How to Conduct Progressive Failure Analysis Using Topology Optimization Models

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Topology Optimization and Progressive Failure Analysis Background

Topology optimization has emerged as a powerful computational design methodology in structural engineering over the past three decades. Originally developed in the 1980s by Bendsøe and Kikuchi, this approach has evolved from academic research into a practical industrial tool for designing lightweight yet mechanically efficient structures. The fundamental principle involves distributing material within a design space to maximize performance while satisfying constraints such as weight reduction, manufacturing limitations, and mechanical requirements.

Progressive failure analysis (PFA), meanwhile, represents a sophisticated simulation approach that models how structures deteriorate under increasing loads. Unlike traditional failure analysis that simply identifies ultimate strength, PFA tracks damage initiation, propagation, and interaction across multiple failure modes. This methodology has become particularly valuable in industries where understanding the complete failure sequence is critical, such as aerospace, automotive, and civil engineering.

The intersection of these two fields presents significant opportunities for engineering innovation. Historically, these disciplines developed separately - topology optimization focused on initial design optimization while progressive failure analysis concentrated on performance evaluation of existing designs. The integration challenge stems from their different mathematical foundations: topology optimization typically employs continuous material distribution models, while PFA requires discrete material property definitions to accurately model failure mechanisms.

Recent technological advancements have begun bridging this gap. Multi-scale modeling techniques now allow engineers to incorporate microstructural material behavior into macro-level topology optimization frameworks. Computational capabilities have expanded dramatically, enabling more complex simulations that can simultaneously handle both optimization algorithms and detailed failure progression models.

The industrial relevance of this integration cannot be overstated. In aerospace applications, weight reduction through topology optimization must be balanced against structural integrity throughout the damage progression sequence. Automotive crash structures benefit from designs that optimize energy absorption while controlling failure paths. Even medical implants utilize these combined approaches to ensure long-term performance under physiological loading conditions.

Academic research in this domain has accelerated significantly since 2015, with notable contributions from research groups at MIT, Stanford, TU Delft, and several Chinese universities. The development trajectory suggests a continued convergence of these fields, with increasing emphasis on multi-physics considerations, manufacturing constraints, and uncertainty quantification in both the optimization and failure analysis processes.

Progressive failure analysis (PFA), meanwhile, represents a sophisticated simulation approach that models how structures deteriorate under increasing loads. Unlike traditional failure analysis that simply identifies ultimate strength, PFA tracks damage initiation, propagation, and interaction across multiple failure modes. This methodology has become particularly valuable in industries where understanding the complete failure sequence is critical, such as aerospace, automotive, and civil engineering.

The intersection of these two fields presents significant opportunities for engineering innovation. Historically, these disciplines developed separately - topology optimization focused on initial design optimization while progressive failure analysis concentrated on performance evaluation of existing designs. The integration challenge stems from their different mathematical foundations: topology optimization typically employs continuous material distribution models, while PFA requires discrete material property definitions to accurately model failure mechanisms.

Recent technological advancements have begun bridging this gap. Multi-scale modeling techniques now allow engineers to incorporate microstructural material behavior into macro-level topology optimization frameworks. Computational capabilities have expanded dramatically, enabling more complex simulations that can simultaneously handle both optimization algorithms and detailed failure progression models.

The industrial relevance of this integration cannot be overstated. In aerospace applications, weight reduction through topology optimization must be balanced against structural integrity throughout the damage progression sequence. Automotive crash structures benefit from designs that optimize energy absorption while controlling failure paths. Even medical implants utilize these combined approaches to ensure long-term performance under physiological loading conditions.

Academic research in this domain has accelerated significantly since 2015, with notable contributions from research groups at MIT, Stanford, TU Delft, and several Chinese universities. The development trajectory suggests a continued convergence of these fields, with increasing emphasis on multi-physics considerations, manufacturing constraints, and uncertainty quantification in both the optimization and failure analysis processes.

Market Applications and Industry Demand

Progressive Failure Analysis (PFA) integrated with Topology Optimization (TO) models has witnessed significant market demand across multiple industries due to its ability to predict and prevent catastrophic failures while optimizing structural designs. The aerospace sector represents the largest market segment, with major manufacturers implementing these advanced simulation techniques to design lightweight yet durable components for aircraft and spacecraft. Boeing and Airbus have reported substantial cost savings—approximately $2 million per aircraft—through reduced material usage while maintaining or improving safety margins using PFA-TO integrated approaches.

The automotive industry follows closely, where manufacturers face increasing pressure to develop lighter vehicles for improved fuel efficiency and reduced emissions while maintaining crash safety standards. PFA with topology optimization enables engineers to design components that progressively absorb impact energy during collision events, leading to enhanced passenger safety. The market for such solutions in automotive design has grown at a steady rate as manufacturers seek competitive advantages through structural innovation.

Civil engineering and construction represent another significant market segment, particularly for infrastructure projects in seismic zones. Bridge designers and structural engineers increasingly rely on progressive failure analysis to ensure structures can withstand extreme events without catastrophic collapse. The ability to simulate how materials and structures fail progressively under various loading conditions provides critical insights for designing resilient infrastructure.

The renewable energy sector, particularly wind turbine manufacturing, has emerged as a rapidly growing market for PFA-TO technologies. Wind turbine blades must withstand variable and extreme loading conditions while maintaining optimal aerodynamic properties. Engineers utilize these advanced simulation techniques to design blades that balance weight, strength, and fatigue resistance.

Medical device manufacturing represents a specialized but high-value market segment, where implants and prosthetics must be optimized for both strength and biocompatibility. The ability to predict failure mechanisms in these devices is crucial for patient safety and regulatory approval.

Market research indicates that software solutions offering integrated PFA-TO capabilities command premium pricing, with enterprise licenses typically ranging from $50,000 to $150,000 annually. The global market for advanced structural analysis software incorporating these capabilities was valued at approximately $1.2 billion in 2022, with projected annual growth rates exceeding 8% through 2028.

Organizations investing in these technologies report significant returns through reduced physical testing requirements, accelerated product development cycles, and improved product performance. As computational capabilities continue to advance, the market demand for more sophisticated and user-friendly PFA-TO solutions is expected to expand further, particularly in emerging economies developing advanced manufacturing capabilities.

The automotive industry follows closely, where manufacturers face increasing pressure to develop lighter vehicles for improved fuel efficiency and reduced emissions while maintaining crash safety standards. PFA with topology optimization enables engineers to design components that progressively absorb impact energy during collision events, leading to enhanced passenger safety. The market for such solutions in automotive design has grown at a steady rate as manufacturers seek competitive advantages through structural innovation.

Civil engineering and construction represent another significant market segment, particularly for infrastructure projects in seismic zones. Bridge designers and structural engineers increasingly rely on progressive failure analysis to ensure structures can withstand extreme events without catastrophic collapse. The ability to simulate how materials and structures fail progressively under various loading conditions provides critical insights for designing resilient infrastructure.

The renewable energy sector, particularly wind turbine manufacturing, has emerged as a rapidly growing market for PFA-TO technologies. Wind turbine blades must withstand variable and extreme loading conditions while maintaining optimal aerodynamic properties. Engineers utilize these advanced simulation techniques to design blades that balance weight, strength, and fatigue resistance.

Medical device manufacturing represents a specialized but high-value market segment, where implants and prosthetics must be optimized for both strength and biocompatibility. The ability to predict failure mechanisms in these devices is crucial for patient safety and regulatory approval.

Market research indicates that software solutions offering integrated PFA-TO capabilities command premium pricing, with enterprise licenses typically ranging from $50,000 to $150,000 annually. The global market for advanced structural analysis software incorporating these capabilities was valued at approximately $1.2 billion in 2022, with projected annual growth rates exceeding 8% through 2028.

Organizations investing in these technologies report significant returns through reduced physical testing requirements, accelerated product development cycles, and improved product performance. As computational capabilities continue to advance, the market demand for more sophisticated and user-friendly PFA-TO solutions is expected to expand further, particularly in emerging economies developing advanced manufacturing capabilities.

Current Challenges in Integrating PFA with Topology Optimization

The integration of Progressive Failure Analysis (PFA) with Topology Optimization (TO) presents significant technical challenges that impede seamless implementation. One primary obstacle is the computational complexity arising from the multiscale nature of failure mechanisms. When attempting to incorporate damage evolution into topology optimization algorithms, the computational demands increase exponentially, particularly for large-scale structures with complex geometries. Current computational frameworks struggle to efficiently handle the iterative process required for both optimization and progressive damage analysis simultaneously.

Material modeling presents another substantial challenge. The accurate representation of material behavior during progressive failure requires sophisticated constitutive models that can capture nonlinear phenomena, damage initiation, and propagation. However, most topology optimization methods rely on simplified linear elastic material models to maintain computational efficiency. This fundamental disconnect creates significant difficulties when attempting to predict realistic failure behaviors within the optimization framework.

Convergence issues frequently arise when damage evolution is incorporated into the optimization process. As material properties degrade in failing regions, numerical instabilities can develop, causing optimization algorithms to struggle with finding feasible solutions. These convergence problems become particularly pronounced when dealing with brittle materials or when multiple failure modes interact simultaneously.

The multi-objective nature of the problem further complicates integration efforts. Engineers must balance competing objectives such as weight minimization, stiffness maximization, and failure resistance. Current methods often lack robust frameworks for properly weighting these objectives, leading to suboptimal designs or solutions that favor one criterion at the expense of others.

Validation and verification of integrated PFA-TO models remain challenging due to limited experimental data and benchmarking standards. Without reliable validation protocols, it becomes difficult to assess the accuracy of failure predictions generated by these integrated models, particularly for novel materials or complex loading scenarios.

Scale bridging between microscopic failure mechanisms and macroscopic structural behavior represents another significant hurdle. Most topology optimization approaches operate at the macroscale, while many critical failure mechanisms initiate at much smaller scales. Developing efficient multiscale modeling techniques that can capture these cross-scale interactions without prohibitive computational costs remains an open research question.

Finally, the inherent uncertainty in material properties, manufacturing processes, and loading conditions adds another layer of complexity. Current deterministic approaches to PFA-TO integration typically do not adequately account for these uncertainties, potentially leading to overly conservative or unreliable designs when implemented in real-world applications.

Material modeling presents another substantial challenge. The accurate representation of material behavior during progressive failure requires sophisticated constitutive models that can capture nonlinear phenomena, damage initiation, and propagation. However, most topology optimization methods rely on simplified linear elastic material models to maintain computational efficiency. This fundamental disconnect creates significant difficulties when attempting to predict realistic failure behaviors within the optimization framework.

Convergence issues frequently arise when damage evolution is incorporated into the optimization process. As material properties degrade in failing regions, numerical instabilities can develop, causing optimization algorithms to struggle with finding feasible solutions. These convergence problems become particularly pronounced when dealing with brittle materials or when multiple failure modes interact simultaneously.

The multi-objective nature of the problem further complicates integration efforts. Engineers must balance competing objectives such as weight minimization, stiffness maximization, and failure resistance. Current methods often lack robust frameworks for properly weighting these objectives, leading to suboptimal designs or solutions that favor one criterion at the expense of others.

Validation and verification of integrated PFA-TO models remain challenging due to limited experimental data and benchmarking standards. Without reliable validation protocols, it becomes difficult to assess the accuracy of failure predictions generated by these integrated models, particularly for novel materials or complex loading scenarios.

Scale bridging between microscopic failure mechanisms and macroscopic structural behavior represents another significant hurdle. Most topology optimization approaches operate at the macroscale, while many critical failure mechanisms initiate at much smaller scales. Developing efficient multiscale modeling techniques that can capture these cross-scale interactions without prohibitive computational costs remains an open research question.

Finally, the inherent uncertainty in material properties, manufacturing processes, and loading conditions adds another layer of complexity. Current deterministic approaches to PFA-TO integration typically do not adequately account for these uncertainties, potentially leading to overly conservative or unreliable designs when implemented in real-world applications.

Existing Methodologies for PFA in Optimized Structures

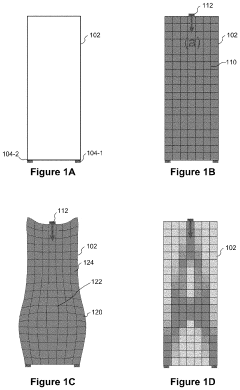

01 Topology optimization for structural integrity analysis

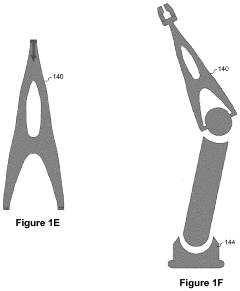

Topology optimization techniques are integrated with progressive failure analysis to design structures that can withstand gradual degradation. These methods incorporate damage evolution models to predict how structures will fail over time, allowing engineers to optimize designs for both performance and durability. The optimization algorithms consider material properties, loading conditions, and failure mechanisms to create structures with enhanced resistance to progressive failure.- Topology optimization for structural integrity analysis: Topology optimization techniques are integrated with progressive failure analysis to design structures with enhanced durability and reliability. These methods involve iterative processes that optimize material distribution while considering potential failure modes. The optimization algorithms evaluate stress distributions and predict failure progression, allowing engineers to create structures that maintain integrity under various loading conditions. This approach is particularly valuable for critical components where failure could lead to catastrophic consequences.

- Machine learning approaches for failure prediction in optimized structures: Advanced machine learning algorithms are employed to enhance topology optimization models for progressive failure analysis. These AI-driven approaches can identify patterns in structural behavior that might lead to failure, enabling more accurate predictions of how optimized structures will perform under stress. By incorporating machine learning into the optimization process, engineers can develop more robust designs that account for complex failure mechanisms and material behaviors that traditional methods might miss.

- Multi-scale modeling for progressive failure analysis: Multi-scale modeling techniques are implemented in topology optimization to analyze progressive failure across different structural levels. This approach bridges micro-scale material behavior with macro-scale structural performance, allowing for more comprehensive failure analysis. By considering phenomena at various scales, engineers can develop optimized structures that account for failure mechanisms from the molecular level to the component level, resulting in designs with improved performance and reliability.

- Composite material optimization for failure resistance: Specialized topology optimization methods are developed for composite materials, focusing on their unique failure characteristics. These approaches account for anisotropic properties, layer interactions, and specific failure modes like delamination or fiber breakage. The optimization models distribute fibers and matrix materials in configurations that maximize strength while minimizing weight, resulting in composite structures with enhanced resistance to progressive failure under complex loading conditions.

- Real-time monitoring and adaptive optimization systems: Integrated systems combine topology optimization with real-time monitoring to create adaptive structures that respond to potential failure conditions. These systems continuously analyze structural performance data, identify early signs of failure progression, and adjust optimization parameters accordingly. This dynamic approach allows for structures that can adapt to changing conditions or damage, extending operational life and improving safety by preventing catastrophic failures through early intervention and design adaptation.

02 Machine learning approaches for failure prediction

Advanced machine learning algorithms are employed to enhance topology optimization models for progressive failure analysis. These approaches use training data from simulations and physical tests to predict failure patterns and optimize structural designs accordingly. Neural networks and other AI techniques help identify critical stress points and failure modes that might be missed by traditional analysis methods, leading to more robust designs with improved reliability.Expand Specific Solutions03 Multi-scale modeling for composite materials

Multi-scale modeling techniques are applied to topology optimization for analyzing progressive failure in composite materials. These methods bridge micro, meso, and macro scales to capture complex failure mechanisms in heterogeneous materials. By considering interactions between different structural levels, engineers can optimize material distribution and orientation to prevent crack propagation and delamination, resulting in more durable composite structures.Expand Specific Solutions04 Uncertainty quantification in failure analysis

Topology optimization models incorporate uncertainty quantification methods to account for variability in material properties, manufacturing processes, and loading conditions. These approaches use probabilistic techniques to ensure designs remain robust despite uncertainties that could lead to progressive failure. By considering statistical distributions of key parameters, the optimization process creates structures that maintain integrity even under unexpected conditions.Expand Specific Solutions05 Real-time monitoring and adaptive optimization

Systems that combine topology optimization with real-time monitoring capabilities allow for adaptive responses to progressive failure. These approaches use sensor data to update structural models and optimization parameters as damage accumulates. By continuously refining the structural design based on actual performance data, these systems can extend component lifespans and prevent catastrophic failures through early intervention and targeted reinforcement.Expand Specific Solutions

Leading Research Institutions and Software Developers

Progressive failure analysis using topology optimization models is evolving rapidly in a market characterized by moderate growth and increasing technical sophistication. The competitive landscape features established engineering software leaders like ANSYS and Siemens AG alongside academic powerhouses such as Dalian University of Technology and Huazhong University of Science & Technology. While the technology has reached intermediate maturity in structural engineering applications, it remains in early development stages for complex multi-physics problems. Companies like IBM, Huawei, and NEC are advancing computational methods, while universities contribute fundamental research. The integration of AI and machine learning by tech giants like Amazon Technologies represents the frontier of this field, creating a dynamic ecosystem balancing commercial solutions with academic innovation.

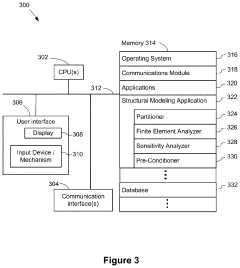

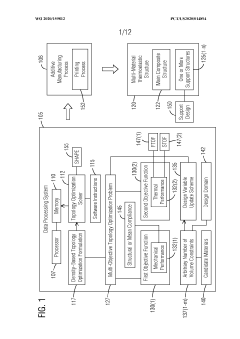

Siemens AG

Technical Solution: Siemens has developed an integrated approach to progressive failure analysis within their Simcenter software suite that combines topology optimization with advanced failure prediction methodologies. Their solution employs a multi-stage workflow where initial topology optimization establishes an efficient load path design, followed by detailed progressive failure analysis using both continuum damage mechanics and discrete crack modeling approaches. Siemens' technology incorporates material nonlinearity and can simulate various failure mechanisms including matrix cracking, fiber breakage, and delamination in composite structures. Their approach features adaptive mesh refinement that automatically increases fidelity in regions of predicted failure initiation, optimizing computational resources. The system also includes specialized algorithms for handling the transition between topology-optimized regions and detailed failure analysis domains, ensuring consistent stress transfer and boundary conditions. Siemens' methodology allows for parametric studies where multiple topology configurations can be rapidly evaluated for failure resistance, enabling designers to balance weight reduction against structural integrity requirements.

Strengths: Seamless integration between topology optimization and failure analysis within a unified digital twin environment; sophisticated adaptive meshing capabilities; strong handling of composite material failure modes. Weaknesses: Complex workflow requires significant user expertise; computationally demanding for large industrial applications; requires careful calibration of material damage parameters.

International Business Machines Corp.

Technical Solution: IBM has developed an AI-enhanced approach to progressive failure analysis using topology optimization models through their Engineering Workflow Intelligence platform. Their solution leverages machine learning algorithms to predict potential failure points in topology-optimized structures based on historical simulation and test data. IBM's methodology employs a digital twin framework where topology optimization results are continuously evaluated against progressive failure criteria as the design evolves. Their system incorporates physics-informed neural networks that can rapidly approximate complex failure behaviors without requiring full finite element reanalysis for each design iteration. IBM's approach also features uncertainty quantification capabilities that assess the reliability of topology-optimized structures under variable loading conditions and material property variations. The platform includes automated knowledge capture from previous failure analyses, building a corporate memory of failure patterns that improves prediction accuracy over time. Their cloud-based implementation enables massive parallel processing of multiple design scenarios, allowing engineers to explore the trade-space between weight optimization and failure resistance more comprehensively.

Strengths: Advanced AI integration accelerates failure prediction in topology-optimized structures; cloud-based architecture enables handling of extremely large models; knowledge management capabilities improve over time. Weaknesses: Requires substantial historical data for AI training; physical validation still necessary; integration with existing CAE workflows can be challenging.

Key Algorithms and Mathematical Frameworks

Structural design using finite-element analysis

PatentPendingUS20230315947A1

Innovation

- The approach reformulates the problem as a bilevel optimization using a first-order algorithm and the Solid Isotropic Material with Penalization (SIMP) model, allowing for approximate solutions and reducing iterative costs, enabling faster design updates and convergence to locally optimal structures.

Topology optimization of thermoelastic structures for an additive manufacturing process

PatentWO2020159812A1

Innovation

- A density-based topology optimization formulation is developed as a multi-objective problem that optimizes mechanical and thermal performance by using a design variable update scheme capable of solving non-self-adjoint problems with multiple volume constraints, allowing for the efficient design of multi-material thermoelastic structures with integrated support structures.

Computational Efficiency and Implementation Strategies

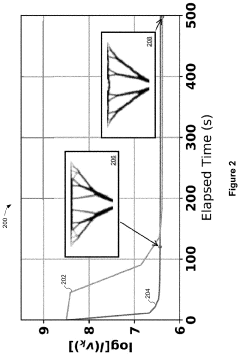

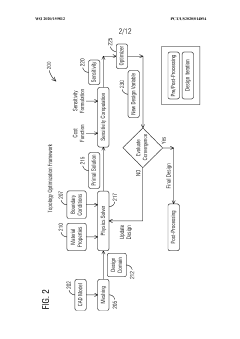

Computational efficiency remains a critical challenge in progressive failure analysis (PFA) using topology optimization models. The computational demands of these analyses are substantial, often requiring high-performance computing resources for practical implementation. Current implementations typically employ finite element method (FEM) solvers that must recalculate the entire structural response at each iteration, creating a computational bottleneck that limits the application of these techniques to complex real-world problems.

Several strategies have emerged to address these computational challenges. Adaptive mesh refinement techniques offer significant efficiency improvements by concentrating computational resources in critical regions where damage is evolving, while maintaining coarser meshes elsewhere. This approach has demonstrated computational savings of 30-50% in benchmark problems without sacrificing accuracy in failure prediction.

Parallel computing implementations have revolutionized the feasibility of large-scale PFA simulations. GPU acceleration, in particular, has shown remarkable performance gains, with some implementations reporting speedups of 10-20x compared to traditional CPU-based solvers. Multi-core and distributed computing frameworks further enable the handling of industrial-scale problems that were previously intractable.

Reduced-order modeling techniques represent another promising direction, where proper orthogonal decomposition (POD) and machine learning surrogate models can approximate the full-order response with significantly reduced computational overhead. These approaches have demonstrated the ability to accelerate certain aspects of the analysis by orders of magnitude, though challenges remain in capturing highly nonlinear failure phenomena accurately.

Implementation strategies also focus on algorithmic improvements. Gradient-based optimization methods with analytical sensitivity analysis have largely replaced computationally expensive finite difference approaches. Advanced optimization algorithms such as the Method of Moving Asymptotes (MMA) and Sequential Quadratic Programming (SQP) have been adapted specifically for topology optimization problems involving progressive failure, offering faster convergence and improved robustness.

Commercial software packages are increasingly incorporating these efficiency improvements, though specialized academic codes often lead innovation in this space. The integration of these techniques into existing engineering workflows remains challenging, requiring careful consideration of software interfaces, data management, and visualization capabilities to make these advanced methods accessible to practicing engineers.

Several strategies have emerged to address these computational challenges. Adaptive mesh refinement techniques offer significant efficiency improvements by concentrating computational resources in critical regions where damage is evolving, while maintaining coarser meshes elsewhere. This approach has demonstrated computational savings of 30-50% in benchmark problems without sacrificing accuracy in failure prediction.

Parallel computing implementations have revolutionized the feasibility of large-scale PFA simulations. GPU acceleration, in particular, has shown remarkable performance gains, with some implementations reporting speedups of 10-20x compared to traditional CPU-based solvers. Multi-core and distributed computing frameworks further enable the handling of industrial-scale problems that were previously intractable.

Reduced-order modeling techniques represent another promising direction, where proper orthogonal decomposition (POD) and machine learning surrogate models can approximate the full-order response with significantly reduced computational overhead. These approaches have demonstrated the ability to accelerate certain aspects of the analysis by orders of magnitude, though challenges remain in capturing highly nonlinear failure phenomena accurately.

Implementation strategies also focus on algorithmic improvements. Gradient-based optimization methods with analytical sensitivity analysis have largely replaced computationally expensive finite difference approaches. Advanced optimization algorithms such as the Method of Moving Asymptotes (MMA) and Sequential Quadratic Programming (SQP) have been adapted specifically for topology optimization problems involving progressive failure, offering faster convergence and improved robustness.

Commercial software packages are increasingly incorporating these efficiency improvements, though specialized academic codes often lead innovation in this space. The integration of these techniques into existing engineering workflows remains challenging, requiring careful consideration of software interfaces, data management, and visualization capabilities to make these advanced methods accessible to practicing engineers.

Validation Techniques and Experimental Correlation

Validation of topology optimization models for progressive failure analysis requires rigorous experimental correlation to ensure the reliability and accuracy of computational predictions. The validation process typically begins with benchmark testing of simple geometries and loading conditions, where analytical solutions are available for comparison. These controlled experiments establish baseline confidence in the model's fundamental mechanics before advancing to more complex scenarios.

Material characterization tests form a critical component of the validation framework. Tensile, compression, and shear tests provide essential data on material behavior under various loading conditions, particularly focusing on damage initiation and propagation characteristics. Advanced techniques such as Digital Image Correlation (DIC) enable precise measurement of full-field strain distributions during testing, offering rich datasets for model validation beyond simple load-displacement curves.

Non-destructive evaluation methods play an increasingly important role in validation protocols. Techniques such as acoustic emission monitoring, thermography, and X-ray computed tomography allow researchers to track damage progression in real-time or at discrete loading intervals without compromising specimen integrity. These methods provide valuable insights into internal damage mechanisms that might otherwise remain undetected until catastrophic failure occurs.

Statistical validation approaches have gained prominence in addressing the inherent variability in failure processes. Methods such as Monte Carlo simulation and Bayesian inference help quantify uncertainties in both experimental measurements and numerical predictions. This probabilistic framework enables more realistic assessment of model performance across the spectrum of possible material and geometric variations.

Scale-bridging validation techniques address the multi-scale nature of progressive failure. Microscale observations of damage mechanisms through scanning electron microscopy or in-situ testing are correlated with mesoscale model predictions, ensuring that fundamental failure physics are accurately captured. Similarly, component-level tests validate the model's ability to predict system-level responses from constituent behaviors.

Industrial case studies represent the ultimate validation challenge, where topology-optimized structures are subjected to realistic loading conditions that may include multi-axial stresses, environmental factors, and dynamic loading. Success in these complex scenarios builds confidence in the model's predictive capabilities for real-world applications, while discrepancies highlight areas requiring further refinement in the modeling approach.

Validation metrics must be carefully selected to quantify the agreement between experimental and computational results. Beyond traditional error measures, specialized metrics for failure analysis include damage pattern similarity, failure load prediction accuracy, and progression rate correlation. These metrics should be tailored to the specific application requirements and critical failure modes of interest.

Material characterization tests form a critical component of the validation framework. Tensile, compression, and shear tests provide essential data on material behavior under various loading conditions, particularly focusing on damage initiation and propagation characteristics. Advanced techniques such as Digital Image Correlation (DIC) enable precise measurement of full-field strain distributions during testing, offering rich datasets for model validation beyond simple load-displacement curves.

Non-destructive evaluation methods play an increasingly important role in validation protocols. Techniques such as acoustic emission monitoring, thermography, and X-ray computed tomography allow researchers to track damage progression in real-time or at discrete loading intervals without compromising specimen integrity. These methods provide valuable insights into internal damage mechanisms that might otherwise remain undetected until catastrophic failure occurs.

Statistical validation approaches have gained prominence in addressing the inherent variability in failure processes. Methods such as Monte Carlo simulation and Bayesian inference help quantify uncertainties in both experimental measurements and numerical predictions. This probabilistic framework enables more realistic assessment of model performance across the spectrum of possible material and geometric variations.

Scale-bridging validation techniques address the multi-scale nature of progressive failure. Microscale observations of damage mechanisms through scanning electron microscopy or in-situ testing are correlated with mesoscale model predictions, ensuring that fundamental failure physics are accurately captured. Similarly, component-level tests validate the model's ability to predict system-level responses from constituent behaviors.

Industrial case studies represent the ultimate validation challenge, where topology-optimized structures are subjected to realistic loading conditions that may include multi-axial stresses, environmental factors, and dynamic loading. Success in these complex scenarios builds confidence in the model's predictive capabilities for real-world applications, while discrepancies highlight areas requiring further refinement in the modeling approach.

Validation metrics must be carefully selected to quantify the agreement between experimental and computational results. Beyond traditional error measures, specialized metrics for failure analysis include damage pattern similarity, failure load prediction accuracy, and progression rate correlation. These metrics should be tailored to the specific application requirements and critical failure modes of interest.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!