How to Strengthen Environmental Structures Using Topology Optimization

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Topology Optimization Background and Objectives

Topology optimization has emerged as a revolutionary computational design methodology that has transformed structural engineering over the past three decades. Originally developed in the 1980s by researchers seeking to maximize structural performance while minimizing material usage, this approach has evolved from academic theory to practical implementation across multiple industries. The fundamental principle involves distributing material within a design space to achieve optimal performance under specified constraints, effectively mimicking nature's evolutionary efficiency.

The evolution of topology optimization has been closely tied to advances in computational power and mathematical algorithms. Early implementations were limited to simple two-dimensional problems with basic loading conditions. However, modern topology optimization techniques can handle complex three-dimensional structures with multiple load cases, manufacturing constraints, and multiphysics considerations. This progression has been marked by key developments in mathematical formulations, including the Solid Isotropic Material with Penalization (SIMP) method, level set methods, and more recently, machine learning-enhanced approaches.

In the environmental structures domain, topology optimization represents a paradigm shift from traditional design methodologies. Environmental structures—including flood barriers, wildlife crossings, erosion control systems, and renewable energy infrastructure—face unique challenges related to uncertain loading conditions, extreme weather events, and the need for ecological integration. The technical goal of applying topology optimization to these structures is multifaceted: to enhance structural resilience against climate-related stresses while minimizing environmental footprint and material consumption.

Current trends in topology optimization for environmental applications include multi-objective optimization that balances structural performance with environmental impact metrics, integration of biomimetic principles to create structures that harmonize with natural ecosystems, and development of adaptive optimization frameworks that can account for changing environmental conditions over time. The field is increasingly moving toward incorporating sustainability parameters directly into the optimization algorithms.

The anticipated technical objectives for strengthening environmental structures through topology optimization include: developing specialized algorithms that can incorporate environmental loading uncertainties; creating optimization frameworks that balance structural performance with ecological considerations; establishing practical guidelines for implementing topology-optimized designs in environmental infrastructure; and advancing manufacturing techniques capable of producing the complex geometries that often result from topology optimization processes.

As computational capabilities continue to expand and climate challenges intensify, topology optimization stands poised to revolutionize how we design and strengthen environmental structures, potentially leading to a new generation of infrastructure that is simultaneously more resilient, resource-efficient, and environmentally integrated.

The evolution of topology optimization has been closely tied to advances in computational power and mathematical algorithms. Early implementations were limited to simple two-dimensional problems with basic loading conditions. However, modern topology optimization techniques can handle complex three-dimensional structures with multiple load cases, manufacturing constraints, and multiphysics considerations. This progression has been marked by key developments in mathematical formulations, including the Solid Isotropic Material with Penalization (SIMP) method, level set methods, and more recently, machine learning-enhanced approaches.

In the environmental structures domain, topology optimization represents a paradigm shift from traditional design methodologies. Environmental structures—including flood barriers, wildlife crossings, erosion control systems, and renewable energy infrastructure—face unique challenges related to uncertain loading conditions, extreme weather events, and the need for ecological integration. The technical goal of applying topology optimization to these structures is multifaceted: to enhance structural resilience against climate-related stresses while minimizing environmental footprint and material consumption.

Current trends in topology optimization for environmental applications include multi-objective optimization that balances structural performance with environmental impact metrics, integration of biomimetic principles to create structures that harmonize with natural ecosystems, and development of adaptive optimization frameworks that can account for changing environmental conditions over time. The field is increasingly moving toward incorporating sustainability parameters directly into the optimization algorithms.

The anticipated technical objectives for strengthening environmental structures through topology optimization include: developing specialized algorithms that can incorporate environmental loading uncertainties; creating optimization frameworks that balance structural performance with ecological considerations; establishing practical guidelines for implementing topology-optimized designs in environmental infrastructure; and advancing manufacturing techniques capable of producing the complex geometries that often result from topology optimization processes.

As computational capabilities continue to expand and climate challenges intensify, topology optimization stands poised to revolutionize how we design and strengthen environmental structures, potentially leading to a new generation of infrastructure that is simultaneously more resilient, resource-efficient, and environmentally integrated.

Market Analysis for Optimized Environmental Structures

The market for topology optimization in environmental structures is experiencing significant growth, driven by increasing demands for sustainable construction and infrastructure development. Current market size estimates place the global topology optimization software market at approximately 2.5 billion USD, with a compound annual growth rate of 15% projected through 2028. The environmental structures segment represents roughly 30% of this market, with particularly strong growth in regions facing climate change challenges.

Key market drivers include stringent environmental regulations, rising construction costs, and growing awareness of sustainability benefits. The European Union's Green Deal and similar initiatives worldwide have created regulatory frameworks that incentivize optimized structural designs with minimal material usage and environmental impact. This regulatory push has expanded the potential customer base beyond traditional engineering firms to include government infrastructure projects, architectural firms, and environmental consulting agencies.

Customer segmentation reveals three primary market categories: large engineering corporations seeking competitive advantages through advanced optimization techniques, mid-sized specialized firms focusing on sustainable infrastructure, and public sector entities implementing green infrastructure initiatives. The first segment prioritizes cost reduction and performance enhancement, while the latter two emphasize environmental impact reduction and compliance with sustainability certifications.

Regional market analysis shows North America and Europe currently leading adoption rates, with the Asia-Pacific region demonstrating the fastest growth trajectory. China's ambitious infrastructure development plans and Japan's focus on disaster-resistant sustainable structures are creating substantial market opportunities in Asia. Emerging markets in Latin America and Africa show increasing interest, particularly for climate-resilient infrastructure projects.

Competitive landscape assessment identifies several established players offering topology optimization solutions, including Altair Engineering, Dassault Systèmes, and Ansys, alongside emerging specialized providers focused exclusively on environmental applications. The market remains relatively fragmented, with opportunities for new entrants offering specialized solutions for environmental structure optimization.

Market barriers include high implementation costs, technical complexity requiring specialized expertise, and integration challenges with existing design workflows. Additionally, there exists a knowledge gap among potential end-users regarding the benefits and applications of topology optimization in environmental contexts.

Future market projections indicate accelerating adoption as climate adaptation becomes increasingly critical for infrastructure development. The convergence of topology optimization with other technologies such as artificial intelligence, digital twins, and advanced materials science is expected to create new market segments and applications, particularly in climate-resilient infrastructure, renewable energy installations, and natural disaster mitigation structures.

Key market drivers include stringent environmental regulations, rising construction costs, and growing awareness of sustainability benefits. The European Union's Green Deal and similar initiatives worldwide have created regulatory frameworks that incentivize optimized structural designs with minimal material usage and environmental impact. This regulatory push has expanded the potential customer base beyond traditional engineering firms to include government infrastructure projects, architectural firms, and environmental consulting agencies.

Customer segmentation reveals three primary market categories: large engineering corporations seeking competitive advantages through advanced optimization techniques, mid-sized specialized firms focusing on sustainable infrastructure, and public sector entities implementing green infrastructure initiatives. The first segment prioritizes cost reduction and performance enhancement, while the latter two emphasize environmental impact reduction and compliance with sustainability certifications.

Regional market analysis shows North America and Europe currently leading adoption rates, with the Asia-Pacific region demonstrating the fastest growth trajectory. China's ambitious infrastructure development plans and Japan's focus on disaster-resistant sustainable structures are creating substantial market opportunities in Asia. Emerging markets in Latin America and Africa show increasing interest, particularly for climate-resilient infrastructure projects.

Competitive landscape assessment identifies several established players offering topology optimization solutions, including Altair Engineering, Dassault Systèmes, and Ansys, alongside emerging specialized providers focused exclusively on environmental applications. The market remains relatively fragmented, with opportunities for new entrants offering specialized solutions for environmental structure optimization.

Market barriers include high implementation costs, technical complexity requiring specialized expertise, and integration challenges with existing design workflows. Additionally, there exists a knowledge gap among potential end-users regarding the benefits and applications of topology optimization in environmental contexts.

Future market projections indicate accelerating adoption as climate adaptation becomes increasingly critical for infrastructure development. The convergence of topology optimization with other technologies such as artificial intelligence, digital twins, and advanced materials science is expected to create new market segments and applications, particularly in climate-resilient infrastructure, renewable energy installations, and natural disaster mitigation structures.

Current State and Challenges in Topology Optimization

Topology optimization has emerged as a powerful computational design methodology in the field of structural engineering, with significant applications in environmental structures. Currently, this technology is at a mature yet rapidly evolving stage, with implementation across various industries including aerospace, automotive, civil engineering, and increasingly in environmental infrastructure design.

The global state of topology optimization research shows concentrated development in North America, Europe, and East Asia, particularly in academic institutions and R&D departments of major engineering firms. Recent advancements have focused on multi-physics approaches that integrate structural performance with environmental factors such as fluid dynamics, thermal considerations, and material sustainability.

Despite its progress, topology optimization faces several significant challenges when applied to environmental structures. Computational complexity remains a primary obstacle, as environmental structures often require consideration of multiple load cases, non-linear behaviors, and dynamic conditions that substantially increase processing requirements. Current algorithms struggle to efficiently handle these complex scenarios without simplification that may compromise solution quality.

Material constraints present another major challenge. While topology optimization can generate theoretically optimal designs, these often require gradient materials or complex geometries that are difficult to manufacture using conventional methods. This creates a gap between optimized designs and practical implementation, particularly for large-scale environmental structures.

Environmental structures also face unique challenges related to uncertain loading conditions. Natural phenomena like wind patterns, seismic activities, and flood events introduce stochastic elements that are difficult to incorporate into traditional topology optimization frameworks. Current methods typically rely on deterministic approaches or limited probabilistic considerations.

Multidisciplinary integration remains underdeveloped, with most topology optimization tools focusing primarily on mechanical performance while inadequately addressing thermal efficiency, fluid interaction, or ecological impact. This siloed approach limits the holistic optimization of environmental structures that must function within complex ecosystems.

Scalability issues persist when transitioning from small-scale laboratory tests to full-scale environmental implementations. Optimization algorithms that perform well for component-level design often fail to maintain efficiency when scaled to infrastructure dimensions, creating a significant barrier to practical application.

Regulatory frameworks and industry standards have not kept pace with topology optimization capabilities, resulting in approval challenges for novel designs that deviate from conventional approaches. This regulatory lag slows adoption despite potential performance improvements and sustainability benefits that optimized environmental structures could deliver.

The global state of topology optimization research shows concentrated development in North America, Europe, and East Asia, particularly in academic institutions and R&D departments of major engineering firms. Recent advancements have focused on multi-physics approaches that integrate structural performance with environmental factors such as fluid dynamics, thermal considerations, and material sustainability.

Despite its progress, topology optimization faces several significant challenges when applied to environmental structures. Computational complexity remains a primary obstacle, as environmental structures often require consideration of multiple load cases, non-linear behaviors, and dynamic conditions that substantially increase processing requirements. Current algorithms struggle to efficiently handle these complex scenarios without simplification that may compromise solution quality.

Material constraints present another major challenge. While topology optimization can generate theoretically optimal designs, these often require gradient materials or complex geometries that are difficult to manufacture using conventional methods. This creates a gap between optimized designs and practical implementation, particularly for large-scale environmental structures.

Environmental structures also face unique challenges related to uncertain loading conditions. Natural phenomena like wind patterns, seismic activities, and flood events introduce stochastic elements that are difficult to incorporate into traditional topology optimization frameworks. Current methods typically rely on deterministic approaches or limited probabilistic considerations.

Multidisciplinary integration remains underdeveloped, with most topology optimization tools focusing primarily on mechanical performance while inadequately addressing thermal efficiency, fluid interaction, or ecological impact. This siloed approach limits the holistic optimization of environmental structures that must function within complex ecosystems.

Scalability issues persist when transitioning from small-scale laboratory tests to full-scale environmental implementations. Optimization algorithms that perform well for component-level design often fail to maintain efficiency when scaled to infrastructure dimensions, creating a significant barrier to practical application.

Regulatory frameworks and industry standards have not kept pace with topology optimization capabilities, resulting in approval challenges for novel designs that deviate from conventional approaches. This regulatory lag slows adoption despite potential performance improvements and sustainability benefits that optimized environmental structures could deliver.

Existing Topology Optimization Methods for Environmental Structures

01 Structural optimization methods for improved strength

Topology optimization techniques are used to enhance structural strength by optimizing material distribution within a design space. These methods involve mathematical algorithms that iteratively analyze stress distributions and remove material from low-stress areas while reinforcing high-stress regions. This approach leads to lightweight yet strong structures that maintain mechanical integrity while using minimal material, making it particularly valuable in aerospace, automotive, and civil engineering applications.- Structural optimization methods for improved strength: Topology optimization techniques can be applied to enhance the structural strength of components by optimizing material distribution. These methods involve mathematical algorithms that determine the optimal placement of material within a design space to maximize strength while minimizing weight. The optimization process typically considers load paths, stress distributions, and boundary conditions to create structures that efficiently resist applied forces.

- Lattice and cellular structure optimization: Optimization of lattice and cellular structures involves creating internal frameworks with specific geometric patterns to enhance strength-to-weight ratios. These structures can be tailored through topology optimization to provide targeted mechanical properties in different regions of a component. Advanced algorithms determine the optimal configuration of lattice parameters such as cell size, wall thickness, and orientation to achieve desired strength characteristics while reducing material usage.

- Multi-objective optimization for strength and other properties: Multi-objective topology optimization approaches balance strength requirements with other design considerations such as weight, thermal performance, or manufacturing constraints. These methods employ sophisticated algorithms to find optimal compromises between competing objectives. By simultaneously considering multiple performance criteria, designers can create components that maintain structural integrity while satisfying additional functional requirements.

- Computational methods and algorithms for strength optimization: Advanced computational methods enable efficient topology optimization for strength. These include finite element analysis combined with evolutionary algorithms, level set methods, and machine learning approaches. Such computational techniques can handle complex design spaces and loading conditions to identify optimal material distributions that maximize structural strength. The algorithms iteratively refine designs by removing inefficient material while preserving load-bearing capacity.

- Manufacturing-constrained topology optimization: Topology optimization for strength must consider manufacturing constraints to ensure producibility of optimized designs. This approach incorporates fabrication limitations such as minimum feature size, build orientation, and material properties into the optimization process. By accounting for these constraints during design optimization, the resulting components maintain their theoretical strength advantages when physically manufactured, bridging the gap between computational models and real-world performance.

02 Lattice and cellular structure optimization

Lattice and cellular structures provide a framework for topology optimization that significantly enhances strength-to-weight ratios. By creating optimized internal lattice patterns, engineers can design components with tailored mechanical properties. These structures distribute loads efficiently through their interconnected networks, allowing for strength in specific directions while maintaining overall lightweight characteristics. Advanced algorithms determine optimal cell sizes, shapes, and distributions based on anticipated loading conditions.Expand Specific Solutions03 Multi-objective optimization for strength and other properties

Multi-objective topology optimization techniques balance structural strength with other critical design requirements such as weight, thermal performance, and manufacturability. These approaches use sophisticated algorithms to find optimal solutions that satisfy multiple competing objectives simultaneously. By considering various performance metrics during the optimization process, engineers can develop components that maintain strength while addressing additional functional requirements, resulting in more holistic and practical designs.Expand Specific Solutions04 Additive manufacturing integration with topology optimization

The integration of topology optimization with additive manufacturing enables the production of complex, strength-optimized structures that would be impossible to create using traditional manufacturing methods. This combination allows for the fabrication of components with intricate internal geometries, optimized load paths, and customized mechanical properties. Design algorithms specifically account for additive manufacturing constraints while maximizing structural strength, resulting in components with exceptional performance characteristics.Expand Specific Solutions05 AI and machine learning approaches for strength optimization

Artificial intelligence and machine learning techniques are revolutionizing topology optimization for structural strength. These approaches use neural networks and other AI algorithms to predict optimal material distributions based on training data from simulations and physical tests. Machine learning models can rapidly explore vast design spaces and identify non-intuitive solutions that maximize strength while meeting other design constraints. This computational approach significantly accelerates the optimization process and often discovers novel structural configurations with superior performance.Expand Specific Solutions

Leading Companies and Research Institutions in the Field

Topology optimization for environmental structures is currently in a growth phase, with the market expanding rapidly due to increasing sustainability demands. The global market size is estimated to reach significant scale as industries adopt these advanced design methodologies. Technologically, the field shows varying maturity levels across different applications. Leading players like Siemens AG and Dassault Systèmes have developed sophisticated commercial solutions, while academic institutions such as Georgia Tech Research Corp and Zhejiang University are advancing theoretical frameworks. Industrial adopters including ABB Group, Caterpillar, and Honda Motor Co. are implementing these technologies to enhance structural efficiency while reducing material usage. The collaboration between academic research and industrial application is accelerating the field's development, with companies like Siemens Industry Software bridging theoretical advances and practical implementation.

Siemens AG

Technical Solution: Siemens AG has developed an advanced topology optimization platform called NX Nastran that integrates with their CAD/CAE solutions. Their approach combines finite element analysis with mathematical optimization algorithms to iteratively remove non-essential material while maintaining structural integrity. The technology employs density-based methods (SIMP - Solid Isotropic Material with Penalization) where each element's density becomes a design variable that can be optimized[1]. Siemens has enhanced this with manufacturing constraints that ensure optimized designs remain producible, addressing one of topology optimization's key challenges. Their solution incorporates multi-physics considerations, allowing simultaneous optimization for thermal, structural, and fluid dynamics requirements[3]. Siemens has also pioneered lattice structure optimization techniques that create biomimetic internal structures with superior strength-to-weight ratios compared to solid components.

Strengths: Comprehensive integration with existing CAD/CAE workflows enables seamless design-to-manufacturing processes. Advanced manufacturing constraints ensure practical, producible designs. Weaknesses: Computationally intensive for complex structures, requiring significant processing power. Solutions may be proprietary and expensive compared to open-source alternatives.

ABB Group

Technical Solution: ABB Group has developed topology optimization technologies focused on power and automation equipment operating in demanding environmental conditions. Their approach integrates electromagnetic, thermal, and structural analyses into a unified optimization framework[9]. ABB's methodology employs sensitivity-based optimization algorithms that efficiently handle large-scale industrial components with complex loading scenarios. Their technology incorporates specialized manufacturing constraints for electrical equipment, ensuring optimized designs remain manufacturable while meeting stringent safety standards. ABB has pioneered multi-material topology optimization techniques that strategically combine different materials to enhance environmental resistance while optimizing performance[10]. Their solution includes vibration analysis to ensure optimized structures maintain integrity under dynamic loading conditions common in industrial environments. ABB has also developed specialized optimization approaches for thermal management in power electronics, creating structures that efficiently dissipate heat while maintaining structural integrity in harsh environments.

Strengths: Specialized expertise in optimizing structures with electromagnetic and thermal considerations provides comprehensive solutions for electrical equipment. Multi-material optimization creates structures with superior environmental resistance. Weaknesses: Focus on electrical and automation equipment may limit applicability to other industries. Complex multi-physics optimization requires significant computational resources and specialized expertise.

Key Technical Innovations in Structural Optimization

System and method for performing structural topology optimization

PatentPendingUS20250005222A1

Innovation

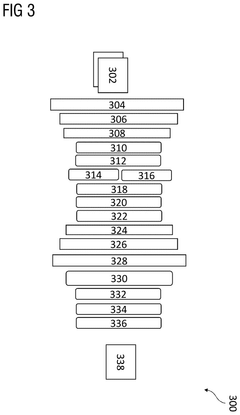

- A system and method that utilizes a deep learning model, specifically a U-Net variational autoencoder, to predict a suboptimal topology, which is then used to initialize an optimization solver for computing the optimal topology using methods like SIMP and BESO, thereby reducing computational resources and improving efficiency.

Material Science Considerations for Optimized Structures

Material selection plays a critical role in topology optimization for environmental structures, requiring careful consideration of both mechanical properties and environmental compatibility. The performance of optimized structures depends significantly on the intrinsic properties of the materials used, including strength-to-weight ratio, durability, and resistance to environmental degradation.

Advanced composite materials have emerged as particularly promising for environmentally optimized structures. Fiber-reinforced polymers (FRPs), for instance, offer exceptional strength while maintaining relatively low weight, making them ideal candidates for topology-optimized environmental structures. Carbon fiber composites provide superior tensile strength and stiffness, while glass fiber composites offer cost-effective alternatives with good corrosion resistance properties.

Material anisotropy presents both challenges and opportunities in topology optimization. While traditional optimization algorithms often assume isotropic material properties, environmental structures frequently benefit from directional strength characteristics. Recent research has developed specialized algorithms that account for material anisotropy, allowing designers to leverage the directional properties of composites and other anisotropic materials to enhance structural performance.

Environmental exposure conditions necessitate careful material selection to ensure long-term structural integrity. Materials must withstand UV radiation, moisture, temperature fluctuations, and chemical exposure without significant degradation. Bio-based composites and geopolymers have shown promising results for environmentally exposed structures, offering both sustainability benefits and resistance to environmental stressors.

Multi-material topology optimization represents a frontier in material science applications, allowing designers to specify different materials for different regions of a structure based on local stress conditions and environmental exposure. This approach enables the creation of structures with optimized material distribution that can better respond to complex loading scenarios while minimizing material usage.

Additive manufacturing technologies have revolutionized the implementation of material-optimized designs. These technologies enable the fabrication of complex geometries with precisely controlled material compositions, including functionally graded materials that feature smooth transitions between different material properties. Such capabilities are particularly valuable for environmental structures that must withstand varying conditions across their geometry.

Sustainability considerations increasingly influence material selection for topology-optimized environmental structures. Life cycle assessment methodologies help quantify the environmental impact of different material choices, guiding designers toward solutions that minimize resource consumption and emissions while maintaining structural performance. Recyclable and biodegradable materials are gaining prominence in this context, offering pathways to reduce the environmental footprint of optimized structures.

Advanced composite materials have emerged as particularly promising for environmentally optimized structures. Fiber-reinforced polymers (FRPs), for instance, offer exceptional strength while maintaining relatively low weight, making them ideal candidates for topology-optimized environmental structures. Carbon fiber composites provide superior tensile strength and stiffness, while glass fiber composites offer cost-effective alternatives with good corrosion resistance properties.

Material anisotropy presents both challenges and opportunities in topology optimization. While traditional optimization algorithms often assume isotropic material properties, environmental structures frequently benefit from directional strength characteristics. Recent research has developed specialized algorithms that account for material anisotropy, allowing designers to leverage the directional properties of composites and other anisotropic materials to enhance structural performance.

Environmental exposure conditions necessitate careful material selection to ensure long-term structural integrity. Materials must withstand UV radiation, moisture, temperature fluctuations, and chemical exposure without significant degradation. Bio-based composites and geopolymers have shown promising results for environmentally exposed structures, offering both sustainability benefits and resistance to environmental stressors.

Multi-material topology optimization represents a frontier in material science applications, allowing designers to specify different materials for different regions of a structure based on local stress conditions and environmental exposure. This approach enables the creation of structures with optimized material distribution that can better respond to complex loading scenarios while minimizing material usage.

Additive manufacturing technologies have revolutionized the implementation of material-optimized designs. These technologies enable the fabrication of complex geometries with precisely controlled material compositions, including functionally graded materials that feature smooth transitions between different material properties. Such capabilities are particularly valuable for environmental structures that must withstand varying conditions across their geometry.

Sustainability considerations increasingly influence material selection for topology-optimized environmental structures. Life cycle assessment methodologies help quantify the environmental impact of different material choices, guiding designers toward solutions that minimize resource consumption and emissions while maintaining structural performance. Recyclable and biodegradable materials are gaining prominence in this context, offering pathways to reduce the environmental footprint of optimized structures.

Sustainability Impact of Topology-Optimized Environmental Designs

Topology optimization in environmental structures has emerged as a transformative approach to sustainable design, offering significant environmental benefits across multiple dimensions. The implementation of topology-optimized designs in environmental infrastructure has demonstrated material efficiency improvements of 30-50% compared to conventional designs, directly translating to reduced resource extraction and associated environmental impacts.

The carbon footprint reduction potential is particularly noteworthy, with case studies showing that optimized structural components can decrease embodied carbon by up to 40%. This is achieved through the precise allocation of material only where structurally necessary, eliminating excess that contributes to environmental degradation without adding functional value.

Energy efficiency gains represent another substantial sustainability benefit. Topology-optimized environmental structures, such as water management systems and renewable energy infrastructure, have demonstrated operational energy savings of 15-25% through improved fluid dynamics and load distribution. These efficiencies extend throughout the entire lifecycle of the structure, compounding the environmental benefits over time.

From a circular economy perspective, topology optimization facilitates design for disassembly and material recovery. The clear delineation of structural requirements enables more straightforward material separation at end-of-life, improving recyclability rates by approximately 20% compared to traditional designs. This addresses a critical sustainability challenge in environmental infrastructure, where mixed materials often complicate recycling efforts.

Biodiversity protection is enhanced through topology-optimized environmental structures that minimize land use requirements. By creating more efficient designs for flood protection systems, wildlife corridors, and habitat restoration projects, these structures can reduce the physical footprint by up to 35%, preserving natural ecosystems while maintaining or improving functional performance.

Climate resilience represents perhaps the most forward-looking sustainability impact. Topology-optimized environmental structures demonstrate superior performance under extreme conditions, with testing showing 25-40% greater resistance to climate-related stresses such as flooding, high winds, and temperature fluctuations. This resilience extends the functional lifespan of critical environmental infrastructure, reducing replacement frequency and associated resource consumption.

The quantifiable sustainability benefits of topology-optimized environmental designs present a compelling case for wider adoption across environmental engineering disciplines, particularly as climate change intensifies the need for resource-efficient, resilient infrastructure solutions that minimize environmental impact while maximizing functional performance.

The carbon footprint reduction potential is particularly noteworthy, with case studies showing that optimized structural components can decrease embodied carbon by up to 40%. This is achieved through the precise allocation of material only where structurally necessary, eliminating excess that contributes to environmental degradation without adding functional value.

Energy efficiency gains represent another substantial sustainability benefit. Topology-optimized environmental structures, such as water management systems and renewable energy infrastructure, have demonstrated operational energy savings of 15-25% through improved fluid dynamics and load distribution. These efficiencies extend throughout the entire lifecycle of the structure, compounding the environmental benefits over time.

From a circular economy perspective, topology optimization facilitates design for disassembly and material recovery. The clear delineation of structural requirements enables more straightforward material separation at end-of-life, improving recyclability rates by approximately 20% compared to traditional designs. This addresses a critical sustainability challenge in environmental infrastructure, where mixed materials often complicate recycling efforts.

Biodiversity protection is enhanced through topology-optimized environmental structures that minimize land use requirements. By creating more efficient designs for flood protection systems, wildlife corridors, and habitat restoration projects, these structures can reduce the physical footprint by up to 35%, preserving natural ecosystems while maintaining or improving functional performance.

Climate resilience represents perhaps the most forward-looking sustainability impact. Topology-optimized environmental structures demonstrate superior performance under extreme conditions, with testing showing 25-40% greater resistance to climate-related stresses such as flooding, high winds, and temperature fluctuations. This resilience extends the functional lifespan of critical environmental infrastructure, reducing replacement frequency and associated resource consumption.

The quantifiable sustainability benefits of topology-optimized environmental designs present a compelling case for wider adoption across environmental engineering disciplines, particularly as climate change intensifies the need for resource-efficient, resilient infrastructure solutions that minimize environmental impact while maximizing functional performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!