How to Implement Design Innovations with Topology Optimization Techniques

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Topology Optimization Background and Objectives

Topology optimization has emerged as a revolutionary approach in engineering design, evolving from theoretical concepts in the 1980s to a practical design methodology widely adopted across industries today. This mathematical method determines the optimal material distribution within a defined design space, subject to specific constraints and performance objectives. The fundamental principle involves removing material from areas that contribute minimally to structural performance while maintaining material in high-stress regions, resulting in organic, efficient structures that would be difficult or impossible to conceive through traditional design approaches.

The evolution of topology optimization has been closely linked with advancements in computational capabilities. Early implementations were limited to simple 2D problems with basic loading conditions, but modern algorithms can handle complex 3D geometries with multiple load cases, manufacturing constraints, and multiphysics considerations. The development of commercial software packages like Altair OptiStruct, ANSYS Mechanical, and Siemens NX Topology Optimization has democratized access to these powerful tools, enabling broader industrial adoption.

Recent technological trends in topology optimization include integration with additive manufacturing processes, which has removed many traditional manufacturing constraints and allowed for the fabrication of complex geometries previously considered unbuildable. Additionally, machine learning approaches are being incorporated to accelerate optimization processes and predict optimal designs based on historical data, reducing computational requirements for complex problems.

The primary objective of implementing design innovations through topology optimization is to achieve performance improvements while reducing material usage and weight. This dual benefit addresses both economic considerations (reduced material costs, lower energy consumption) and environmental concerns (sustainability through material efficiency). In industries like aerospace and automotive, where weight directly impacts operational costs and emissions, topology optimization has become an essential tool for competitive design.

Another critical objective is to expand design possibilities beyond conventional thinking. By allowing algorithms to determine optimal material distribution based purely on performance criteria, designers can discover novel solutions that challenge traditional design paradigms. This computational creativity often results in biomimetic structures that resemble natural formations evolved over millions of years.

Looking forward, the field aims to develop more sophisticated algorithms capable of handling increasingly complex design problems with multiple competing objectives. Integration with other design methodologies, such as generative design and digital twins, represents a promising direction for creating comprehensive design ecosystems that leverage the strengths of each approach while mitigating limitations.

The evolution of topology optimization has been closely linked with advancements in computational capabilities. Early implementations were limited to simple 2D problems with basic loading conditions, but modern algorithms can handle complex 3D geometries with multiple load cases, manufacturing constraints, and multiphysics considerations. The development of commercial software packages like Altair OptiStruct, ANSYS Mechanical, and Siemens NX Topology Optimization has democratized access to these powerful tools, enabling broader industrial adoption.

Recent technological trends in topology optimization include integration with additive manufacturing processes, which has removed many traditional manufacturing constraints and allowed for the fabrication of complex geometries previously considered unbuildable. Additionally, machine learning approaches are being incorporated to accelerate optimization processes and predict optimal designs based on historical data, reducing computational requirements for complex problems.

The primary objective of implementing design innovations through topology optimization is to achieve performance improvements while reducing material usage and weight. This dual benefit addresses both economic considerations (reduced material costs, lower energy consumption) and environmental concerns (sustainability through material efficiency). In industries like aerospace and automotive, where weight directly impacts operational costs and emissions, topology optimization has become an essential tool for competitive design.

Another critical objective is to expand design possibilities beyond conventional thinking. By allowing algorithms to determine optimal material distribution based purely on performance criteria, designers can discover novel solutions that challenge traditional design paradigms. This computational creativity often results in biomimetic structures that resemble natural formations evolved over millions of years.

Looking forward, the field aims to develop more sophisticated algorithms capable of handling increasingly complex design problems with multiple competing objectives. Integration with other design methodologies, such as generative design and digital twins, represents a promising direction for creating comprehensive design ecosystems that leverage the strengths of each approach while mitigating limitations.

Market Demand Analysis for Optimized Design Solutions

The global market for topology optimization solutions is experiencing robust growth, driven by increasing demand for lightweight, high-performance components across multiple industries. Current market valuations indicate the topology optimization software market exceeds $1.2 billion annually, with projected compound annual growth rates of 15-18% through 2028. This acceleration is primarily fueled by industries seeking to reduce material costs while maintaining or improving structural performance.

Aerospace and automotive sectors represent the largest market segments, collectively accounting for approximately 60% of topology optimization implementations. These industries face intense pressure to reduce weight for fuel efficiency and emissions compliance, while simultaneously improving safety and durability. For instance, major automotive manufacturers have reported weight reductions of 20-30% in structural components through topology optimization, translating to measurable fuel economy improvements.

The medical device industry has emerged as a rapidly expanding market for topology optimization, particularly in implant design and customized prosthetics. The ability to create patient-specific solutions with optimized mechanical properties has opened new commercial opportunities, with the medical segment growing at nearly 25% annually. Additive manufacturing capabilities have significantly expanded the commercial viability of these optimized designs.

Industrial equipment manufacturers represent another substantial market segment, seeking optimization solutions to reduce material costs and improve performance in machinery components. This sector values topology optimization for its ability to reduce vibration, improve thermal management, and extend component lifespan.

Market research indicates a significant gap between current implementation rates and potential adoption. Only 35-40% of eligible manufacturing companies currently utilize topology optimization in their design processes, suggesting substantial room for market expansion. Primary barriers to adoption include software complexity, integration challenges with existing CAD/CAM systems, and knowledge gaps among engineering teams.

Customer demand increasingly focuses on integrated solutions that combine topology optimization with other design tools and manufacturing processes. The highest market growth is observed in solutions offering seamless workflows from optimization to production, particularly those compatible with additive manufacturing technologies. Companies providing comprehensive training and implementation support alongside their optimization tools report 40% higher customer retention rates.

Regional analysis shows North America and Europe as the most mature markets, while Asia-Pacific represents the fastest-growing region with annual growth exceeding 20%. This growth is driven by rapid industrialization and significant investments in advanced manufacturing capabilities, particularly in China, Japan, and South Korea.

Aerospace and automotive sectors represent the largest market segments, collectively accounting for approximately 60% of topology optimization implementations. These industries face intense pressure to reduce weight for fuel efficiency and emissions compliance, while simultaneously improving safety and durability. For instance, major automotive manufacturers have reported weight reductions of 20-30% in structural components through topology optimization, translating to measurable fuel economy improvements.

The medical device industry has emerged as a rapidly expanding market for topology optimization, particularly in implant design and customized prosthetics. The ability to create patient-specific solutions with optimized mechanical properties has opened new commercial opportunities, with the medical segment growing at nearly 25% annually. Additive manufacturing capabilities have significantly expanded the commercial viability of these optimized designs.

Industrial equipment manufacturers represent another substantial market segment, seeking optimization solutions to reduce material costs and improve performance in machinery components. This sector values topology optimization for its ability to reduce vibration, improve thermal management, and extend component lifespan.

Market research indicates a significant gap between current implementation rates and potential adoption. Only 35-40% of eligible manufacturing companies currently utilize topology optimization in their design processes, suggesting substantial room for market expansion. Primary barriers to adoption include software complexity, integration challenges with existing CAD/CAM systems, and knowledge gaps among engineering teams.

Customer demand increasingly focuses on integrated solutions that combine topology optimization with other design tools and manufacturing processes. The highest market growth is observed in solutions offering seamless workflows from optimization to production, particularly those compatible with additive manufacturing technologies. Companies providing comprehensive training and implementation support alongside their optimization tools report 40% higher customer retention rates.

Regional analysis shows North America and Europe as the most mature markets, while Asia-Pacific represents the fastest-growing region with annual growth exceeding 20%. This growth is driven by rapid industrialization and significant investments in advanced manufacturing capabilities, particularly in China, Japan, and South Korea.

Current State and Challenges in Topology Optimization

Topology optimization has evolved significantly over the past three decades, transitioning from an academic concept to a practical industrial tool. Currently, the technology is widely implemented across various sectors including aerospace, automotive, and medical device manufacturing. The most prevalent methods include Solid Isotropic Material with Penalization (SIMP), level set methods, and evolutionary structural optimization (ESO/BESO). These approaches have demonstrated remarkable success in weight reduction while maintaining structural integrity, with some aerospace components achieving weight reductions of 30-50%.

Despite these advancements, topology optimization faces several significant challenges. Computational expense remains a major hurdle, particularly for complex 3D structures with multiple load cases. Even with high-performance computing resources, optimization of intricate components can require days or weeks of processing time, creating bottlenecks in design workflows. This computational burden often forces engineers to simplify models, potentially compromising solution quality.

Manufacturing constraints represent another substantial challenge. While topology optimization can generate theoretically optimal designs, these frequently include complex geometries that are difficult or impossible to produce using conventional manufacturing methods. Although additive manufacturing has alleviated some of these limitations, it introduces its own constraints related to build orientation, support structures, and material properties. The gap between optimized designs and manufacturable components remains problematic.

Multi-physics integration presents additional complexity. Real-world engineering problems rarely involve purely structural considerations; they often require simultaneous optimization across thermal, fluid dynamic, and electromagnetic domains. Current topology optimization frameworks struggle to efficiently handle these coupled physics problems, particularly when objectives conflict.

Verification and validation of topology-optimized designs pose further challenges. Traditional engineering validation approaches are often inadequate for the complex, organic geometries that emerge from topology optimization. This creates uncertainty in performance prediction and complicates regulatory approval processes in safety-critical applications.

Globally, research in topology optimization shows distinct regional characteristics. North American institutions focus heavily on aerospace and defense applications, while European research emphasizes automotive and sustainable design implementations. Asian research centers, particularly in China and South Korea, are advancing manufacturing-oriented optimization techniques. This geographical distribution of expertise creates both collaboration opportunities and competitive dynamics in the global technology landscape.

Despite these advancements, topology optimization faces several significant challenges. Computational expense remains a major hurdle, particularly for complex 3D structures with multiple load cases. Even with high-performance computing resources, optimization of intricate components can require days or weeks of processing time, creating bottlenecks in design workflows. This computational burden often forces engineers to simplify models, potentially compromising solution quality.

Manufacturing constraints represent another substantial challenge. While topology optimization can generate theoretically optimal designs, these frequently include complex geometries that are difficult or impossible to produce using conventional manufacturing methods. Although additive manufacturing has alleviated some of these limitations, it introduces its own constraints related to build orientation, support structures, and material properties. The gap between optimized designs and manufacturable components remains problematic.

Multi-physics integration presents additional complexity. Real-world engineering problems rarely involve purely structural considerations; they often require simultaneous optimization across thermal, fluid dynamic, and electromagnetic domains. Current topology optimization frameworks struggle to efficiently handle these coupled physics problems, particularly when objectives conflict.

Verification and validation of topology-optimized designs pose further challenges. Traditional engineering validation approaches are often inadequate for the complex, organic geometries that emerge from topology optimization. This creates uncertainty in performance prediction and complicates regulatory approval processes in safety-critical applications.

Globally, research in topology optimization shows distinct regional characteristics. North American institutions focus heavily on aerospace and defense applications, while European research emphasizes automotive and sustainable design implementations. Asian research centers, particularly in China and South Korea, are advancing manufacturing-oriented optimization techniques. This geographical distribution of expertise creates both collaboration opportunities and competitive dynamics in the global technology landscape.

Current Implementation Approaches and Algorithms

01 Generative design and AI-driven topology optimization

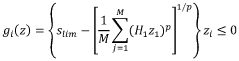

Advanced computational methods that leverage artificial intelligence and machine learning algorithms to generate optimal structural designs. These techniques can automatically explore design spaces, predict performance characteristics, and create innovative structures that would be difficult to conceive using traditional methods. The approach enables engineers to specify design constraints and objectives while the system generates multiple optimized design alternatives that meet specified criteria.- Generative design and AI-driven topology optimization: Advanced computational methods that leverage artificial intelligence and machine learning algorithms to generate optimal structural designs. These techniques can automatically explore design spaces, identify optimal material distributions, and create innovative structures that meet specific performance criteria while minimizing material usage. The AI-driven approaches can handle complex constraints and multiple objectives simultaneously, leading to designs that would be difficult to conceive using traditional methods.

- Multi-objective and constraint-based optimization techniques: Methodologies that simultaneously optimize multiple design objectives while satisfying various constraints. These techniques balance competing requirements such as weight reduction, structural strength, thermal performance, and manufacturing feasibility. By formulating the topology optimization problem with appropriate constraints and multiple objective functions, designers can achieve balanced solutions that represent optimal trade-offs between different performance metrics and practical limitations.

- Lattice and cellular structure optimization: Specialized topology optimization approaches focused on designing lightweight internal structures with periodic or variable cellular architectures. These techniques create optimized lattice structures that maintain mechanical performance while significantly reducing weight. The resulting designs often feature complex geometries with variable density distributions that would be impossible to manufacture using conventional methods but are well-suited for additive manufacturing processes.

- Manufacturing-aware topology optimization: Optimization methodologies that incorporate manufacturing constraints and considerations directly into the design process. These techniques ensure that the optimized designs can be practically manufactured using specific production methods such as additive manufacturing, injection molding, or traditional machining. By accounting for manufacturing limitations during the optimization process rather than as a post-processing step, these approaches produce designs that are both theoretically optimal and practically producible.

- Application-specific topology optimization frameworks: Specialized optimization frameworks developed for particular engineering domains or applications, such as heat transfer, fluid flow, electromagnetic performance, or specific industries like aerospace or automotive. These tailored approaches incorporate domain-specific physics, constraints, and performance metrics to generate optimized designs for particular use cases. The frameworks often include specialized algorithms and modeling techniques that address the unique challenges of specific applications.

02 Multi-objective and constraint-based optimization techniques

Methodologies that simultaneously consider multiple design objectives and constraints during the topology optimization process. These techniques balance competing factors such as weight reduction, structural strength, manufacturing feasibility, and cost efficiency. By incorporating various constraints like stress limitations, displacement boundaries, and manufacturing restrictions, these methods produce practical designs that satisfy real-world engineering requirements while achieving optimal performance across multiple criteria.Expand Specific Solutions03 Lattice and cellular structure optimization

Specialized topology optimization techniques focused on creating lightweight yet strong structures through the strategic placement of lattice and cellular geometries. These methods generate complex internal architectures with optimized density distributions, creating structures that maintain mechanical performance while significantly reducing material usage. The approach is particularly valuable for additive manufacturing applications where complex geometries can be produced without traditional manufacturing constraints.Expand Specific Solutions04 Manufacturing-aware topology optimization

Design methodologies that incorporate manufacturing constraints and capabilities directly into the topology optimization process. These techniques ensure that optimized designs can be practically manufactured using specific production methods such as additive manufacturing, casting, or machining. By considering factors like minimum feature size, build orientation, support structures, and material properties during the optimization process, these approaches bridge the gap between theoretical optimization and practical manufacturing.Expand Specific Solutions05 Dynamic and multiphysics topology optimization

Advanced optimization techniques that consider time-dependent behaviors and multiple physical phenomena simultaneously. These methods optimize structures for dynamic loading conditions, vibration characteristics, thermal performance, fluid-structure interactions, and other coupled physics problems. By accounting for complex real-world operating conditions beyond simple static mechanical loads, these approaches produce designs with superior performance across various physical domains and operating scenarios.Expand Specific Solutions

Leading Companies and Research Institutions in the Field

Topology optimization technology is currently in a growth phase, with increasing adoption across industries. The market is expanding rapidly, driven by demand for lightweight, efficient designs in automotive, aerospace, and manufacturing sectors. Technologically, the field is maturing with established players like Siemens, ANSYS, Altair Engineering, and Dassault Systèmes leading commercial software development. Academic institutions including Huazhong University of Science & Technology, University of Michigan, and Northwestern University contribute significant research advancements. The competitive landscape features software giants offering comprehensive solutions alongside specialized tools from engineering-focused companies like Autodesk. Honda, Toyota, and Caterpillar represent major industrial adopters implementing these techniques to achieve design innovations, weight reduction, and performance optimization in their products.

Siemens AG

Technical Solution: Siemens has pioneered an integrated topology optimization approach within their NX and Simcenter software environments. Their technology employs both the Solid Isotropic Material with Penalization (SIMP) method and level-set methods to generate optimized structures. Siemens' implementation is distinguished by its seamless CAD-to-optimization workflow that maintains parametric control throughout the process. Their solution incorporates advanced manufacturing constraints specifically tailored for additive manufacturing, including overhang angle restrictions, support structure minimization, and build direction optimization. Siemens has also developed specialized algorithms for lattice structure optimization that can create variable-density internal structures to balance weight, strength, and thermal properties. Their recent innovations include AI-assisted topology optimization that leverages machine learning to predict optimal starting points and reduce computational time by up to 40% compared to traditional methods. The platform also features unique capabilities for multi-material optimization, allowing designers to specify different materials across the design space.

Strengths: Exceptional CAD integration allowing for easier post-processing of optimized designs; comprehensive manufacturing constraints for various production methods; advanced lattice optimization capabilities. Weaknesses: Complex user interface with steep learning curve; requires significant computational resources; optimization setup can be time-consuming for complex multi-physics problems.

ANSYS, Inc.

Technical Solution: ANSYS has developed comprehensive topology optimization solutions integrated within their Mechanical and Discovery software suites. Their approach combines parametric optimization algorithms with advanced finite element analysis (FEA) to generate lightweight structures that meet specific performance criteria. ANSYS's implementation utilizes density-based methods where each element in the design space is assigned a relative density value between 0 (void) and 1 (solid), which is iteratively updated based on sensitivity analysis. Their technology incorporates manufacturing constraints such as minimum member size, symmetry requirements, and extrusion directions to ensure producibility. The platform also features multi-physics capabilities, allowing simultaneous optimization for structural, thermal, and fluid dynamics considerations, which is particularly valuable for aerospace and automotive applications where weight reduction must be balanced with thermal management and aerodynamic performance.

Strengths: Seamless integration with comprehensive simulation ecosystem; robust multi-physics capabilities; advanced manufacturing constraints implementation. Weaknesses: Computationally intensive for complex models; requires significant expertise to set up optimization problems effectively; licensing costs can be prohibitive for smaller organizations.

Key Technical Innovations and Patents in Topology Optimization

Topology optimization with local overhang constraints for 3D printing

PatentWO2021025906A1

Innovation

- A method to generate self-supporting CAD models by detecting and removing unsupported elements using directional kernels and local constraints, allowing for the direct printing of structures without additional support material by converting the optimized model into machine-executable instructions.

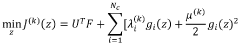

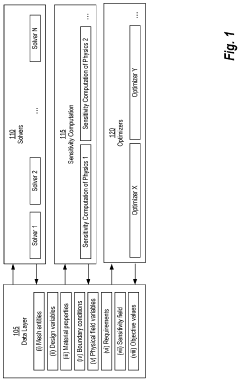

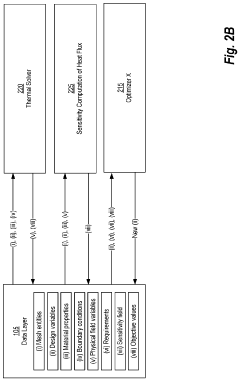

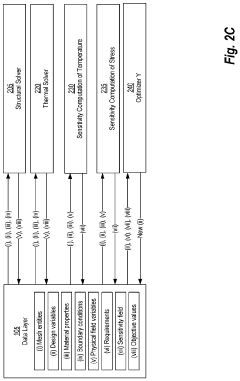

Topology optimization with design-dependent loads and boundary conditions for multi-physics applications

PatentInactiveUS20210004512A1

Innovation

- A framework comprising a meshing module, physics solvers, sensitivity computation modules, and optimizer modules that iteratively generate and update design variables to handle changing boundary conditions and loads, using flood-filling techniques and material interpolation schemes to manage complexity and ensure convergence.

Integration with Advanced Manufacturing Technologies

The successful implementation of topology optimization techniques in design innovation is increasingly dependent on their integration with advanced manufacturing technologies. Additive manufacturing (AM), particularly 3D printing, has emerged as the most compatible production method for topology-optimized designs due to its layer-by-layer fabrication approach that can realize complex geometries without traditional manufacturing constraints. The synergy between topology optimization and AM has created unprecedented opportunities for lightweight structures, enhanced performance components, and material efficiency across industries.

Recent developments in metal-based AM technologies, including Selective Laser Melting (SLM) and Electron Beam Melting (EBM), have significantly expanded the application scope of topology optimization beyond prototyping to end-use parts in aerospace, automotive, and medical industries. These technologies can now produce topology-optimized components with mechanical properties comparable to traditionally manufactured counterparts, while achieving weight reductions of 30-50% in certain applications.

Computer Numerical Control (CNC) machining has also evolved to accommodate topology-optimized designs through multi-axis capabilities and advanced toolpath generation algorithms. Hybrid manufacturing systems that combine additive and subtractive processes represent a particularly promising direction, allowing for the production of topology-optimized parts with superior surface finish and dimensional accuracy in critical functional areas.

Software integration between topology optimization tools and manufacturing platforms has become increasingly seamless, with CAD/CAM systems now incorporating design for manufacturability (DFM) constraints directly into the optimization process. This integration enables designers to generate solutions that are not only theoretically optimal but also practically manufacturable without extensive redesign.

Material science advancements have paralleled these manufacturing developments, with new alloys, composites, and functionally graded materials specifically formulated for topology optimization applications. These materials often feature properties tailored to both the optimization objectives and the manufacturing process requirements, such as reduced thermal distortion in AM processes.

Quality assurance and certification processes have also evolved to address the unique challenges of topology-optimized components. Non-destructive testing methods, including CT scanning and ultrasonic inspection, have been adapted to verify the internal integrity of complex geometries that would be impossible to inspect using conventional techniques.

The economic viability of implementing topology-optimized designs continues to improve as manufacturing technologies mature and become more accessible. Cost models indicate that despite higher initial production costs, the performance benefits and material savings often result in favorable lifecycle economics, particularly for high-value applications where weight reduction translates directly to operational savings.

Recent developments in metal-based AM technologies, including Selective Laser Melting (SLM) and Electron Beam Melting (EBM), have significantly expanded the application scope of topology optimization beyond prototyping to end-use parts in aerospace, automotive, and medical industries. These technologies can now produce topology-optimized components with mechanical properties comparable to traditionally manufactured counterparts, while achieving weight reductions of 30-50% in certain applications.

Computer Numerical Control (CNC) machining has also evolved to accommodate topology-optimized designs through multi-axis capabilities and advanced toolpath generation algorithms. Hybrid manufacturing systems that combine additive and subtractive processes represent a particularly promising direction, allowing for the production of topology-optimized parts with superior surface finish and dimensional accuracy in critical functional areas.

Software integration between topology optimization tools and manufacturing platforms has become increasingly seamless, with CAD/CAM systems now incorporating design for manufacturability (DFM) constraints directly into the optimization process. This integration enables designers to generate solutions that are not only theoretically optimal but also practically manufacturable without extensive redesign.

Material science advancements have paralleled these manufacturing developments, with new alloys, composites, and functionally graded materials specifically formulated for topology optimization applications. These materials often feature properties tailored to both the optimization objectives and the manufacturing process requirements, such as reduced thermal distortion in AM processes.

Quality assurance and certification processes have also evolved to address the unique challenges of topology-optimized components. Non-destructive testing methods, including CT scanning and ultrasonic inspection, have been adapted to verify the internal integrity of complex geometries that would be impossible to inspect using conventional techniques.

The economic viability of implementing topology-optimized designs continues to improve as manufacturing technologies mature and become more accessible. Cost models indicate that despite higher initial production costs, the performance benefits and material savings often result in favorable lifecycle economics, particularly for high-value applications where weight reduction translates directly to operational savings.

Sustainability Impact and Material Efficiency Considerations

Topology optimization techniques are increasingly recognized for their significant contributions to sustainability and material efficiency in modern design and manufacturing processes. By mathematically determining the optimal distribution of material within a given design space, these techniques enable the creation of structures that maintain required performance characteristics while minimizing material usage. This fundamental principle directly addresses one of the core challenges of sustainable engineering: achieving more with less.

The material reduction capabilities of topology optimization translate into substantial environmental benefits across the product lifecycle. Optimized designs typically require 30-50% less raw material compared to traditional designs, significantly reducing resource extraction impacts and associated carbon emissions. This efficiency extends to the manufacturing phase, where less material processing results in lower energy consumption and reduced waste generation. A 2021 study in the Journal of Cleaner Production demonstrated that topology-optimized automotive components reduced embodied carbon by up to 40% compared to conventional counterparts.

Transportation efficiency represents another critical sustainability advantage. Lightweight structures produced through topology optimization contribute to improved fuel efficiency in vehicles and reduced energy requirements for shipping and handling. In aerospace applications, every kilogram of weight reduction can save thousands of liters of fuel over an aircraft's operational lifetime, with corresponding reductions in greenhouse gas emissions.

The material selection flexibility inherent in topology optimization further enhances sustainability potential. The technique allows designers to specify environmentally preferable materials that might otherwise be cost-prohibitive in conventional designs. This capability facilitates the integration of recycled, renewable, or lower-impact materials while maintaining performance standards. Additionally, the precision of material placement reduces the need for joining different materials, potentially eliminating environmentally problematic adhesives or fasteners.

End-of-life considerations also benefit from topology optimization approaches. The reduced material complexity and quantity in optimized designs can simplify disassembly and recycling processes. Some research indicates that topology-optimized components may offer up to 25% improvement in recyclability rates compared to traditional designs, particularly when material homogeneity is prioritized during the optimization process.

Despite these advantages, challenges remain in fully realizing the sustainability potential of topology optimization. Manufacturing constraints sometimes necessitate compromises that reduce material efficiency, while the computational intensity of optimization processes carries its own environmental footprint. Future research directions include developing optimization algorithms that explicitly incorporate lifecycle environmental impacts as constraints or objectives, potentially transforming topology optimization from a material efficiency tool into a comprehensive sustainability enabler.

The material reduction capabilities of topology optimization translate into substantial environmental benefits across the product lifecycle. Optimized designs typically require 30-50% less raw material compared to traditional designs, significantly reducing resource extraction impacts and associated carbon emissions. This efficiency extends to the manufacturing phase, where less material processing results in lower energy consumption and reduced waste generation. A 2021 study in the Journal of Cleaner Production demonstrated that topology-optimized automotive components reduced embodied carbon by up to 40% compared to conventional counterparts.

Transportation efficiency represents another critical sustainability advantage. Lightweight structures produced through topology optimization contribute to improved fuel efficiency in vehicles and reduced energy requirements for shipping and handling. In aerospace applications, every kilogram of weight reduction can save thousands of liters of fuel over an aircraft's operational lifetime, with corresponding reductions in greenhouse gas emissions.

The material selection flexibility inherent in topology optimization further enhances sustainability potential. The technique allows designers to specify environmentally preferable materials that might otherwise be cost-prohibitive in conventional designs. This capability facilitates the integration of recycled, renewable, or lower-impact materials while maintaining performance standards. Additionally, the precision of material placement reduces the need for joining different materials, potentially eliminating environmentally problematic adhesives or fasteners.

End-of-life considerations also benefit from topology optimization approaches. The reduced material complexity and quantity in optimized designs can simplify disassembly and recycling processes. Some research indicates that topology-optimized components may offer up to 25% improvement in recyclability rates compared to traditional designs, particularly when material homogeneity is prioritized during the optimization process.

Despite these advantages, challenges remain in fully realizing the sustainability potential of topology optimization. Manufacturing constraints sometimes necessitate compromises that reduce material efficiency, while the computational intensity of optimization processes carries its own environmental footprint. Future research directions include developing optimization algorithms that explicitly incorporate lifecycle environmental impacts as constraints or objectives, potentially transforming topology optimization from a material efficiency tool into a comprehensive sustainability enabler.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!