How to Ensure Accurate Load Predictions with Topology Optimization Models

SEP 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Topology Optimization Background and Objectives

Topology optimization has emerged as a revolutionary approach in structural design, evolving from academic research in the 1980s to a widely adopted industrial methodology. This mathematical technique systematically determines the optimal material distribution within a design space, subject to specified constraints and load conditions. The fundamental objective is to maximize structural performance while minimizing material usage, leading to lightweight yet robust designs that would be difficult or impossible to conceive using traditional design approaches.

The evolution of topology optimization has been closely linked with advancements in computational capabilities. Early implementations were limited to simple 2D problems with basic loading conditions, but modern algorithms can handle complex 3D geometries with multiple load cases, manufacturing constraints, and multiphysics considerations. This progression has transformed topology optimization from a theoretical concept to a practical design tool implemented across industries including aerospace, automotive, and medical device manufacturing.

Current technological trends in topology optimization focus on improving the accuracy of load predictions within optimization models. This is critical because the performance of topology-optimized structures is highly dependent on the accuracy of the applied boundary conditions and load cases. Inaccurate load predictions can lead to suboptimal designs that fail to perform as expected in real-world applications, potentially resulting in structural failure or unnecessary overdesign.

The integration of topology optimization with machine learning and artificial intelligence represents another significant trend, enabling more sophisticated prediction models that can account for uncertainties in loading conditions. Additionally, the development of multi-scale optimization approaches allows designers to consider both macro-level structural performance and micro-level material behavior, leading to more comprehensive optimization results.

The primary technical objectives in this field include developing robust methodologies for accurately predicting and incorporating complex, variable, and uncertain load conditions into topology optimization models. This involves creating algorithms that can effectively handle dynamic loads, non-linear material behavior, and manufacturing constraints while maintaining computational efficiency. Another key goal is to establish validation frameworks that can verify the accuracy of load predictions against experimental data, ensuring that optimized designs perform as expected in real-world applications.

Furthermore, there is a growing emphasis on developing user-friendly interfaces and workflows that enable engineers without specialized expertise in optimization theory to effectively utilize these advanced tools, democratizing access to topology optimization technology across various engineering disciplines.

The evolution of topology optimization has been closely linked with advancements in computational capabilities. Early implementations were limited to simple 2D problems with basic loading conditions, but modern algorithms can handle complex 3D geometries with multiple load cases, manufacturing constraints, and multiphysics considerations. This progression has transformed topology optimization from a theoretical concept to a practical design tool implemented across industries including aerospace, automotive, and medical device manufacturing.

Current technological trends in topology optimization focus on improving the accuracy of load predictions within optimization models. This is critical because the performance of topology-optimized structures is highly dependent on the accuracy of the applied boundary conditions and load cases. Inaccurate load predictions can lead to suboptimal designs that fail to perform as expected in real-world applications, potentially resulting in structural failure or unnecessary overdesign.

The integration of topology optimization with machine learning and artificial intelligence represents another significant trend, enabling more sophisticated prediction models that can account for uncertainties in loading conditions. Additionally, the development of multi-scale optimization approaches allows designers to consider both macro-level structural performance and micro-level material behavior, leading to more comprehensive optimization results.

The primary technical objectives in this field include developing robust methodologies for accurately predicting and incorporating complex, variable, and uncertain load conditions into topology optimization models. This involves creating algorithms that can effectively handle dynamic loads, non-linear material behavior, and manufacturing constraints while maintaining computational efficiency. Another key goal is to establish validation frameworks that can verify the accuracy of load predictions against experimental data, ensuring that optimized designs perform as expected in real-world applications.

Furthermore, there is a growing emphasis on developing user-friendly interfaces and workflows that enable engineers without specialized expertise in optimization theory to effectively utilize these advanced tools, democratizing access to topology optimization technology across various engineering disciplines.

Market Demand Analysis for Accurate Load Prediction

The market for accurate load prediction technologies integrated with topology optimization models has experienced significant growth in recent years, driven primarily by industries seeking to enhance structural efficiency while maintaining safety standards. The aerospace and automotive sectors represent the largest market segments, collectively accounting for approximately 45% of the total market share, as these industries prioritize weight reduction without compromising structural integrity.

Manufacturing companies are increasingly adopting advanced simulation technologies to reduce material costs and development cycles. According to recent industry reports, companies implementing accurate load prediction systems have reported material savings between 15-30% and development time reductions of up to 40% compared to traditional design approaches. This translates to substantial cost savings, particularly in industries where materials represent a significant portion of production costs.

The global market for structural optimization software, including topology optimization with load prediction capabilities, was valued at $1.2 billion in 2022 and is projected to grow at a compound annual growth rate of 16.8% through 2028. This growth is fueled by increasing adoption across diverse sectors including civil engineering, medical device manufacturing, and consumer electronics.

Regionally, North America and Europe currently dominate the market with approximately 65% combined market share, attributed to their strong aerospace, automotive, and industrial manufacturing bases. However, the Asia-Pacific region is experiencing the fastest growth rate at 22.3% annually, driven by rapid industrialization in China and India, and significant investments in advanced manufacturing technologies.

Customer demand patterns indicate a clear shift toward cloud-based solutions that offer scalable computing resources for complex simulations. Subscription-based pricing models are gaining popularity, with 68% of new implementations choosing this option over traditional perpetual licensing. This trend reflects the industry's need for flexible, accessible tools that can evolve with technological advancements.

The market also shows increasing demand for integrated solutions that combine topology optimization with machine learning capabilities to improve prediction accuracy over time. Companies are willing to pay premium prices for systems that demonstrate measurable improvements in prediction accuracy, with surveys indicating that a 10% improvement in prediction accuracy can command a 25-35% price premium in the market.

Regulatory pressures, particularly in safety-critical industries, are further driving demand for reliable load prediction technologies as companies seek to meet stringent certification requirements while optimizing designs for performance and efficiency.

Manufacturing companies are increasingly adopting advanced simulation technologies to reduce material costs and development cycles. According to recent industry reports, companies implementing accurate load prediction systems have reported material savings between 15-30% and development time reductions of up to 40% compared to traditional design approaches. This translates to substantial cost savings, particularly in industries where materials represent a significant portion of production costs.

The global market for structural optimization software, including topology optimization with load prediction capabilities, was valued at $1.2 billion in 2022 and is projected to grow at a compound annual growth rate of 16.8% through 2028. This growth is fueled by increasing adoption across diverse sectors including civil engineering, medical device manufacturing, and consumer electronics.

Regionally, North America and Europe currently dominate the market with approximately 65% combined market share, attributed to their strong aerospace, automotive, and industrial manufacturing bases. However, the Asia-Pacific region is experiencing the fastest growth rate at 22.3% annually, driven by rapid industrialization in China and India, and significant investments in advanced manufacturing technologies.

Customer demand patterns indicate a clear shift toward cloud-based solutions that offer scalable computing resources for complex simulations. Subscription-based pricing models are gaining popularity, with 68% of new implementations choosing this option over traditional perpetual licensing. This trend reflects the industry's need for flexible, accessible tools that can evolve with technological advancements.

The market also shows increasing demand for integrated solutions that combine topology optimization with machine learning capabilities to improve prediction accuracy over time. Companies are willing to pay premium prices for systems that demonstrate measurable improvements in prediction accuracy, with surveys indicating that a 10% improvement in prediction accuracy can command a 25-35% price premium in the market.

Regulatory pressures, particularly in safety-critical industries, are further driving demand for reliable load prediction technologies as companies seek to meet stringent certification requirements while optimizing designs for performance and efficiency.

Current Challenges in Topology Optimization Models

Despite significant advancements in topology optimization modeling, several critical challenges persist that hinder the accuracy of load predictions. One of the primary obstacles is the inherent uncertainty in material properties and boundary conditions. Real-world materials often exhibit anisotropic behaviors and non-linear responses that are difficult to capture in standard optimization models. This discrepancy between idealized material models and actual material behavior can lead to substantial errors in load prediction, particularly in complex structural applications.

Computational limitations represent another significant challenge. High-fidelity topology optimization models require immense computational resources, often forcing engineers to compromise between model accuracy and computational efficiency. This trade-off frequently results in simplified models that may not adequately capture the complex stress distributions and load paths in optimized structures, leading to suboptimal designs or unexpected failure modes.

The multi-scale nature of many engineering problems further complicates accurate load prediction. Microscale features can significantly influence macroscale structural behavior, yet incorporating these cross-scale interactions into topology optimization models remains computationally prohibitive. Current approaches often rely on homogenization techniques that may oversimplify these complex interactions.

Manufacturing constraints and uncertainties pose additional challenges. The gap between optimized designs and manufactured products—often referred to as the "reality gap"—can substantially affect load-bearing capacity. Current models struggle to incorporate manufacturing variability and tolerances effectively, resulting in optimized designs that may perform differently when manufactured.

Dynamic loading conditions present particular difficulties for topology optimization models. Most current approaches are optimized for static loading scenarios, with limited capability to account for time-dependent loads, fatigue considerations, or impact scenarios. This limitation is especially problematic in applications such as aerospace or automotive components that experience complex, variable loading conditions throughout their service life.

Validation and verification of topology optimization models remain challenging due to the complex geometries they generate. Traditional testing methodologies may not be directly applicable to these intricate structures, making it difficult to confirm the accuracy of load predictions. This verification gap increases uncertainty in the reliability of optimized designs, particularly in safety-critical applications.

Integration with other design considerations, such as thermal effects, fluid-structure interactions, and multi-physics phenomena, represents an emerging challenge. These coupled physics problems significantly influence load distribution but are rarely fully incorporated into topology optimization frameworks due to their computational complexity.

Computational limitations represent another significant challenge. High-fidelity topology optimization models require immense computational resources, often forcing engineers to compromise between model accuracy and computational efficiency. This trade-off frequently results in simplified models that may not adequately capture the complex stress distributions and load paths in optimized structures, leading to suboptimal designs or unexpected failure modes.

The multi-scale nature of many engineering problems further complicates accurate load prediction. Microscale features can significantly influence macroscale structural behavior, yet incorporating these cross-scale interactions into topology optimization models remains computationally prohibitive. Current approaches often rely on homogenization techniques that may oversimplify these complex interactions.

Manufacturing constraints and uncertainties pose additional challenges. The gap between optimized designs and manufactured products—often referred to as the "reality gap"—can substantially affect load-bearing capacity. Current models struggle to incorporate manufacturing variability and tolerances effectively, resulting in optimized designs that may perform differently when manufactured.

Dynamic loading conditions present particular difficulties for topology optimization models. Most current approaches are optimized for static loading scenarios, with limited capability to account for time-dependent loads, fatigue considerations, or impact scenarios. This limitation is especially problematic in applications such as aerospace or automotive components that experience complex, variable loading conditions throughout their service life.

Validation and verification of topology optimization models remain challenging due to the complex geometries they generate. Traditional testing methodologies may not be directly applicable to these intricate structures, making it difficult to confirm the accuracy of load predictions. This verification gap increases uncertainty in the reliability of optimized designs, particularly in safety-critical applications.

Integration with other design considerations, such as thermal effects, fluid-structure interactions, and multi-physics phenomena, represents an emerging challenge. These coupled physics problems significantly influence load distribution but are rarely fully incorporated into topology optimization frameworks due to their computational complexity.

Current Load Prediction Solutions and Approaches

01 Structural optimization using finite element analysis

Topology optimization models utilize finite element analysis to predict load distributions and structural responses. These models simulate how different design configurations perform under various loading conditions, allowing engineers to identify optimal material distributions. The process involves iterative calculations that progressively refine the structure based on stress analysis and load path predictions, ultimately creating lightweight yet strong components that meet specific performance criteria.- Finite Element Analysis for Topology Optimization: Finite Element Analysis (FEA) is used in topology optimization to predict structural behavior under various load conditions. This method divides complex structures into smaller elements to analyze stress distribution, deformation, and material efficiency. By simulating different load scenarios, engineers can optimize designs to achieve maximum strength with minimum material usage, leading to lightweight yet durable structures that meet performance requirements.

- Machine Learning Approaches for Load Prediction: Machine learning algorithms are increasingly applied to topology optimization to predict load patterns and structural responses. These approaches use historical data and simulation results to train models that can anticipate stress distributions and material behavior under various conditions. Neural networks and other AI techniques help identify optimal design configurations by learning from previous optimization results, significantly reducing computational time while maintaining or improving prediction accuracy.

- Multi-physics Optimization Models: Multi-physics optimization models integrate multiple physical phenomena such as structural mechanics, heat transfer, and fluid dynamics to create more comprehensive load predictions. These models consider the interaction between different physical fields when optimizing topology, resulting in designs that perform optimally across various operating conditions. By simultaneously analyzing multiple physical aspects, engineers can develop structures that maintain integrity under complex real-world loading scenarios.

- Generative Design for Load-Optimized Structures: Generative design techniques automatically create multiple design iterations based on specified constraints and load predictions. These approaches use algorithms to explore design spaces that humans might not consider, generating innovative structural solutions optimized for anticipated loads. The process typically involves defining performance goals and constraints, then allowing the system to evolve designs that efficiently distribute material where needed to handle predicted loads.

- Real-time Adaptive Optimization Systems: Real-time adaptive optimization systems continuously update topology models based on actual load data collected during operation. These systems use sensors and monitoring devices to gather performance data, which is then fed back into the optimization algorithm to refine predictions and adjust designs accordingly. This dynamic approach allows structures to evolve over time in response to changing load conditions, ensuring optimal performance throughout the lifecycle of the product.

02 Machine learning approaches for load prediction

Advanced machine learning algorithms are being integrated into topology optimization workflows to enhance load prediction accuracy. These AI-based methods can analyze historical performance data, identify patterns in structural responses, and predict optimal designs for new loading scenarios. Neural networks and other machine learning techniques help reduce computational time while improving the reliability of load predictions, especially for complex non-linear problems where traditional methods may struggle.Expand Specific Solutions03 Multi-physics and multi-objective optimization frameworks

Modern topology optimization models incorporate multi-physics simulations to predict loads across different physical domains simultaneously. These frameworks consider thermal, mechanical, fluid, and electromagnetic interactions to create more realistic load predictions. Multi-objective optimization approaches balance competing design goals such as weight reduction, stress minimization, and manufacturing constraints, resulting in more practical and implementable designs that perform well under real-world loading conditions.Expand Specific Solutions04 Additive manufacturing-oriented load optimization

Topology optimization models specifically designed for additive manufacturing processes incorporate specialized load prediction capabilities. These models account for the unique constraints and opportunities of 3D printing technologies, such as support structure requirements and layer-by-layer fabrication effects on load-bearing capacity. The optimization algorithms predict how printed parts will respond to loads while considering material anisotropy and process-induced variations, enabling designs that fully leverage the geometric freedom of additive manufacturing.Expand Specific Solutions05 Real-time adaptive optimization with sensor feedback

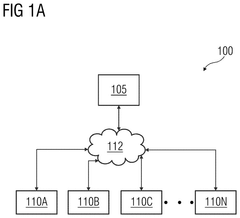

Emerging topology optimization approaches incorporate real-time sensor data to continuously refine load predictions during operation. These systems use digital twins and IoT sensor networks to monitor actual loading conditions, compare them with predicted values, and adaptively update the optimization models. This feedback loop enables structures to evolve over time based on real usage patterns, improving prediction accuracy for future designs and allowing for preventive maintenance based on detected load anomalies.Expand Specific Solutions

Key Industry Players in Topology Optimization

The topology optimization market for load prediction is currently in a growth phase, characterized by increasing adoption across industries like power grid management, automotive design, and telecommunications. The market size is expanding rapidly, driven by the need for more efficient infrastructure planning and resource allocation. Technologically, the field is maturing with companies like Siemens AG and IBM leading innovation through advanced AI-driven predictive models. State Grid Corp. of China and Mercedes-Benz are implementing practical applications in large-scale infrastructure and vehicle design respectively. NEC and Georgia Tech Research Corp. are advancing the academic foundations, while Dassault Systèmes and Siemens Energy are developing specialized software solutions that integrate topology optimization with load prediction capabilities for industrial applications.

Siemens AG

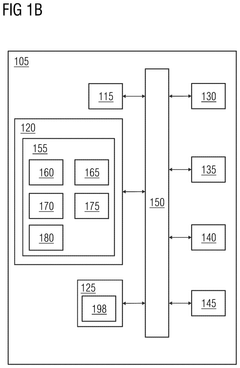

Technical Solution: Siemens AG has developed advanced topology optimization models for load prediction that integrate machine learning algorithms with physics-based simulations. Their approach combines historical load data with real-time monitoring through their SCADA systems to create dynamic prediction models. The technology employs multi-level validation processes where predictions are continuously compared against actual measurements to refine accuracy[1]. Siemens' solution incorporates digital twin technology that creates virtual replicas of physical grid systems, allowing for scenario testing and optimization without disrupting operations[3]. Their predictive models account for both regular consumption patterns and anomalous events by implementing adaptive algorithms that can detect and respond to unexpected changes in load distribution across complex network topologies[5]. The system also features automated topology reconfiguration recommendations based on predicted load changes to maintain optimal power flow and minimize losses.

Strengths: Comprehensive integration with existing industrial control systems; extensive historical data access for model training; proven implementation across diverse grid environments. Weaknesses: Requires significant computational resources; implementation complexity in legacy systems; higher initial investment compared to simpler solutions.

State Grid Corp. of China

Technical Solution: State Grid Corporation of China has developed a comprehensive topology-aware load prediction system that leverages their vast network infrastructure data. Their approach combines traditional power flow analysis with advanced deep learning techniques, particularly using spatial-temporal graph neural networks that explicitly model the physical connectivity of the power grid[2]. The system incorporates multi-source data fusion, integrating weather forecasts, holiday calendars, economic indicators, and historical consumption patterns to improve prediction accuracy. State Grid's solution features an adaptive topology recognition module that automatically detects network reconfiguration events and updates the prediction models accordingly, ensuring continued accuracy during maintenance or fault conditions[4]. Their technology employs a hierarchical prediction framework that operates at multiple time scales, from real-time operations to day-ahead and week-ahead forecasting, with appropriate model adjustments for each horizon. The platform includes specialized algorithms for handling load transfers during topology changes, maintaining prediction accuracy even during significant network reconfiguration events[7]. State Grid has implemented this system across multiple provincial grids, demonstrating scalability and consistent performance improvements in load prediction accuracy.

Strengths: Exceptional scalability for very large networks; robust performance during topology changes; comprehensive data integration capabilities. Weaknesses: High implementation complexity; significant data requirements; substantial computational resources needed for real-time operation.

Critical Technologies for Accurate Load Prediction

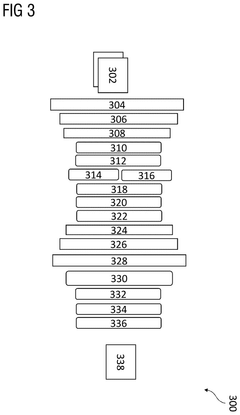

System and method for performing structural topology optimization

PatentPendingUS20250005222A1

Innovation

- A system and method that utilizes a deep learning model, specifically a U-Net variational autoencoder, to predict a suboptimal topology, which is then used to initialize an optimization solver for computing the optimal topology using methods like SIMP and BESO, thereby reducing computational resources and improving efficiency.

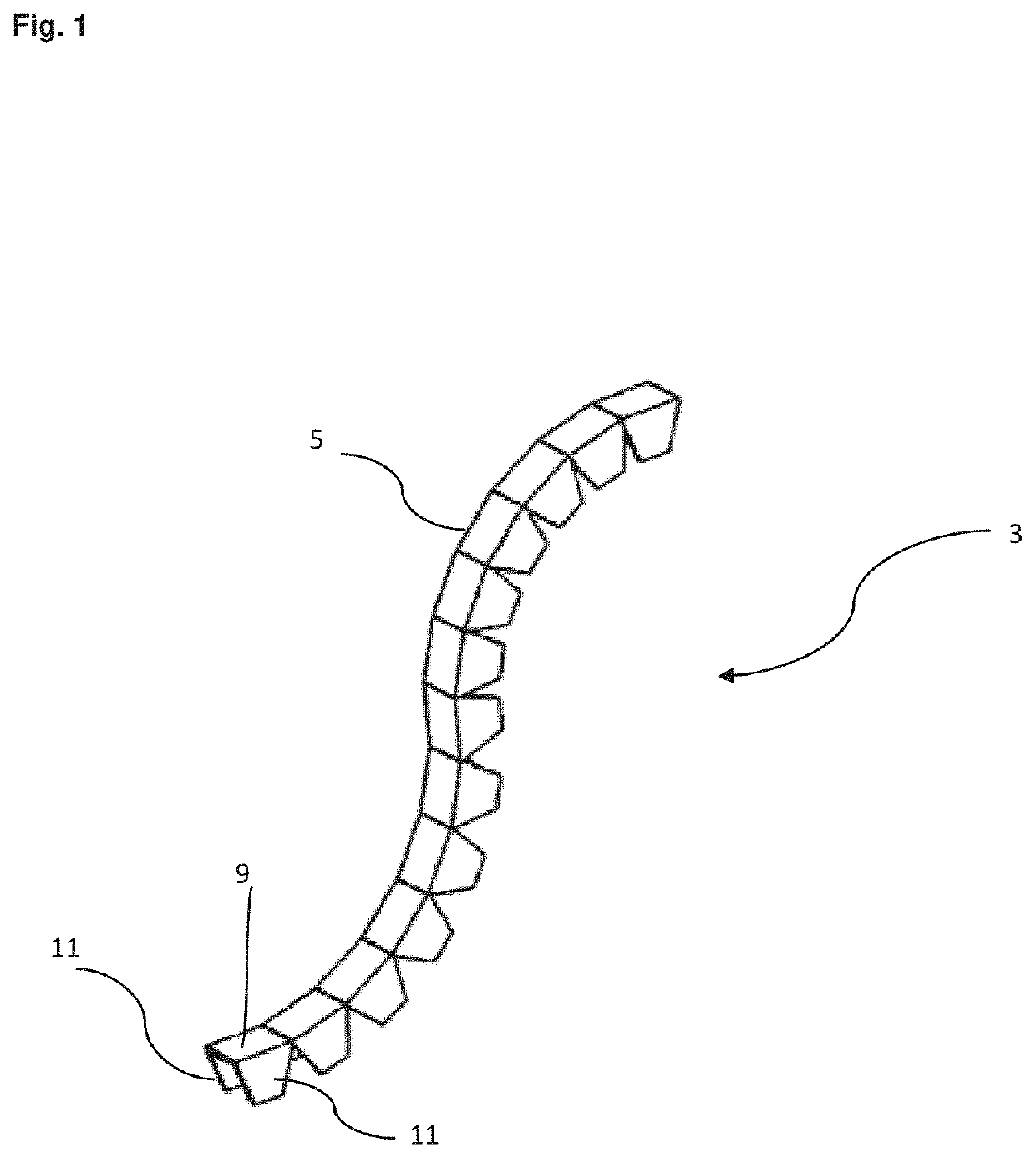

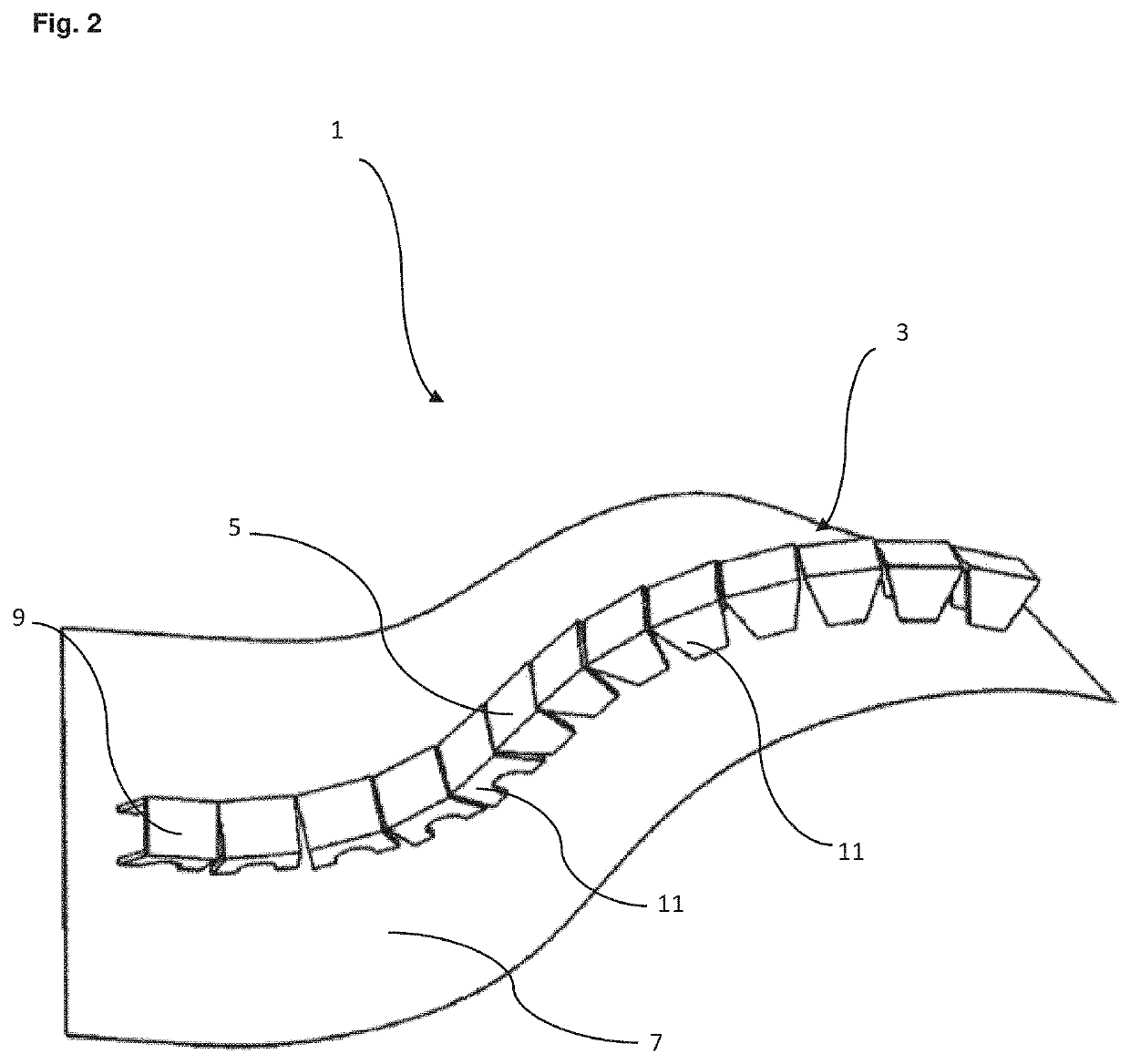

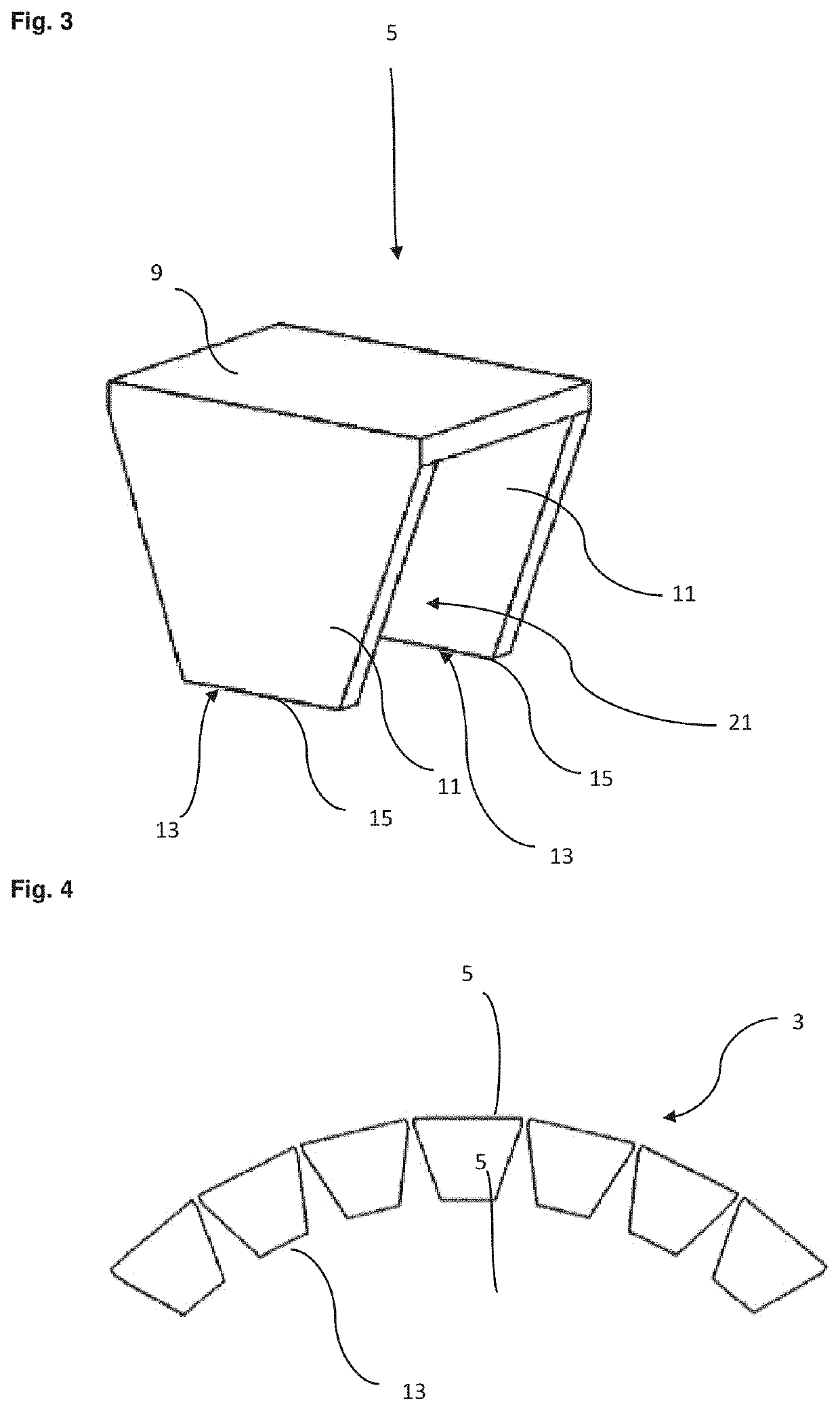

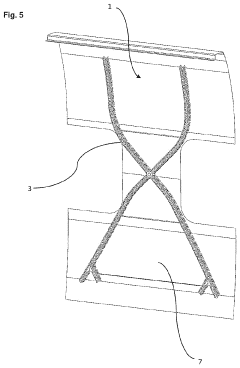

Reinforcement structure and process for reinforcement of a panel element

PatentActiveUS20220016865A1

Innovation

- A method involving the sequential attachment of stiffening modules with flanges and webs along non-rectilinear load paths, determined through stress-optimized simulations, using conventional manufacturing processes to create a stiffening structure that is both weight-saving and material-efficient, allowing for the production of larger, complex structures without continuous webs, and utilizing laser beam welding for connections.

Computational Resource Requirements and Limitations

Topology optimization models demand substantial computational resources due to their iterative nature and complex mathematical operations. High-fidelity models typically require significant processing power, with memory requirements scaling exponentially with mesh refinement. For industrial applications, workstations with minimum 32GB RAM and multi-core processors are often necessary, while more complex simulations may require specialized high-performance computing (HPC) environments with hundreds of cores and terabytes of memory.

Storage requirements present another challenge, as optimization processes generate large datasets of intermediate results. A single topology optimization run can produce several gigabytes of data, necessitating robust storage solutions and efficient data management strategies. Organizations must implement appropriate archiving protocols to balance accessibility with storage constraints.

Processing time represents a critical limitation, with complex simulations potentially taking days or weeks to complete. This creates a fundamental trade-off between accuracy and computational efficiency that engineers must carefully navigate. Parallel computing techniques have emerged as essential strategies to mitigate these time constraints, with domain decomposition methods allowing distribution of computational loads across multiple processors.

Cloud computing resources offer scalable alternatives to on-premises infrastructure, providing on-demand access to computational power. However, this approach introduces considerations regarding data security, transfer speeds, and ongoing operational costs that must be evaluated against capital expenditure for dedicated hardware.

Hardware acceleration technologies, including GPUs and specialized FPGAs, have demonstrated significant performance improvements for specific topology optimization algorithms. Recent benchmarks show up to 10x speedup for certain operations when leveraging GPU acceleration compared to traditional CPU-only implementations.

Software optimization techniques also play crucial roles in maximizing resource efficiency. Adaptive mesh refinement, multi-resolution approaches, and surrogate modeling can substantially reduce computational requirements while maintaining acceptable accuracy levels. Modern topology optimization frameworks increasingly incorporate these techniques to balance performance with precision.

As model complexity increases, particularly with multi-physics simulations incorporating thermal, fluid, and structural analyses simultaneously, computational demands grow exponentially. Organizations must develop comprehensive resource planning strategies that account for both current requirements and anticipated future needs as optimization models continue to evolve in sophistication and scope.

Storage requirements present another challenge, as optimization processes generate large datasets of intermediate results. A single topology optimization run can produce several gigabytes of data, necessitating robust storage solutions and efficient data management strategies. Organizations must implement appropriate archiving protocols to balance accessibility with storage constraints.

Processing time represents a critical limitation, with complex simulations potentially taking days or weeks to complete. This creates a fundamental trade-off between accuracy and computational efficiency that engineers must carefully navigate. Parallel computing techniques have emerged as essential strategies to mitigate these time constraints, with domain decomposition methods allowing distribution of computational loads across multiple processors.

Cloud computing resources offer scalable alternatives to on-premises infrastructure, providing on-demand access to computational power. However, this approach introduces considerations regarding data security, transfer speeds, and ongoing operational costs that must be evaluated against capital expenditure for dedicated hardware.

Hardware acceleration technologies, including GPUs and specialized FPGAs, have demonstrated significant performance improvements for specific topology optimization algorithms. Recent benchmarks show up to 10x speedup for certain operations when leveraging GPU acceleration compared to traditional CPU-only implementations.

Software optimization techniques also play crucial roles in maximizing resource efficiency. Adaptive mesh refinement, multi-resolution approaches, and surrogate modeling can substantially reduce computational requirements while maintaining acceptable accuracy levels. Modern topology optimization frameworks increasingly incorporate these techniques to balance performance with precision.

As model complexity increases, particularly with multi-physics simulations incorporating thermal, fluid, and structural analyses simultaneously, computational demands grow exponentially. Organizations must develop comprehensive resource planning strategies that account for both current requirements and anticipated future needs as optimization models continue to evolve in sophistication and scope.

Verification and Validation Methodologies

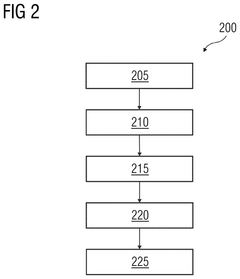

Verification and validation methodologies form the cornerstone of ensuring accurate load predictions in topology optimization models. These methodologies encompass systematic approaches to confirm that computational models correctly implement their intended mathematical formulations and adequately represent physical reality. For topology optimization specifically, verification focuses on mathematical accuracy while validation addresses physical relevance.

The verification process typically involves mesh convergence studies, where progressively refined meshes are used to ensure solution stability. This approach helps identify the optimal mesh density that balances computational efficiency with numerical accuracy. Additionally, code verification through the method of manufactured solutions provides a powerful technique for assessing the correctness of numerical implementations by comparing computed results against known analytical solutions.

Sensitivity analysis represents another critical verification component, examining how variations in input parameters affect optimization outcomes. By systematically perturbing input variables such as material properties, boundary conditions, and loading scenarios, engineers can quantify result reliability and identify parameters requiring more precise definition. This process helps establish confidence intervals for load predictions and highlights potential numerical instabilities.

For validation purposes, experimental testing serves as the gold standard. Physical prototypes derived from topology optimization models undergo controlled loading conditions, with measured responses compared against computational predictions. Advanced measurement techniques including digital image correlation, strain gauging, and vibration analysis provide high-fidelity data for comprehensive validation. The discrepancies between predicted and measured responses inform model refinement iterations.

Benchmark testing against established reference problems constitutes another validation approach. By comparing optimization results with well-documented test cases from literature or industry standards, engineers can assess their model's performance relative to accepted solutions. This comparative analysis helps identify systematic biases or limitations in the modeling approach.

Multi-fidelity validation strategies have emerged as particularly effective for topology optimization. These approaches integrate data from various sources—simplified analytical models, detailed finite element analyses, and physical experiments—to create a comprehensive validation framework. By triangulating results across different fidelity levels, engineers can better understand model limitations and establish appropriate safety factors for design implementation.

Uncertainty quantification methods further enhance validation by explicitly accounting for variabilities in material properties, manufacturing processes, and operating conditions. Techniques such as Monte Carlo simulation, polynomial chaos expansion, and Bayesian inference help characterize the probabilistic nature of load predictions, providing designers with statistical confidence measures rather than deterministic values.

The verification process typically involves mesh convergence studies, where progressively refined meshes are used to ensure solution stability. This approach helps identify the optimal mesh density that balances computational efficiency with numerical accuracy. Additionally, code verification through the method of manufactured solutions provides a powerful technique for assessing the correctness of numerical implementations by comparing computed results against known analytical solutions.

Sensitivity analysis represents another critical verification component, examining how variations in input parameters affect optimization outcomes. By systematically perturbing input variables such as material properties, boundary conditions, and loading scenarios, engineers can quantify result reliability and identify parameters requiring more precise definition. This process helps establish confidence intervals for load predictions and highlights potential numerical instabilities.

For validation purposes, experimental testing serves as the gold standard. Physical prototypes derived from topology optimization models undergo controlled loading conditions, with measured responses compared against computational predictions. Advanced measurement techniques including digital image correlation, strain gauging, and vibration analysis provide high-fidelity data for comprehensive validation. The discrepancies between predicted and measured responses inform model refinement iterations.

Benchmark testing against established reference problems constitutes another validation approach. By comparing optimization results with well-documented test cases from literature or industry standards, engineers can assess their model's performance relative to accepted solutions. This comparative analysis helps identify systematic biases or limitations in the modeling approach.

Multi-fidelity validation strategies have emerged as particularly effective for topology optimization. These approaches integrate data from various sources—simplified analytical models, detailed finite element analyses, and physical experiments—to create a comprehensive validation framework. By triangulating results across different fidelity levels, engineers can better understand model limitations and establish appropriate safety factors for design implementation.

Uncertainty quantification methods further enhance validation by explicitly accounting for variabilities in material properties, manufacturing processes, and operating conditions. Techniques such as Monte Carlo simulation, polynomial chaos expansion, and Bayesian inference help characterize the probabilistic nature of load predictions, providing designers with statistical confidence measures rather than deterministic values.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!