Topology Optimization vs Form Finding: Best Approach for Architectural Applications

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Topology Optimization and Form Finding Evolution

Topology optimization and form finding represent two distinct yet complementary methodologies in computational design that have evolved significantly over the past decades. Topology optimization emerged from structural engineering in the 1980s, pioneered by researchers like Martin Bendsøe and Ole Sigmund, focusing on material distribution within a design space to achieve optimal performance under specified constraints. This approach utilizes mathematical algorithms to iteratively remove material from a design domain while maintaining structural integrity.

Form finding, conversely, has deeper historical roots dating back to Antoni Gaudí's hanging chain models and Frei Otto's physical experiments in the mid-20th century. It evolved from physical to digital methodologies, emphasizing the discovery of structurally efficient forms through simulation of natural forces and material behaviors. Unlike topology optimization's subtractive approach, form finding typically works through an additive or transformative process.

The 1990s marked a significant transition period when both methodologies began migrating from purely academic research into practical architectural applications. The development of more accessible computational tools and increased computing power enabled architects to experiment with these techniques beyond theoretical exercises. Software platforms like Grasshopper for Rhino, with plugins such as Millipede and Kangaroo, democratized access to these complex computational methods.

By the early 2000s, the distinction between these approaches began blurring as hybrid methodologies emerged. Architects and engineers started combining topology optimization's efficiency-driven approach with form finding's more intuitive, physics-based processes. This convergence was particularly evident in landmark projects like the Beijing National Stadium (Bird's Nest) and London's 30 St Mary Axe (The Gherkin), which demonstrated how computationally derived forms could be both structurally efficient and architecturally expressive.

The 2010s witnessed further evolution with the integration of machine learning and artificial intelligence. These technologies enhanced both methodologies by enabling more complex optimization criteria beyond purely structural considerations, incorporating factors such as environmental performance, material usage, and fabrication constraints. This period also saw increased emphasis on multi-objective optimization, allowing designers to balance competing priorities rather than pursuing singular performance metrics.

Most recently, the development of real-time feedback systems has transformed how designers interact with these tools, shifting from batch processing to interactive design exploration. This evolution reflects a broader trend toward more intuitive interfaces that allow architects to maintain creative control while leveraging computational power, representing a maturation of both methodologies from specialized technical tools to integrated design approaches.

Form finding, conversely, has deeper historical roots dating back to Antoni Gaudí's hanging chain models and Frei Otto's physical experiments in the mid-20th century. It evolved from physical to digital methodologies, emphasizing the discovery of structurally efficient forms through simulation of natural forces and material behaviors. Unlike topology optimization's subtractive approach, form finding typically works through an additive or transformative process.

The 1990s marked a significant transition period when both methodologies began migrating from purely academic research into practical architectural applications. The development of more accessible computational tools and increased computing power enabled architects to experiment with these techniques beyond theoretical exercises. Software platforms like Grasshopper for Rhino, with plugins such as Millipede and Kangaroo, democratized access to these complex computational methods.

By the early 2000s, the distinction between these approaches began blurring as hybrid methodologies emerged. Architects and engineers started combining topology optimization's efficiency-driven approach with form finding's more intuitive, physics-based processes. This convergence was particularly evident in landmark projects like the Beijing National Stadium (Bird's Nest) and London's 30 St Mary Axe (The Gherkin), which demonstrated how computationally derived forms could be both structurally efficient and architecturally expressive.

The 2010s witnessed further evolution with the integration of machine learning and artificial intelligence. These technologies enhanced both methodologies by enabling more complex optimization criteria beyond purely structural considerations, incorporating factors such as environmental performance, material usage, and fabrication constraints. This period also saw increased emphasis on multi-objective optimization, allowing designers to balance competing priorities rather than pursuing singular performance metrics.

Most recently, the development of real-time feedback systems has transformed how designers interact with these tools, shifting from batch processing to interactive design exploration. This evolution reflects a broader trend toward more intuitive interfaces that allow architects to maintain creative control while leveraging computational power, representing a maturation of both methodologies from specialized technical tools to integrated design approaches.

Architectural Market Demand Analysis

The architectural industry is experiencing a significant shift towards computational design methodologies, with topology optimization and form finding emerging as critical technologies. Market research indicates that the global architectural services market, valued at approximately $300 billion in 2022, is increasingly demanding innovative structural solutions that balance aesthetics, functionality, and sustainability. Within this context, computational design tools are growing at a compound annual growth rate of 15%, significantly outpacing the broader architectural software market.

The demand for topology optimization and form finding technologies stems from several converging market forces. First, sustainability requirements have become paramount, with 78% of architectural firms reporting increased client requests for environmentally optimized designs. These technologies enable material reduction of 30-50% while maintaining structural integrity, directly addressing this market need. Second, the complexity of contemporary architectural projects has intensified, with 65% of large-scale developments now incorporating non-standard geometries that traditional design methods struggle to accommodate efficiently.

Cost pressures represent another significant market driver. Construction material costs have risen by 23% since 2020, creating urgent demand for optimization technologies that can reduce material usage while ensuring structural performance. Firms implementing computational optimization report average project cost reductions of 15-20%, creating a compelling business case for adoption.

Regional market analysis reveals varying adoption rates. European markets show the highest integration of these technologies, with 42% of architectural firms utilizing some form of computational optimization. North American adoption follows at 35%, while Asia-Pacific markets are experiencing the fastest growth rate at 22% annually, particularly in China, Singapore, and Japan where complex architectural projects are proliferating.

Client expectations are evolving rapidly, with 83% of architectural clients now requesting evidence of optimization in design proposals for major projects. This shift is particularly pronounced in public infrastructure projects, where demonstrable efficiency in material usage has become a competitive advantage and often a tender requirement.

The educational sector is responding to this market demand, with 67% of leading architectural schools now incorporating computational design methodologies into their core curriculum, creating a new generation of practitioners skilled in these technologies. This educational trend is expected to accelerate market adoption as these graduates enter the workforce and influence firm practices.

The demand for topology optimization and form finding technologies stems from several converging market forces. First, sustainability requirements have become paramount, with 78% of architectural firms reporting increased client requests for environmentally optimized designs. These technologies enable material reduction of 30-50% while maintaining structural integrity, directly addressing this market need. Second, the complexity of contemporary architectural projects has intensified, with 65% of large-scale developments now incorporating non-standard geometries that traditional design methods struggle to accommodate efficiently.

Cost pressures represent another significant market driver. Construction material costs have risen by 23% since 2020, creating urgent demand for optimization technologies that can reduce material usage while ensuring structural performance. Firms implementing computational optimization report average project cost reductions of 15-20%, creating a compelling business case for adoption.

Regional market analysis reveals varying adoption rates. European markets show the highest integration of these technologies, with 42% of architectural firms utilizing some form of computational optimization. North American adoption follows at 35%, while Asia-Pacific markets are experiencing the fastest growth rate at 22% annually, particularly in China, Singapore, and Japan where complex architectural projects are proliferating.

Client expectations are evolving rapidly, with 83% of architectural clients now requesting evidence of optimization in design proposals for major projects. This shift is particularly pronounced in public infrastructure projects, where demonstrable efficiency in material usage has become a competitive advantage and often a tender requirement.

The educational sector is responding to this market demand, with 67% of leading architectural schools now incorporating computational design methodologies into their core curriculum, creating a new generation of practitioners skilled in these technologies. This educational trend is expected to accelerate market adoption as these graduates enter the workforce and influence firm practices.

Current State and Technical Challenges

Topology optimization and form finding represent two distinct methodological approaches in computational design for architecture, each with its own current state of development and unique challenges. Globally, these technologies have seen significant advancement in recent years, though their adoption and implementation vary considerably across different regions and architectural practices.

In North America and Europe, topology optimization has gained substantial traction in architectural applications, with research centers at institutions like MIT, ETH Zurich, and TU Delft pushing boundaries in this field. The technology has matured significantly for structural engineering applications but faces challenges when translated to architectural contexts where aesthetic considerations and multifunctional requirements complicate the optimization parameters.

Form finding, with its roots in the physical modeling techniques pioneered by architects like Frei Otto and Antoni Gaudí, has evolved into sophisticated digital methodologies. Currently, it enjoys widespread adoption in avant-garde architectural practices globally, particularly in projects where organic forms and material efficiency are prioritized.

The primary technical challenge for topology optimization in architecture lies in the integration of multiple performance criteria beyond structural efficiency. While the algorithm excels at minimizing material usage while maintaining structural integrity, it struggles to simultaneously account for spatial quality, programmatic requirements, fabrication constraints, and aesthetic considerations that are essential in architectural design.

Computational complexity presents another significant hurdle. High-resolution topology optimization for building-scale applications demands enormous computational resources, often making real-time design exploration impractical. This limitation restricts its application in iterative design processes that are fundamental to architectural practice.

Form finding methodologies face different challenges, primarily in the translation from digital models to physical construction. The complex geometries generated through form finding often require advanced fabrication techniques and custom components, increasing costs and complicating construction logistics.

Interoperability between these computational design tools and standard Building Information Modeling (BIM) platforms remains problematic. The specialized data structures used in topology optimization and form finding do not easily translate to conventional architectural documentation and construction information systems.

Material behavior modeling represents another frontier challenge. Current algorithms often rely on simplified material models that may not accurately predict the performance of heterogeneous or anisotropic materials commonly used in architecture. This gap between computational prediction and actual material performance creates uncertainty in the design process.

Regulatory frameworks and building codes have not kept pace with these computational design methodologies, creating barriers to implementation. Many jurisdictions lack clear guidelines for evaluating and approving structures designed through topology optimization or form finding processes, adding risk and complexity to projects employing these approaches.

In North America and Europe, topology optimization has gained substantial traction in architectural applications, with research centers at institutions like MIT, ETH Zurich, and TU Delft pushing boundaries in this field. The technology has matured significantly for structural engineering applications but faces challenges when translated to architectural contexts where aesthetic considerations and multifunctional requirements complicate the optimization parameters.

Form finding, with its roots in the physical modeling techniques pioneered by architects like Frei Otto and Antoni Gaudí, has evolved into sophisticated digital methodologies. Currently, it enjoys widespread adoption in avant-garde architectural practices globally, particularly in projects where organic forms and material efficiency are prioritized.

The primary technical challenge for topology optimization in architecture lies in the integration of multiple performance criteria beyond structural efficiency. While the algorithm excels at minimizing material usage while maintaining structural integrity, it struggles to simultaneously account for spatial quality, programmatic requirements, fabrication constraints, and aesthetic considerations that are essential in architectural design.

Computational complexity presents another significant hurdle. High-resolution topology optimization for building-scale applications demands enormous computational resources, often making real-time design exploration impractical. This limitation restricts its application in iterative design processes that are fundamental to architectural practice.

Form finding methodologies face different challenges, primarily in the translation from digital models to physical construction. The complex geometries generated through form finding often require advanced fabrication techniques and custom components, increasing costs and complicating construction logistics.

Interoperability between these computational design tools and standard Building Information Modeling (BIM) platforms remains problematic. The specialized data structures used in topology optimization and form finding do not easily translate to conventional architectural documentation and construction information systems.

Material behavior modeling represents another frontier challenge. Current algorithms often rely on simplified material models that may not accurately predict the performance of heterogeneous or anisotropic materials commonly used in architecture. This gap between computational prediction and actual material performance creates uncertainty in the design process.

Regulatory frameworks and building codes have not kept pace with these computational design methodologies, creating barriers to implementation. Many jurisdictions lack clear guidelines for evaluating and approving structures designed through topology optimization or form finding processes, adding risk and complexity to projects employing these approaches.

Comparative Analysis of Current Methodologies

01 Computational methods for topology optimization

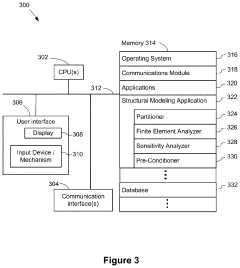

Various computational methods can be employed for topology optimization, including finite element analysis, genetic algorithms, and machine learning approaches. These methods help in finding the optimal distribution of material within a design space to meet specific performance criteria while minimizing material usage. The computational approaches enable engineers to explore complex design spaces efficiently and identify optimal structural configurations that would be difficult to discover through traditional design methods.- Computational methods for topology optimization: Various computational methods are employed for topology optimization to find the optimal distribution of material within a design space. These methods include finite element analysis (FEA), genetic algorithms, and machine learning approaches. By systematically analyzing structural performance under given constraints, these computational techniques can generate optimized designs that meet specific performance criteria while minimizing material usage.

- Integration of topology optimization with additive manufacturing: The combination of topology optimization with additive manufacturing technologies enables the production of complex, optimized structures that would be difficult or impossible to create using traditional manufacturing methods. This approach allows for the fabrication of lightweight components with enhanced performance characteristics, such as improved strength-to-weight ratios and thermal properties, by leveraging the design freedom offered by additive manufacturing processes.

- Form finding through parametric design and generative algorithms: Parametric design and generative algorithms provide powerful approaches to form finding by exploring design spaces through variable parameters and rule-based systems. These methods can generate multiple design iterations based on specified constraints and objectives, allowing designers to discover novel forms that might not be intuitive. By incorporating feedback loops and optimization criteria, these algorithms can evolve designs toward optimal solutions for specific performance requirements.

- Multi-objective optimization frameworks: Multi-objective optimization frameworks address the complexity of real-world design problems by simultaneously considering multiple, often competing, performance criteria. These frameworks enable designers to explore trade-offs between objectives such as structural efficiency, material usage, thermal performance, and manufacturing constraints. By generating Pareto-optimal solution sets, these approaches provide decision-makers with a range of viable design options that represent different compromises between competing objectives.

- AI-enhanced topology optimization and form finding: Artificial intelligence and machine learning techniques are increasingly being applied to enhance topology optimization and form finding processes. These approaches can learn from previous designs, predict performance characteristics, and suggest novel solutions that might not be discovered through traditional methods. By leveraging neural networks, reinforcement learning, and other AI techniques, designers can accelerate the optimization process and uncover innovative structural forms that meet or exceed performance requirements.

02 Integration of form finding with additive manufacturing

Form finding techniques can be effectively integrated with additive manufacturing processes to create optimized structures. This approach allows for the fabrication of complex geometries that would be difficult or impossible to produce using traditional manufacturing methods. The combination of topology optimization algorithms with 3D printing technologies enables the creation of lightweight yet strong structures with optimized material distribution, leading to improved performance and reduced material consumption in various applications.Expand Specific Solutions03 Bio-inspired approaches to form finding

Bio-inspired or biomimetic approaches leverage natural structures and growth patterns found in biological systems to inform topology optimization. These methods mimic evolutionary processes and natural structural optimization that has occurred over millions of years. By studying and implementing principles from natural structures such as bones, trees, and cellular structures, engineers can develop more efficient and resilient designs that optimize material usage while maintaining or enhancing structural performance.Expand Specific Solutions04 Multi-objective optimization frameworks

Multi-objective optimization frameworks allow designers to simultaneously consider multiple performance criteria in topology optimization and form finding. These frameworks enable the balancing of competing objectives such as structural strength, weight reduction, thermal performance, and manufacturing constraints. By employing techniques such as Pareto optimization and weighted objective functions, engineers can identify design solutions that represent optimal trade-offs between different performance requirements.Expand Specific Solutions05 Real-time interactive form finding tools

Real-time interactive tools for topology optimization allow designers to visualize and manipulate optimization results during the design process. These tools provide immediate feedback on how design changes affect performance metrics, enabling more intuitive exploration of the design space. By combining computational optimization algorithms with interactive user interfaces, these tools bridge the gap between automated optimization and human design intuition, resulting in more practical and aesthetically pleasing optimized designs.Expand Specific Solutions

Key Industry Players and Competitors

Topology optimization and form finding represent evolving approaches in architectural design, with the market currently in a growth phase as computational design gains prominence. The global market for these technologies is expanding rapidly, projected to reach significant scale as architecture firms increasingly adopt algorithmic design methods. In terms of technical maturity, companies like Autodesk and Dassault Systèmes lead with established software platforms incorporating both methodologies, while academic institutions such as University of Michigan, Northwestern University, and Zhejiang University contribute significant research advancements. ANSYS and Siemens Industry Software offer robust simulation tools that bridge theoretical concepts with practical applications, though implementation challenges remain in translating optimized forms into constructible designs. The competitive landscape features collaboration between software developers and academic institutions to advance practical applications.

Autodesk, Inc.

Technical Solution: Autodesk has developed an integrated approach combining topology optimization and form finding in their Fusion 360 and Revit platforms. Their technology utilizes generative design algorithms that can simultaneously consider structural performance, material efficiency, and manufacturing constraints. The company's Project Dreamcatcher employs machine learning to generate thousands of design alternatives based on specified goals and constraints, allowing architects to explore a wider solution space. Autodesk's technology enables designers to input functional requirements and material constraints, then algorithmically generates optimal structural forms that meet these criteria while minimizing material usage. Their cloud-based computing infrastructure allows for complex simulations that would be prohibitive on local workstations, democratizing access to advanced computational design tools for architectural firms of all sizes.

Strengths: Seamless integration with existing BIM workflows; user-friendly interfaces making advanced optimization accessible to non-engineers; cloud computing capabilities enabling complex calculations. Weaknesses: Computational intensity requiring significant processing resources; potential over-reliance on algorithmic solutions without sufficient consideration for aesthetic and contextual factors.

Siemens AG

Technical Solution: Siemens has developed an integrated digital twin approach to architectural optimization through their NX software suite and Simcenter solutions. Their technology uniquely combines topology optimization with generative design methodologies that incorporate both structural and energy performance criteria. Siemens' platform employs parametric optimization techniques that maintain design intent while exploring structural efficiency, allowing architects greater control over aesthetic outcomes compared to pure topology optimization approaches. Their solution incorporates machine learning algorithms that learn from previous design iterations to suggest improvements that balance structural performance with architectural considerations. Siemens has also pioneered the integration of building systems optimization within the structural form-finding process, allowing simultaneous optimization of structural elements and mechanical/electrical pathways—a capability particularly valuable for complex institutional buildings.

Strengths: Comprehensive digital twin capabilities connecting design to operational performance; strong integration with building systems engineering; advanced manufacturing constraints ensuring buildability of optimized designs. Weaknesses: Complex ecosystem requiring significant investment in software and training; optimization processes sometimes prioritize engineering metrics over architectural qualities; limited integration with common architectural design platforms.

Critical Patents and Research Breakthroughs

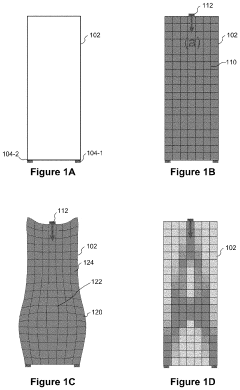

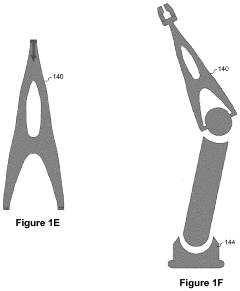

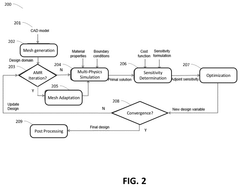

Structural design using finite-element analysis

PatentPendingUS20230315947A1

Innovation

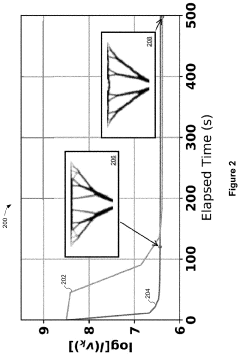

- The approach reformulates the problem as a bilevel optimization using a first-order algorithm and the Solid Isotropic Material with Penalization (SIMP) model, allowing for approximate solutions and reducing iterative costs, enabling faster design updates and convergence to locally optimal structures.

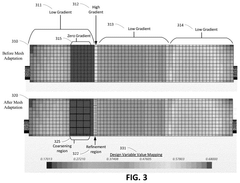

Topology optimization with bidirectional mesh adaptation

PatentPendingUS20250181800A1

Innovation

- The implementation of bidirectional mesh adaptation, which refines and coarsens mesh elements based on detected gradients of design variables, allowing for selective adaptation during the optimization process to accelerate convergence and reduce computational costs.

Sustainability and Material Efficiency Considerations

Sustainability considerations have become increasingly critical in architectural design, with both Topology Optimization (TO) and Form Finding (FF) offering distinct advantages in this domain. TO demonstrates superior material efficiency by mathematically determining the optimal distribution of material based on load paths and structural requirements. This approach typically results in material reductions of 30-50% compared to conventional design methods, significantly decreasing the embodied carbon footprint of architectural structures.

Form Finding methods complement sustainability goals through their inherent connection to natural processes. By mimicking natural formation principles, FF solutions often align with biomimetic design principles that have evolved for resource efficiency. Studies comparing TO and FF approaches in similar architectural applications have shown that while TO may achieve marginally better material reduction in purely structural terms, FF solutions frequently offer better holistic performance when considering thermal properties, natural ventilation, and passive design strategies.

The environmental impact assessment of both methodologies reveals interesting patterns. TO-derived structures typically excel in reducing primary material usage but may require more complex manufacturing processes with higher energy demands. Conversely, FF approaches often lead to designs that can be constructed using lower-energy methods and locally available materials, potentially offsetting the slightly higher material requirements.

Life cycle analysis (LCA) of buildings designed using these methodologies indicates that TO may provide greater benefits in high-rise or long-span structures where material volume dominates environmental impact calculations. FF demonstrates advantages in medium-scale projects where operational energy and construction methodology significantly influence sustainability metrics.

Recent advancements in material science have expanded the sustainability potential of both approaches. Biodegradable materials, recycled composites, and low-carbon alternatives can be integrated into both TO and FF workflows. However, TO algorithms have shown greater adaptability in optimizing for novel materials with complex performance characteristics, while FF methods excel when working with traditional sustainable materials like timber, bamboo, and earth-based composites.

The circular economy perspective favors designs that facilitate future adaptation, disassembly, and material recovery. In this context, FF approaches often produce more intuitive structural systems that can be more easily modified or deconstructed. TO-generated geometries, while highly efficient, may create more integrated systems that present challenges for component separation at end-of-life stages.

Form Finding methods complement sustainability goals through their inherent connection to natural processes. By mimicking natural formation principles, FF solutions often align with biomimetic design principles that have evolved for resource efficiency. Studies comparing TO and FF approaches in similar architectural applications have shown that while TO may achieve marginally better material reduction in purely structural terms, FF solutions frequently offer better holistic performance when considering thermal properties, natural ventilation, and passive design strategies.

The environmental impact assessment of both methodologies reveals interesting patterns. TO-derived structures typically excel in reducing primary material usage but may require more complex manufacturing processes with higher energy demands. Conversely, FF approaches often lead to designs that can be constructed using lower-energy methods and locally available materials, potentially offsetting the slightly higher material requirements.

Life cycle analysis (LCA) of buildings designed using these methodologies indicates that TO may provide greater benefits in high-rise or long-span structures where material volume dominates environmental impact calculations. FF demonstrates advantages in medium-scale projects where operational energy and construction methodology significantly influence sustainability metrics.

Recent advancements in material science have expanded the sustainability potential of both approaches. Biodegradable materials, recycled composites, and low-carbon alternatives can be integrated into both TO and FF workflows. However, TO algorithms have shown greater adaptability in optimizing for novel materials with complex performance characteristics, while FF methods excel when working with traditional sustainable materials like timber, bamboo, and earth-based composites.

The circular economy perspective favors designs that facilitate future adaptation, disassembly, and material recovery. In this context, FF approaches often produce more intuitive structural systems that can be more easily modified or deconstructed. TO-generated geometries, while highly efficient, may create more integrated systems that present challenges for component separation at end-of-life stages.

Integration with BIM and Digital Fabrication

The integration of Topology Optimization (TO) and Form Finding (FF) methodologies with Building Information Modeling (BIM) and digital fabrication represents a critical advancement in architectural applications. BIM platforms provide comprehensive digital representations of buildings, encompassing both physical and functional characteristics, while digital fabrication technologies enable the direct translation of complex computational designs into physical structures.

Current BIM software packages such as Autodesk Revit, ArchiCAD, and Bentley Systems increasingly incorporate plugins and extensions that support TO and FF workflows. These integrations allow architects to seamlessly transition from conceptual design to detailed documentation and construction planning. For instance, TO-generated structural solutions can be directly imported into BIM environments where they are enriched with material specifications, cost data, and construction sequencing information.

Digital fabrication technologies, including additive manufacturing (3D printing), CNC milling, and robotic fabrication, have dramatically expanded the feasibility of implementing complex geometries derived from TO and FF processes. The direct digital workflow from computational design to fabrication eliminates traditional interpretation steps, reducing errors and enabling the realization of previously unbuildable forms.

TO approaches typically generate highly optimized but often geometrically complex components that present challenges for traditional construction methods. However, when paired with advanced digital fabrication techniques, these complexities become manageable. For example, topology-optimized structural nodes can be 3D printed in metal, while larger optimized components can be produced through multi-axis CNC milling.

FF methodologies generally produce more fluid, continuous surfaces that align well with certain digital fabrication techniques such as robotic hot-wire cutting for formwork or large-scale 3D printing. The natural forms generated through FF often require less post-processing for manufacturability compared to the intricate geometries of TO.

Interoperability remains a significant challenge in these integrations. While neutral file formats like IFC (Industry Foundation Classes) facilitate data exchange, information loss often occurs when transferring complex parametric relationships between specialized TO/FF software and BIM platforms. Several research initiatives and commercial developments are addressing these limitations through improved APIs and direct integration modules.

The economic implications of integrating TO and FF with BIM and digital fabrication are substantial. While initial implementation costs may be higher, the potential for material savings (10-30% in structural applications), reduced construction time, and enhanced building performance can deliver significant long-term value. Furthermore, this integration supports sustainable construction practices by optimizing material usage and enabling more efficient building systems.

Current BIM software packages such as Autodesk Revit, ArchiCAD, and Bentley Systems increasingly incorporate plugins and extensions that support TO and FF workflows. These integrations allow architects to seamlessly transition from conceptual design to detailed documentation and construction planning. For instance, TO-generated structural solutions can be directly imported into BIM environments where they are enriched with material specifications, cost data, and construction sequencing information.

Digital fabrication technologies, including additive manufacturing (3D printing), CNC milling, and robotic fabrication, have dramatically expanded the feasibility of implementing complex geometries derived from TO and FF processes. The direct digital workflow from computational design to fabrication eliminates traditional interpretation steps, reducing errors and enabling the realization of previously unbuildable forms.

TO approaches typically generate highly optimized but often geometrically complex components that present challenges for traditional construction methods. However, when paired with advanced digital fabrication techniques, these complexities become manageable. For example, topology-optimized structural nodes can be 3D printed in metal, while larger optimized components can be produced through multi-axis CNC milling.

FF methodologies generally produce more fluid, continuous surfaces that align well with certain digital fabrication techniques such as robotic hot-wire cutting for formwork or large-scale 3D printing. The natural forms generated through FF often require less post-processing for manufacturability compared to the intricate geometries of TO.

Interoperability remains a significant challenge in these integrations. While neutral file formats like IFC (Industry Foundation Classes) facilitate data exchange, information loss often occurs when transferring complex parametric relationships between specialized TO/FF software and BIM platforms. Several research initiatives and commercial developments are addressing these limitations through improved APIs and direct integration modules.

The economic implications of integrating TO and FF with BIM and digital fabrication are substantial. While initial implementation costs may be higher, the potential for material savings (10-30% in structural applications), reduced construction time, and enhanced building performance can deliver significant long-term value. Furthermore, this integration supports sustainable construction practices by optimizing material usage and enabling more efficient building systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!