How Topology Optimization Facilitates Future-Ready Product Design

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Topology Optimization Background and Objectives

Topology optimization emerged in the late 1980s as a mathematical approach to material distribution within a design space, subject to specific constraints and performance criteria. This methodology has evolved from simple compliance minimization problems to addressing complex multi-physics and multi-objective design challenges. The fundamental principle involves determining the optimal distribution of material to maximize performance while minimizing resource usage, representing a paradigm shift from traditional design methodologies that relied heavily on intuition and iterative testing.

The evolution of topology optimization has been accelerated by advancements in computational power and algorithm efficiency. Early implementations were limited to simple 2D structures and basic loading conditions, whereas modern applications extend to complex 3D geometries with multiple load cases, manufacturing constraints, and material considerations. The integration of finite element analysis (FEA) with optimization algorithms has been pivotal in this progression, enabling more sophisticated and realistic design solutions.

Current technological trends indicate a convergence of topology optimization with machine learning and artificial intelligence, creating more intelligent design systems capable of learning from previous optimizations and predicting optimal solutions for new design challenges. This synergy promises to further enhance the efficiency and effectiveness of the optimization process, potentially revolutionizing product development workflows.

The primary objective of topology optimization in modern product design is to create structures that achieve optimal performance-to-weight ratios, crucial for industries where efficiency and sustainability are paramount. By systematically removing unnecessary material while maintaining structural integrity, designers can create lightweight yet robust components that reduce material consumption, energy usage, and environmental impact throughout the product lifecycle.

Another significant goal is to facilitate the exploration of novel design solutions that might not be intuitive or accessible through conventional design approaches. Topology optimization algorithms can generate organic, nature-inspired structures that often outperform traditional designs in terms of strength, weight, and material efficiency. These innovative forms represent a departure from conventional design paradigms and open new possibilities for product functionality and aesthetics.

In the context of future-ready product design, topology optimization aims to address the increasing demand for customization and rapid product development. By automating aspects of the design process and enabling quick iterations, it supports agile manufacturing paradigms and reduces time-to-market. Furthermore, it aligns with the growing emphasis on sustainable design practices by optimizing material usage and enhancing product performance, contributing to reduced environmental footprints across various industries.

The evolution of topology optimization has been accelerated by advancements in computational power and algorithm efficiency. Early implementations were limited to simple 2D structures and basic loading conditions, whereas modern applications extend to complex 3D geometries with multiple load cases, manufacturing constraints, and material considerations. The integration of finite element analysis (FEA) with optimization algorithms has been pivotal in this progression, enabling more sophisticated and realistic design solutions.

Current technological trends indicate a convergence of topology optimization with machine learning and artificial intelligence, creating more intelligent design systems capable of learning from previous optimizations and predicting optimal solutions for new design challenges. This synergy promises to further enhance the efficiency and effectiveness of the optimization process, potentially revolutionizing product development workflows.

The primary objective of topology optimization in modern product design is to create structures that achieve optimal performance-to-weight ratios, crucial for industries where efficiency and sustainability are paramount. By systematically removing unnecessary material while maintaining structural integrity, designers can create lightweight yet robust components that reduce material consumption, energy usage, and environmental impact throughout the product lifecycle.

Another significant goal is to facilitate the exploration of novel design solutions that might not be intuitive or accessible through conventional design approaches. Topology optimization algorithms can generate organic, nature-inspired structures that often outperform traditional designs in terms of strength, weight, and material efficiency. These innovative forms represent a departure from conventional design paradigms and open new possibilities for product functionality and aesthetics.

In the context of future-ready product design, topology optimization aims to address the increasing demand for customization and rapid product development. By automating aspects of the design process and enabling quick iterations, it supports agile manufacturing paradigms and reduces time-to-market. Furthermore, it aligns with the growing emphasis on sustainable design practices by optimizing material usage and enhancing product performance, contributing to reduced environmental footprints across various industries.

Market Demand for Lightweight and Efficient Designs

The global market for lightweight and efficient product designs has experienced exponential growth over the past decade, driven primarily by increasing environmental regulations, rising energy costs, and evolving consumer preferences. Industries ranging from aerospace and automotive to consumer electronics and medical devices are actively seeking solutions that reduce material usage while maintaining or enhancing performance characteristics.

In the automotive sector, stringent fuel efficiency standards and the rapid transition toward electric vehicles have created unprecedented demand for weight reduction technologies. According to market research, automotive manufacturers can achieve a 6-10% improvement in fuel economy for every 10% reduction in vehicle weight, creating a powerful economic incentive for topology optimization implementation.

Aerospace remains another critical market driver, with commercial airlines facing dual pressures of environmental compliance and operational cost reduction. The industry's focus on reducing carbon emissions while managing rising fuel costs has positioned lightweight design optimization as a strategic priority, with major manufacturers investing heavily in advanced computational design methods.

Consumer electronics manufacturers are similarly motivated by material efficiency, but with additional emphasis on thermal management and structural integrity within increasingly compact form factors. The miniaturization trend continues to push designers toward more sophisticated optimization techniques that can balance multiple competing performance requirements simultaneously.

The medical device industry represents an emerging market for topology optimization, particularly in implantable devices and prosthetics where customization, biocompatibility, and mechanical performance must be precisely balanced. The growing adoption of additive manufacturing in medical applications has further accelerated interest in topology optimization as these technologies are naturally complementary.

From a geographical perspective, demand is strongest in regions with advanced manufacturing capabilities and stringent environmental regulations. North America, Western Europe, and East Asia currently lead adoption, though emerging economies are showing increasing interest as they develop their manufacturing capabilities and face similar sustainability pressures.

Market analysts project the global software market for topology optimization tools to grow at a compound annual rate exceeding 15% through 2028, reflecting the technology's transition from specialized application to mainstream design methodology. This growth is further supported by the parallel expansion of additive manufacturing capabilities, which enable the production of complex geometries that were previously impossible to manufacture.

The business case for topology optimization continues to strengthen as organizations recognize benefits beyond simple material reduction, including accelerated product development cycles, enhanced product performance, and opportunities for product differentiation through novel designs that would be difficult to conceive using traditional methods.

In the automotive sector, stringent fuel efficiency standards and the rapid transition toward electric vehicles have created unprecedented demand for weight reduction technologies. According to market research, automotive manufacturers can achieve a 6-10% improvement in fuel economy for every 10% reduction in vehicle weight, creating a powerful economic incentive for topology optimization implementation.

Aerospace remains another critical market driver, with commercial airlines facing dual pressures of environmental compliance and operational cost reduction. The industry's focus on reducing carbon emissions while managing rising fuel costs has positioned lightweight design optimization as a strategic priority, with major manufacturers investing heavily in advanced computational design methods.

Consumer electronics manufacturers are similarly motivated by material efficiency, but with additional emphasis on thermal management and structural integrity within increasingly compact form factors. The miniaturization trend continues to push designers toward more sophisticated optimization techniques that can balance multiple competing performance requirements simultaneously.

The medical device industry represents an emerging market for topology optimization, particularly in implantable devices and prosthetics where customization, biocompatibility, and mechanical performance must be precisely balanced. The growing adoption of additive manufacturing in medical applications has further accelerated interest in topology optimization as these technologies are naturally complementary.

From a geographical perspective, demand is strongest in regions with advanced manufacturing capabilities and stringent environmental regulations. North America, Western Europe, and East Asia currently lead adoption, though emerging economies are showing increasing interest as they develop their manufacturing capabilities and face similar sustainability pressures.

Market analysts project the global software market for topology optimization tools to grow at a compound annual rate exceeding 15% through 2028, reflecting the technology's transition from specialized application to mainstream design methodology. This growth is further supported by the parallel expansion of additive manufacturing capabilities, which enable the production of complex geometries that were previously impossible to manufacture.

The business case for topology optimization continues to strengthen as organizations recognize benefits beyond simple material reduction, including accelerated product development cycles, enhanced product performance, and opportunities for product differentiation through novel designs that would be difficult to conceive using traditional methods.

Current State and Technical Barriers in Topology Optimization

Topology optimization has evolved significantly over the past three decades, transitioning from an academic concept to a practical industrial tool. Currently, the technology is widely implemented across various industries including aerospace, automotive, and medical device manufacturing. Commercial software solutions such as Altair OptiStruct, ANSYS Mechanical, and Siemens NX have made topology optimization accessible to design engineers, enabling lightweight structures with optimized material distribution while maintaining structural integrity.

Despite these advancements, topology optimization faces several technical barriers that limit its full potential. The computational intensity of optimization algorithms remains a significant challenge, particularly for complex models with millions of elements, often requiring hours or days to complete even on high-performance computing systems. This computational burden restricts real-time design exploration and iterative refinement processes that are essential for innovative product development.

Manufacturing constraints represent another major obstacle. While topology optimization can generate theoretically optimal designs, these frequently include complex geometries with intricate internal structures that conventional manufacturing methods cannot produce. Although additive manufacturing has alleviated some of these limitations, it introduces its own constraints related to build orientation, support structures, and material properties that must be incorporated into the optimization process.

Multi-physics integration presents a growing challenge as modern products must simultaneously satisfy mechanical, thermal, electromagnetic, and fluid dynamic requirements. Current topology optimization frameworks struggle to effectively handle these coupled physics problems, often requiring separate optimization processes that may yield conflicting design recommendations. The lack of unified multi-physics optimization capabilities forces engineers to make compromises that result in sub-optimal designs.

Material anisotropy and nonlinearity considerations remain underdeveloped in commercial topology optimization tools. Most algorithms assume linear elastic material behavior and isotropy, which does not accurately represent advanced composites, metamaterials, or materials exhibiting nonlinear responses under operational conditions. This limitation restricts the application of topology optimization in cutting-edge materials science and high-performance applications.

Verification and validation methodologies for topology-optimized designs are still evolving. The complex organic shapes generated through optimization often lack intuitive load paths, making traditional engineering validation approaches insufficient. Engineers frequently resort to extensive physical testing or conservative safety factors, negating some of the weight and performance benefits that optimization should provide.

Knowledge gaps in design interpretation and manufacturing translation further complicate implementation. Converting the raw optimization results (typically density distributions) into manufacturable CAD models requires significant manual intervention and engineering judgment, introducing potential inefficiencies and errors in the design-to-manufacturing workflow.

Despite these advancements, topology optimization faces several technical barriers that limit its full potential. The computational intensity of optimization algorithms remains a significant challenge, particularly for complex models with millions of elements, often requiring hours or days to complete even on high-performance computing systems. This computational burden restricts real-time design exploration and iterative refinement processes that are essential for innovative product development.

Manufacturing constraints represent another major obstacle. While topology optimization can generate theoretically optimal designs, these frequently include complex geometries with intricate internal structures that conventional manufacturing methods cannot produce. Although additive manufacturing has alleviated some of these limitations, it introduces its own constraints related to build orientation, support structures, and material properties that must be incorporated into the optimization process.

Multi-physics integration presents a growing challenge as modern products must simultaneously satisfy mechanical, thermal, electromagnetic, and fluid dynamic requirements. Current topology optimization frameworks struggle to effectively handle these coupled physics problems, often requiring separate optimization processes that may yield conflicting design recommendations. The lack of unified multi-physics optimization capabilities forces engineers to make compromises that result in sub-optimal designs.

Material anisotropy and nonlinearity considerations remain underdeveloped in commercial topology optimization tools. Most algorithms assume linear elastic material behavior and isotropy, which does not accurately represent advanced composites, metamaterials, or materials exhibiting nonlinear responses under operational conditions. This limitation restricts the application of topology optimization in cutting-edge materials science and high-performance applications.

Verification and validation methodologies for topology-optimized designs are still evolving. The complex organic shapes generated through optimization often lack intuitive load paths, making traditional engineering validation approaches insufficient. Engineers frequently resort to extensive physical testing or conservative safety factors, negating some of the weight and performance benefits that optimization should provide.

Knowledge gaps in design interpretation and manufacturing translation further complicate implementation. Converting the raw optimization results (typically density distributions) into manufacturable CAD models requires significant manual intervention and engineering judgment, introducing potential inefficiencies and errors in the design-to-manufacturing workflow.

Contemporary Topology Optimization Algorithms and Tools

01 Computational methods for topology optimization

Various computational methods are employed for topology optimization in product design, including finite element analysis, mathematical algorithms, and simulation techniques. These methods help in determining the optimal material distribution within a design space to meet specific performance criteria while minimizing material usage. The optimization process typically involves iterative calculations that analyze stress distribution, load paths, and structural performance to achieve the most efficient design solution.- Computational methods for topology optimization: Various computational methods are employed for topology optimization in product design, including finite element analysis, mathematical algorithms, and simulation techniques. These methods help engineers determine the optimal material distribution within a design space to meet specific performance criteria while minimizing material usage. Advanced algorithms can handle complex constraints and multiple load cases to generate optimized structures that would be difficult to conceive through traditional design approaches.

- Integration of topology optimization in CAD/CAE systems: Topology optimization is increasingly being integrated into computer-aided design (CAD) and computer-aided engineering (CAE) systems to streamline the product development process. This integration allows designers to perform optimization studies directly within their familiar design environments, facilitating iterative design refinement. The seamless workflow between optimization and design tools enables more efficient product development cycles and helps translate optimized concepts into manufacturable designs.

- Additive manufacturing and topology optimization: Topology optimization is particularly well-suited for additive manufacturing (3D printing) processes, as these technologies can produce complex geometries that would be impossible with traditional manufacturing methods. The combination of topology optimization and additive manufacturing enables the creation of lightweight, high-performance components with organic structures that efficiently distribute material only where needed. This synergy is driving innovation in industries such as aerospace, automotive, and medical device manufacturing.

- Multi-objective and multi-physics optimization approaches: Advanced topology optimization techniques incorporate multiple objectives and physics considerations simultaneously. These approaches allow designers to optimize products for various performance criteria such as structural strength, thermal management, fluid flow, and electromagnetic properties. By considering multiple physical phenomena and competing design objectives, engineers can develop products with balanced performance characteristics that meet complex real-world requirements.

- Machine learning enhanced topology optimization: Machine learning and artificial intelligence techniques are being applied to enhance topology optimization processes. These approaches can accelerate optimization calculations, predict performance outcomes, and learn from previous design iterations to suggest improved solutions. By leveraging data from past designs and simulations, AI-enhanced topology optimization can identify non-intuitive design patterns and help engineers explore innovative design spaces more efficiently.

02 Integration of topology optimization in CAD/CAM systems

Topology optimization is increasingly being integrated into Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) systems to streamline the product development process. This integration allows designers to automatically generate optimized structures within their familiar design environments, facilitating the transition from conceptual design to manufacturing. The systems can incorporate various constraints such as manufacturing limitations, material properties, and performance requirements to produce designs that are both optimized and manufacturable.Expand Specific Solutions03 Additive manufacturing and topology optimization

Additive manufacturing technologies have enabled the production of complex geometries resulting from topology optimization that were previously impossible to manufacture. This synergy between topology optimization and 3D printing allows for the creation of lightweight structures with organic forms that maximize performance while minimizing material usage. The process typically involves generating an optimized design, converting it to a printable format, and manufacturing the component layer by layer, enabling the realization of highly efficient designs with internal lattice structures and complex geometries.Expand Specific Solutions04 Multi-objective topology optimization for product design

Multi-objective topology optimization approaches allow designers to simultaneously consider multiple performance criteria when optimizing a product design. These methods balance competing objectives such as structural stiffness, weight reduction, thermal management, and vibration damping to create designs that perform well across various metrics. Advanced algorithms are used to find Pareto-optimal solutions that represent the best possible trade-offs between different design objectives, giving engineers flexibility in selecting the final design based on specific application requirements.Expand Specific Solutions05 Machine learning applications in topology optimization

Machine learning techniques are being applied to enhance topology optimization processes in product design. These approaches use artificial intelligence to predict optimal designs based on training data from previous optimization results, significantly reducing computational time. Neural networks and other machine learning models can learn patterns from successful designs and apply them to new problems, accelerating the optimization process and potentially discovering novel design solutions that traditional methods might miss. This integration of AI with topology optimization is particularly valuable for complex products with multiple design constraints.Expand Specific Solutions

Leading Companies and Research Institutions in the Field

Topology optimization is currently in a growth phase within the product design industry, with an expanding market driven by increasing demand for lightweight, efficient designs across automotive, aerospace, and industrial sectors. The technology has reached moderate maturity, with leading companies like Siemens AG, Autodesk, Dassault Systèmes, and ANSYS offering sophisticated commercial solutions. Academic institutions including Georgia Tech, Huazhong University of Science & Technology, and Northwestern University are advancing fundamental research. While large corporations like Honda and Toyota are implementing topology optimization in manufacturing processes, the technology is becoming more accessible to smaller companies through cloud-based platforms, indicating a market transitioning from early adoption to mainstream implementation with continued innovation potential.

Siemens AG

Technical Solution: Siemens has developed comprehensive topology optimization solutions integrated within their Simcenter and NX software suites. Their approach combines parametric CAD modeling with advanced simulation capabilities to create lightweight yet structurally sound components. Siemens' topology optimization technology employs mathematical algorithms that distribute material efficiently based on defined load cases and boundary conditions, removing unnecessary material while maintaining structural integrity. Their solution incorporates manufacturing constraints such as minimum member size, symmetry requirements, and extrusion directions to ensure designs are producible[1]. Siemens has particularly focused on additive manufacturing integration, allowing designers to create complex organic structures that would be impossible with traditional manufacturing methods. Their software can automatically generate lattice structures and optimize their density distribution based on stress patterns, significantly reducing weight while maintaining performance requirements[2]. Siemens also offers cloud-based high-performance computing capabilities to handle complex optimization problems efficiently.

Strengths: Seamless integration across design and manufacturing workflows; robust manufacturing constraint handling; specialized solutions for additive manufacturing; cloud computing capabilities for complex problems. Weaknesses: Steep learning curve for new users; high computational requirements for complex optimizations; requires significant expertise to fully leverage advanced features.

Autodesk, Inc.

Technical Solution: Autodesk has pioneered generative design approaches to topology optimization through their Fusion 360 platform. Their technology utilizes cloud computing to explore thousands of design alternatives simultaneously based on specified constraints and performance goals. Autodesk's solution employs machine learning algorithms that learn from previous optimization results to improve future iterations, creating a continuously evolving design system[3]. Their approach allows engineers to input manufacturing constraints, material specifications, and performance requirements, then generates multiple viable design options that meet these criteria. Autodesk's system particularly excels at multi-objective optimization, balancing competing factors like weight reduction, strength requirements, and manufacturing costs. The platform includes simulation capabilities that validate optimized designs against real-world conditions, including structural, thermal, and fluid dynamics analyses[4]. Autodesk has also developed specialized tools for specific industries, such as aerospace and automotive, with pre-configured optimization parameters tailored to those sectors' requirements.

Strengths: Intuitive user interface accessible to non-specialists; cloud-based processing for rapid iteration; multi-objective optimization capabilities; strong visualization tools for comparing design alternatives. Weaknesses: Subscription-based pricing model can be costly for smaller organizations; limited control over optimization algorithms compared to some specialized tools; occasional connectivity issues with cloud-based processing.

Key Patents and Research Breakthroughs in Optimization Methods

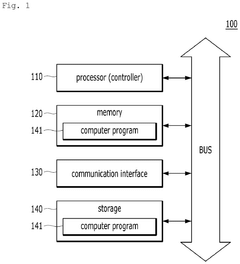

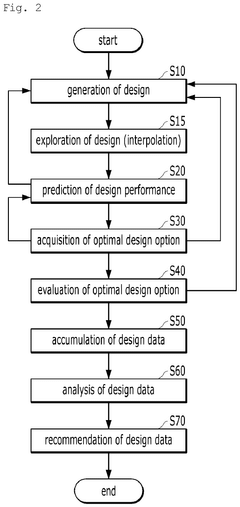

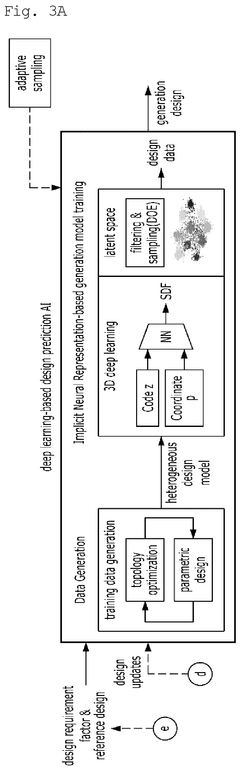

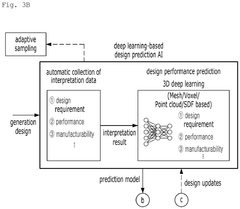

Artificial intelligence-based generative design method and device, and computer program

PatentPendingEP4524807A1

Innovation

- An artificial intelligence-based generative design method that uses topology optimization and parametric design to generate new product designs, predicts performance, and provides optimal design models trained with performance data, leveraging implicit neural representations and reference data to overcome data scarcity and expert shortages.

Topology optimization for designing engineering product

PatentActiveUS8126684B2

Innovation

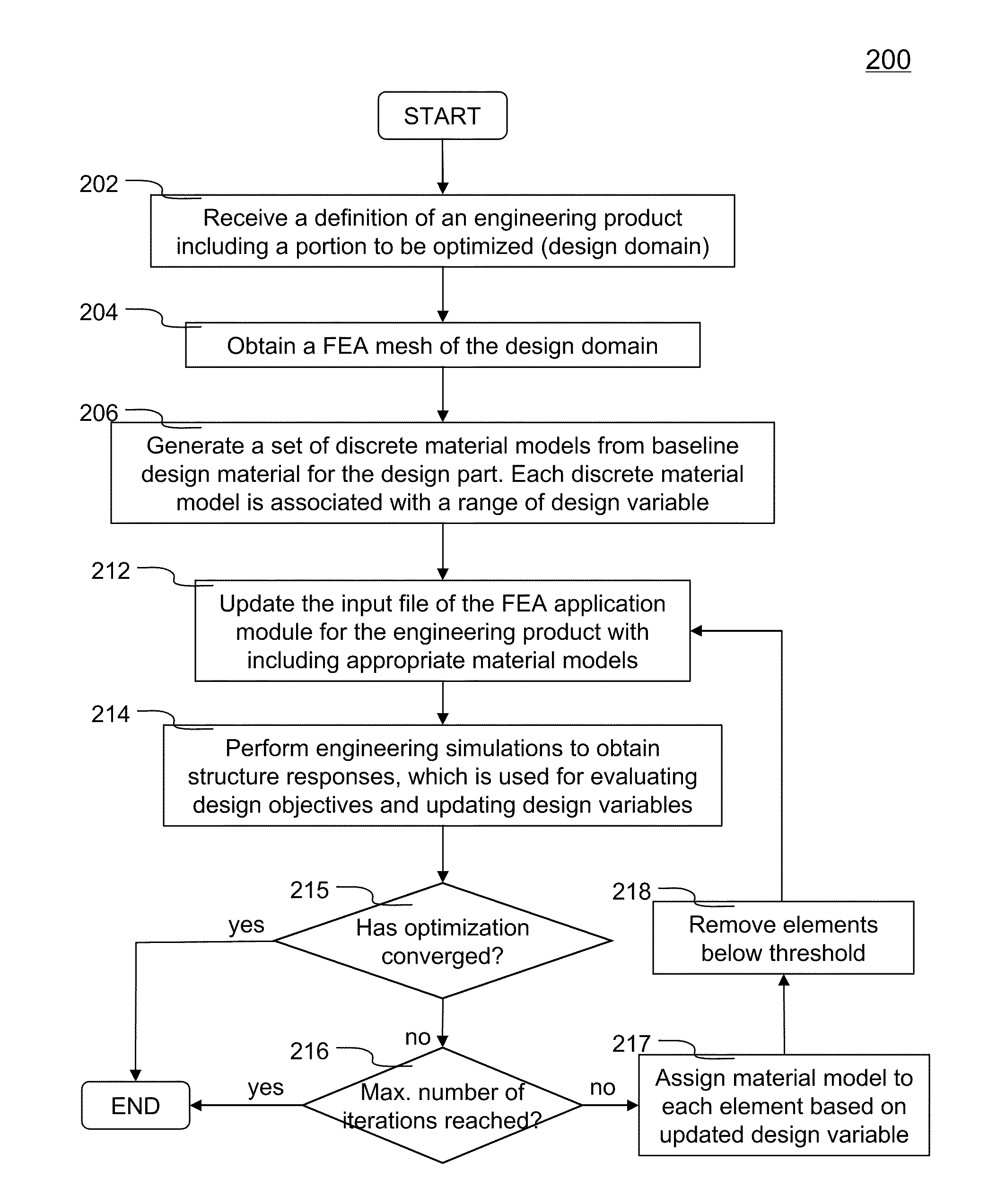

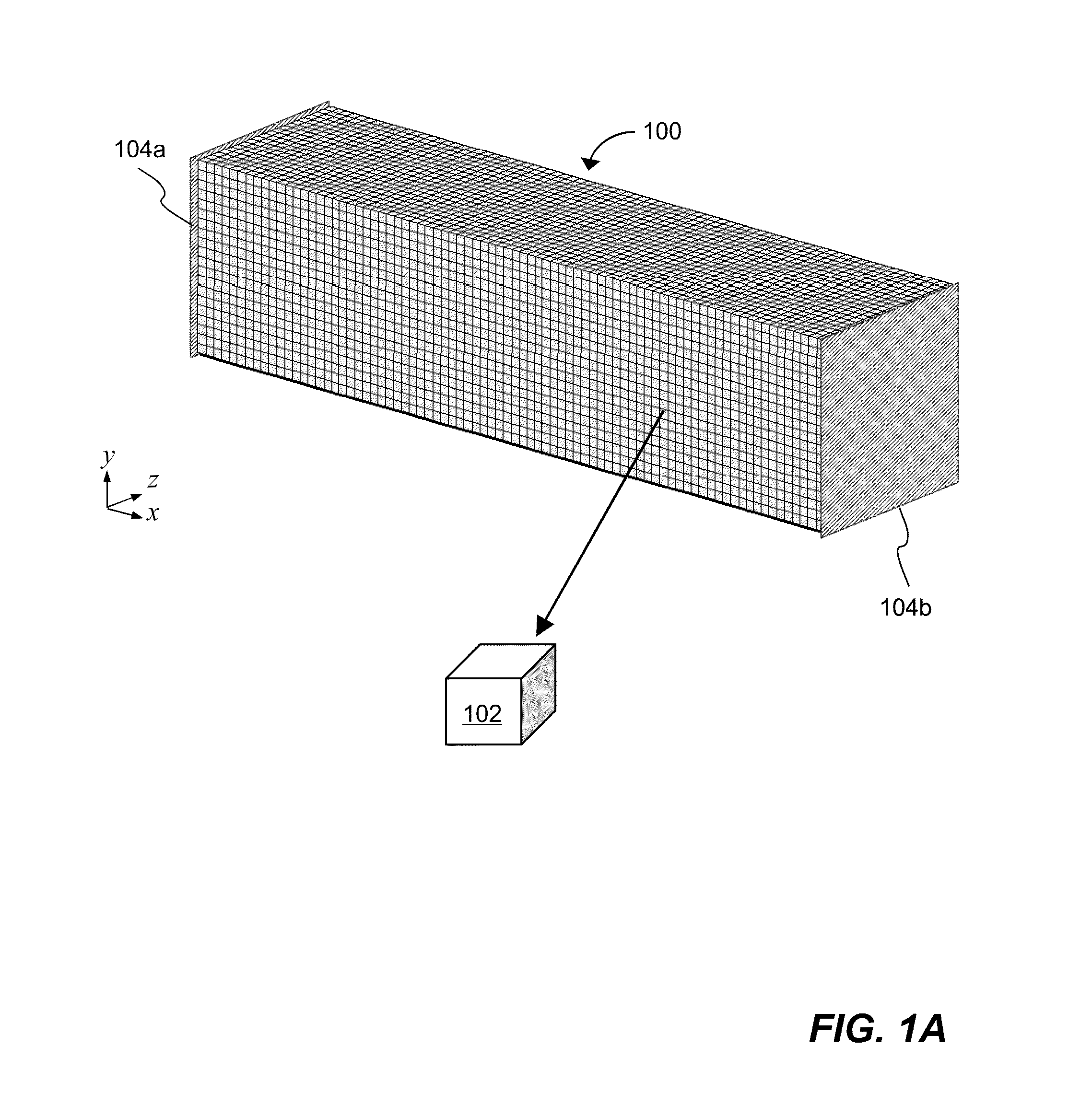

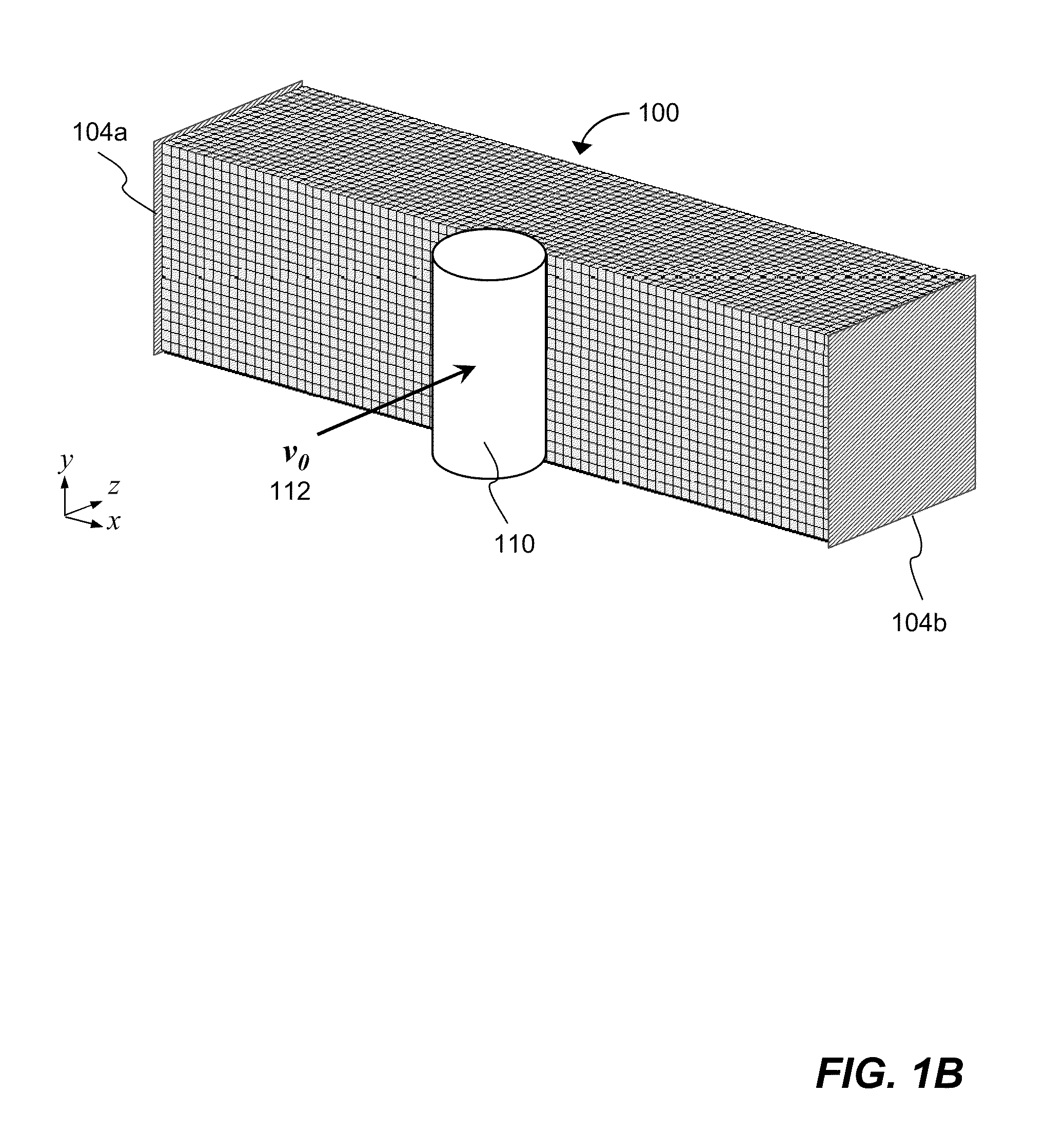

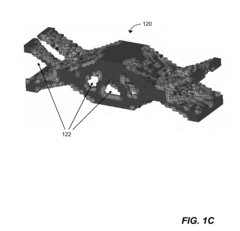

- The method involves defining a design domain with discrete material models, iterative finite element analysis, and hybrid cellular automata to converge on an optimal topology by updating design variables and removing elements below a threshold, reducing numerical discontinuity and achieving design objectives within constraints.

Manufacturing Considerations for Topology-Optimized Components

The manufacturing of topology-optimized components presents unique challenges that require careful consideration throughout the design and production process. Traditional manufacturing methods often struggle with the complex geometries that result from topology optimization algorithms, necessitating innovative approaches to production.

Additive manufacturing (AM) technologies, particularly metal 3D printing processes like Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS), have emerged as primary enablers for topology-optimized designs. These technologies can produce complex organic structures with internal cavities and lattice frameworks that would be impossible to create using conventional manufacturing methods. However, they introduce considerations regarding build orientation, support structures, and post-processing requirements that must be addressed during the design phase.

Design for Manufacturability (DFM) principles must be adapted specifically for topology-optimized components. This includes establishing minimum feature size constraints, controlling overhang angles, and ensuring proper powder removal channels for metal AM processes. Engineers must balance the theoretical optimal design with practical manufacturing constraints, often requiring iterative refinement of optimization parameters.

Material selection becomes increasingly critical for topology-optimized components. The anisotropic properties of additively manufactured parts can significantly impact performance, particularly in high-stress applications. Material characterization and qualification processes must account for these directional properties and potential variations in mechanical behavior compared to traditionally manufactured counterparts.

Post-processing requirements represent another significant consideration. Topology-optimized components frequently require support removal, surface finishing, heat treatment, and machining of critical interfaces. These steps add complexity and cost to the manufacturing process, potentially offsetting some of the material savings achieved through optimization.

Hybrid manufacturing approaches are gaining traction as practical solutions for topology-optimized components. These methods combine additive manufacturing for complex geometric features with traditional machining for critical functional surfaces, offering a balance between design freedom and manufacturing precision.

Quality assurance presents unique challenges for topology-optimized components. Non-destructive testing methods must be adapted to inspect complex internal geometries, often requiring advanced techniques like computed tomography (CT) scanning. Process monitoring during manufacturing becomes essential to ensure consistent quality, particularly for critical applications in aerospace and medical industries.

Cost considerations remain a significant factor in the adoption of topology-optimized designs. While material savings can be substantial, the increased manufacturing complexity and specialized equipment requirements may result in higher production costs, particularly for low-volume applications. A comprehensive cost-benefit analysis must account for both direct manufacturing costs and lifecycle performance improvements.

Additive manufacturing (AM) technologies, particularly metal 3D printing processes like Selective Laser Melting (SLM) and Direct Metal Laser Sintering (DMLS), have emerged as primary enablers for topology-optimized designs. These technologies can produce complex organic structures with internal cavities and lattice frameworks that would be impossible to create using conventional manufacturing methods. However, they introduce considerations regarding build orientation, support structures, and post-processing requirements that must be addressed during the design phase.

Design for Manufacturability (DFM) principles must be adapted specifically for topology-optimized components. This includes establishing minimum feature size constraints, controlling overhang angles, and ensuring proper powder removal channels for metal AM processes. Engineers must balance the theoretical optimal design with practical manufacturing constraints, often requiring iterative refinement of optimization parameters.

Material selection becomes increasingly critical for topology-optimized components. The anisotropic properties of additively manufactured parts can significantly impact performance, particularly in high-stress applications. Material characterization and qualification processes must account for these directional properties and potential variations in mechanical behavior compared to traditionally manufactured counterparts.

Post-processing requirements represent another significant consideration. Topology-optimized components frequently require support removal, surface finishing, heat treatment, and machining of critical interfaces. These steps add complexity and cost to the manufacturing process, potentially offsetting some of the material savings achieved through optimization.

Hybrid manufacturing approaches are gaining traction as practical solutions for topology-optimized components. These methods combine additive manufacturing for complex geometric features with traditional machining for critical functional surfaces, offering a balance between design freedom and manufacturing precision.

Quality assurance presents unique challenges for topology-optimized components. Non-destructive testing methods must be adapted to inspect complex internal geometries, often requiring advanced techniques like computed tomography (CT) scanning. Process monitoring during manufacturing becomes essential to ensure consistent quality, particularly for critical applications in aerospace and medical industries.

Cost considerations remain a significant factor in the adoption of topology-optimized designs. While material savings can be substantial, the increased manufacturing complexity and specialized equipment requirements may result in higher production costs, particularly for low-volume applications. A comprehensive cost-benefit analysis must account for both direct manufacturing costs and lifecycle performance improvements.

Sustainability Impact of Topology-Optimized Product Design

Topology optimization is emerging as a powerful tool for sustainable product design, offering significant environmental benefits throughout the product lifecycle. By optimizing material distribution and minimizing waste, topology-optimized designs typically require 30-50% less raw material than traditional designs, directly reducing resource consumption and associated environmental impacts from extraction and processing activities.

The manufacturing phase benefits substantially from these optimized designs. The reduced material requirements translate to lower energy consumption during production processes, with studies indicating energy savings of up to 40% for certain metal components. Additionally, the lightweight nature of topology-optimized parts contributes to reduced carbon emissions during transportation and distribution phases.

During the product use phase, topology-optimized components deliver enhanced sustainability through improved performance efficiency. In automotive and aerospace applications, weight reductions of 25-60% have been documented, directly correlating with fuel efficiency improvements of 5-15% depending on the component and application. These efficiency gains compound over the product lifecycle, representing significant energy savings and emissions reductions.

End-of-life considerations also demonstrate sustainability advantages. The precise material allocation in topology-optimized designs facilitates more effective recycling processes, as components often contain fewer material types and more homogeneous structures. This design approach aligns well with circular economy principles, enabling easier disassembly and material recovery.

Quantitative lifecycle assessments of topology-optimized products consistently demonstrate reduced environmental footprints. A comprehensive study of aerospace components showed a 35% reduction in overall carbon footprint compared to conventionally designed parts, while automotive applications demonstrated 20-40% reductions in lifecycle environmental impact scores across multiple impact categories.

The economic dimension of sustainability also benefits, as material savings and performance improvements often offset the higher initial design costs. Organizations implementing topology optimization report average material cost reductions of 25-45%, with additional savings realized through reduced energy consumption and extended product lifespans due to optimized stress distribution and fatigue resistance.

As computational capabilities advance, topology optimization's sustainability benefits continue to expand. Integration with multi-material optimization and design for additive manufacturing further enhances the sustainability potential, enabling even more resource-efficient products with optimized performance characteristics and minimal environmental impact throughout their lifecycle.

The manufacturing phase benefits substantially from these optimized designs. The reduced material requirements translate to lower energy consumption during production processes, with studies indicating energy savings of up to 40% for certain metal components. Additionally, the lightweight nature of topology-optimized parts contributes to reduced carbon emissions during transportation and distribution phases.

During the product use phase, topology-optimized components deliver enhanced sustainability through improved performance efficiency. In automotive and aerospace applications, weight reductions of 25-60% have been documented, directly correlating with fuel efficiency improvements of 5-15% depending on the component and application. These efficiency gains compound over the product lifecycle, representing significant energy savings and emissions reductions.

End-of-life considerations also demonstrate sustainability advantages. The precise material allocation in topology-optimized designs facilitates more effective recycling processes, as components often contain fewer material types and more homogeneous structures. This design approach aligns well with circular economy principles, enabling easier disassembly and material recovery.

Quantitative lifecycle assessments of topology-optimized products consistently demonstrate reduced environmental footprints. A comprehensive study of aerospace components showed a 35% reduction in overall carbon footprint compared to conventionally designed parts, while automotive applications demonstrated 20-40% reductions in lifecycle environmental impact scores across multiple impact categories.

The economic dimension of sustainability also benefits, as material savings and performance improvements often offset the higher initial design costs. Organizations implementing topology optimization report average material cost reductions of 25-45%, with additional savings realized through reduced energy consumption and extended product lifespans due to optimized stress distribution and fatigue resistance.

As computational capabilities advance, topology optimization's sustainability benefits continue to expand. Integration with multi-material optimization and design for additive manufacturing further enhances the sustainability potential, enabling even more resource-efficient products with optimized performance characteristics and minimal environmental impact throughout their lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!