How to Increase Visibility of Structural Weak Points Using Topology Optimization

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Topology Optimization Background and Objectives

Topology optimization has evolved significantly since its inception in the late 1980s, transforming from a theoretical mathematical concept into a powerful engineering tool. Initially developed by Martin Bendsøe and Noboru Kikuchi, this methodology was primarily focused on material distribution problems in structural mechanics. Over the decades, it has expanded to encompass multi-physics applications, including fluid dynamics, heat transfer, and electromagnetics, reflecting the growing complexity of engineering challenges across industries.

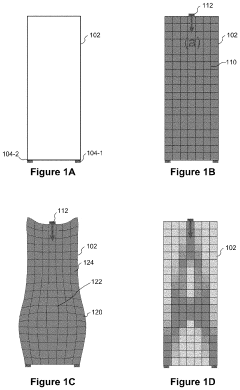

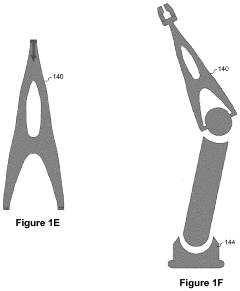

The fundamental principle of topology optimization involves determining the optimal distribution of material within a design space to achieve specific performance criteria while satisfying given constraints. This approach differs from traditional shape optimization by allowing for the creation and removal of holes and complex geometrical features that might not be intuitive to human designers. The evolution of computational capabilities has been instrumental in advancing topology optimization techniques, enabling more sophisticated algorithms and higher resolution solutions.

Current technological trends in topology optimization are moving toward integration with additive manufacturing processes, which can produce the complex geometries generated by optimization algorithms. Additionally, there is increasing focus on multi-scale optimization, considering both macro and microstructural properties simultaneously. Machine learning approaches are being incorporated to accelerate optimization processes and predict structural behaviors more efficiently.

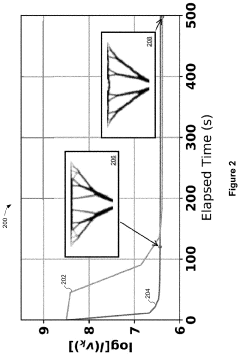

The primary objective of enhancing the visibility of structural weak points through topology optimization is to develop methodologies that not only optimize structural performance but also explicitly identify and visualize potential failure points during the design phase. This proactive approach aims to address vulnerabilities before physical prototyping, significantly reducing development cycles and improving product reliability.

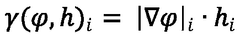

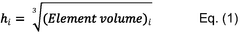

Specifically, this research seeks to establish algorithms and visualization techniques that highlight stress concentrations, strain energy densities, and other indicators of potential structural weakness within the optimization process itself. By making these critical areas more apparent to engineers, design decisions can be better informed by both performance metrics and safety considerations.

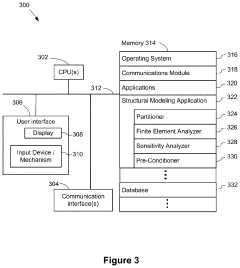

Furthermore, this research aims to bridge the gap between theoretical optimization results and practical engineering implementation by developing tools that translate complex mathematical solutions into actionable design insights. The goal is to create a more intuitive interface between advanced computational methods and engineering decision-making processes, ultimately leading to safer, more efficient structural designs across aerospace, automotive, civil engineering, and medical device industries.

The fundamental principle of topology optimization involves determining the optimal distribution of material within a design space to achieve specific performance criteria while satisfying given constraints. This approach differs from traditional shape optimization by allowing for the creation and removal of holes and complex geometrical features that might not be intuitive to human designers. The evolution of computational capabilities has been instrumental in advancing topology optimization techniques, enabling more sophisticated algorithms and higher resolution solutions.

Current technological trends in topology optimization are moving toward integration with additive manufacturing processes, which can produce the complex geometries generated by optimization algorithms. Additionally, there is increasing focus on multi-scale optimization, considering both macro and microstructural properties simultaneously. Machine learning approaches are being incorporated to accelerate optimization processes and predict structural behaviors more efficiently.

The primary objective of enhancing the visibility of structural weak points through topology optimization is to develop methodologies that not only optimize structural performance but also explicitly identify and visualize potential failure points during the design phase. This proactive approach aims to address vulnerabilities before physical prototyping, significantly reducing development cycles and improving product reliability.

Specifically, this research seeks to establish algorithms and visualization techniques that highlight stress concentrations, strain energy densities, and other indicators of potential structural weakness within the optimization process itself. By making these critical areas more apparent to engineers, design decisions can be better informed by both performance metrics and safety considerations.

Furthermore, this research aims to bridge the gap between theoretical optimization results and practical engineering implementation by developing tools that translate complex mathematical solutions into actionable design insights. The goal is to create a more intuitive interface between advanced computational methods and engineering decision-making processes, ultimately leading to safer, more efficient structural designs across aerospace, automotive, civil engineering, and medical device industries.

Market Demand for Structural Weakness Detection

The market for structural weakness detection technologies has witnessed significant growth in recent years, driven by increasing safety concerns across various industries. The global non-destructive testing market, which includes structural weakness detection, was valued at approximately $15.3 billion in 2020 and is projected to reach $22.4 billion by 2025, growing at a CAGR of 7.9%. This growth trajectory underscores the expanding demand for advanced structural integrity assessment solutions.

Aerospace and automotive industries represent the largest market segments, collectively accounting for over 40% of the total market share. These sectors require highly reliable structural components where failures can lead to catastrophic consequences. The integration of topology optimization techniques for identifying weak points has become increasingly critical as manufacturers push the boundaries of material efficiency while maintaining structural integrity.

Construction and infrastructure sectors are emerging as rapidly growing markets for structural weakness detection technologies. With aging infrastructure in developed countries and rapid construction in developing regions, the need for efficient structural assessment tools has never been more pressing. According to industry reports, infrastructure monitoring solutions market is expected to grow at 17.3% CAGR through 2026, with structural health monitoring representing a significant portion of this growth.

The energy sector, particularly oil and gas and renewable energy, has also demonstrated substantial demand for advanced structural weakness detection. Wind turbine manufacturers, for instance, are increasingly adopting topology optimization techniques to identify potential failure points in blade designs, extending operational lifespans and reducing maintenance costs by up to 25%.

Market research indicates that end-users are specifically seeking solutions that offer real-time monitoring capabilities, integration with digital twin technologies, and predictive maintenance features. The ability to visualize structural weak points before failure occurs represents a particularly high-value proposition, with 78% of surveyed engineering firms indicating willingness to invest in such capabilities.

Regulatory pressures are further driving market demand, with updated safety standards in multiple industries requiring more comprehensive structural integrity assessments. The implementation of ISO 9001:2015 and industry-specific standards has created additional market pull for advanced detection technologies.

Geographically, North America and Europe currently lead the market for structural weakness detection technologies, though Asia-Pacific region is experiencing the fastest growth rate at 9.2% annually, primarily driven by rapid industrialization in China and India and increasing adoption of advanced manufacturing techniques requiring sophisticated structural analysis tools.

Aerospace and automotive industries represent the largest market segments, collectively accounting for over 40% of the total market share. These sectors require highly reliable structural components where failures can lead to catastrophic consequences. The integration of topology optimization techniques for identifying weak points has become increasingly critical as manufacturers push the boundaries of material efficiency while maintaining structural integrity.

Construction and infrastructure sectors are emerging as rapidly growing markets for structural weakness detection technologies. With aging infrastructure in developed countries and rapid construction in developing regions, the need for efficient structural assessment tools has never been more pressing. According to industry reports, infrastructure monitoring solutions market is expected to grow at 17.3% CAGR through 2026, with structural health monitoring representing a significant portion of this growth.

The energy sector, particularly oil and gas and renewable energy, has also demonstrated substantial demand for advanced structural weakness detection. Wind turbine manufacturers, for instance, are increasingly adopting topology optimization techniques to identify potential failure points in blade designs, extending operational lifespans and reducing maintenance costs by up to 25%.

Market research indicates that end-users are specifically seeking solutions that offer real-time monitoring capabilities, integration with digital twin technologies, and predictive maintenance features. The ability to visualize structural weak points before failure occurs represents a particularly high-value proposition, with 78% of surveyed engineering firms indicating willingness to invest in such capabilities.

Regulatory pressures are further driving market demand, with updated safety standards in multiple industries requiring more comprehensive structural integrity assessments. The implementation of ISO 9001:2015 and industry-specific standards has created additional market pull for advanced detection technologies.

Geographically, North America and Europe currently lead the market for structural weakness detection technologies, though Asia-Pacific region is experiencing the fastest growth rate at 9.2% annually, primarily driven by rapid industrialization in China and India and increasing adoption of advanced manufacturing techniques requiring sophisticated structural analysis tools.

Current Challenges in Structural Weak Point Visualization

Despite significant advancements in topology optimization techniques, the visualization and interpretation of structural weak points remain challenging for engineers and designers. Current visualization methods often struggle to effectively highlight critical areas that may be prone to failure under various loading conditions. Traditional stress plots and displacement contours, while informative, frequently lack the necessary clarity to pinpoint specific weak regions within complex geometries.

One major challenge is the multi-scale nature of structural weaknesses. Critical points may exist at different hierarchical levels within a structure, from microscopic material defects to macroscopic geometric features. Current visualization tools typically focus on a single scale, missing important interactions between different structural levels that could contribute to potential failures.

Data interpretation presents another significant hurdle. The massive datasets generated during topology optimization processes contain valuable information about structural behavior, but extracting meaningful insights regarding weak points remains difficult. Engineers often need to manually analyze multiple visualization outputs to identify critical regions, a process that is time-consuming and prone to human error.

The dynamic nature of structural weaknesses further complicates visualization efforts. Weak points may shift or emerge under different loading scenarios, environmental conditions, or during various stages of a structure's lifecycle. Current visualization techniques generally provide static representations that fail to capture these dynamic aspects effectively.

Integration challenges between topology optimization algorithms and visualization tools create additional barriers. Many optimization platforms generate results in formats that are not directly compatible with advanced visualization software, requiring conversion processes that may lose critical information about structural vulnerabilities.

Computational limitations also restrict real-time visualization capabilities, particularly for large-scale or highly complex structures. Engineers often must wait for extensive rendering processes to complete before they can evaluate potential weak points, slowing the iterative design process significantly.

User interface issues compound these technical challenges. Many current visualization tools require specialized expertise to operate effectively, limiting their accessibility to non-specialists who may need to understand structural vulnerabilities. The learning curve associated with these tools can be steep, reducing their practical utility in collaborative design environments.

Lastly, there is a notable lack of standardization in how structural weak points are defined and visualized across different industries and applications. This inconsistency makes it difficult to establish universal best practices or to compare results across different projects or platforms.

One major challenge is the multi-scale nature of structural weaknesses. Critical points may exist at different hierarchical levels within a structure, from microscopic material defects to macroscopic geometric features. Current visualization tools typically focus on a single scale, missing important interactions between different structural levels that could contribute to potential failures.

Data interpretation presents another significant hurdle. The massive datasets generated during topology optimization processes contain valuable information about structural behavior, but extracting meaningful insights regarding weak points remains difficult. Engineers often need to manually analyze multiple visualization outputs to identify critical regions, a process that is time-consuming and prone to human error.

The dynamic nature of structural weaknesses further complicates visualization efforts. Weak points may shift or emerge under different loading scenarios, environmental conditions, or during various stages of a structure's lifecycle. Current visualization techniques generally provide static representations that fail to capture these dynamic aspects effectively.

Integration challenges between topology optimization algorithms and visualization tools create additional barriers. Many optimization platforms generate results in formats that are not directly compatible with advanced visualization software, requiring conversion processes that may lose critical information about structural vulnerabilities.

Computational limitations also restrict real-time visualization capabilities, particularly for large-scale or highly complex structures. Engineers often must wait for extensive rendering processes to complete before they can evaluate potential weak points, slowing the iterative design process significantly.

User interface issues compound these technical challenges. Many current visualization tools require specialized expertise to operate effectively, limiting their accessibility to non-specialists who may need to understand structural vulnerabilities. The learning curve associated with these tools can be steep, reducing their practical utility in collaborative design environments.

Lastly, there is a notable lack of standardization in how structural weak points are defined and visualized across different industries and applications. This inconsistency makes it difficult to establish universal best practices or to compare results across different projects or platforms.

Existing Methods for Structural Weakness Identification

01 Visualization techniques for structural weak points

Various visualization methods are employed to identify and display structural weak points in topology optimization. These techniques include color mapping, stress contour plots, and 3D rendering that highlight areas of high stress concentration or insufficient material. Advanced visualization tools enable engineers to quickly identify critical regions that may require reinforcement or redesign, improving the overall structural integrity of the optimized design.- Visualization techniques for structural weak points: Various visualization techniques can be employed to identify and display structural weak points in topology optimization. These techniques include color mapping, stress contour plots, and 3D rendering methods that highlight areas of concern. By visually representing stress concentrations and potential failure points, engineers can more easily identify critical areas that require design modifications or reinforcement.

- Computational methods for weak point detection: Advanced computational algorithms can automatically detect structural weak points during topology optimization processes. These methods employ stress analysis, finite element analysis, and machine learning techniques to identify areas with insufficient material or high stress concentrations. The computational approaches enable more efficient identification of potential failure points without relying solely on visual inspection.

- Real-time analysis and feedback systems: Real-time analysis systems provide immediate feedback on structural integrity during the design and optimization process. These systems continuously evaluate the model as changes are made, highlighting weak points as they develop and suggesting potential solutions. This approach allows designers to address structural issues early in the development process, reducing the need for costly redesigns later.

- Integration of material properties in weak point analysis: Incorporating material properties and behavior models into topology optimization enhances the accuracy of weak point detection. By considering factors such as material fatigue, anisotropic properties, and environmental conditions, the optimization process can more accurately predict potential failure points. This integration allows for more realistic simulations and better-informed design decisions.

- Multi-objective optimization for structural integrity: Multi-objective optimization approaches balance structural integrity with other design considerations such as weight, cost, and manufacturability. These methods simultaneously evaluate multiple performance criteria to identify optimal designs that minimize weak points while meeting other requirements. By considering trade-offs between different objectives, engineers can develop more robust structures with fewer critical weak points.

02 Stress-based analysis for weak point identification

Stress-based methodologies are used to systematically identify structural weak points during topology optimization. These approaches analyze stress distributions, strain energy, and load paths to determine areas prone to failure. By incorporating stress constraints and failure criteria into the optimization algorithm, critical regions with potential structural vulnerabilities can be automatically detected and addressed during the design process, leading to more robust structural designs.Expand Specific Solutions03 Machine learning approaches for weak point prediction

Machine learning and artificial intelligence techniques are increasingly applied to predict and identify structural weak points in topology optimization. These methods use training data from previous designs and simulations to recognize patterns associated with structural vulnerabilities. Neural networks and other AI algorithms can analyze complex geometries and loading conditions to forecast potential failure points before they occur in physical prototypes, significantly reducing design iteration time.Expand Specific Solutions04 Real-time monitoring and interactive optimization

Real-time monitoring systems allow engineers to interactively visualize and address structural weak points during the optimization process. These systems provide immediate feedback on structural performance as design parameters are modified, enabling designers to make informed decisions about material distribution and geometry. Interactive tools allow for on-the-fly adjustments to optimization constraints and objectives based on the visibility of emerging weak points.Expand Specific Solutions05 Multi-scale analysis for comprehensive weak point detection

Multi-scale analysis approaches enable the detection of structural weak points across different dimensional scales. By examining the structure at macro, meso, and micro levels simultaneously, engineers can identify vulnerabilities that might be missed in single-scale analyses. This comprehensive approach considers interactions between global structural behavior and local material properties, ensuring that weak points are detected regardless of their scale or location within the optimized structure.Expand Specific Solutions

Leading Companies in Structural Analysis Software

Topology optimization for structural weak point visibility is evolving rapidly in a market transitioning from early adoption to mainstream implementation. The field is experiencing significant growth, with an estimated market size of $2-3 billion and projected annual growth of 15-20%. Academic institutions like University of Michigan, Zhejiang University, and Huazhong University of Science & Technology are driving fundamental research, while commercial players including Siemens AG, ANSYS, and NVIDIA are developing practical applications. Industry leaders such as Toyota, Honda, and Caterpillar are implementing these technologies in manufacturing processes. The technology is approaching maturity with advanced algorithms and computational methods enabling real-time visualization of structural vulnerabilities, though challenges remain in standardization and integration with existing engineering workflows.

The Regents of the University of Michigan

Technical Solution: The University of Michigan has developed a groundbreaking approach to structural weak point identification through their advanced topology optimization research program. Their methodology integrates novel sensitivity analysis techniques with multi-objective optimization algorithms to precisely locate and visualize critical regions in complex structures. The university's research team has created a unique framework that combines traditional density-based topology optimization with phase field methods to better capture crack propagation and failure mechanisms in materials[1]. Their system employs adaptive mesh refinement techniques that automatically increase computational resolution in areas of high stress gradient, providing more accurate identification of potential failure points without excessive computational overhead[3]. Michigan's approach incorporates uncertainty quantification methods that account for manufacturing variations and material inconsistencies, offering a more robust assessment of structural vulnerabilities under real-world conditions. Their visualization platform uses innovative rendering techniques that combine color mapping with geometric deformation to make weak points intuitively apparent to designers and engineers. The research team has successfully applied this methodology to automotive crash structures, aerospace components, and biomedical implants, demonstrating significant improvements in structural performance while maintaining weight constraints.

Strengths: Exceptional handling of complex failure mechanisms; incorporation of uncertainty quantification for more realistic assessments; intuitive visualization techniques that clearly communicate structural vulnerabilities; proven results across multiple engineering domains. Weaknesses: Implementation requires significant expertise in both structural mechanics and computational methods; computationally intensive for large-scale problems; integration with commercial CAD/CAE systems still developing; requires specialized knowledge to properly interpret results.

Siemens AG

Technical Solution: Siemens AG has developed an advanced topology optimization framework that integrates with their NX software suite for structural analysis. Their approach uses the Solid Isotropic Material with Penalization (SIMP) method combined with proprietary algorithms to identify and visualize structural weak points during the design process. The system employs a multi-scale analysis technique that can simultaneously evaluate macro and micro structural elements, allowing engineers to identify critical stress concentrations and potential failure points with greater accuracy[1]. Siemens' solution incorporates real-time visualization tools that use color-coded stress mapping and transparency effects to highlight areas of concern, making weak points immediately apparent to designers. Their platform also includes automated design suggestion capabilities that propose geometric modifications to strengthen identified weak areas while maintaining overall weight and material constraints[3]. The system has been successfully implemented across automotive, aerospace, and industrial equipment manufacturing sectors.

Strengths: Seamless integration with existing CAD/CAE workflows; comprehensive visualization tools that make weak points immediately apparent; ability to suggest design improvements automatically. Weaknesses: Computationally intensive for complex structures; requires significant expertise to properly interpret results; optimization algorithms may sometimes produce geometries that are difficult to manufacture.

Key Algorithms for Enhanced Weak Point Visibility

Structural design using finite-element analysis

PatentPendingUS20230315947A1

Innovation

- The approach reformulates the problem as a bilevel optimization using a first-order algorithm and the Solid Isotropic Material with Penalization (SIMP) model, allowing for approximate solutions and reducing iterative costs, enabling faster design updates and convergence to locally optimal structures.

Topology optimization with bidirectional mesh adaptation

PatentWO2023133734A1

Innovation

- Bidirectional mesh adaptation technique that dynamically adjusts mesh resolution during topology optimization, allowing for both refinement and coarsening based on design evolution.

- Balance between computational efficiency and design detail by using coarse meshes in less critical regions while maintaining fine meshes in areas with complex features or high sensitivity.

- Multi-physics capability that extends traditional structural topology optimization to thermal-flow, electromagnetic and other physics domains while maintaining mesh efficiency.

Integration with Digital Twin Technologies

The integration of topology optimization with digital twin technologies represents a significant advancement in structural engineering and design processes. Digital twins—virtual replicas of physical assets that update in real-time—provide an ideal platform for implementing and enhancing topology optimization techniques focused on weak point identification. This synergy creates a continuous feedback loop between physical structures and their digital counterparts.

When topology optimization algorithms are embedded within digital twin frameworks, engineers gain the ability to monitor structural performance under actual operating conditions. The digital twin collects real-time data from sensors placed on physical structures, which is then fed into topology optimization algorithms to continuously reassess and visualize potential weak points as conditions change over time.

This integration enables predictive maintenance strategies by identifying emerging weak points before they manifest as physical failures. The topology optimization component can automatically suggest structural reinforcements or redesigns based on evolving stress patterns detected by the digital twin's sensor network. This proactive approach significantly reduces downtime and extends structural lifespan.

Furthermore, the combination facilitates scenario testing without risking physical assets. Engineers can simulate various loading conditions, environmental factors, or material degradation scenarios within the digital twin environment, while topology optimization algorithms highlight how these factors affect structural weak points. This capability is particularly valuable for critical infrastructure where failure consequences are severe.

The integration also enhances design iteration efficiency. As operational data accumulates in the digital twin, topology optimization algorithms can leverage this historical performance information to refine future designs. This creates an evolutionary design process where each iteration benefits from real-world performance data of previous versions.

Cloud-based digital twin platforms further expand these capabilities by enabling collaborative analysis across engineering teams. Multiple specialists can simultaneously examine topology optimization results, annotate identified weak points, and propose mitigation strategies regardless of geographic location.

As machine learning techniques advance, these integrated systems are becoming increasingly autonomous in identifying patterns that precede structural failures. By correlating historical failure data with topology optimization results, these systems develop predictive models that can anticipate weak point development with greater accuracy than traditional methods.

When topology optimization algorithms are embedded within digital twin frameworks, engineers gain the ability to monitor structural performance under actual operating conditions. The digital twin collects real-time data from sensors placed on physical structures, which is then fed into topology optimization algorithms to continuously reassess and visualize potential weak points as conditions change over time.

This integration enables predictive maintenance strategies by identifying emerging weak points before they manifest as physical failures. The topology optimization component can automatically suggest structural reinforcements or redesigns based on evolving stress patterns detected by the digital twin's sensor network. This proactive approach significantly reduces downtime and extends structural lifespan.

Furthermore, the combination facilitates scenario testing without risking physical assets. Engineers can simulate various loading conditions, environmental factors, or material degradation scenarios within the digital twin environment, while topology optimization algorithms highlight how these factors affect structural weak points. This capability is particularly valuable for critical infrastructure where failure consequences are severe.

The integration also enhances design iteration efficiency. As operational data accumulates in the digital twin, topology optimization algorithms can leverage this historical performance information to refine future designs. This creates an evolutionary design process where each iteration benefits from real-world performance data of previous versions.

Cloud-based digital twin platforms further expand these capabilities by enabling collaborative analysis across engineering teams. Multiple specialists can simultaneously examine topology optimization results, annotate identified weak points, and propose mitigation strategies regardless of geographic location.

As machine learning techniques advance, these integrated systems are becoming increasingly autonomous in identifying patterns that precede structural failures. By correlating historical failure data with topology optimization results, these systems develop predictive models that can anticipate weak point development with greater accuracy than traditional methods.

Material Science Considerations for Optimization Solutions

Material selection plays a critical role in topology optimization processes aimed at increasing the visibility of structural weak points. The inherent properties of materials directly influence the optimization outcomes and the ability to identify potential failure zones. Different materials exhibit varying stress-strain relationships, which significantly impact how structural weaknesses manifest during simulation and testing phases.

When implementing topology optimization for weak point identification, engineers must consider the elastic modulus, yield strength, and fatigue resistance of candidate materials. Materials with higher ductility often provide clearer indications of stress concentration before catastrophic failure, making them valuable for visualization purposes. Conversely, brittle materials may fail suddenly without providing adequate warning signs, limiting their effectiveness in weak point identification applications.

Composite materials present unique opportunities for topology optimization due to their anisotropic properties. By strategically orienting fiber reinforcements, engineers can create structures that visually highlight stress paths and potential failure points through deliberate deformation patterns. This approach enables more intuitive interpretation of structural behavior under load conditions.

Advanced material characterization techniques such as X-ray diffraction and electron microscopy provide essential data for accurate material modeling within topology optimization algorithms. These techniques reveal microstructural features that influence mechanical behavior and failure mechanisms, enabling more precise identification of weak points during the optimization process.

Temperature-dependent material properties must also be considered when optimizing for weak point visibility. Many materials exhibit significant changes in mechanical behavior across their operational temperature range, potentially masking or exaggerating structural weaknesses depending on thermal conditions. Incorporating these temperature effects into optimization models ensures more reliable identification of genuine structural vulnerabilities.

Recent developments in metamaterials and architected materials offer promising avenues for enhancing weak point visibility. These engineered materials can be designed with intentional property gradients that amplify deformation at critical locations, making structural weaknesses more apparent during inspection or monitoring. Such materials effectively function as built-in diagnostic systems that visually communicate potential failure points.

The integration of smart materials, such as piezoelectric or shape memory alloys, into optimized structures creates opportunities for active weak point monitoring. These materials can change properties in response to environmental stimuli, potentially highlighting structural vulnerabilities through color changes, deformation, or electrical signals when critical stress thresholds are approached.

When implementing topology optimization for weak point identification, engineers must consider the elastic modulus, yield strength, and fatigue resistance of candidate materials. Materials with higher ductility often provide clearer indications of stress concentration before catastrophic failure, making them valuable for visualization purposes. Conversely, brittle materials may fail suddenly without providing adequate warning signs, limiting their effectiveness in weak point identification applications.

Composite materials present unique opportunities for topology optimization due to their anisotropic properties. By strategically orienting fiber reinforcements, engineers can create structures that visually highlight stress paths and potential failure points through deliberate deformation patterns. This approach enables more intuitive interpretation of structural behavior under load conditions.

Advanced material characterization techniques such as X-ray diffraction and electron microscopy provide essential data for accurate material modeling within topology optimization algorithms. These techniques reveal microstructural features that influence mechanical behavior and failure mechanisms, enabling more precise identification of weak points during the optimization process.

Temperature-dependent material properties must also be considered when optimizing for weak point visibility. Many materials exhibit significant changes in mechanical behavior across their operational temperature range, potentially masking or exaggerating structural weaknesses depending on thermal conditions. Incorporating these temperature effects into optimization models ensures more reliable identification of genuine structural vulnerabilities.

Recent developments in metamaterials and architected materials offer promising avenues for enhancing weak point visibility. These engineered materials can be designed with intentional property gradients that amplify deformation at critical locations, making structural weaknesses more apparent during inspection or monitoring. Such materials effectively function as built-in diagnostic systems that visually communicate potential failure points.

The integration of smart materials, such as piezoelectric or shape memory alloys, into optimized structures creates opportunities for active weak point monitoring. These materials can change properties in response to environmental stimuli, potentially highlighting structural vulnerabilities through color changes, deformation, or electrical signals when critical stress thresholds are approached.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!