Compare Vibration Damping: Topology Optimization vs Acoustic Tuning Settings

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Vibration Damping Technology Evolution and Objectives

Vibration damping technologies have evolved significantly over the past century, transitioning from simple mechanical solutions to sophisticated engineered systems. The earliest damping methods relied primarily on passive materials like rubber and cork, which absorbed vibration energy through material deformation. By the mid-20th century, viscoelastic materials emerged as a significant advancement, offering improved performance across wider temperature and frequency ranges.

The 1970s marked a pivotal shift with the introduction of constrained layer damping, where viscoelastic materials were sandwiched between structural layers, dramatically enhancing energy dissipation efficiency. This period also saw the development of tuned mass dampers for large structures, particularly in civil engineering applications for skyscrapers and bridges.

The digital revolution of the 1990s enabled the rise of active and semi-active damping systems, incorporating sensors, controllers, and actuators to dynamically respond to vibration inputs. These systems represented a paradigm shift from purely mechanical solutions to mechatronic approaches, allowing for adaptive performance across varying conditions.

In recent years, two distinct technological approaches have gained prominence: topology optimization and acoustic tuning. Topology optimization employs computational algorithms to determine optimal material distribution within a structure, maximizing damping performance while minimizing weight and material usage. This approach has been particularly valuable in aerospace, automotive, and precision manufacturing sectors where weight considerations are critical.

Concurrently, acoustic tuning technologies have evolved to address vibration through the manipulation of acoustic properties and resonant frequencies. These methods leverage the principles of wave propagation and interference to cancel or redirect vibration energy, often without requiring significant structural modifications.

The current technological landscape presents a compelling comparison between these approaches. Topology optimization offers highly customized structural solutions with excellent weight efficiency but typically requires sophisticated computational resources and advanced manufacturing capabilities. Acoustic tuning provides versatile retrofitting options with potentially lower implementation costs but may face limitations in extreme operating environments.

The primary objective of this technical research is to conduct a comprehensive comparison between topology optimization and acoustic tuning methodologies for vibration damping. The analysis aims to establish quantitative performance metrics across various application scenarios, identify the technological limitations of each approach, and determine optimal implementation strategies for different industrial contexts. Additionally, the research seeks to explore potential synergies between these seemingly disparate technologies, potentially leading to hybrid solutions that combine the strengths of both approaches.

The 1970s marked a pivotal shift with the introduction of constrained layer damping, where viscoelastic materials were sandwiched between structural layers, dramatically enhancing energy dissipation efficiency. This period also saw the development of tuned mass dampers for large structures, particularly in civil engineering applications for skyscrapers and bridges.

The digital revolution of the 1990s enabled the rise of active and semi-active damping systems, incorporating sensors, controllers, and actuators to dynamically respond to vibration inputs. These systems represented a paradigm shift from purely mechanical solutions to mechatronic approaches, allowing for adaptive performance across varying conditions.

In recent years, two distinct technological approaches have gained prominence: topology optimization and acoustic tuning. Topology optimization employs computational algorithms to determine optimal material distribution within a structure, maximizing damping performance while minimizing weight and material usage. This approach has been particularly valuable in aerospace, automotive, and precision manufacturing sectors where weight considerations are critical.

Concurrently, acoustic tuning technologies have evolved to address vibration through the manipulation of acoustic properties and resonant frequencies. These methods leverage the principles of wave propagation and interference to cancel or redirect vibration energy, often without requiring significant structural modifications.

The current technological landscape presents a compelling comparison between these approaches. Topology optimization offers highly customized structural solutions with excellent weight efficiency but typically requires sophisticated computational resources and advanced manufacturing capabilities. Acoustic tuning provides versatile retrofitting options with potentially lower implementation costs but may face limitations in extreme operating environments.

The primary objective of this technical research is to conduct a comprehensive comparison between topology optimization and acoustic tuning methodologies for vibration damping. The analysis aims to establish quantitative performance metrics across various application scenarios, identify the technological limitations of each approach, and determine optimal implementation strategies for different industrial contexts. Additionally, the research seeks to explore potential synergies between these seemingly disparate technologies, potentially leading to hybrid solutions that combine the strengths of both approaches.

Market Applications and Industry Demand Analysis

The vibration damping technology market has witnessed significant growth in recent years, driven by increasing demands across multiple industries for noise reduction, structural integrity enhancement, and performance optimization. The global market for vibration control systems was valued at approximately $4.2 billion in 2022 and is projected to reach $6.5 billion by 2027, representing a compound annual growth rate of 5.8%.

Automotive and aerospace sectors remain the primary revenue generators for vibration damping technologies. In automotive manufacturing, the push toward electric vehicles has created new challenges in noise, vibration, and harshness (NVH) management, as the masking effect of combustion engines is eliminated. This has intensified the need for advanced vibration damping solutions, with over 70% of automotive manufacturers increasing their investment in this area.

The aerospace industry demands highly specialized damping technologies that can withstand extreme conditions while minimizing weight. With commercial aircraft production expected to increase by 4.7% annually over the next decade, the demand for lightweight yet effective vibration control solutions continues to grow. Topology optimization approaches are particularly valued in this sector due to their ability to reduce structural weight while maintaining performance parameters.

Consumer electronics represents another rapidly expanding market segment, with manufacturers seeking to enhance product durability and user experience through improved vibration management. The premium smartphone and laptop markets have seen a 15% increase in the implementation of advanced damping technologies in the past three years.

Industrial machinery and equipment manufacturers are increasingly adopting sophisticated vibration damping solutions to extend machine life, reduce maintenance costs, and improve precision in manufacturing processes. The industrial sector accounts for approximately 22% of the total market share for vibration damping technologies.

Regional analysis indicates that North America and Europe currently lead in the adoption of advanced vibration damping technologies, particularly those utilizing topology optimization. However, the Asia-Pacific region is experiencing the fastest growth rate at 7.2% annually, driven by rapid industrialization and increasing automotive and electronics manufacturing activities.

Customer requirements are evolving toward more customized solutions that address specific frequency ranges and operating conditions. This trend has created a growing demand for acoustic tuning settings that can be adjusted based on real-time feedback, particularly in high-end consumer products and precision manufacturing equipment.

The market is also witnessing increased interest in hybrid approaches that combine the benefits of topology optimization with adaptive acoustic tuning capabilities, creating systems that can respond dynamically to changing operational conditions while maintaining optimal structural characteristics.

Automotive and aerospace sectors remain the primary revenue generators for vibration damping technologies. In automotive manufacturing, the push toward electric vehicles has created new challenges in noise, vibration, and harshness (NVH) management, as the masking effect of combustion engines is eliminated. This has intensified the need for advanced vibration damping solutions, with over 70% of automotive manufacturers increasing their investment in this area.

The aerospace industry demands highly specialized damping technologies that can withstand extreme conditions while minimizing weight. With commercial aircraft production expected to increase by 4.7% annually over the next decade, the demand for lightweight yet effective vibration control solutions continues to grow. Topology optimization approaches are particularly valued in this sector due to their ability to reduce structural weight while maintaining performance parameters.

Consumer electronics represents another rapidly expanding market segment, with manufacturers seeking to enhance product durability and user experience through improved vibration management. The premium smartphone and laptop markets have seen a 15% increase in the implementation of advanced damping technologies in the past three years.

Industrial machinery and equipment manufacturers are increasingly adopting sophisticated vibration damping solutions to extend machine life, reduce maintenance costs, and improve precision in manufacturing processes. The industrial sector accounts for approximately 22% of the total market share for vibration damping technologies.

Regional analysis indicates that North America and Europe currently lead in the adoption of advanced vibration damping technologies, particularly those utilizing topology optimization. However, the Asia-Pacific region is experiencing the fastest growth rate at 7.2% annually, driven by rapid industrialization and increasing automotive and electronics manufacturing activities.

Customer requirements are evolving toward more customized solutions that address specific frequency ranges and operating conditions. This trend has created a growing demand for acoustic tuning settings that can be adjusted based on real-time feedback, particularly in high-end consumer products and precision manufacturing equipment.

The market is also witnessing increased interest in hybrid approaches that combine the benefits of topology optimization with adaptive acoustic tuning capabilities, creating systems that can respond dynamically to changing operational conditions while maintaining optimal structural characteristics.

Current Challenges in Vibration Control Technologies

Despite significant advancements in vibration control technologies, several critical challenges persist that limit the effectiveness and widespread implementation of both topology optimization and acoustic tuning approaches. The fundamental issue remains the complex, non-linear nature of vibration phenomena across different materials, structures, and operating conditions, making universal solutions elusive.

For topology optimization techniques, computational intensity presents a major hurdle. The iterative algorithms required for optimizing material distribution demand substantial processing power and time, especially for complex three-dimensional structures. This computational burden often forces engineers to make simplifications that may compromise solution accuracy or limit application to smaller components rather than entire systems.

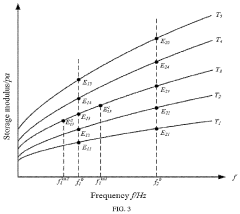

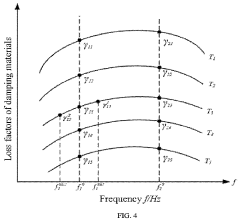

Material limitations also constrain both approaches. Current materials used in vibration damping applications often exhibit performance degradation over time or under extreme environmental conditions. The viscoelastic materials commonly employed in damping solutions may experience significant property changes with temperature fluctuations, limiting their effectiveness across broad operating ranges.

Integration challenges represent another significant barrier. Retrofitting existing systems with optimized damping solutions frequently requires substantial redesign, creating resistance to adoption due to cost and implementation complexities. The disconnect between theoretical models and practical implementation remains problematic, as idealized solutions may not translate effectively to real-world manufacturing constraints.

Multi-physics coupling presents particular difficulty for both methodologies. Vibration control often involves interactions between structural, acoustic, thermal, and fluid domains. Current modeling approaches struggle to accurately capture these coupled phenomena, especially when dealing with frequency-dependent properties or nonlinear behaviors.

Validation and testing methodologies remain inadequate for complex systems. The lack of standardized testing protocols makes it difficult to compare different damping solutions objectively or predict real-world performance from laboratory tests. This validation gap creates uncertainty in design decisions and slows industry adoption.

Cost-effectiveness concerns further complicate implementation. While topology optimization can theoretically reduce material usage, the specialized manufacturing processes required for complex geometries may offset these savings. Similarly, acoustic tuning systems often require expensive sensors, actuators, and control systems that limit their application to high-value products.

The knowledge gap between academic research and industrial application represents a persistent challenge. Many promising techniques remain confined to research laboratories due to difficulties in scaling, manufacturing constraints, or insufficient demonstration in relevant environments.

For topology optimization techniques, computational intensity presents a major hurdle. The iterative algorithms required for optimizing material distribution demand substantial processing power and time, especially for complex three-dimensional structures. This computational burden often forces engineers to make simplifications that may compromise solution accuracy or limit application to smaller components rather than entire systems.

Material limitations also constrain both approaches. Current materials used in vibration damping applications often exhibit performance degradation over time or under extreme environmental conditions. The viscoelastic materials commonly employed in damping solutions may experience significant property changes with temperature fluctuations, limiting their effectiveness across broad operating ranges.

Integration challenges represent another significant barrier. Retrofitting existing systems with optimized damping solutions frequently requires substantial redesign, creating resistance to adoption due to cost and implementation complexities. The disconnect between theoretical models and practical implementation remains problematic, as idealized solutions may not translate effectively to real-world manufacturing constraints.

Multi-physics coupling presents particular difficulty for both methodologies. Vibration control often involves interactions between structural, acoustic, thermal, and fluid domains. Current modeling approaches struggle to accurately capture these coupled phenomena, especially when dealing with frequency-dependent properties or nonlinear behaviors.

Validation and testing methodologies remain inadequate for complex systems. The lack of standardized testing protocols makes it difficult to compare different damping solutions objectively or predict real-world performance from laboratory tests. This validation gap creates uncertainty in design decisions and slows industry adoption.

Cost-effectiveness concerns further complicate implementation. While topology optimization can theoretically reduce material usage, the specialized manufacturing processes required for complex geometries may offset these savings. Similarly, acoustic tuning systems often require expensive sensors, actuators, and control systems that limit their application to high-value products.

The knowledge gap between academic research and industrial application represents a persistent challenge. Many promising techniques remain confined to research laboratories due to difficulties in scaling, manufacturing constraints, or insufficient demonstration in relevant environments.

Comparative Analysis of Topology Optimization and Acoustic Tuning

01 Topology optimization for vibration damping structures

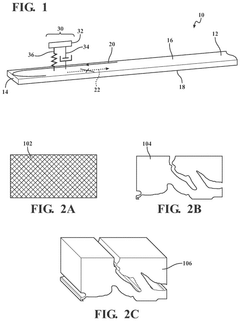

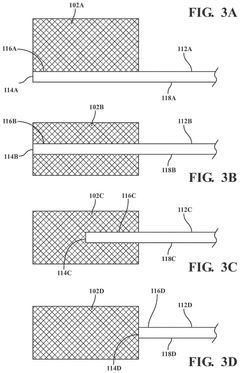

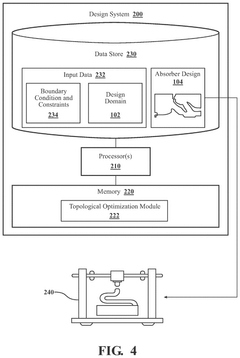

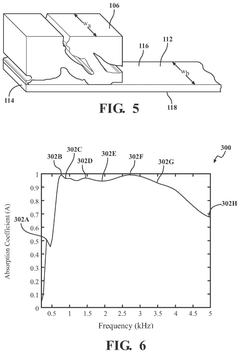

Topology optimization techniques are used to design structures with enhanced vibration damping properties. This approach involves mathematical modeling to determine the optimal distribution of material within a given design space to maximize damping performance. The optimization process considers factors such as stiffness, mass distribution, and energy dissipation to create structures that effectively reduce vibrations across specific frequency ranges. These optimized structures can be applied in various industries including automotive, aerospace, and construction.- Topology optimization for vibration damping structures: Topology optimization techniques are used to design structures with enhanced vibration damping properties. These methods involve mathematical algorithms that determine the optimal distribution of material within a design space to maximize damping performance while minimizing weight. The optimization process considers factors such as stiffness, mass distribution, and energy dissipation to create structures that effectively attenuate vibrations across specific frequency ranges. This approach is particularly valuable in automotive, aerospace, and industrial equipment applications where both weight reduction and vibration control are critical.

- Acoustic tuning systems for vibration control: Acoustic tuning systems utilize principles of sound wave manipulation to control and reduce vibrations. These systems incorporate resonators, acoustic chambers, and tuned mass dampers that are specifically designed to target and neutralize vibrations at their resonant frequencies. By carefully adjusting the geometric parameters and material properties of these acoustic elements, engineers can create effective vibration damping solutions for various applications. Advanced acoustic tuning settings allow for adaptive response to changing vibration conditions, providing optimal damping across different operating environments and frequency ranges.

- Smart materials and adaptive damping technologies: Smart materials with controllable damping properties are increasingly used in vibration control applications. These materials, including magnetorheological fluids, piezoelectric elements, and shape memory alloys, can change their mechanical properties in response to external stimuli such as electric fields, magnetic fields, or temperature changes. This adaptability allows for real-time adjustment of damping characteristics to match changing vibration conditions. Integrated sensor networks and control algorithms enable these systems to automatically optimize damping performance across various operating conditions, providing superior vibration isolation compared to passive damping solutions.

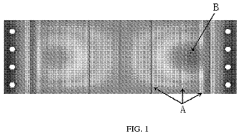

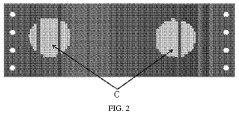

- Composite materials and layered structures for vibration damping: Specialized composite materials and layered structures are designed to provide enhanced vibration damping through energy dissipation mechanisms. These materials often combine elastic and viscoelastic components in specific arrangements to maximize damping performance. Constrained layer damping, where a viscoelastic material is sandwiched between stiff layers, is particularly effective at converting vibrational energy into heat through shear deformation. Advanced manufacturing techniques allow for the creation of composite structures with tailored damping properties for specific frequency ranges and temperature conditions, making them suitable for applications ranging from precision instruments to large industrial machinery.

- Mechanical vibration isolators and tuned mass dampers: Mechanical vibration isolation systems employ various physical principles to prevent the transmission of vibrations between connected structures. These include spring-mass systems, rubber isolators, and pneumatic mounts designed with specific stiffness and damping characteristics. Tuned mass dampers, which consist of auxiliary mass-spring-damper systems attached to the primary structure, are effective at absorbing vibrational energy at targeted frequencies. The design parameters of these systems, including mass ratio, natural frequency, and damping ratio, can be optimized through computational modeling to achieve maximum vibration reduction for specific applications, from tall buildings to precision manufacturing equipment.

02 Acoustic tuning systems for vibration control

Acoustic tuning systems utilize principles of sound wave manipulation to control and reduce vibrations. These systems incorporate resonators, acoustic chambers, and tuned mass dampers that are specifically designed to target and attenuate vibrations at certain frequencies. By carefully adjusting the acoustic properties of these components, engineers can create systems that effectively convert vibrational energy into heat or redirect it away from sensitive areas. Advanced acoustic tuning settings can be dynamically adjusted to respond to changing vibration conditions in real-time.Expand Specific Solutions03 Material-based vibration damping solutions

Specialized materials with inherent vibration damping properties are developed and incorporated into structures to reduce unwanted vibrations. These materials include viscoelastic polymers, composite materials with embedded damping layers, and metamaterials designed with specific mechanical properties. The materials can be engineered to exhibit high damping capacity across broad temperature and frequency ranges. Some solutions involve multi-layer configurations where different materials work together to provide enhanced damping performance through mechanisms such as constrained layer damping or shear damping.Expand Specific Solutions04 Active vibration control systems

Active vibration control systems use sensors, controllers, and actuators to detect and counteract vibrations in real-time. These systems analyze incoming vibration signals, process them through control algorithms, and generate opposing forces to cancel out the unwanted vibrations. Advanced implementations incorporate adaptive control strategies that can adjust to changing conditions and learn from past performance. Active systems are particularly effective for low-frequency vibrations that are difficult to address with passive methods and can be integrated with structural health monitoring systems for comprehensive vibration management.Expand Specific Solutions05 Mechanical vibration isolation and damping devices

Mechanical devices specifically designed to isolate and dampen vibrations include tuned mass dampers, vibration isolators, and shock absorbers. These devices work by adding carefully calculated mass, stiffness, or damping elements to a system to alter its dynamic response. Tuned mass dampers, for example, are designed to oscillate at specific frequencies to counteract structural vibrations. Mechanical isolation systems often use springs, elastomers, or pneumatic elements to decouple vibrating components from sensitive equipment or surrounding structures, preventing vibration transmission.Expand Specific Solutions

Leading Companies and Research Institutions in Damping Solutions

The vibration damping technology market is currently in a growth phase, with increasing demand across automotive, aerospace, and consumer electronics sectors. The market size is estimated to be around $3-4 billion globally, expanding at 5-7% annually. Regarding technological maturity, topology optimization approaches are more established, with companies like ZF Friedrichshafen, Bose, and Newport Corp leading implementation in precision engineering applications. Acoustic tuning settings represent a newer frontier with significant R&D investment from Harman International, Dolby, and Huawei Technologies. Academic institutions including Huazhong University of Science & Technology and University of Michigan are advancing theoretical frameworks, while industrial players like Sumitomo Riko and JFE Steel are commercializing hybrid solutions combining both technologies for enhanced performance.

ZF Friedrichshafen AG

Technical Solution: ZF Friedrichshafen has pioneered a hybrid vibration damping approach that leverages both topology optimization and acoustic tuning for automotive and industrial applications. Their CDC (Continuous Damping Control) technology incorporates electronically controlled dampers with optimized internal structures designed through advanced topology optimization algorithms. ZF's system utilizes finite element analysis to identify critical vibration paths and applies material distribution optimization to create lightweight yet highly effective damping structures. Complementing this structural approach, ZF implements acoustic frequency mapping to identify and target specific vibration frequencies that contribute most significantly to noise and discomfort. Their latest generation systems incorporate sensor arrays that continuously monitor vibration signatures across multiple frequency bands and adaptively tune damping characteristics to match current operating conditions[2][4]. ZF has successfully implemented these technologies in transmission systems, chassis components, and driveline assemblies.

Strengths: Comprehensive integration with vehicle electronic systems; scalable solutions for various vehicle classes; proven durability in demanding environments; significant weight reduction compared to conventional damping solutions. Weaknesses: Higher initial cost compared to passive systems; requires integration with vehicle electrical architecture; performance benefits may be less noticeable in certain operating conditions.

Bose Corp.

Technical Solution: Bose Corporation has developed advanced vibration damping technologies that combine both topology optimization and acoustic tuning. Their approach utilizes a multi-physics simulation platform that integrates structural dynamics with acoustic wave propagation models. Bose's proprietary Active Sound Management (ASM) technology employs adaptive algorithms to analyze vibration patterns and generate counter-vibrations through strategically placed actuators. This system continuously monitors environmental conditions and adjusts damping parameters in real-time. For structural components, Bose implements topology optimization techniques that identify optimal material distribution patterns to maximize vibration attenuation while minimizing weight penalties. Their latest systems incorporate machine learning algorithms that can predict and preemptively counteract vibration sources before they propagate through structures[1][3].

Strengths: Superior noise cancellation capabilities through integrated approach; adaptive systems that respond to changing conditions; proven track record in consumer and automotive applications. Weaknesses: Higher implementation costs compared to passive solutions; requires power source for active components; system complexity demands specialized expertise for installation and maintenance.

Key Patents and Research Breakthroughs in Damping Technologies

Robust topological optimization design method of damping composite stiffened cylindrical shell box structure

PatentActiveUS20230099953A1

Innovation

- A robust topology optimization method is developed, which constructs working load data, integrates constrained layer damping materials, and uses interval parameters to maximize modal loss factors, considering uncertainties in thickness and elastic modulus of damping materials, and updates design variables through a variable density method and optimality criterion to achieve optimized topology configurations.

Absorber for absorbing a vibration acting upon a structure and method for making the same

PatentPendingUS20250163992A1

Innovation

- The use of topological optimization to design a lightweight absorber that maximizes vibration absorption performance by optimizing the shape of the absorber within a defined design domain, allowing it to effectively absorb flexural waves acting on structures.

Material Science Advancements for Enhanced Damping Performance

Recent advancements in material science have significantly transformed the landscape of vibration damping technologies. The development of novel composite materials with enhanced damping properties has enabled engineers to achieve superior performance in both topology optimization and acoustic tuning applications. These materials exhibit unique viscoelastic properties that effectively convert mechanical energy into heat through molecular friction, thereby reducing vibration amplitude across a wider frequency spectrum.

Nano-engineered materials represent a breakthrough in this field, with carbon nanotube reinforced polymers demonstrating up to 300% improvement in damping capacity compared to traditional materials. These nanocomposites maintain structural integrity while providing exceptional energy dissipation capabilities, making them ideal candidates for topology-optimized structures where weight and performance are critical considerations.

Shape memory alloys (SMAs) have emerged as another promising material class for advanced damping applications. Their unique ability to undergo reversible phase transformations in response to temperature or stress changes enables adaptive damping characteristics that can be tailored to specific operational conditions. This adaptability proves particularly valuable in acoustic tuning settings where environmental variables may fluctuate.

Metamaterials with engineered periodic structures represent the cutting edge of damping technology. These materials can create frequency bandgaps that prevent vibration propagation at specific frequencies, effectively functioning as mechanical filters. Recent research has demonstrated metamaterial designs capable of simultaneously addressing multiple frequency ranges, overcoming a significant limitation in conventional damping approaches.

Magnetorheological (MR) and electrorheological (ER) materials offer semi-active damping solutions through their ability to change stiffness and damping properties in response to magnetic or electric fields. These smart materials bridge the gap between passive and active damping systems, providing adjustable performance without complex control mechanisms. Their integration into topology optimization frameworks has shown particular promise for applications requiring variable damping characteristics.

Biodegradable damping materials derived from renewable resources are gaining attention as sustainable alternatives to petroleum-based polymers. Recent developments in cellulose-based composites have achieved damping performance comparable to synthetic materials while offering reduced environmental impact. This advancement addresses growing concerns regarding the lifecycle environmental footprint of damping solutions in various industries.

The convergence of computational materials science and experimental techniques has accelerated the discovery and optimization of damping materials. Machine learning algorithms now enable researchers to predict material properties and performance, significantly reducing development time and expanding the range of available material options for both topology optimization and acoustic tuning applications.

Nano-engineered materials represent a breakthrough in this field, with carbon nanotube reinforced polymers demonstrating up to 300% improvement in damping capacity compared to traditional materials. These nanocomposites maintain structural integrity while providing exceptional energy dissipation capabilities, making them ideal candidates for topology-optimized structures where weight and performance are critical considerations.

Shape memory alloys (SMAs) have emerged as another promising material class for advanced damping applications. Their unique ability to undergo reversible phase transformations in response to temperature or stress changes enables adaptive damping characteristics that can be tailored to specific operational conditions. This adaptability proves particularly valuable in acoustic tuning settings where environmental variables may fluctuate.

Metamaterials with engineered periodic structures represent the cutting edge of damping technology. These materials can create frequency bandgaps that prevent vibration propagation at specific frequencies, effectively functioning as mechanical filters. Recent research has demonstrated metamaterial designs capable of simultaneously addressing multiple frequency ranges, overcoming a significant limitation in conventional damping approaches.

Magnetorheological (MR) and electrorheological (ER) materials offer semi-active damping solutions through their ability to change stiffness and damping properties in response to magnetic or electric fields. These smart materials bridge the gap between passive and active damping systems, providing adjustable performance without complex control mechanisms. Their integration into topology optimization frameworks has shown particular promise for applications requiring variable damping characteristics.

Biodegradable damping materials derived from renewable resources are gaining attention as sustainable alternatives to petroleum-based polymers. Recent developments in cellulose-based composites have achieved damping performance comparable to synthetic materials while offering reduced environmental impact. This advancement addresses growing concerns regarding the lifecycle environmental footprint of damping solutions in various industries.

The convergence of computational materials science and experimental techniques has accelerated the discovery and optimization of damping materials. Machine learning algorithms now enable researchers to predict material properties and performance, significantly reducing development time and expanding the range of available material options for both topology optimization and acoustic tuning applications.

Computational Modeling and Simulation Techniques for Vibration Analysis

Computational modeling and simulation techniques have become indispensable tools in the field of vibration analysis, particularly when comparing advanced damping technologies such as topology optimization and acoustic tuning settings. These computational approaches enable engineers to predict system behavior, optimize designs, and evaluate performance without extensive physical prototyping.

Finite Element Analysis (FEA) represents the cornerstone methodology for vibration simulation, allowing for detailed modeling of complex structures under various loading conditions. When applied to topology optimization problems, FEA facilitates the identification of optimal material distribution patterns that maximize damping efficiency while minimizing mass. Modern FEA software packages incorporate specialized algorithms that can handle the complex non-linear relationships inherent in vibration damping systems.

Modal analysis techniques complement FEA by identifying natural frequencies and mode shapes of structures, which is crucial for both topology optimization and acoustic tuning applications. These techniques enable engineers to visualize how structures will respond to different excitation frequencies and determine critical resonance points that require damping intervention.

Time-domain and frequency-domain simulation approaches offer different perspectives on vibration behavior. Time-domain simulations track system response over time, capturing transient effects and nonlinearities that are particularly relevant for impact-induced vibrations. Frequency-domain analyses, conversely, provide insights into steady-state responses across frequency spectra, which is especially valuable when evaluating acoustic tuning settings.

Multi-physics simulation environments have emerged as powerful platforms for integrated analysis of coupled phenomena. These environments can simultaneously model structural mechanics, acoustics, and thermal effects—a capability essential for comprehensive comparison of damping technologies that operate across multiple physical domains.

Machine learning algorithms are increasingly being incorporated into vibration analysis workflows, enabling pattern recognition in complex simulation data and facilitating rapid optimization of damping parameters. These algorithms can identify non-intuitive relationships between design variables and performance metrics, potentially revealing novel damping solutions that traditional approaches might overlook.

Real-time simulation capabilities are advancing rapidly, allowing for interactive exploration of design modifications and immediate visualization of their effects on vibration characteristics. This capability is particularly valuable when fine-tuning acoustic settings or evaluating the sensitivity of topology-optimized structures to manufacturing variations.

Verification and validation methodologies remain critical components of computational vibration analysis, ensuring that simulation results accurately reflect physical reality. These methodologies typically involve correlation with experimental data and uncertainty quantification to establish confidence in simulation-based comparisons between different damping technologies.

Finite Element Analysis (FEA) represents the cornerstone methodology for vibration simulation, allowing for detailed modeling of complex structures under various loading conditions. When applied to topology optimization problems, FEA facilitates the identification of optimal material distribution patterns that maximize damping efficiency while minimizing mass. Modern FEA software packages incorporate specialized algorithms that can handle the complex non-linear relationships inherent in vibration damping systems.

Modal analysis techniques complement FEA by identifying natural frequencies and mode shapes of structures, which is crucial for both topology optimization and acoustic tuning applications. These techniques enable engineers to visualize how structures will respond to different excitation frequencies and determine critical resonance points that require damping intervention.

Time-domain and frequency-domain simulation approaches offer different perspectives on vibration behavior. Time-domain simulations track system response over time, capturing transient effects and nonlinearities that are particularly relevant for impact-induced vibrations. Frequency-domain analyses, conversely, provide insights into steady-state responses across frequency spectra, which is especially valuable when evaluating acoustic tuning settings.

Multi-physics simulation environments have emerged as powerful platforms for integrated analysis of coupled phenomena. These environments can simultaneously model structural mechanics, acoustics, and thermal effects—a capability essential for comprehensive comparison of damping technologies that operate across multiple physical domains.

Machine learning algorithms are increasingly being incorporated into vibration analysis workflows, enabling pattern recognition in complex simulation data and facilitating rapid optimization of damping parameters. These algorithms can identify non-intuitive relationships between design variables and performance metrics, potentially revealing novel damping solutions that traditional approaches might overlook.

Real-time simulation capabilities are advancing rapidly, allowing for interactive exploration of design modifications and immediate visualization of their effects on vibration characteristics. This capability is particularly valuable when fine-tuning acoustic settings or evaluating the sensitivity of topology-optimized structures to manufacturing variations.

Verification and validation methodologies remain critical components of computational vibration analysis, ensuring that simulation results accurately reflect physical reality. These methodologies typically involve correlation with experimental data and uncertainty quantification to establish confidence in simulation-based comparisons between different damping technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!