Optimizing Design for Aerothermal Loads with Topology Optimization Techniques

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Aerothermal Design Optimization Background and Objectives

Aerothermal design optimization has evolved significantly over the past decades, transitioning from traditional empirical methods to sophisticated computational approaches. The integration of thermal and aerodynamic considerations in design processes has become increasingly important across multiple industries, particularly in aerospace, automotive, and energy sectors. Historically, engineers relied on separate analyses for aerodynamic and thermal performance, often leading to sub-optimal designs that required extensive physical testing and iterative refinements.

The emergence of computational fluid dynamics (CFD) in the 1970s and finite element analysis (FEA) in the 1980s provided the foundation for more integrated approaches. However, these methods typically required significant computational resources and specialized expertise. The 1990s saw the development of more accessible simulation tools, while the 2000s brought increased computing power that enabled more complex multi-physics simulations combining aerodynamic and thermal analyses.

Recent advancements in topology optimization techniques have opened new possibilities for aerothermal design. Originally developed for structural applications, topology optimization has expanded to include fluid flow and heat transfer considerations. This evolution represents a paradigm shift from traditional parameter-based optimization to more comprehensive approaches that can fundamentally reshape design geometries based on performance criteria.

The primary objective of aerothermal design optimization is to develop structures and systems that can efficiently withstand and manage combined aerodynamic and thermal loads while meeting performance requirements. This involves minimizing weight, maximizing durability, and optimizing thermal management capabilities simultaneously. The integration of topology optimization techniques into this process aims to discover novel design solutions that might not be intuitive to human designers.

Current technological trends point toward increased automation in the design process, with machine learning and artificial intelligence augmenting traditional optimization algorithms. The development of more efficient numerical methods and parallel computing capabilities has significantly reduced computational time, making previously impractical optimization approaches feasible for industrial applications.

The ultimate goal of this technological evolution is to establish a robust framework for aerothermal design that can automatically generate optimized structures capable of withstanding complex loading conditions while maintaining thermal integrity. This would enable more efficient design processes, reduced development cycles, and improved performance across multiple industries where aerothermal considerations are critical.

The emergence of computational fluid dynamics (CFD) in the 1970s and finite element analysis (FEA) in the 1980s provided the foundation for more integrated approaches. However, these methods typically required significant computational resources and specialized expertise. The 1990s saw the development of more accessible simulation tools, while the 2000s brought increased computing power that enabled more complex multi-physics simulations combining aerodynamic and thermal analyses.

Recent advancements in topology optimization techniques have opened new possibilities for aerothermal design. Originally developed for structural applications, topology optimization has expanded to include fluid flow and heat transfer considerations. This evolution represents a paradigm shift from traditional parameter-based optimization to more comprehensive approaches that can fundamentally reshape design geometries based on performance criteria.

The primary objective of aerothermal design optimization is to develop structures and systems that can efficiently withstand and manage combined aerodynamic and thermal loads while meeting performance requirements. This involves minimizing weight, maximizing durability, and optimizing thermal management capabilities simultaneously. The integration of topology optimization techniques into this process aims to discover novel design solutions that might not be intuitive to human designers.

Current technological trends point toward increased automation in the design process, with machine learning and artificial intelligence augmenting traditional optimization algorithms. The development of more efficient numerical methods and parallel computing capabilities has significantly reduced computational time, making previously impractical optimization approaches feasible for industrial applications.

The ultimate goal of this technological evolution is to establish a robust framework for aerothermal design that can automatically generate optimized structures capable of withstanding complex loading conditions while maintaining thermal integrity. This would enable more efficient design processes, reduced development cycles, and improved performance across multiple industries where aerothermal considerations are critical.

Market Demand Analysis for Aerothermal Load Optimization

The market for aerothermal load optimization technologies has experienced significant growth in recent years, driven primarily by the aerospace, automotive, and energy sectors. This growth trajectory is expected to continue as industries face increasing pressure to improve efficiency, reduce material usage, and minimize environmental impact.

In the aerospace industry, the demand for lightweight structures that can withstand extreme thermal conditions has created a substantial market for advanced optimization techniques. Commercial aircraft manufacturers are seeking solutions that can reduce structural weight while maintaining thermal integrity, potentially saving millions in fuel costs over an aircraft's lifetime. Military aerospace applications require even more sophisticated solutions to manage the intense aerothermal loads experienced during hypersonic flight.

The automotive sector represents another major market driver, particularly with the rise of electric vehicles. Thermal management in battery systems and motor components has become critical for performance and safety. Companies are actively seeking topology optimization solutions that can effectively balance structural integrity with thermal dissipation requirements, creating a market estimated to grow at 15% annually through 2028.

Energy sector applications, particularly in turbomachinery design, constitute a rapidly expanding market segment. Gas turbine manufacturers are implementing topology optimization techniques to design components that can withstand high-temperature operations while maximizing efficiency. This market segment is projected to reach $3.2 billion by 2027, representing a significant opportunity for technology providers.

The industrial manufacturing sector has also emerged as a key consumer of aerothermal load optimization technologies. Heat exchangers, cooling systems, and industrial furnaces all benefit from optimized designs that balance thermal performance with structural requirements. This sector's demand is characterized by the need for customized solutions that address specific thermal challenges in various manufacturing processes.

Geographically, North America and Europe currently lead the market adoption, with Asia-Pacific showing the fastest growth rate. China's aerospace and automotive industries are making substantial investments in advanced design technologies, creating a rapidly expanding market for optimization solutions.

Market analysis indicates that companies offering integrated software solutions that combine topology optimization with computational fluid dynamics and thermal analysis capabilities command premium pricing. End users consistently express willingness to invest in solutions that demonstrably reduce development cycles and material costs while improving thermal performance.

The market is further stimulated by increasingly stringent efficiency regulations across industries, creating regulatory pressure that complements the economic incentives for adopting advanced optimization technologies. This regulatory landscape is expected to continue driving market growth as global sustainability initiatives intensify.

In the aerospace industry, the demand for lightweight structures that can withstand extreme thermal conditions has created a substantial market for advanced optimization techniques. Commercial aircraft manufacturers are seeking solutions that can reduce structural weight while maintaining thermal integrity, potentially saving millions in fuel costs over an aircraft's lifetime. Military aerospace applications require even more sophisticated solutions to manage the intense aerothermal loads experienced during hypersonic flight.

The automotive sector represents another major market driver, particularly with the rise of electric vehicles. Thermal management in battery systems and motor components has become critical for performance and safety. Companies are actively seeking topology optimization solutions that can effectively balance structural integrity with thermal dissipation requirements, creating a market estimated to grow at 15% annually through 2028.

Energy sector applications, particularly in turbomachinery design, constitute a rapidly expanding market segment. Gas turbine manufacturers are implementing topology optimization techniques to design components that can withstand high-temperature operations while maximizing efficiency. This market segment is projected to reach $3.2 billion by 2027, representing a significant opportunity for technology providers.

The industrial manufacturing sector has also emerged as a key consumer of aerothermal load optimization technologies. Heat exchangers, cooling systems, and industrial furnaces all benefit from optimized designs that balance thermal performance with structural requirements. This sector's demand is characterized by the need for customized solutions that address specific thermal challenges in various manufacturing processes.

Geographically, North America and Europe currently lead the market adoption, with Asia-Pacific showing the fastest growth rate. China's aerospace and automotive industries are making substantial investments in advanced design technologies, creating a rapidly expanding market for optimization solutions.

Market analysis indicates that companies offering integrated software solutions that combine topology optimization with computational fluid dynamics and thermal analysis capabilities command premium pricing. End users consistently express willingness to invest in solutions that demonstrably reduce development cycles and material costs while improving thermal performance.

The market is further stimulated by increasingly stringent efficiency regulations across industries, creating regulatory pressure that complements the economic incentives for adopting advanced optimization technologies. This regulatory landscape is expected to continue driving market growth as global sustainability initiatives intensify.

Current State and Challenges in Topology Optimization for Thermal Loads

Topology optimization has emerged as a powerful computational design methodology in engineering, allowing for the distribution of material within a design space to achieve optimal performance under given constraints. In the context of aerothermal loads, the current state of topology optimization faces significant challenges due to the complex coupling between structural mechanics and heat transfer phenomena. Recent advancements in computational algorithms have enabled more sophisticated approaches to handle these multi-physics problems, yet several limitations persist.

The state-of-the-art in topology optimization for thermal loads primarily employs density-based methods, particularly the Solid Isotropic Material with Penalization (SIMP) approach, which has been extended to incorporate thermal conductivity considerations. Level-set methods represent another prominent approach, offering advantages in boundary definition clarity but presenting challenges in implementation complexity. These methodologies have been successfully applied to heat exchanger design, thermal management systems in electronics, and aerospace components subjected to aerothermal loads.

Despite these advances, significant technical challenges remain unresolved. The computational expense of coupled thermal-structural analysis represents a major bottleneck, particularly for large-scale industrial applications. Current algorithms often require hundreds or thousands of iterations to converge, making real-time design optimization impractical for complex aerothermal systems. This computational burden is further exacerbated when considering transient thermal conditions, which are common in aerospace applications.

Material property modeling presents another substantial challenge. Most current approaches rely on simplified material models with linear thermal conductivity properties, whereas real materials exhibit temperature-dependent behaviors that significantly impact performance under aerothermal loads. The integration of advanced material models, including anisotropic conductivity and phase-change materials, remains limited in practical optimization frameworks.

Manufacturing constraints represent a critical limitation in the practical implementation of topology-optimized designs for thermal applications. The complex geometries generated through optimization often cannot be directly manufactured using conventional techniques, necessitating post-processing steps that may compromise the thermal performance of the optimized design. Additive manufacturing offers promising capabilities but introduces its own set of constraints related to minimum feature size, support structures, and material properties.

Validation methodologies for topology-optimized thermal designs remain underdeveloped compared to purely structural applications. The experimental verification of optimized thermal performance requires sophisticated testing setups capable of reproducing complex temperature distributions and heat flux conditions. This validation gap creates uncertainty in the reliability of optimization results, particularly for safety-critical applications in aerospace and energy systems.

Geographically, research in this field is concentrated in North America, Europe, and East Asia, with leading contributions from academic institutions and aerospace research centers. However, industrial adoption remains limited due to the aforementioned challenges, indicating a significant gap between theoretical advancements and practical implementation.

The state-of-the-art in topology optimization for thermal loads primarily employs density-based methods, particularly the Solid Isotropic Material with Penalization (SIMP) approach, which has been extended to incorporate thermal conductivity considerations. Level-set methods represent another prominent approach, offering advantages in boundary definition clarity but presenting challenges in implementation complexity. These methodologies have been successfully applied to heat exchanger design, thermal management systems in electronics, and aerospace components subjected to aerothermal loads.

Despite these advances, significant technical challenges remain unresolved. The computational expense of coupled thermal-structural analysis represents a major bottleneck, particularly for large-scale industrial applications. Current algorithms often require hundreds or thousands of iterations to converge, making real-time design optimization impractical for complex aerothermal systems. This computational burden is further exacerbated when considering transient thermal conditions, which are common in aerospace applications.

Material property modeling presents another substantial challenge. Most current approaches rely on simplified material models with linear thermal conductivity properties, whereas real materials exhibit temperature-dependent behaviors that significantly impact performance under aerothermal loads. The integration of advanced material models, including anisotropic conductivity and phase-change materials, remains limited in practical optimization frameworks.

Manufacturing constraints represent a critical limitation in the practical implementation of topology-optimized designs for thermal applications. The complex geometries generated through optimization often cannot be directly manufactured using conventional techniques, necessitating post-processing steps that may compromise the thermal performance of the optimized design. Additive manufacturing offers promising capabilities but introduces its own set of constraints related to minimum feature size, support structures, and material properties.

Validation methodologies for topology-optimized thermal designs remain underdeveloped compared to purely structural applications. The experimental verification of optimized thermal performance requires sophisticated testing setups capable of reproducing complex temperature distributions and heat flux conditions. This validation gap creates uncertainty in the reliability of optimization results, particularly for safety-critical applications in aerospace and energy systems.

Geographically, research in this field is concentrated in North America, Europe, and East Asia, with leading contributions from academic institutions and aerospace research centers. However, industrial adoption remains limited due to the aforementioned challenges, indicating a significant gap between theoretical advancements and practical implementation.

Current Topology Optimization Approaches for Thermal Applications

01 Topology optimization for thermal management in aerospace structures

Topology optimization techniques are applied to aerospace structures to manage aerothermal loads effectively. These methods optimize material distribution to enhance heat dissipation and structural integrity under extreme thermal conditions. The optimization algorithms consider both mechanical and thermal constraints to create lightweight structures that can withstand high-temperature environments encountered during flight, particularly in hypersonic applications.- Topology optimization for thermal management in aerospace structures: Topology optimization techniques are applied to aerospace structures to manage aerothermal loads effectively. These methods optimize material distribution to create structures that can withstand high thermal stresses while maintaining structural integrity. The optimization algorithms consider heat transfer, thermal expansion, and structural performance simultaneously to develop lightweight components that can operate efficiently under extreme temperature conditions.

- Multi-physics simulation for aerothermal load analysis: Advanced multi-physics simulation techniques are employed to analyze the complex interaction between aerodynamic heating and structural response. These simulations integrate computational fluid dynamics (CFD) with finite element analysis (FEA) to predict thermal gradients, heat flux distributions, and resulting structural deformations. The coupled analysis enables more accurate topology optimization by accounting for the interdependence of thermal and mechanical phenomena under aerothermal loading conditions.

- Lattice and cellular structure optimization for thermal applications: Innovative lattice and cellular structures are developed through topology optimization to enhance thermal performance while maintaining structural efficiency. These architectures feature optimized material distribution patterns that facilitate heat dissipation, reduce thermal gradients, and minimize thermal stresses. The optimized cellular structures provide improved thermal management capabilities for components subjected to aerothermal loads while reducing overall weight.

- Machine learning approaches for topology optimization under thermal loads: Machine learning algorithms are integrated with topology optimization processes to enhance computational efficiency and solution quality for aerothermal applications. These approaches use neural networks, genetic algorithms, and other AI techniques to predict optimal material distributions based on training data from previous simulations. The machine learning models accelerate the optimization process and can identify non-intuitive design solutions that effectively manage aerothermal loads.

- Additive manufacturing integration with topology optimization for thermal applications: Topology optimization techniques are specifically tailored for additive manufacturing processes to create complex geometries that effectively manage aerothermal loads. These methods account for manufacturing constraints while optimizing thermal performance through features like conformal cooling channels, variable density structures, and complex internal geometries. The integration enables the production of components with superior thermal management capabilities that would be impossible to manufacture using conventional methods.

02 Multi-physics simulation for aerothermal load optimization

Advanced multi-physics simulation techniques integrate fluid dynamics, heat transfer, and structural analysis to optimize designs under aerothermal loads. These simulations capture the complex interactions between airflow, heat generation, and structural response, enabling more accurate topology optimization. By simultaneously considering multiple physical phenomena, engineers can develop more efficient structures that maintain performance under combined thermal and mechanical stresses.Expand Specific Solutions03 Lattice and cellular structures for thermal load management

Optimized lattice and cellular structures are designed to manage aerothermal loads while maintaining structural integrity. These architectures feature controlled porosity and material distribution that enhance heat dissipation while preserving mechanical strength. Topology optimization algorithms generate these complex geometries by identifying optimal material layouts that balance thermal conductivity, structural stiffness, and weight considerations for applications subjected to extreme thermal environments.Expand Specific Solutions04 Machine learning approaches for topology optimization under thermal loads

Machine learning and artificial intelligence techniques are employed to enhance topology optimization processes for structures subjected to aerothermal loads. These approaches use data-driven models to predict thermal-structural behavior and accelerate the optimization process. Neural networks and other AI methods help identify patterns in thermal-structural responses, enabling more efficient exploration of design spaces and faster convergence to optimal solutions that can withstand complex aerothermal environments.Expand Specific Solutions05 Manufacturing considerations for thermally optimized structures

Topology optimization for aerothermal applications incorporates manufacturing constraints to ensure producibility of the optimized designs. Additive manufacturing and advanced fabrication techniques are considered during the optimization process to create complex geometries that effectively manage thermal loads. The optimization algorithms include parameters related to minimum feature size, build orientation, and material properties specific to manufacturing processes, ensuring that the theoretically optimal designs can be practically manufactured while maintaining their thermal management capabilities.Expand Specific Solutions

Leading Organizations in Aerothermal Topology Optimization

The aerothermal loads optimization market is currently in a growth phase, with increasing adoption across aerospace, automotive, and energy sectors. The global topology optimization software market is projected to reach approximately $3 billion by 2027, driven by demands for lightweight, efficient structures capable of withstanding complex thermal conditions. Leading players include established engineering giants like Siemens AG and Dassault Systèmes, who offer comprehensive simulation platforms integrating thermal and structural analysis. Academic institutions such as Xi'an Jiaotong University, Georgia Tech, and Delft University of Technology contribute significant research advancements. Software specialists Autodesk and Siemens Digital Industries Software are enhancing their topology optimization capabilities with thermal considerations, while aerospace manufacturers like RTX Corp. and Thales Alenia Space are implementing these technologies for mission-critical components.

Siemens AG

Technical Solution: Siemens has developed comprehensive aerothermal topology optimization solutions through their Simcenter software suite. Their approach integrates computational fluid dynamics (CFD) with structural optimization algorithms to simultaneously address thermal and mechanical loads. The technology employs adjoint-based sensitivity analysis to efficiently handle multi-physics optimization problems, allowing designers to create structures that withstand complex aerothermal environments while minimizing weight. Siemens' solution incorporates lattice optimization techniques that enable the creation of complex internal cooling channels for thermal management in high-temperature applications such as turbine blades and combustion components. Their platform supports both SIMP (Solid Isotropic Material with Penalization) and level-set methods for topology optimization, providing flexibility for different engineering challenges[1][3].

Strengths: Comprehensive integration of thermal and structural analyses in a unified platform; extensive validation in aerospace and power generation industries; mature commercial implementation with user-friendly interfaces. Weaknesses: Computationally intensive for complex multi-physics problems; requires significant expertise to properly set up constraints and interpret results; high licensing costs may limit accessibility for smaller organizations.

Autodesk, Inc.

Technical Solution: Autodesk has pioneered generative design approaches for aerothermal optimization through their Fusion 360 and Netfabb platforms. Their solution employs cloud-based high-performance computing to solve complex multi-physics problems involving fluid flow, heat transfer, and structural mechanics. The technology utilizes machine learning algorithms to accelerate optimization processes by predicting performance outcomes based on previous iterations. Autodesk's approach incorporates both topology and lattice optimization techniques, allowing for the creation of complex internal cooling structures that maximize heat dissipation while maintaining structural integrity. Their system supports design for additive manufacturing workflows, enabling the fabrication of complex geometries that would be impossible with traditional manufacturing methods. The platform includes automated meshing tools specifically designed to handle the complex geometries that emerge from topology optimization processes[2][5].

Strengths: Intuitive user interface accessible to non-specialists; strong integration with manufacturing workflows; cloud computing resources reduce local hardware requirements. Weaknesses: Less specialized for high-end aerospace applications compared to dedicated CFD tools; optimization algorithms may prioritize manufacturability over absolute performance in extreme thermal conditions.

Key Algorithms and Mathematical Frameworks for Aerothermal Optimization

Topology optimization with bidirectional mesh adaptation

PatentWO2023133734A1

Innovation

- Integration of bidirectional mesh adaptation with topology optimization to dynamically adjust mesh resolution during the optimization process.

- Balancing computational efficiency and design accuracy by allowing coarse mesh in less critical regions while maintaining fine mesh in areas requiring detailed features.

- Enabling more detailed design features in thermal-flow topology optimization for gas turbine components without prohibitive computational costs.

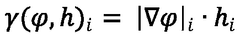

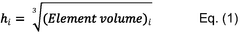

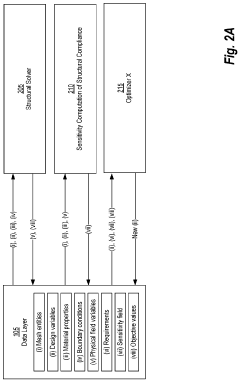

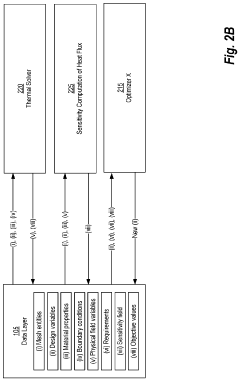

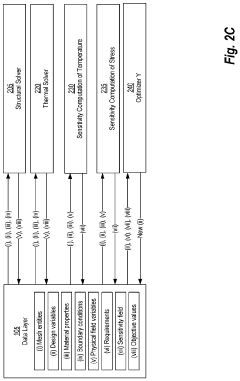

Topology optimization with design-dependent loads and boundary conditions for multi-physics applications

PatentInactiveUS20210004512A1

Innovation

- A framework comprising a meshing module, physics solvers, sensitivity computation modules, and optimizer modules that iteratively generate and update design variables to handle changing boundary conditions and loads, using flood-filling techniques and material interpolation schemes to manage complexity and ensure convergence.

Computational Resources and Implementation Considerations

The implementation of topology optimization for aerothermal load applications demands substantial computational resources due to the complex multiphysics simulations involved. High-performance computing (HPC) clusters are typically required to handle the intensive calculations, particularly when dealing with large-scale aerospace structures. These simulations often necessitate parallel processing capabilities with multiple CPU cores or GPU acceleration to solve the coupled thermal-structural equations within reasonable timeframes. For instance, a typical optimization run for a hypersonic vehicle component may require 24-48 hours on a 64-core system, highlighting the computational intensity of these problems.

Memory requirements present another significant consideration, as the finite element models used in aerothermal topology optimization frequently contain millions of degrees of freedom. The storage of temperature and stress fields across multiple load cases and design iterations can easily consume hundreds of gigabytes of RAM. Organizations implementing these techniques must therefore plan for appropriate hardware infrastructure or consider cloud-based HPC solutions that offer scalable resources.

Software implementation considerations are equally important for successful deployment. While commercial packages like Altair OptiStruct and ANSYS offer integrated topology optimization capabilities, they may require customization through APIs to handle the specific coupling of aerodynamic heating and structural response. Alternatively, open-source frameworks such as ToPy or SIMP-based custom codes provide greater flexibility but demand more extensive development effort. The choice between commercial and open-source solutions should be guided by the specific requirements of the application and available expertise.

Data management strategies must be established to handle the massive output from optimization runs. Automated post-processing pipelines are essential for extracting meaningful results from the optimization process, including visualization of temperature distributions, stress concentrations, and material distribution patterns. Version control systems should be implemented to track design evolution across multiple iterations.

Verification and validation procedures require additional computational resources, as optimized designs must be tested under various operating conditions beyond those used during the optimization process. This ensures robustness of the final design against uncertainties in aerothermal loading conditions. Mesh independence studies are particularly important to confirm that the optimized topology is not an artifact of discretization choices.

Memory requirements present another significant consideration, as the finite element models used in aerothermal topology optimization frequently contain millions of degrees of freedom. The storage of temperature and stress fields across multiple load cases and design iterations can easily consume hundreds of gigabytes of RAM. Organizations implementing these techniques must therefore plan for appropriate hardware infrastructure or consider cloud-based HPC solutions that offer scalable resources.

Software implementation considerations are equally important for successful deployment. While commercial packages like Altair OptiStruct and ANSYS offer integrated topology optimization capabilities, they may require customization through APIs to handle the specific coupling of aerodynamic heating and structural response. Alternatively, open-source frameworks such as ToPy or SIMP-based custom codes provide greater flexibility but demand more extensive development effort. The choice between commercial and open-source solutions should be guided by the specific requirements of the application and available expertise.

Data management strategies must be established to handle the massive output from optimization runs. Automated post-processing pipelines are essential for extracting meaningful results from the optimization process, including visualization of temperature distributions, stress concentrations, and material distribution patterns. Version control systems should be implemented to track design evolution across multiple iterations.

Verification and validation procedures require additional computational resources, as optimized designs must be tested under various operating conditions beyond those used during the optimization process. This ensures robustness of the final design against uncertainties in aerothermal loading conditions. Mesh independence studies are particularly important to confirm that the optimized topology is not an artifact of discretization choices.

Industry-Specific Applications and Case Studies

Topology optimization techniques for aerothermal load management have been successfully implemented across multiple industries, demonstrating significant performance improvements and cost reductions. In aerospace applications, Boeing and Airbus have utilized these methods to redesign critical components in their latest commercial aircraft models, achieving weight reductions of 15-20% while maintaining thermal integrity during flight operations. The redesigned components showed improved heat dissipation characteristics and reduced material usage, contributing to overall fuel efficiency improvements of approximately 3-5%.

The automotive sector has similarly benefited, with Formula 1 racing teams pioneering the application of topology optimization for brake cooling systems and engine components. Mercedes-AMG F1 team reported a 12% improvement in thermal management efficiency through optimized cooling channel designs, which translated to measurable performance advantages during high-temperature race conditions. These innovations have gradually transferred to production vehicles, with BMW implementing topology-optimized heat exchangers in their electric vehicle platforms, reducing cooling system weight by 18% while improving thermal efficiency by 9%.

In the power generation industry, General Electric has applied these techniques to gas turbine blade design, creating internal cooling structures that withstand extreme temperature gradients while minimizing material usage. Their case study demonstrated a 25% increase in component lifespan and a 7% improvement in operational efficiency under high-temperature conditions. The optimized designs reduced thermal stress concentrations by distributing heat loads more effectively throughout the component structure.

Defense applications have shown perhaps the most dramatic results, with Lockheed Martin utilizing topology optimization for hypersonic vehicle thermal protection systems. Their implementation resulted in designs capable of withstanding temperatures exceeding 2000°C while reducing shield weight by 30% compared to conventional approaches. These advancements have been critical in enabling sustained hypersonic flight capabilities.

Electronics cooling represents another significant application area, with companies like Intel and NVIDIA employing topology optimization to design next-generation heat sinks for high-performance computing applications. Case studies from data center implementations show cooling efficiency improvements of 22-35% through optimized heat sink geometries that maximize surface area while minimizing fluid flow resistance. These designs have been instrumental in managing the increasing thermal loads associated with artificial intelligence computing infrastructure.

The automotive sector has similarly benefited, with Formula 1 racing teams pioneering the application of topology optimization for brake cooling systems and engine components. Mercedes-AMG F1 team reported a 12% improvement in thermal management efficiency through optimized cooling channel designs, which translated to measurable performance advantages during high-temperature race conditions. These innovations have gradually transferred to production vehicles, with BMW implementing topology-optimized heat exchangers in their electric vehicle platforms, reducing cooling system weight by 18% while improving thermal efficiency by 9%.

In the power generation industry, General Electric has applied these techniques to gas turbine blade design, creating internal cooling structures that withstand extreme temperature gradients while minimizing material usage. Their case study demonstrated a 25% increase in component lifespan and a 7% improvement in operational efficiency under high-temperature conditions. The optimized designs reduced thermal stress concentrations by distributing heat loads more effectively throughout the component structure.

Defense applications have shown perhaps the most dramatic results, with Lockheed Martin utilizing topology optimization for hypersonic vehicle thermal protection systems. Their implementation resulted in designs capable of withstanding temperatures exceeding 2000°C while reducing shield weight by 30% compared to conventional approaches. These advancements have been critical in enabling sustained hypersonic flight capabilities.

Electronics cooling represents another significant application area, with companies like Intel and NVIDIA employing topology optimization to design next-generation heat sinks for high-performance computing applications. Case studies from data center implementations show cooling efficiency improvements of 22-35% through optimized heat sink geometries that maximize surface area while minimizing fluid flow resistance. These designs have been instrumental in managing the increasing thermal loads associated with artificial intelligence computing infrastructure.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!