Topology Optimization vs Fabrication Constraints: Solving Design Challenges

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Topology Optimization Evolution and Objectives

Topology optimization has evolved significantly since its inception in the late 1980s, transforming from a theoretical mathematical concept into a practical design methodology widely adopted across multiple industries. Initially developed by researchers like Martin Bendsøe and Noboru Kikuchi, the early approaches focused on material distribution methods that optimized structural performance under specific loading conditions. These foundational methods, however, were limited by computational constraints and often produced designs that were theoretically optimal but practically unfabricable.

The evolution of topology optimization has been closely tied to advancements in computational power and numerical methods. The 1990s saw the development of the Solid Isotropic Material with Penalization (SIMP) method, which became a cornerstone approach by effectively addressing the intermediate density problem. This period marked the transition from purely academic research to early industrial applications, primarily in automotive and aerospace sectors where weight reduction directly translated to performance gains.

By the early 2000s, the integration of manufacturing constraints into topology optimization algorithms began to emerge as a critical research direction. This shift acknowledged that theoretical optimality had limited value if the resulting designs could not be manufactured using available technologies. Level set methods and phase field approaches were developed during this period, offering new mathematical frameworks for handling complex geometries and multiple physics domains.

The past decade has witnessed an acceleration in topology optimization development, driven by the rise of additive manufacturing technologies that have dramatically expanded the realm of manufacturable geometries. This synergy between design freedom and manufacturing capability has pushed researchers to develop multi-scale, multi-physics optimization approaches that can simultaneously address structural, thermal, fluid, and electromagnetic performance criteria.

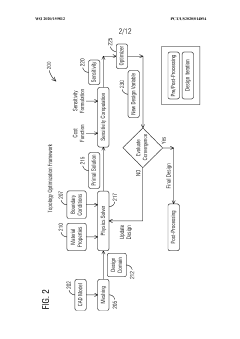

Current objectives in topology optimization research center around several key challenges. First is the seamless integration of manufacturing constraints directly within the optimization process, rather than as post-processing steps. Second is the development of robust optimization methods that account for uncertainties in loading conditions, material properties, and manufacturing tolerances. Third is computational efficiency, particularly for large-scale, high-resolution models that better capture complex geometries and physics.

The ultimate goal of modern topology optimization is to create a unified design methodology that bridges the gap between theoretical performance and practical manufacturability. This involves not only algorithm development but also the creation of intuitive design interfaces that allow engineers to effectively communicate their design intent and constraints to optimization systems, thereby democratizing access to these powerful design tools across industries.

The evolution of topology optimization has been closely tied to advancements in computational power and numerical methods. The 1990s saw the development of the Solid Isotropic Material with Penalization (SIMP) method, which became a cornerstone approach by effectively addressing the intermediate density problem. This period marked the transition from purely academic research to early industrial applications, primarily in automotive and aerospace sectors where weight reduction directly translated to performance gains.

By the early 2000s, the integration of manufacturing constraints into topology optimization algorithms began to emerge as a critical research direction. This shift acknowledged that theoretical optimality had limited value if the resulting designs could not be manufactured using available technologies. Level set methods and phase field approaches were developed during this period, offering new mathematical frameworks for handling complex geometries and multiple physics domains.

The past decade has witnessed an acceleration in topology optimization development, driven by the rise of additive manufacturing technologies that have dramatically expanded the realm of manufacturable geometries. This synergy between design freedom and manufacturing capability has pushed researchers to develop multi-scale, multi-physics optimization approaches that can simultaneously address structural, thermal, fluid, and electromagnetic performance criteria.

Current objectives in topology optimization research center around several key challenges. First is the seamless integration of manufacturing constraints directly within the optimization process, rather than as post-processing steps. Second is the development of robust optimization methods that account for uncertainties in loading conditions, material properties, and manufacturing tolerances. Third is computational efficiency, particularly for large-scale, high-resolution models that better capture complex geometries and physics.

The ultimate goal of modern topology optimization is to create a unified design methodology that bridges the gap between theoretical performance and practical manufacturability. This involves not only algorithm development but also the creation of intuitive design interfaces that allow engineers to effectively communicate their design intent and constraints to optimization systems, thereby democratizing access to these powerful design tools across industries.

Market Demand for Optimized Design Solutions

The market for optimized design solutions has experienced significant growth in recent years, driven by increasing demands for lightweight, high-performance components across multiple industries. According to recent market analyses, the global topology optimization software market reached approximately $2.3 billion in 2022 and is projected to grow at a CAGR of 15.7% through 2028, reflecting the expanding adoption of these advanced design methodologies.

Manufacturing sectors, particularly aerospace and automotive industries, represent the largest market segments for topology optimization solutions. These industries face intense pressure to reduce material usage while maintaining or improving structural performance, directly translating to weight reduction, fuel efficiency, and decreased carbon emissions. For instance, the aerospace industry has documented weight reductions of 30-50% in certain components through topology optimization, resulting in substantial fuel savings over aircraft lifespans.

The healthcare sector has emerged as a rapidly growing market for optimized design solutions, particularly in medical implants and prosthetics. Patient-specific designs created through topology optimization have demonstrated improved biocompatibility and functional outcomes. Market research indicates this segment is growing at nearly 20% annually, outpacing the overall market.

Consumer electronics manufacturers are increasingly leveraging topology optimization to address thermal management challenges in compact devices. As devices become smaller yet more powerful, the need for optimized heat dissipation solutions has created a specialized market niche estimated at $450 million annually.

Industrial equipment manufacturers represent another significant market segment, seeking optimized designs to reduce material costs and improve operational efficiency. Heavy machinery components optimized through these techniques have shown material cost reductions of 15-25% while maintaining required performance specifications.

The market demand is further characterized by a growing preference for integrated solutions that bridge the gap between theoretical optimization and practical manufacturing constraints. End users increasingly seek platforms that can simultaneously consider design optimization and fabrication limitations, rather than addressing these as separate challenges. This trend is evidenced by the premium pricing commanded by software solutions offering such integrated capabilities.

Regional analysis reveals that North America and Europe currently dominate market consumption of topology optimization solutions, accounting for approximately 65% of global market share. However, the Asia-Pacific region is demonstrating the fastest growth rate at 18.2% annually, driven by rapid industrialization and manufacturing advancement in countries like China, Japan, and South Korea.

Manufacturing sectors, particularly aerospace and automotive industries, represent the largest market segments for topology optimization solutions. These industries face intense pressure to reduce material usage while maintaining or improving structural performance, directly translating to weight reduction, fuel efficiency, and decreased carbon emissions. For instance, the aerospace industry has documented weight reductions of 30-50% in certain components through topology optimization, resulting in substantial fuel savings over aircraft lifespans.

The healthcare sector has emerged as a rapidly growing market for optimized design solutions, particularly in medical implants and prosthetics. Patient-specific designs created through topology optimization have demonstrated improved biocompatibility and functional outcomes. Market research indicates this segment is growing at nearly 20% annually, outpacing the overall market.

Consumer electronics manufacturers are increasingly leveraging topology optimization to address thermal management challenges in compact devices. As devices become smaller yet more powerful, the need for optimized heat dissipation solutions has created a specialized market niche estimated at $450 million annually.

Industrial equipment manufacturers represent another significant market segment, seeking optimized designs to reduce material costs and improve operational efficiency. Heavy machinery components optimized through these techniques have shown material cost reductions of 15-25% while maintaining required performance specifications.

The market demand is further characterized by a growing preference for integrated solutions that bridge the gap between theoretical optimization and practical manufacturing constraints. End users increasingly seek platforms that can simultaneously consider design optimization and fabrication limitations, rather than addressing these as separate challenges. This trend is evidenced by the premium pricing commanded by software solutions offering such integrated capabilities.

Regional analysis reveals that North America and Europe currently dominate market consumption of topology optimization solutions, accounting for approximately 65% of global market share. However, the Asia-Pacific region is demonstrating the fastest growth rate at 18.2% annually, driven by rapid industrialization and manufacturing advancement in countries like China, Japan, and South Korea.

Current Challenges in Topology Optimization Implementation

Despite the significant advancements in topology optimization (TO) algorithms, implementing these solutions in real-world manufacturing scenarios remains challenging. The fundamental disconnect between mathematically optimal designs and fabrication realities creates implementation barriers that engineers must overcome. Current TO software typically generates complex organic structures that, while theoretically optimal, often contain features impossible to manufacture using conventional methods.

Manufacturing constraints represent the most significant challenge in TO implementation. Traditional manufacturing processes like machining have inherent limitations regarding minimum feature size, internal cavities, and geometric complexity. When TO algorithms generate thin-walled structures, intricate lattices, or enclosed voids, these features may be theoretically optimal but practically unfeasible to produce. This disconnect necessitates time-consuming manual redesign, undermining the efficiency gains promised by TO.

Computational challenges further complicate implementation. High-fidelity TO models require substantial computing resources, creating a trade-off between solution accuracy and processing time. Many engineering teams lack access to sufficient computational infrastructure, forcing compromises in model resolution or optimization parameters. Additionally, the non-linear nature of many TO problems leads to convergence issues and solution instability, particularly when incorporating multiple manufacturing constraints.

Integration with existing CAD/CAM workflows presents another significant hurdle. Most engineering organizations have established design processes built around traditional CAD systems, which operate on boundary representation models. TO solutions, however, typically generate volumetric or mesh-based geometries that require conversion for downstream applications. This translation process often introduces approximation errors and geometric inconsistencies that must be manually corrected.

Knowledge gaps among engineering teams exacerbate these challenges. Many designers lack sufficient understanding of TO principles and constraint formulation, leading to suboptimal problem definition. Without proper training in interpreting and adapting TO results, engineers may struggle to translate mathematical solutions into manufacturable designs. This expertise deficit slows adoption and limits the practical benefits of TO implementation.

Verification and validation of TO designs present additional complications. Traditional engineering validation methods rely on well-established analytical approaches for conventional geometries. TO-generated structures, with their complex geometries and non-intuitive load paths, often require extensive finite element analysis and physical testing to verify performance. This increases development time and costs, particularly for safety-critical applications where certification requirements are stringent.

Manufacturing constraints represent the most significant challenge in TO implementation. Traditional manufacturing processes like machining have inherent limitations regarding minimum feature size, internal cavities, and geometric complexity. When TO algorithms generate thin-walled structures, intricate lattices, or enclosed voids, these features may be theoretically optimal but practically unfeasible to produce. This disconnect necessitates time-consuming manual redesign, undermining the efficiency gains promised by TO.

Computational challenges further complicate implementation. High-fidelity TO models require substantial computing resources, creating a trade-off between solution accuracy and processing time. Many engineering teams lack access to sufficient computational infrastructure, forcing compromises in model resolution or optimization parameters. Additionally, the non-linear nature of many TO problems leads to convergence issues and solution instability, particularly when incorporating multiple manufacturing constraints.

Integration with existing CAD/CAM workflows presents another significant hurdle. Most engineering organizations have established design processes built around traditional CAD systems, which operate on boundary representation models. TO solutions, however, typically generate volumetric or mesh-based geometries that require conversion for downstream applications. This translation process often introduces approximation errors and geometric inconsistencies that must be manually corrected.

Knowledge gaps among engineering teams exacerbate these challenges. Many designers lack sufficient understanding of TO principles and constraint formulation, leading to suboptimal problem definition. Without proper training in interpreting and adapting TO results, engineers may struggle to translate mathematical solutions into manufacturable designs. This expertise deficit slows adoption and limits the practical benefits of TO implementation.

Verification and validation of TO designs present additional complications. Traditional engineering validation methods rely on well-established analytical approaches for conventional geometries. TO-generated structures, with their complex geometries and non-intuitive load paths, often require extensive finite element analysis and physical testing to verify performance. This increases development time and costs, particularly for safety-critical applications where certification requirements are stringent.

Existing Approaches to Address Fabrication Constraints

01 Computational challenges in topology optimization

Topology optimization faces significant computational challenges due to the complex mathematical calculations required. These include handling large-scale design spaces, managing computational resources efficiently, and developing algorithms that can converge to optimal solutions within reasonable timeframes. Advanced numerical methods and parallel computing techniques are being developed to address these computational bottlenecks, enabling more efficient optimization processes for complex structural designs.- Computational challenges in topology optimization: Topology optimization faces significant computational challenges due to the complex mathematical calculations required. These include handling large-scale design spaces, managing multiple design variables, and dealing with intensive computational resources needed for iterative optimization processes. Advanced algorithms and parallel computing techniques are being developed to address these computational bottlenecks and improve efficiency in solving topology optimization problems.

- Multi-physics and multi-objective optimization challenges: Topology optimization becomes increasingly complex when dealing with multiple physics domains simultaneously or when optimizing for multiple competing objectives. Challenges include balancing thermal, structural, and fluid dynamics considerations in a single design, or finding optimal trade-offs between conflicting goals such as minimizing weight while maximizing strength. These scenarios require sophisticated mathematical models and specialized algorithms to handle the interdependencies between different physical phenomena and design objectives.

- Manufacturing constraints and design interpretation: A major challenge in topology optimization is translating mathematically optimized designs into manufacturable components. This includes addressing issues such as minimum feature size, overhang angles for additive manufacturing, and tool accessibility for traditional manufacturing methods. Additionally, the interpretation of optimization results often requires post-processing to create smooth, well-defined boundaries and eliminate artifacts that may be mathematically optimal but physically impractical to produce.

- Integration with CAD systems and design workflows: Integrating topology optimization tools with existing CAD systems and engineering workflows presents significant challenges. Issues include data compatibility between optimization software and CAD platforms, maintaining parametric design capabilities, and enabling seamless iterations between optimization and detailed design phases. Improved integration is needed to make topology optimization more accessible to designers and to reduce the time required to move from conceptual optimization to final detailed design.

- Material property considerations and uncertainty management: Topology optimization must account for material properties and their variations, which presents challenges in accurately modeling nonlinear, anisotropic, or composite materials. Additionally, managing uncertainties in loading conditions, material properties, and manufacturing processes requires robust optimization approaches that can produce designs that perform well across a range of possible scenarios rather than just under ideal conditions. These challenges necessitate advanced material models and uncertainty quantification methods to ensure reliable optimization outcomes.

02 Multi-physics and multi-objective optimization challenges

Topology optimization becomes particularly challenging when dealing with multiple physics domains simultaneously or when optimizing for multiple competing objectives. Engineers must balance structural performance with thermal, fluid, acoustic, or electromagnetic considerations. This requires sophisticated modeling approaches that can accurately capture the interactions between different physical phenomena and optimization algorithms capable of finding Pareto-optimal solutions that represent acceptable trade-offs between competing design goals.Expand Specific Solutions03 Manufacturing constraints and design interpretation

A major challenge in topology optimization is translating mathematically optimal designs into manufacturable components. Raw optimization results often contain features that are difficult or impossible to manufacture using conventional methods. Incorporating manufacturing constraints directly into the optimization process is essential, including minimum feature size, overhang angle limitations for additive manufacturing, or draft angle requirements for casting. Post-processing techniques are also needed to interpret and refine optimization results into practical designs.Expand Specific Solutions04 Integration with CAD systems and design workflows

Integrating topology optimization tools with existing CAD systems and engineering workflows presents significant challenges. There are often compatibility issues between the voxel or element-based representations used in topology optimization and the boundary representation (B-rep) models used in CAD systems. Developing seamless workflows that allow for efficient design iteration, modification, and validation remains a challenge. Solutions include developing better interoperability standards and creating specialized tools for converting optimization results into parametric CAD models.Expand Specific Solutions05 Uncertainty and robustness in optimization

Addressing uncertainties in loading conditions, material properties, and manufacturing variations is a significant challenge in topology optimization. Traditional deterministic approaches may produce designs that are highly optimized for specific conditions but perform poorly when those conditions vary. Robust topology optimization methods aim to create designs that maintain performance across a range of possible scenarios, incorporating statistical approaches and sensitivity analyses to account for these uncertainties. This requires more sophisticated algorithms and significantly higher computational resources.Expand Specific Solutions

Leading Companies and Research Institutions in the Field

Topology optimization in manufacturing faces a critical challenge balancing design freedom with fabrication constraints, currently positioned at the growth stage of industry development. The global market for this technology is expanding rapidly, estimated at $2-3 billion annually with 15-20% growth rate. Leading companies like Siemens AG, Autodesk, and ANSYS have developed mature solutions integrating topology optimization with manufacturing constraints, while academic institutions (Georgia Tech, Northwestern University, Politecnico di Milano) continue advancing theoretical frameworks. Emerging players include Dassault Systèmes and Engineering Technology Associates, focusing on industry-specific applications. The technology shows increasing maturity with recent developments in multi-constraint optimization algorithms and real-time feedback systems for automotive, aerospace, and industrial equipment sectors.

Siemens AG

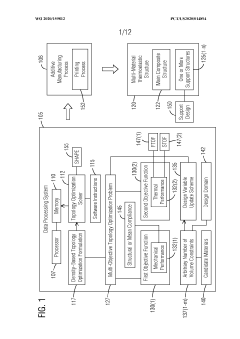

Technical Solution: Siemens has developed an advanced topology optimization platform that integrates manufacturing constraints directly into the design process. Their solution employs a multi-physics approach combining structural, thermal, and fluid dynamics analyses to create optimized designs that are manufacturable from the outset. The platform utilizes SIMP (Solid Isotropic Material with Penalization) methodology enhanced with manufacturing constraint filters that account for minimum feature size, symmetry requirements, and material-specific limitations. Siemens' NX software incorporates these capabilities through its Generative Design module, which can automatically generate multiple design alternatives while adhering to specified fabrication constraints. The system employs machine learning algorithms to predict manufacturing issues before they occur, reducing the iterative cycle between design and production. Their approach also includes specialized algorithms for additive manufacturing constraints, addressing overhang angles, support structure minimization, and build orientation optimization[1][3].

Strengths: Comprehensive integration across the entire product development workflow; robust handling of multi-physics constraints; extensive manufacturing knowledge database. Weaknesses: Complex implementation requiring significant computational resources; steep learning curve for new users; higher initial investment compared to standalone topology optimization tools.

Autodesk, Inc.

Technical Solution: Autodesk has pioneered a generative design approach to topology optimization that directly incorporates fabrication constraints. Their Fusion 360 platform utilizes cloud computing to generate multiple design iterations simultaneously while considering manufacturing methods such as 3D printing, CNC machining, and casting. The system employs a unique constraint-driven algorithm that preserves design intent while ensuring manufacturability through features like minimum thickness controls, symmetry preservation, and extrusion direction constraints. Autodesk's solution implements adaptive meshing techniques that concentrate computational resources on critical areas while maintaining manufacturing feasibility. Their technology incorporates machine learning to improve optimization outcomes based on previous designs and manufacturing feedback. The platform also features specialized modules for different manufacturing processes, with parameters tailored to specific equipment capabilities and material properties. Autodesk's approach emphasizes accessibility, allowing designers without extensive optimization expertise to create manufacturable, optimized designs[2][5].

Strengths: User-friendly interface making advanced optimization accessible to non-specialists; cloud-based computation enabling rapid iteration; strong integration with downstream manufacturing workflows. Weaknesses: Subscription-based pricing model may increase long-term costs; occasional disconnects between optimization results and real-world manufacturing outcomes; limited customization for highly specialized manufacturing processes.

Key Algorithms and Mathematical Foundations

Topology optimization of thermoelastic structures for an additive manufacturing process

PatentWO2020159812A1

Innovation

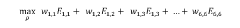

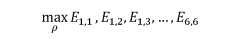

- A density-based topology optimization formulation is developed as a multi-objective problem that optimizes mechanical and thermal performance by using a design variable update scheme capable of solving non-self-adjoint problems with multiple volume constraints, allowing for the efficient design of multi-material thermoelastic structures with integrated support structures.

Method, system, device for topology optimization, topology optimized component

PatentWO2023061628A1

Innovation

- The method employs a surrogate model that relates unit cell stiffness tensors to average density, using importance weights to optimize the stiffness tensor elements, ensuring that microstructures lie on a Pareto front, allowing for flexible and efficient design optimization without restricting the design space.

Material Science Considerations for Optimized Structures

Material selection plays a pivotal role in topology optimization processes, directly influencing the performance, manufacturability, and economic viability of optimized structures. The interplay between material properties and structural design creates a complex relationship that engineers must navigate carefully when implementing topology optimization solutions.

Traditional engineering materials such as metals, polymers, and composites each present distinct advantages and limitations when subjected to topology optimization algorithms. Metals offer high strength-to-weight ratios and predictable behavior under various loading conditions, making them suitable candidates for optimized structures in aerospace and automotive applications. However, their isotropic nature sometimes limits the full potential of topology optimization, which often generates organic, complex geometries.

Advanced composite materials have emerged as particularly promising for topology-optimized structures due to their anisotropic properties. By strategically orienting fiber directions in conjunction with topology optimization, engineers can achieve unprecedented performance improvements. Carbon fiber reinforced polymers (CFRP), for instance, enable weight reductions of up to 40% compared to traditional metal designs while maintaining equivalent structural integrity.

Material homogeneity assumptions present significant challenges in topology optimization workflows. While algorithms typically assume uniform material properties throughout the design domain, real-world materials exhibit variations in microstructure, grain orientation, and property distribution. These inconsistencies can lead to discrepancies between predicted and actual performance of manufactured components, necessitating robust validation protocols.

The emergence of functionally graded materials (FGMs) represents a paradigm shift in topology optimization approaches. Unlike conventional materials with uniform properties, FGMs feature spatially varying compositions and microstructures, allowing for optimized property distribution throughout a component. This synergy between material science and topology optimization enables designers to address multiple, often competing, performance requirements simultaneously.

Additive manufacturing has dramatically expanded material possibilities for topology-optimized structures. Novel metal alloys, polymer blends, and ceramic composites specifically formulated for 3D printing processes have enabled the realization of previously unbuildable geometries. However, these materials often exhibit anisotropic mechanical properties due to layer-by-layer fabrication, requiring sophisticated material models within optimization algorithms to accurately predict structural behavior.

Environmental considerations increasingly influence material selection for topology-optimized structures. Sustainable materials with reduced environmental footprints, such as recycled polymers or bio-based composites, are gaining traction despite their sometimes challenging mechanical properties. The integration of life cycle assessment metrics into topology optimization workflows represents an emerging frontier in sustainable engineering design.

Traditional engineering materials such as metals, polymers, and composites each present distinct advantages and limitations when subjected to topology optimization algorithms. Metals offer high strength-to-weight ratios and predictable behavior under various loading conditions, making them suitable candidates for optimized structures in aerospace and automotive applications. However, their isotropic nature sometimes limits the full potential of topology optimization, which often generates organic, complex geometries.

Advanced composite materials have emerged as particularly promising for topology-optimized structures due to their anisotropic properties. By strategically orienting fiber directions in conjunction with topology optimization, engineers can achieve unprecedented performance improvements. Carbon fiber reinforced polymers (CFRP), for instance, enable weight reductions of up to 40% compared to traditional metal designs while maintaining equivalent structural integrity.

Material homogeneity assumptions present significant challenges in topology optimization workflows. While algorithms typically assume uniform material properties throughout the design domain, real-world materials exhibit variations in microstructure, grain orientation, and property distribution. These inconsistencies can lead to discrepancies between predicted and actual performance of manufactured components, necessitating robust validation protocols.

The emergence of functionally graded materials (FGMs) represents a paradigm shift in topology optimization approaches. Unlike conventional materials with uniform properties, FGMs feature spatially varying compositions and microstructures, allowing for optimized property distribution throughout a component. This synergy between material science and topology optimization enables designers to address multiple, often competing, performance requirements simultaneously.

Additive manufacturing has dramatically expanded material possibilities for topology-optimized structures. Novel metal alloys, polymer blends, and ceramic composites specifically formulated for 3D printing processes have enabled the realization of previously unbuildable geometries. However, these materials often exhibit anisotropic mechanical properties due to layer-by-layer fabrication, requiring sophisticated material models within optimization algorithms to accurately predict structural behavior.

Environmental considerations increasingly influence material selection for topology-optimized structures. Sustainable materials with reduced environmental footprints, such as recycled polymers or bio-based composites, are gaining traction despite their sometimes challenging mechanical properties. The integration of life cycle assessment metrics into topology optimization workflows represents an emerging frontier in sustainable engineering design.

Cost-Benefit Analysis of Advanced Optimization Techniques

When evaluating the implementation of topology optimization techniques against fabrication constraints, a thorough cost-benefit analysis becomes essential for decision-makers. Advanced optimization techniques offer significant potential advantages in terms of material efficiency, structural performance, and design innovation, but these benefits must be weighed against implementation costs.

The initial investment in topology optimization technology represents a substantial financial commitment. Software licensing for commercial topology optimization tools typically ranges from $10,000 to $50,000 annually, depending on capabilities and vendor support packages. Additionally, organizations must consider hardware requirements, which often necessitate high-performance computing infrastructure to process complex optimization algorithms efficiently.

Personnel training constitutes another significant cost factor. Engineering teams require specialized training to effectively utilize topology optimization software, interpret results, and translate optimized designs into manufacturable components. This training period typically spans 3-6 months before teams achieve proficiency, representing both direct training costs and productivity opportunity costs.

Implementation timelines also impact the cost-benefit equation. While traditional design approaches may yield faster initial results, topology optimization often requires longer design cycles initially but can reduce material usage by 30-50% and improve structural performance by 15-25% in many applications. These efficiency gains typically manifest after the learning curve has been overcome, usually within 6-12 months of implementation.

Manufacturing adaptation costs must be factored into the analysis as well. Topology-optimized designs frequently require advanced manufacturing methods such as additive manufacturing, which may necessitate additional capital investment if these capabilities are not already available in-house. The cost premium for these manufacturing methods can range from 1.5x to 3x compared to conventional manufacturing, though this gap continues to narrow as technologies mature.

Return on investment calculations indicate that organizations typically achieve positive ROI within 18-24 months for medium to large-scale implementation projects. Industries with high material costs or weight-sensitive applications (aerospace, automotive) tend to realize benefits more rapidly than those where material costs represent a smaller portion of overall product costs.

Risk mitigation strategies should be incorporated into the cost-benefit analysis. Phased implementation approaches, beginning with non-critical components, allow organizations to develop expertise while minimizing potential disruption to production schedules and product reliability.

The initial investment in topology optimization technology represents a substantial financial commitment. Software licensing for commercial topology optimization tools typically ranges from $10,000 to $50,000 annually, depending on capabilities and vendor support packages. Additionally, organizations must consider hardware requirements, which often necessitate high-performance computing infrastructure to process complex optimization algorithms efficiently.

Personnel training constitutes another significant cost factor. Engineering teams require specialized training to effectively utilize topology optimization software, interpret results, and translate optimized designs into manufacturable components. This training period typically spans 3-6 months before teams achieve proficiency, representing both direct training costs and productivity opportunity costs.

Implementation timelines also impact the cost-benefit equation. While traditional design approaches may yield faster initial results, topology optimization often requires longer design cycles initially but can reduce material usage by 30-50% and improve structural performance by 15-25% in many applications. These efficiency gains typically manifest after the learning curve has been overcome, usually within 6-12 months of implementation.

Manufacturing adaptation costs must be factored into the analysis as well. Topology-optimized designs frequently require advanced manufacturing methods such as additive manufacturing, which may necessitate additional capital investment if these capabilities are not already available in-house. The cost premium for these manufacturing methods can range from 1.5x to 3x compared to conventional manufacturing, though this gap continues to narrow as technologies mature.

Return on investment calculations indicate that organizations typically achieve positive ROI within 18-24 months for medium to large-scale implementation projects. Industries with high material costs or weight-sensitive applications (aerospace, automotive) tend to realize benefits more rapidly than those where material costs represent a smaller portion of overall product costs.

Risk mitigation strategies should be incorporated into the cost-benefit analysis. Phased implementation approaches, beginning with non-critical components, allow organizations to develop expertise while minimizing potential disruption to production schedules and product reliability.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!