications that can compromise the theoretical performance benefits identified during the optimization process.

Additive manufacturing technologies, particularly metal 3D printing, offer promising solutions for producing topology-optimized large equipment components. However, these technologies present their own constraints, including build volume limitations, material property variations, and post-processing requirements. For large equipment applications, the maximum build envelope of current industrial 3D printers (typically under 1m³) often necessitates segmentation of components and subsequent joining, introducing potential weak points and additional manufacturing steps.

Material selection represents another critical manufacturing constraint. While topology optimization can work with various materials theoretically, the actual manufacturability differs significantly. Certain materials may exhibit anisotropic properties when processed through additive manufacturing, potentially undermining the structural integrity calculated during optimization. Additionally, the thermal behavior during manufacturing processes can induce residual stresses and distortions, particularly problematic for large-scale components.

Production costs and lead times constitute practical constraints that significantly impact industrial applicability. The complexity of topology-optimized designs often increases manufacturing time and requires specialized equipment, raising production costs compared to conventional designs. This economic consideration must be balanced against the performance improvements and potential material savings. For large equipment with low production volumes, the initial tooling and setup costs may be difficult to amortize effectively.

Quality assurance and inspection present unique challenges for topology-optimized large equipment. The complex internal structures and non-standard geometries make conventional inspection methods insufficient. Advanced techniques such as CT scanning may be necessary but are limited by the physical dimensions of large equipment components. This inspection challenge can impact certification processes, particularly in highly regulated industries like aerospace, energy, and heavy machinery.

Surface finish requirements also impose constraints on topology optimization implementation. Many industrial applications demand specific surface characteristics for functional reasons (fluid flow, wear resistance) or aesthetic purposes. Post-processing operations to achieve these surface requirements can be particularly challenging for the complex geometries resulting from topology optimization, potentially adding significant costs and time to the manufacturing process.

Additive manufacturing technologies, particularly metal 3D printing, offer promising solutions for producing topology-optimized large equipment components. However, these technologies present their own constraints, including build volume limitations, material property variations, and post-processing requirements. For large equipment applications, the maximum build envelope of current industrial 3D printers (typically under 1m³) often necessitates segmentation of components and subsequent joining, introducing potential weak points and additional manufacturing steps.

Material selection represents another critical manufacturing constraint. While topology optimization can work with various materials theoretically, the actual manufacturability differs significantly. Certain materials may exhibit anisotropic properties when processed through additive manufacturing, potentially undermining the structural integrity calculated during optimization. Additionally, the thermal behavior during manufacturing processes can induce residual stresses and distortions, particularly problematic for large-scale components.

Production costs and lead times constitute practical constraints that significantly impact industrial applicability. The complexity of topology-optimized designs often increases manufacturing time and requires specialized equipment, raising production costs compared to conventional designs. This economic consideration must be balanced against the performance improvements and potential material savings. For large equipment with low production volumes, the initial tooling and setup costs may be difficult to amortize effectively.

Quality assurance and inspection present unique challenges for topology-optimized large equipment. The complex internal structures and non-standard geometries make conventional inspection methods insufficient. Advanced techniques such as CT scanning may be necessary but are limited by the physical dimensions of large equipment components. This inspection challenge can impact certification processes, particularly in highly regulated industries like aerospace, energy, and heavy machinery.

Surface finish requirements also impose constraints on topology optimization implementation. Many industrial applications demand specific surface characteristics for functional reasons (fluid flow, wear resistance) or aesthetic purposes. Post-processing operations to achieve these surface requirements can be particularly challenging for the complex geometries resulting from topology optimization, potentially adding significant costs and time to the manufacturing process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!