Compare Durability Features: Topology Optimization vs Stress-Relieved Design

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Topology Optimization and Stress-Relief Design Background

Topology optimization and stress-relieved design represent two distinct approaches in engineering design methodology, each with its own historical development trajectory and technical foundations. Topology optimization emerged in the late 1980s as a mathematical method for optimizing material layout within a given design space. The pioneering work of Martin Bendsøe and Noboru Kikuchi in 1988 established the theoretical foundation through the homogenization method, which was later refined into the Solid Isotropic Material with Penalization (SIMP) approach that remains widely used today.

In contrast, stress-relieved design has evolved from traditional engineering practices focused on identifying and mitigating stress concentrations in structures. This approach gained systematic formalization in the mid-20th century with advances in stress analysis techniques and the development of finite element analysis (FEA) tools in the 1960s, which enabled more precise identification of high-stress regions in complex geometries.

The fundamental difference between these approaches lies in their underlying philosophy. Topology optimization adopts a "ground-up" methodology, starting with a maximum design space and systematically removing material to achieve an optimal structure based on specified load conditions and constraints. This process is inherently mathematical and often produces organic, non-intuitive geometries that can be challenging to manufacture using conventional methods.

Stress-relieved design, conversely, follows a more traditional "top-down" approach where engineers start with a baseline design and iteratively modify it to reduce stress concentrations through features such as fillets, chamfers, and strategic material distribution. This methodology relies heavily on engineering intuition, established design principles, and empirical knowledge.

The technological evolution of both approaches has been significantly accelerated by advancements in computational power and algorithm development. For topology optimization, the introduction of level-set methods in the early 2000s and more recently, machine learning techniques, has expanded its applicability across industries. Similarly, stress-relieved design has benefited from increasingly sophisticated simulation tools that can predict structural behavior with greater accuracy.

Today, these methodologies exist along a continuum of design approaches, with hybrid methods emerging that leverage the strengths of both. The integration of topology optimization results with stress-relieved features represents a growing trend in engineering design, particularly in industries where durability requirements are paramount, such as aerospace, automotive, and medical device manufacturing.

In contrast, stress-relieved design has evolved from traditional engineering practices focused on identifying and mitigating stress concentrations in structures. This approach gained systematic formalization in the mid-20th century with advances in stress analysis techniques and the development of finite element analysis (FEA) tools in the 1960s, which enabled more precise identification of high-stress regions in complex geometries.

The fundamental difference between these approaches lies in their underlying philosophy. Topology optimization adopts a "ground-up" methodology, starting with a maximum design space and systematically removing material to achieve an optimal structure based on specified load conditions and constraints. This process is inherently mathematical and often produces organic, non-intuitive geometries that can be challenging to manufacture using conventional methods.

Stress-relieved design, conversely, follows a more traditional "top-down" approach where engineers start with a baseline design and iteratively modify it to reduce stress concentrations through features such as fillets, chamfers, and strategic material distribution. This methodology relies heavily on engineering intuition, established design principles, and empirical knowledge.

The technological evolution of both approaches has been significantly accelerated by advancements in computational power and algorithm development. For topology optimization, the introduction of level-set methods in the early 2000s and more recently, machine learning techniques, has expanded its applicability across industries. Similarly, stress-relieved design has benefited from increasingly sophisticated simulation tools that can predict structural behavior with greater accuracy.

Today, these methodologies exist along a continuum of design approaches, with hybrid methods emerging that leverage the strengths of both. The integration of topology optimization results with stress-relieved features represents a growing trend in engineering design, particularly in industries where durability requirements are paramount, such as aerospace, automotive, and medical device manufacturing.

Market Demand for Durable Structural Solutions

The global market for durable structural solutions has witnessed significant growth in recent years, driven by increasing demands across various industries including aerospace, automotive, construction, and medical devices. This growth trajectory is expected to continue as industries seek more efficient, lightweight, and durable structural components that can withstand complex loading conditions while minimizing material usage.

The market size for advanced structural optimization technologies was valued at approximately $3.2 billion in 2022 and is projected to reach $5.7 billion by 2027, representing a compound annual growth rate of 12.3%. This growth is particularly pronounced in sectors where weight reduction directly translates to operational efficiency, such as aerospace and automotive industries.

Topology optimization solutions have gained substantial market traction, with adoption rates increasing by 18% annually over the past five years. This acceleration is driven by the technology's ability to reduce material usage by 30-50% while maintaining or improving structural performance. The market demand is further bolstered by sustainability initiatives and regulatory pressures to reduce carbon footprints across manufacturing sectors.

Stress-relieved design approaches continue to maintain a significant market share, particularly in industries with established manufacturing processes and stringent safety requirements. The market for stress-relieved design solutions was estimated at $2.1 billion in 2022, with steady growth projected at 7-8% annually through 2027.

Regional analysis indicates that North America and Europe currently lead in the adoption of advanced structural optimization technologies, accounting for approximately 65% of the global market. However, the Asia-Pacific region is experiencing the fastest growth rate at 15.2% annually, driven by rapid industrialization and increasing R&D investments in countries like China, Japan, and South Korea.

Industry surveys reveal that 78% of engineering firms cite durability as a critical factor in structural design decisions, with 63% actively seeking solutions that can predict and enhance component lifespan under variable loading conditions. This represents a significant shift from traditional design approaches that primarily focused on static strength parameters.

The market is also witnessing increased demand for integrated solutions that combine topology optimization with stress-relief considerations, reflecting a growing recognition that optimal durability requires a multifaceted approach. This integration trend is expected to create new market opportunities, with early adopters reporting 15-20% improvements in component lifespan compared to using either approach in isolation.

The market size for advanced structural optimization technologies was valued at approximately $3.2 billion in 2022 and is projected to reach $5.7 billion by 2027, representing a compound annual growth rate of 12.3%. This growth is particularly pronounced in sectors where weight reduction directly translates to operational efficiency, such as aerospace and automotive industries.

Topology optimization solutions have gained substantial market traction, with adoption rates increasing by 18% annually over the past five years. This acceleration is driven by the technology's ability to reduce material usage by 30-50% while maintaining or improving structural performance. The market demand is further bolstered by sustainability initiatives and regulatory pressures to reduce carbon footprints across manufacturing sectors.

Stress-relieved design approaches continue to maintain a significant market share, particularly in industries with established manufacturing processes and stringent safety requirements. The market for stress-relieved design solutions was estimated at $2.1 billion in 2022, with steady growth projected at 7-8% annually through 2027.

Regional analysis indicates that North America and Europe currently lead in the adoption of advanced structural optimization technologies, accounting for approximately 65% of the global market. However, the Asia-Pacific region is experiencing the fastest growth rate at 15.2% annually, driven by rapid industrialization and increasing R&D investments in countries like China, Japan, and South Korea.

Industry surveys reveal that 78% of engineering firms cite durability as a critical factor in structural design decisions, with 63% actively seeking solutions that can predict and enhance component lifespan under variable loading conditions. This represents a significant shift from traditional design approaches that primarily focused on static strength parameters.

The market is also witnessing increased demand for integrated solutions that combine topology optimization with stress-relief considerations, reflecting a growing recognition that optimal durability requires a multifaceted approach. This integration trend is expected to create new market opportunities, with early adopters reporting 15-20% improvements in component lifespan compared to using either approach in isolation.

Current Challenges in Durability Engineering

Durability engineering faces significant challenges in today's rapidly evolving manufacturing landscape. The increasing demand for lightweight yet robust structures has pushed traditional design methodologies to their limits. Engineers must now balance material efficiency with structural integrity while meeting stringent performance requirements across diverse operating conditions.

One of the primary challenges is the accurate prediction of fatigue life under complex loading scenarios. Current computational models often struggle to account for multiaxial stress states, variable amplitude loading, and environmental factors simultaneously. This limitation frequently leads to over-conservative designs or, conversely, unexpected failures in service.

Material inconsistency presents another substantial hurdle. Even with advanced manufacturing processes, variations in material properties can significantly impact durability performance. These inconsistencies become particularly problematic when designing critical components where failure could lead to catastrophic consequences, necessitating extensive testing and validation protocols.

The integration of new materials, particularly composites and additively manufactured components, introduces additional complexity. These materials often exhibit anisotropic properties and failure mechanisms that differ substantially from traditional metals. Existing durability assessment methodologies developed for isotropic materials may not adequately capture the behavior of these advanced materials, creating a significant knowledge gap.

Topology optimization and stress-relieved design approaches each present their own unique challenges. While topology optimization can generate geometrically complex structures with theoretically optimal material distribution, the resulting designs may contain stress concentrations that are difficult to manufacture and potentially compromise durability. Conversely, stress-relieved designs may address localized stress issues but often result in suboptimal material usage and weight penalties.

The validation of durability models represents another significant challenge. Accelerated testing methods may not accurately represent real-world conditions, while full-scale testing is time-consuming and expensive. This creates a persistent tension between confidence in design durability and time-to-market pressures.

Furthermore, the industry faces a growing need to incorporate sustainability considerations into durability engineering. Designs must not only withstand mechanical loads but also account for environmental impacts throughout the product lifecycle. This expanded scope requires new methodologies that can simultaneously optimize for durability, material efficiency, and environmental footprint.

As computational capabilities advance, managing the increasing complexity of simulation models becomes more challenging. Engineers must determine appropriate fidelity levels and validation strategies to ensure reliable durability predictions while maintaining reasonable computational costs and development timelines.

One of the primary challenges is the accurate prediction of fatigue life under complex loading scenarios. Current computational models often struggle to account for multiaxial stress states, variable amplitude loading, and environmental factors simultaneously. This limitation frequently leads to over-conservative designs or, conversely, unexpected failures in service.

Material inconsistency presents another substantial hurdle. Even with advanced manufacturing processes, variations in material properties can significantly impact durability performance. These inconsistencies become particularly problematic when designing critical components where failure could lead to catastrophic consequences, necessitating extensive testing and validation protocols.

The integration of new materials, particularly composites and additively manufactured components, introduces additional complexity. These materials often exhibit anisotropic properties and failure mechanisms that differ substantially from traditional metals. Existing durability assessment methodologies developed for isotropic materials may not adequately capture the behavior of these advanced materials, creating a significant knowledge gap.

Topology optimization and stress-relieved design approaches each present their own unique challenges. While topology optimization can generate geometrically complex structures with theoretically optimal material distribution, the resulting designs may contain stress concentrations that are difficult to manufacture and potentially compromise durability. Conversely, stress-relieved designs may address localized stress issues but often result in suboptimal material usage and weight penalties.

The validation of durability models represents another significant challenge. Accelerated testing methods may not accurately represent real-world conditions, while full-scale testing is time-consuming and expensive. This creates a persistent tension between confidence in design durability and time-to-market pressures.

Furthermore, the industry faces a growing need to incorporate sustainability considerations into durability engineering. Designs must not only withstand mechanical loads but also account for environmental impacts throughout the product lifecycle. This expanded scope requires new methodologies that can simultaneously optimize for durability, material efficiency, and environmental footprint.

As computational capabilities advance, managing the increasing complexity of simulation models becomes more challenging. Engineers must determine appropriate fidelity levels and validation strategies to ensure reliable durability predictions while maintaining reasonable computational costs and development timelines.

Comparative Analysis of Current Durability Solutions

01 Topology optimization methods for stress reduction

Topology optimization techniques can be employed to design structures with reduced stress concentrations. These methods involve mathematical algorithms that distribute material within a design space to minimize stress while maintaining structural integrity. By optimizing the material layout, designers can create components with more uniform stress distribution, leading to improved durability and longer service life. The optimization process typically considers loading conditions, boundary constraints, and manufacturing limitations to produce practical designs with enhanced stress characteristics.- Topology optimization methods for stress reduction: Topology optimization techniques can be employed to design structures with optimized material distribution that minimizes stress concentrations. These methods use mathematical algorithms to determine the optimal shape and material layout that can withstand specified loads while reducing stress hotspots. By strategically removing material from low-stress areas and reinforcing high-stress regions, these approaches create designs with improved durability and longevity while maintaining structural integrity.

- Stress-relieved design through simulation and analysis: Advanced simulation and analysis tools enable engineers to identify stress concentrations and optimize designs accordingly. These tools incorporate finite element analysis (FEA) to predict stress distribution under various loading conditions, allowing for iterative design improvements. By simulating real-world conditions before physical prototyping, designers can identify potential failure points and implement stress-relieving features such as fillets, chamfers, or material transitions that enhance durability while maintaining performance requirements.

- Multi-objective optimization for durability enhancement: Multi-objective optimization approaches balance competing design goals such as weight reduction, stress minimization, and durability enhancement. These methods consider multiple performance criteria simultaneously, allowing designers to find optimal trade-offs between conflicting objectives. By incorporating durability metrics directly into the optimization process, these techniques produce designs that maintain structural integrity over extended service lives while meeting other performance requirements such as weight targets or manufacturing constraints.

- Lattice and cellular structures for stress distribution: Lattice and cellular structures provide effective means for distributing stress throughout a component. These architectures feature repeating patterns of interconnected struts or cells that can be tailored to manage load paths and stress concentrations. By optimizing the geometry, orientation, and density of these structures, designers can create lightweight components with improved stress distribution characteristics. These approaches are particularly valuable in additive manufacturing contexts, where complex internal geometries can be readily produced.

- Manufacturing considerations for stress-relieved designs: Manufacturing processes significantly impact the stress characteristics and durability of optimized designs. Considerations such as build orientation, support structures, and post-processing treatments must be integrated into the topology optimization workflow to ensure that theoretical benefits are realized in physical components. Techniques such as heat treatment, shot peening, and strategic machining can be applied to relieve residual stresses introduced during manufacturing, further enhancing component durability and fatigue resistance.

02 Simulation-based design validation for durability

Advanced simulation techniques are used to validate designs for durability under various stress conditions. These approaches involve finite element analysis, computational fluid dynamics, and other numerical methods to predict how designs will perform under operational loads. By simulating real-world conditions, engineers can identify potential failure points before physical prototyping, allowing for design refinements that enhance durability. The simulation process may include static and dynamic loading scenarios, thermal effects, and fatigue analysis to comprehensively assess design performance.Expand Specific Solutions03 Multi-objective optimization for balanced design performance

Multi-objective optimization approaches balance stress reduction with other critical design parameters such as weight, cost, and manufacturability. These methods use algorithms that consider multiple competing objectives simultaneously to find optimal design solutions. By incorporating various performance metrics into the optimization process, engineers can develop designs that achieve stress relief while maintaining practical constraints. This balanced approach ensures that durability improvements don't compromise other essential aspects of product performance, resulting in holistically optimized designs.Expand Specific Solutions04 Lattice and cellular structures for stress distribution

Lattice and cellular structures provide effective means for distributing stress throughout a component. These architectures feature repeating patterns of material and void space that can be tailored to manage load paths and minimize stress concentrations. By strategically designing these microstructures, engineers can create lightweight components with enhanced durability. Advanced manufacturing techniques like additive manufacturing enable the production of complex lattice geometries that would be impossible with traditional manufacturing methods, opening new possibilities for stress-optimized designs.Expand Specific Solutions05 Machine learning approaches for durability prediction

Machine learning algorithms are increasingly applied to predict and improve design durability under stress conditions. These data-driven approaches analyze patterns from simulation results, physical tests, and field performance to identify relationships between design parameters and durability outcomes. By leveraging historical data and computational intelligence, engineers can develop more accurate predictions of how designs will perform over time and under various loading conditions. Machine learning models can also suggest design modifications that might not be obvious through traditional engineering approaches, leading to innovative stress-relieved solutions.Expand Specific Solutions

Leading Companies in Advanced Structural Design

The topology optimization vs stress-relieved design durability comparison reveals an evolving competitive landscape in advanced structural engineering. Currently in a growth phase, this field is expanding rapidly with a market size estimated at several billion dollars annually. Technologically, academic institutions like Huazhong University of Science & Technology and Zhejiang University are driving fundamental research, while commercial implementation is led by Autodesk, Siemens AG, and Dassault Systèmes. These companies have integrated topology optimization into their CAD/CAE platforms, with automotive manufacturers like Honda and industrial equipment producers like Caterpillar applying these technologies to achieve weight reduction while maintaining structural integrity. The technology is approaching maturity in aerospace and automotive sectors but remains emergent in broader manufacturing applications.

Autodesk, Inc.

Technical Solution: Autodesk has developed advanced topology optimization solutions through their Fusion 360 and Generative Design platforms. Their approach integrates simulation-driven design with manufacturing constraints to create lightweight yet durable structures. The technology employs mathematical algorithms that distribute material efficiently within a defined design space while meeting specified performance criteria. Autodesk's solution analyzes multiple load cases simultaneously and optimizes material distribution to achieve maximum stiffness-to-weight ratios. Their platform incorporates stress analysis tools that can predict high-stress concentrations and automatically refine designs to eliminate potential failure points. The system also includes validation capabilities that compare topology-optimized designs against traditional stress-relieved approaches, providing quantitative metrics on performance improvements, weight reduction, and material savings.

Strengths: Seamless integration with CAD/CAM workflows, intuitive user interface, and cloud-based computing resources for complex optimizations. Weaknesses: Higher computational requirements for complex models and potential challenges in manufacturing highly optimized organic shapes without post-processing.

Siemens AG

Technical Solution: Siemens has pioneered comprehensive solutions for both topology optimization and stress-relieved design through their NX and Simcenter software suites. Their approach integrates advanced finite element analysis with manufacturing constraints to create production-ready optimized components. Siemens' technology employs multi-physics simulation capabilities that account for thermal, structural, and dynamic loads simultaneously when optimizing topology. Their platform features specialized algorithms that can identify and mitigate stress concentrations through automated design refinement processes. Siemens has developed proprietary methods for comparing topology-optimized designs against traditional stress-relieved approaches, quantifying improvements in durability, weight reduction, and performance metrics. The system incorporates machine learning techniques to predict potential failure modes and automatically suggest design modifications to enhance durability while maintaining optimal material distribution.

Strengths: Comprehensive digital twin capabilities, extensive manufacturing constraint options, and robust validation tools for industrial applications. Weaknesses: Complex software ecosystem with steep learning curve and significant computational resources required for large-scale optimization problems.

Key Technical Innovations in Both Design Approaches

Stress-based Topology Optimization Method and Tool

PatentInactiveUS20100274537A1

Innovation

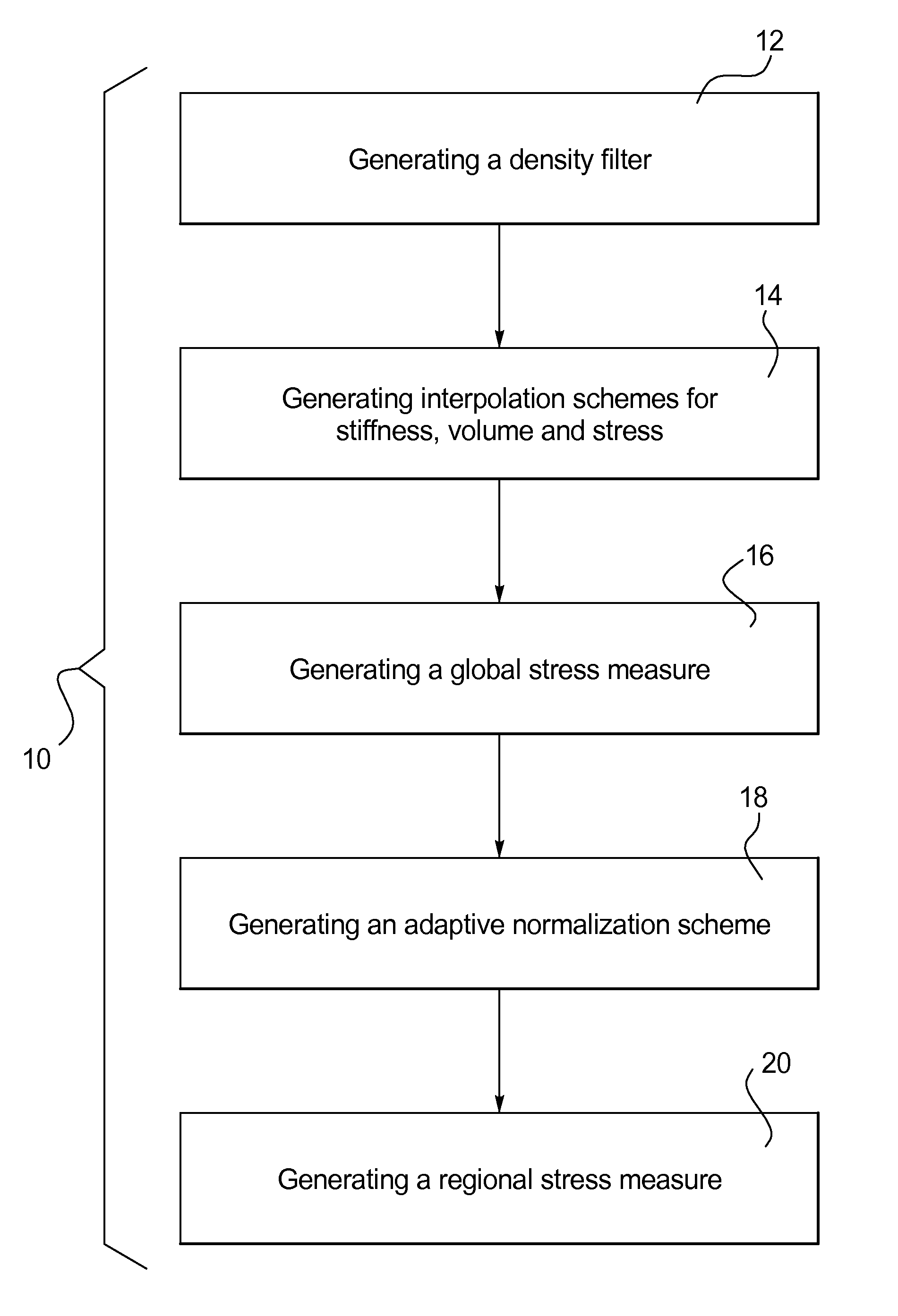

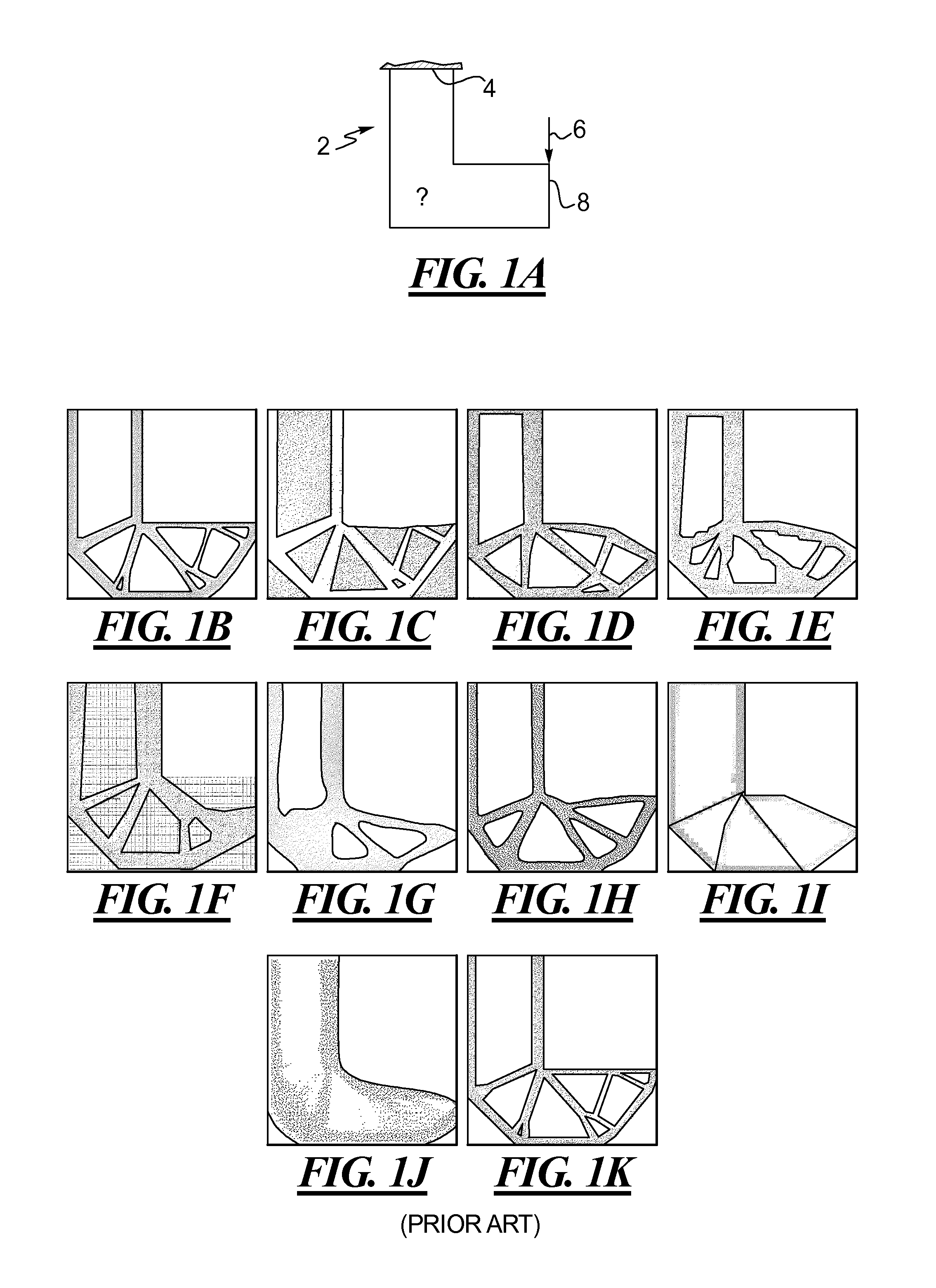

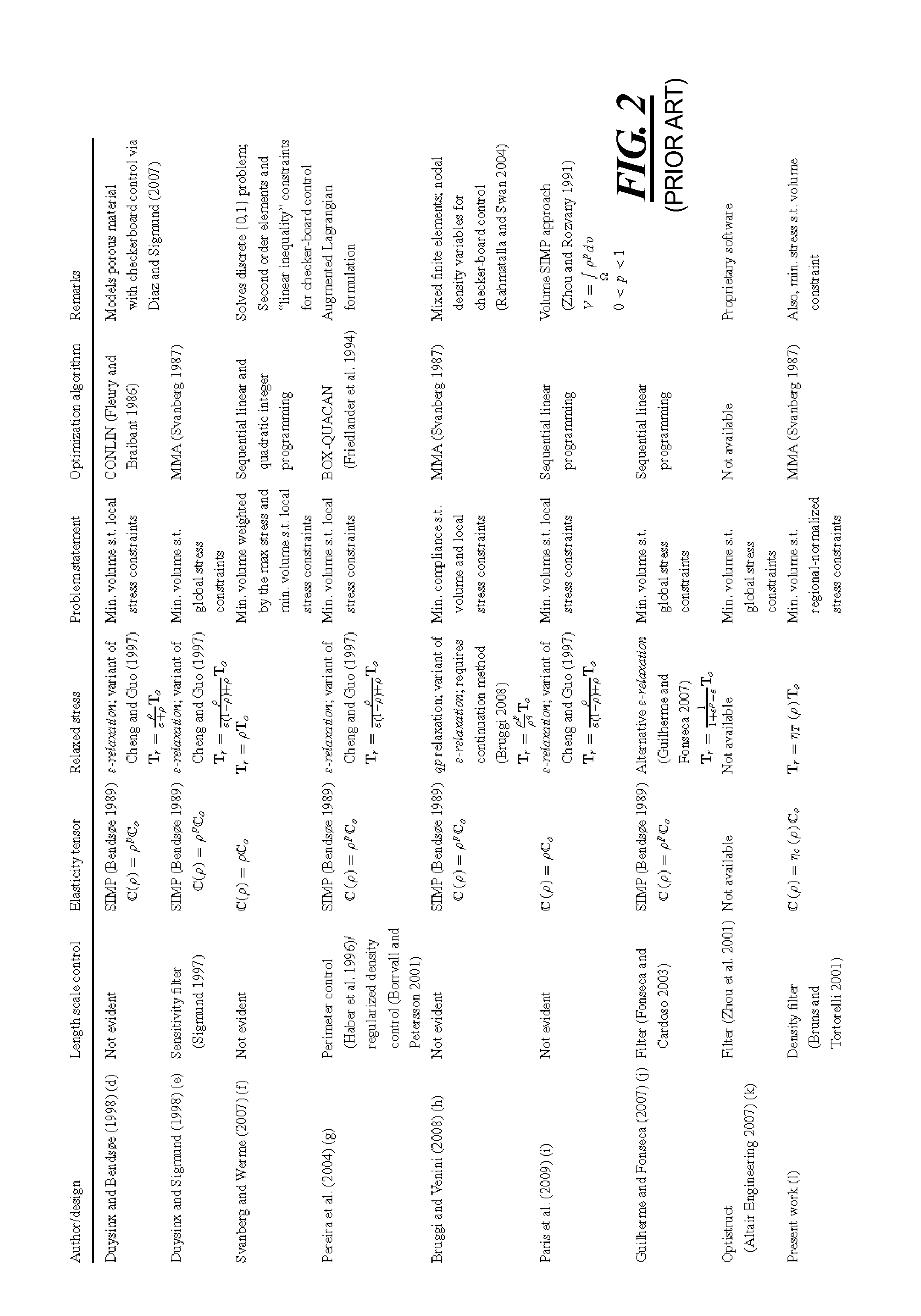

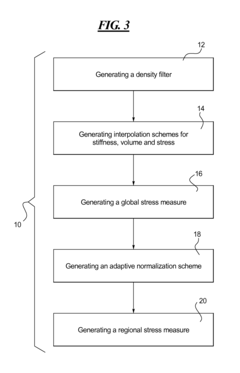

- A method involving density filtering, interpolation schemes for stiffness, volume, and stress, adaptive normalization, and regional stress measures to generate optimized solutions for stress-based topology optimization, using techniques like SIMP and p-norm to control length scale and stress distribution efficiently.

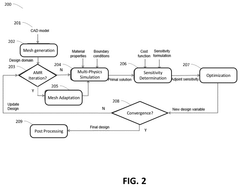

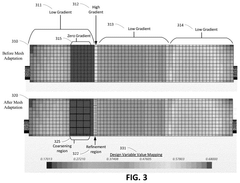

Topology optimization with bidirectional mesh adaptation

PatentPendingUS20250181800A1

Innovation

- The implementation of bidirectional mesh adaptation, which refines and coarsens mesh elements based on detected gradients of design variables, allowing for selective adaptation during the optimization process to accelerate convergence and reduce computational costs.

Material Selection Considerations for Enhanced Durability

Material selection plays a pivotal role in determining the durability performance of components designed through either topology optimization or stress-relieved approaches. When comparing these two design methodologies, material properties must be carefully considered to maximize structural integrity and longevity under operational conditions.

For topology optimized structures, materials with high strength-to-weight ratios are particularly advantageous. Titanium alloys, aluminum alloys, and advanced composites have emerged as preferred choices due to their ability to maintain structural integrity while minimizing mass. The anisotropic properties of certain materials can be strategically leveraged in topology optimization algorithms to align material strength with principal stress directions, further enhancing durability.

Stress-relieved designs, conversely, benefit from materials with excellent fatigue resistance and predictable stress-strain behaviors. Medium to high carbon steels, nickel-based superalloys, and certain polymer composites demonstrate superior performance in applications where cyclic loading is prevalent. The homogeneity and isotropy of these materials contribute significantly to their reliability in stress-relieved configurations.

Material ductility represents another critical consideration. Topology optimized structures often incorporate regions with complex geometries and potential stress concentrations, making materials with higher ductility preferable to prevent brittle failure modes. Stress-relieved designs can accommodate materials with lower ductility provided that stress concentrations are effectively mitigated through careful geometric transitions.

Environmental factors substantially influence material selection decisions. Topology optimized components frequently feature intricate surface geometries that may increase susceptibility to corrosion or environmental degradation. Consequently, materials with inherent corrosion resistance or those amenable to protective coatings are essential for maintaining long-term durability. Stress-relieved designs typically present fewer challenges in this regard due to their more conventional geometries.

Manufacturing considerations also impact material selection. Additive manufacturing techniques, commonly employed for topology optimized components, impose specific material constraints related to processability, thermal behavior during fabrication, and resultant microstructural characteristics. Traditional manufacturing methods used for stress-relieved designs offer greater material flexibility but may limit geometric complexity.

Cost-benefit analysis reveals that topology optimized structures often justify premium materials due to their weight-saving advantages in high-performance applications. Stress-relieved designs may prioritize materials with established supply chains and processing methods to optimize economic efficiency while maintaining acceptable durability standards.

For topology optimized structures, materials with high strength-to-weight ratios are particularly advantageous. Titanium alloys, aluminum alloys, and advanced composites have emerged as preferred choices due to their ability to maintain structural integrity while minimizing mass. The anisotropic properties of certain materials can be strategically leveraged in topology optimization algorithms to align material strength with principal stress directions, further enhancing durability.

Stress-relieved designs, conversely, benefit from materials with excellent fatigue resistance and predictable stress-strain behaviors. Medium to high carbon steels, nickel-based superalloys, and certain polymer composites demonstrate superior performance in applications where cyclic loading is prevalent. The homogeneity and isotropy of these materials contribute significantly to their reliability in stress-relieved configurations.

Material ductility represents another critical consideration. Topology optimized structures often incorporate regions with complex geometries and potential stress concentrations, making materials with higher ductility preferable to prevent brittle failure modes. Stress-relieved designs can accommodate materials with lower ductility provided that stress concentrations are effectively mitigated through careful geometric transitions.

Environmental factors substantially influence material selection decisions. Topology optimized components frequently feature intricate surface geometries that may increase susceptibility to corrosion or environmental degradation. Consequently, materials with inherent corrosion resistance or those amenable to protective coatings are essential for maintaining long-term durability. Stress-relieved designs typically present fewer challenges in this regard due to their more conventional geometries.

Manufacturing considerations also impact material selection. Additive manufacturing techniques, commonly employed for topology optimized components, impose specific material constraints related to processability, thermal behavior during fabrication, and resultant microstructural characteristics. Traditional manufacturing methods used for stress-relieved designs offer greater material flexibility but may limit geometric complexity.

Cost-benefit analysis reveals that topology optimized structures often justify premium materials due to their weight-saving advantages in high-performance applications. Stress-relieved designs may prioritize materials with established supply chains and processing methods to optimize economic efficiency while maintaining acceptable durability standards.

Manufacturing Implications of Design Choices

The manufacturing process selection for topology-optimized designs versus stress-relieved designs presents significant implications for production efficiency, cost, and final product quality. Topology optimization typically generates complex geometries with organic shapes that can be challenging to manufacture using traditional methods. These designs often require advanced additive manufacturing techniques such as selective laser melting (SLM) or direct metal laser sintering (DMLS), which allow for the creation of intricate internal structures and optimized material distribution.

Manufacturing topology-optimized components generally involves higher initial tooling costs and longer production times compared to conventional stress-relieved designs. The complex geometries may necessitate specialized support structures during the printing process, adding to material waste and post-processing requirements. Additionally, the surface finish of topology-optimized parts often requires secondary operations like machining or polishing to achieve desired tolerances and aesthetic qualities.

Stress-relieved designs, conversely, are typically more compatible with traditional manufacturing methods such as casting, forging, and machining. These conventional approaches benefit from established production workflows, standardized tooling, and predictable outcomes. The simpler geometries of stress-relieved designs generally result in fewer manufacturing constraints and lower production costs for high-volume manufacturing scenarios.

Material selection also differs significantly between these design approaches. Topology optimization often leverages advanced materials with superior strength-to-weight ratios to maximize the benefits of material reduction. These specialized materials may have specific processing requirements that further impact manufacturing complexity and cost. Stress-relieved designs typically utilize more conventional materials with well-documented manufacturing parameters.

Quality control presents another key difference. Topology-optimized components may require advanced inspection techniques such as CT scanning to verify internal structures and ensure manufacturing defects haven't compromised the optimized design. Stress-relieved designs can often be inspected using more conventional methods, simplifying quality assurance protocols.

Scalability considerations favor stress-relieved designs for mass production scenarios, while topology optimization may offer advantages for low-volume, high-value applications where performance improvements justify the increased manufacturing complexity. The decision between these approaches must balance the performance benefits against practical manufacturing constraints, production volumes, and available manufacturing technologies.

Manufacturing topology-optimized components generally involves higher initial tooling costs and longer production times compared to conventional stress-relieved designs. The complex geometries may necessitate specialized support structures during the printing process, adding to material waste and post-processing requirements. Additionally, the surface finish of topology-optimized parts often requires secondary operations like machining or polishing to achieve desired tolerances and aesthetic qualities.

Stress-relieved designs, conversely, are typically more compatible with traditional manufacturing methods such as casting, forging, and machining. These conventional approaches benefit from established production workflows, standardized tooling, and predictable outcomes. The simpler geometries of stress-relieved designs generally result in fewer manufacturing constraints and lower production costs for high-volume manufacturing scenarios.

Material selection also differs significantly between these design approaches. Topology optimization often leverages advanced materials with superior strength-to-weight ratios to maximize the benefits of material reduction. These specialized materials may have specific processing requirements that further impact manufacturing complexity and cost. Stress-relieved designs typically utilize more conventional materials with well-documented manufacturing parameters.

Quality control presents another key difference. Topology-optimized components may require advanced inspection techniques such as CT scanning to verify internal structures and ensure manufacturing defects haven't compromised the optimized design. Stress-relieved designs can often be inspected using more conventional methods, simplifying quality assurance protocols.

Scalability considerations favor stress-relieved designs for mass production scenarios, while topology optimization may offer advantages for low-volume, high-value applications where performance improvements justify the increased manufacturing complexity. The decision between these approaches must balance the performance benefits against practical manufacturing constraints, production volumes, and available manufacturing technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!