Integrating Topology Optimization in Fiber-Reinforced Polymers for Better Performance

SEP 16, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Topology Optimization in FRP: Background and Objectives

Topology optimization has emerged as a revolutionary approach in structural design, allowing engineers to achieve optimal material distribution within a given design space. The integration of this methodology with Fiber-Reinforced Polymers (FRPs) represents a significant advancement in composite material engineering. Historically, FRPs have been valued for their exceptional strength-to-weight ratio, corrosion resistance, and design flexibility, making them ideal for applications in aerospace, automotive, and civil infrastructure.

The evolution of topology optimization techniques dates back to the 1980s with homogenization methods, followed by the Solid Isotropic Material with Penalization (SIMP) approach in the 1990s. However, the application of these techniques to anisotropic materials like FRPs has been relatively recent, gaining momentum only in the past decade with advancements in computational capabilities and algorithm development.

Current research trends indicate a growing interest in multi-scale optimization approaches that consider both the macroscopic structural layout and the microscopic fiber orientation. This dual-level optimization promises to unlock unprecedented performance improvements in FRP components by aligning material properties with load paths in a more sophisticated manner than traditional design methods allow.

The primary objective of integrating topology optimization with FRPs is to maximize structural performance while minimizing material usage. This involves developing algorithms that can simultaneously optimize the distribution of composite material and the orientation of reinforcing fibers throughout the structure. Such optimization must account for manufacturing constraints, including fiber continuity, minimum feature size, and production feasibility.

Another critical goal is to enhance the damage tolerance and durability of FRP structures through optimized designs that distribute stress more effectively and reduce failure-prone regions. This is particularly important in high-performance applications where reliability under extreme conditions is paramount.

Furthermore, there is a pressing need to develop more efficient computational methods that can handle the complexity of anisotropic material properties inherent in FRPs. Current optimization processes often require significant computational resources, limiting their practical application in industry settings.

The integration of topology optimization with FRPs also aims to address sustainability concerns by reducing material waste and energy consumption in manufacturing processes. By creating more efficient structures that require less material, this technology aligns with global efforts to minimize environmental impact across industries.

Looking forward, the field is moving toward incorporating multi-physics considerations into the optimization process, accounting for thermal, acoustic, and electromagnetic properties alongside mechanical performance. This holistic approach will enable designers to create truly optimized FRP components for next-generation applications in renewable energy, transportation, and infrastructure.

The evolution of topology optimization techniques dates back to the 1980s with homogenization methods, followed by the Solid Isotropic Material with Penalization (SIMP) approach in the 1990s. However, the application of these techniques to anisotropic materials like FRPs has been relatively recent, gaining momentum only in the past decade with advancements in computational capabilities and algorithm development.

Current research trends indicate a growing interest in multi-scale optimization approaches that consider both the macroscopic structural layout and the microscopic fiber orientation. This dual-level optimization promises to unlock unprecedented performance improvements in FRP components by aligning material properties with load paths in a more sophisticated manner than traditional design methods allow.

The primary objective of integrating topology optimization with FRPs is to maximize structural performance while minimizing material usage. This involves developing algorithms that can simultaneously optimize the distribution of composite material and the orientation of reinforcing fibers throughout the structure. Such optimization must account for manufacturing constraints, including fiber continuity, minimum feature size, and production feasibility.

Another critical goal is to enhance the damage tolerance and durability of FRP structures through optimized designs that distribute stress more effectively and reduce failure-prone regions. This is particularly important in high-performance applications where reliability under extreme conditions is paramount.

Furthermore, there is a pressing need to develop more efficient computational methods that can handle the complexity of anisotropic material properties inherent in FRPs. Current optimization processes often require significant computational resources, limiting their practical application in industry settings.

The integration of topology optimization with FRPs also aims to address sustainability concerns by reducing material waste and energy consumption in manufacturing processes. By creating more efficient structures that require less material, this technology aligns with global efforts to minimize environmental impact across industries.

Looking forward, the field is moving toward incorporating multi-physics considerations into the optimization process, accounting for thermal, acoustic, and electromagnetic properties alongside mechanical performance. This holistic approach will enable designers to create truly optimized FRP components for next-generation applications in renewable energy, transportation, and infrastructure.

Market Analysis for Optimized Fiber-Reinforced Polymers

The global market for fiber-reinforced polymers (FRPs) has been experiencing robust growth, valued at approximately $114 billion in 2022 and projected to reach $185 billion by 2028, with a compound annual growth rate of 8.4%. This growth is primarily driven by increasing demand across automotive, aerospace, construction, and renewable energy sectors, where lightweight yet strong materials are essential for performance optimization and energy efficiency.

Topology optimization in FRPs represents a significant market opportunity, as it addresses the critical need for materials that maximize strength-to-weight ratios while minimizing material usage. The automotive industry, currently accounting for about 32% of the FRP market, is particularly receptive to optimized FRPs due to stringent fuel efficiency regulations and the transition toward electric vehicles, where weight reduction directly correlates with extended range capabilities.

The aerospace sector presents another substantial market for optimized FRPs, valued at approximately $24 billion in 2022. Major aircraft manufacturers are increasingly incorporating topology-optimized composite structures to reduce aircraft weight by up to 20%, resulting in significant fuel savings and reduced emissions. This trend is expected to accelerate as the industry commits to carbon neutrality goals.

Construction represents the fastest-growing application segment for optimized FRPs, with a growth rate of 9.7%. The demand is particularly strong in regions prone to seismic activity, where the superior strength-to-weight ratio and customizable mechanical properties of topology-optimized FRPs offer enhanced structural resilience while reducing overall building mass.

Regional analysis reveals that North America and Europe currently dominate the market for advanced FRPs, collectively accounting for 58% of global consumption. However, the Asia-Pacific region is emerging as the fastest-growing market, with China, Japan, and South Korea making substantial investments in manufacturing capabilities and research infrastructure for next-generation composite materials.

Market segmentation by optimization approach shows that computational design-driven FRPs command premium pricing, typically 30-45% higher than conventional composites. This price premium is justified by performance improvements, with topology-optimized FRPs demonstrating up to 40% better mechanical properties while using 25% less material in certain applications.

Customer demand analysis indicates a growing preference for customized solutions, with 67% of industrial buyers prioritizing performance optimization over initial cost. This shift represents a significant opportunity for companies that can effectively integrate topology optimization into their FRP manufacturing processes, potentially capturing higher margins and establishing technological leadership in this evolving market segment.

Topology optimization in FRPs represents a significant market opportunity, as it addresses the critical need for materials that maximize strength-to-weight ratios while minimizing material usage. The automotive industry, currently accounting for about 32% of the FRP market, is particularly receptive to optimized FRPs due to stringent fuel efficiency regulations and the transition toward electric vehicles, where weight reduction directly correlates with extended range capabilities.

The aerospace sector presents another substantial market for optimized FRPs, valued at approximately $24 billion in 2022. Major aircraft manufacturers are increasingly incorporating topology-optimized composite structures to reduce aircraft weight by up to 20%, resulting in significant fuel savings and reduced emissions. This trend is expected to accelerate as the industry commits to carbon neutrality goals.

Construction represents the fastest-growing application segment for optimized FRPs, with a growth rate of 9.7%. The demand is particularly strong in regions prone to seismic activity, where the superior strength-to-weight ratio and customizable mechanical properties of topology-optimized FRPs offer enhanced structural resilience while reducing overall building mass.

Regional analysis reveals that North America and Europe currently dominate the market for advanced FRPs, collectively accounting for 58% of global consumption. However, the Asia-Pacific region is emerging as the fastest-growing market, with China, Japan, and South Korea making substantial investments in manufacturing capabilities and research infrastructure for next-generation composite materials.

Market segmentation by optimization approach shows that computational design-driven FRPs command premium pricing, typically 30-45% higher than conventional composites. This price premium is justified by performance improvements, with topology-optimized FRPs demonstrating up to 40% better mechanical properties while using 25% less material in certain applications.

Customer demand analysis indicates a growing preference for customized solutions, with 67% of industrial buyers prioritizing performance optimization over initial cost. This shift represents a significant opportunity for companies that can effectively integrate topology optimization into their FRP manufacturing processes, potentially capturing higher margins and establishing technological leadership in this evolving market segment.

Current Challenges in FRP Topology Optimization

Despite significant advancements in topology optimization (TO) for fiber-reinforced polymers (FRPs), several critical challenges continue to impede the full integration and effectiveness of these techniques. One of the primary obstacles is the inherent anisotropic nature of FRPs, which creates computational complexity far exceeding that of isotropic materials. Current algorithms struggle to efficiently handle the directional properties of fibers while simultaneously optimizing the overall structure topology.

Material modeling presents another significant hurdle. The heterogeneous composition of FRPs, with distinct fiber and matrix phases exhibiting different mechanical behaviors, makes it difficult to develop accurate constitutive models that can be seamlessly incorporated into topology optimization frameworks. This challenge is further compounded when considering non-linear behaviors, damage progression, and failure mechanisms specific to composite materials.

Manufacturing constraints represent a substantial practical limitation. While topology optimization may generate theoretically optimal designs, these often include complex fiber orientations and distributions that exceed current manufacturing capabilities. The disconnect between optimized designs and producible components creates implementation barriers that diminish the practical value of advanced optimization techniques.

Multi-scale modeling remains inadequately addressed in current FRP topology optimization approaches. Effectively capturing both microscale fiber-matrix interactions and macroscale structural behavior simultaneously is computationally intensive and methodologically challenging. Most existing frameworks operate at a single scale, missing critical cross-scale effects that influence overall performance.

Computational efficiency continues to be a significant bottleneck. The increased design variables in FRP optimization—including fiber orientation, volume fraction, and topology—exponentially increase the solution space compared to conventional materials. This leads to prohibitively long computation times for complex structures, limiting industrial application.

Validation methodologies for optimized FRP designs lack standardization and robustness. The gap between numerical predictions and experimental results remains wider for composite structures than for metallic counterparts, creating uncertainty in the reliability of optimization outcomes.

Integration with other design considerations such as thermal performance, vibration characteristics, and cost efficiency is still in nascent stages. Most current approaches focus exclusively on mechanical performance, neglecting the multifunctional requirements typical in industrial applications.

Lastly, the absence of user-friendly software tools that specifically address FRP topology optimization creates accessibility barriers for engineers without specialized expertise in composite materials and advanced optimization techniques. This limits the broader adoption of these powerful design methodologies across industries that could benefit from lightweight, high-performance FRP structures.

Material modeling presents another significant hurdle. The heterogeneous composition of FRPs, with distinct fiber and matrix phases exhibiting different mechanical behaviors, makes it difficult to develop accurate constitutive models that can be seamlessly incorporated into topology optimization frameworks. This challenge is further compounded when considering non-linear behaviors, damage progression, and failure mechanisms specific to composite materials.

Manufacturing constraints represent a substantial practical limitation. While topology optimization may generate theoretically optimal designs, these often include complex fiber orientations and distributions that exceed current manufacturing capabilities. The disconnect between optimized designs and producible components creates implementation barriers that diminish the practical value of advanced optimization techniques.

Multi-scale modeling remains inadequately addressed in current FRP topology optimization approaches. Effectively capturing both microscale fiber-matrix interactions and macroscale structural behavior simultaneously is computationally intensive and methodologically challenging. Most existing frameworks operate at a single scale, missing critical cross-scale effects that influence overall performance.

Computational efficiency continues to be a significant bottleneck. The increased design variables in FRP optimization—including fiber orientation, volume fraction, and topology—exponentially increase the solution space compared to conventional materials. This leads to prohibitively long computation times for complex structures, limiting industrial application.

Validation methodologies for optimized FRP designs lack standardization and robustness. The gap between numerical predictions and experimental results remains wider for composite structures than for metallic counterparts, creating uncertainty in the reliability of optimization outcomes.

Integration with other design considerations such as thermal performance, vibration characteristics, and cost efficiency is still in nascent stages. Most current approaches focus exclusively on mechanical performance, neglecting the multifunctional requirements typical in industrial applications.

Lastly, the absence of user-friendly software tools that specifically address FRP topology optimization creates accessibility barriers for engineers without specialized expertise in composite materials and advanced optimization techniques. This limits the broader adoption of these powerful design methodologies across industries that could benefit from lightweight, high-performance FRP structures.

Existing Methodologies for FRP Topology Optimization

01 Topology optimization methods for fiber-reinforced composites

Various computational methods are employed to optimize the topology of fiber-reinforced polymer structures. These methods include finite element analysis, genetic algorithms, and machine learning approaches that determine optimal fiber placement and orientation. The optimization process considers multiple parameters such as stress distribution, weight reduction, and mechanical performance to create structures with enhanced strength-to-weight ratios and customized mechanical properties.- Topology optimization methods for fiber-reinforced composites: Various computational methods are employed to optimize the topology of fiber-reinforced polymer composites. These methods include finite element analysis, genetic algorithms, and machine learning approaches to determine optimal fiber placement and orientation. The optimization processes consider multiple parameters such as stress distribution, weight reduction, and mechanical performance to achieve structures with enhanced strength-to-weight ratios and improved load-bearing capabilities.

- Fiber orientation and distribution optimization: Techniques for optimizing the orientation and distribution of fibers within polymer matrices to enhance structural performance. These approaches focus on aligning fibers along principal stress directions, creating variable fiber density distributions, and developing anisotropic structures that respond optimally to applied loads. Advanced algorithms determine ideal fiber placement patterns to maximize stiffness, strength, and energy absorption while minimizing material usage.

- Multi-material and hybrid composite optimization: Development of optimization strategies for multi-material and hybrid fiber-reinforced polymer composites. These approaches combine different fiber types, varying fiber volume fractions, and multiple polymer matrices to create functionally graded materials with location-specific properties. The optimization considers interfaces between different materials and creates structures with tailored mechanical, thermal, and electrical properties for specific applications.

- Manufacturing-constrained topology optimization: Topology optimization methods that incorporate manufacturing constraints specific to fiber-reinforced polymer production processes. These approaches consider fabrication limitations such as minimum feature size, fiber continuity requirements, molding constraints, and additive manufacturing parameters. The optimization algorithms generate designs that are not only theoretically optimal but also practically manufacturable using techniques like automated fiber placement, injection molding, or 3D printing.

- Performance-driven optimization for specific applications: Application-specific topology optimization approaches for fiber-reinforced polymers targeting particular performance requirements. These methods focus on optimizing composites for specialized needs such as impact resistance, vibration damping, thermal management, or fatigue life. The optimization processes incorporate multi-physics simulations to address complex loading conditions and environmental factors relevant to automotive, aerospace, construction, and consumer product applications.

02 Fiber orientation and distribution optimization

Controlling the orientation and distribution of fibers within polymer matrices significantly impacts the mechanical properties of the composite. Advanced techniques allow for precise fiber alignment in load-bearing directions and strategic distribution to address stress concentrations. This optimization approach enables tailored mechanical responses, improved load transfer between fibers and matrix, and enhanced overall structural performance while minimizing material usage.Expand Specific Solutions03 Multi-material and hybrid composite structures

Combining different types of fibers, polymers, or additional materials creates hybrid composite structures with superior performance characteristics. These multi-material approaches allow for local property customization within a single component, enabling designers to address varying performance requirements across different regions of the structure. The strategic integration of materials with complementary properties results in composites with enhanced mechanical behavior, damage tolerance, and functional capabilities.Expand Specific Solutions04 Additive manufacturing of optimized fiber-reinforced polymers

Advanced additive manufacturing techniques enable the fabrication of topologically optimized fiber-reinforced polymer structures with complex geometries. These processes allow for precise control over fiber placement, orientation, and concentration during the printing process. The integration of topology optimization algorithms with additive manufacturing enables the production of lightweight, high-performance components with customized mechanical properties that would be difficult or impossible to achieve using conventional manufacturing methods.Expand Specific Solutions05 Performance validation and testing methodologies

Specialized testing methodologies and validation techniques are essential for evaluating the performance of topologically optimized fiber-reinforced polymers. These include mechanical testing under various loading conditions, non-destructive evaluation techniques, and digital twin approaches that combine physical testing with computational models. The validation process ensures that optimized designs meet performance requirements and helps refine optimization algorithms by providing feedback on real-world behavior of the composite structures.Expand Specific Solutions

Leading Companies and Research Institutions in FRP Optimization

The integration of topology optimization in fiber-reinforced polymers represents an evolving technological landscape currently in its growth phase. The market is expanding rapidly, with an estimated global value exceeding $10 billion, driven by increasing demand for lightweight, high-performance materials across automotive, aerospace, and industrial sectors. Leading companies like BASF, Arkema, and DSM IP Assets are advancing material science innovations, while academic institutions including Dalian University of Technology and Zhejiang University contribute significant research. Automotive manufacturers such as Volkswagen and technology providers like Dassault Systèmes and Siemens are developing integrated design solutions. The technology is approaching maturity in simulation capabilities but remains in development for manufacturing implementation, with companies like Milliken and Johns Manville focusing on bridging theoretical optimization with practical production processes.

BASF Corp.

Technical Solution: BASF has pioneered an integrated topology optimization framework specifically for their Ultramid® and Ultradur® fiber-reinforced polymer systems. Their approach combines multi-scale modeling with advanced manufacturing techniques to create optimized structures that maximize performance-to-weight ratios. BASF's methodology begins with characterizing the anisotropic behavior of fiber-reinforced materials at the microscale, then incorporates this data into macroscale topology optimization algorithms. Their proprietary software predicts fiber orientation during manufacturing processes like injection molding, allowing engineers to account for process-induced anisotropy in the optimization workflow. BASF has developed specialized material models that capture the complex behavior of short and long fiber reinforcements, enabling more accurate predictions of structural performance. Their system also incorporates manufacturing constraints directly into the optimization process, ensuring designs are producible using conventional equipment. Recent advancements include integration with additive manufacturing techniques, allowing for complex geometries with optimized fiber architectures.

Strengths: Comprehensive integration of material science and structural optimization; solutions applicable across multiple industries including automotive and consumer goods. Weaknesses: Optimization algorithms may require significant computational resources; implementation requires specialized knowledge of both materials science and structural engineering.

Dassault Systèmes SE

Technical Solution: Dassault Systèmes has developed an integrated topology optimization solution for fiber-reinforced polymers through their SIMULIA and CATIA platforms. Their approach combines parametric design capabilities with advanced simulation tools to optimize composite structures. The system utilizes the TOSCA Structure module, which has been enhanced specifically for anisotropic materials like fiber-reinforced polymers. Dassault's technology incorporates fiber orientation as a design variable, allowing simultaneous optimization of structural geometry and reinforcement architecture. Their solution includes specialized algorithms that account for manufacturing constraints specific to composite materials, such as minimum radius for fiber placement and maximum allowable fiber angle changes. The platform features multi-scale modeling capabilities, enabling engineers to optimize at both the component and system levels. Dassault has implemented advanced homogenization techniques that efficiently represent the complex microstructure of fiber composites in large-scale simulations. Their system also includes process simulation tools that predict how manufacturing methods affect fiber orientation and resulting mechanical properties, allowing for more realistic optimization outcomes.

Strengths: Comprehensive end-to-end solution from concept to manufacturing; excellent integration with existing product lifecycle management systems. Weaknesses: High licensing costs may be prohibitive for smaller organizations; requires significant expertise to fully leverage advanced capabilities.

Key Patents and Research in FRP Structural Optimization

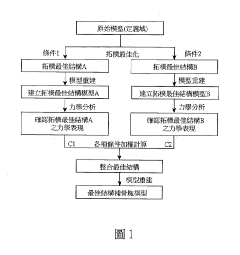

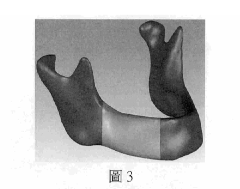

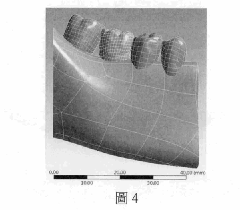

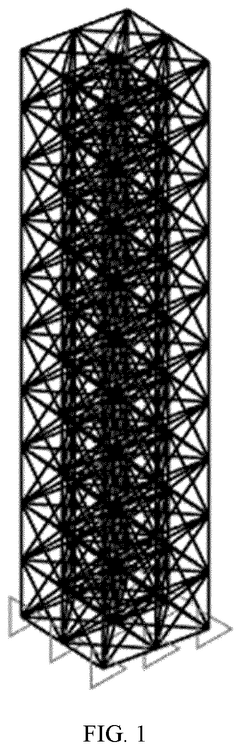

Method of integration of topology optimization, complementary bone structure manufactured by the method, and method for manufacturing the structure capable of providing multi-faceted mechanical support while maintaining light weight

PatentActiveTW202017536A

Innovation

- A topological optimization integration method combining density matrices from multiple mechanical conditions, using weighted operations to create a three-dimensional structural model, integrated with finite element analysis and metal laminated manufacturing, to design a bone prosthetic structure that meets clinical needs.

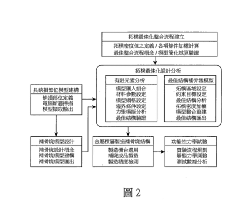

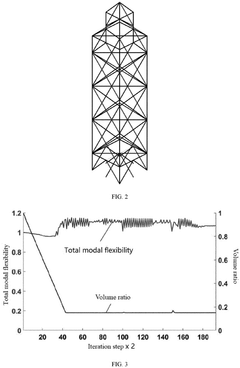

An integrate topology and size optimization method for frame structure considering Anti-seismic performance requirements

PatentPendingEP4435658A1

Innovation

- An integrated topology and size optimization method is developed, which discretizes the design domain into hexahedral finite element meshes, performs modal analysis, and uses pseudo-modal recognition and equivalent modal forces to minimize modal flexibility while adhering to volume constraints, optimizing both beam layout and size to enhance anti-seismic performance.

Sustainability Aspects of Optimized FRP Structures

The integration of sustainability principles into topology optimization for fiber-reinforced polymers (FRPs) represents a critical advancement in material science and engineering design. As environmental concerns become increasingly prominent, optimized FRP structures offer significant potential for reducing ecological footprints while maintaining or enhancing performance characteristics.

Life cycle assessment (LCA) studies of topology-optimized FRP components demonstrate substantial material savings ranging from 30-50% compared to conventional designs, directly translating to reduced raw material extraction and associated environmental impacts. This material efficiency contributes significantly to lowering embodied carbon, with recent research indicating potential carbon footprint reductions of up to 40% for aerospace and automotive applications.

Energy consumption during manufacturing processes presents another sustainability dimension where topology optimization delivers measurable benefits. Optimized fiber layouts require less energy-intensive processing, with studies showing energy savings of 15-25% during production phases. Additionally, the precision placement of reinforcement fibers minimizes waste generation, addressing a traditional challenge in composite manufacturing where material waste rates can exceed 30%.

The end-of-life management of FRP components has historically been problematic due to the inherent difficulty in separating fibers from polymer matrices. However, recent innovations in topology optimization have begun incorporating design-for-disassembly principles, creating structures with predetermined fracture paths that facilitate material separation during recycling processes. This approach has shown promising results in laboratory settings, with recovery rates improving by 20-35% for carbon fiber composites.

Weight reduction achieved through topology optimization directly impacts operational sustainability, particularly in transportation applications. For automotive components, optimized FRP structures have demonstrated fuel efficiency improvements of 3-7% through weight reduction, while in aerospace applications, similar optimizations contribute to reduced emissions throughout the service life of components.

Durability and longevity represent additional sustainability benefits, as topology-optimized FRP structures typically exhibit enhanced fatigue resistance and damage tolerance. Research indicates service life extensions of 15-40% compared to conventional designs, reducing replacement frequency and associated resource consumption. This extended durability is particularly valuable in infrastructure applications where maintenance and replacement cycles have significant environmental and economic implications.

The economic dimension of sustainability also benefits from topology optimization in FRPs, with total cost of ownership analyses showing favorable outcomes despite potentially higher initial manufacturing costs. The combination of material savings, extended service life, and improved operational efficiency typically yields positive return on investment within 2-5 years, depending on application specifics.

Life cycle assessment (LCA) studies of topology-optimized FRP components demonstrate substantial material savings ranging from 30-50% compared to conventional designs, directly translating to reduced raw material extraction and associated environmental impacts. This material efficiency contributes significantly to lowering embodied carbon, with recent research indicating potential carbon footprint reductions of up to 40% for aerospace and automotive applications.

Energy consumption during manufacturing processes presents another sustainability dimension where topology optimization delivers measurable benefits. Optimized fiber layouts require less energy-intensive processing, with studies showing energy savings of 15-25% during production phases. Additionally, the precision placement of reinforcement fibers minimizes waste generation, addressing a traditional challenge in composite manufacturing where material waste rates can exceed 30%.

The end-of-life management of FRP components has historically been problematic due to the inherent difficulty in separating fibers from polymer matrices. However, recent innovations in topology optimization have begun incorporating design-for-disassembly principles, creating structures with predetermined fracture paths that facilitate material separation during recycling processes. This approach has shown promising results in laboratory settings, with recovery rates improving by 20-35% for carbon fiber composites.

Weight reduction achieved through topology optimization directly impacts operational sustainability, particularly in transportation applications. For automotive components, optimized FRP structures have demonstrated fuel efficiency improvements of 3-7% through weight reduction, while in aerospace applications, similar optimizations contribute to reduced emissions throughout the service life of components.

Durability and longevity represent additional sustainability benefits, as topology-optimized FRP structures typically exhibit enhanced fatigue resistance and damage tolerance. Research indicates service life extensions of 15-40% compared to conventional designs, reducing replacement frequency and associated resource consumption. This extended durability is particularly valuable in infrastructure applications where maintenance and replacement cycles have significant environmental and economic implications.

The economic dimension of sustainability also benefits from topology optimization in FRPs, with total cost of ownership analyses showing favorable outcomes despite potentially higher initial manufacturing costs. The combination of material savings, extended service life, and improved operational efficiency typically yields positive return on investment within 2-5 years, depending on application specifics.

Manufacturing Feasibility of Topology-Optimized FRP Components

The manufacturing feasibility of topology-optimized FRP components represents a critical challenge in translating theoretical designs into practical applications. Current manufacturing processes for fiber-reinforced polymers must be significantly adapted to accommodate the complex geometries that typically result from topology optimization algorithms.

Traditional FRP manufacturing methods such as hand lay-up, compression molding, and pultrusion have inherent limitations when dealing with variable-thickness sections and intricate internal structures that topology optimization often generates. These conventional processes are optimized for relatively uniform cross-sections and consistent material distribution.

Advanced manufacturing techniques show greater promise for realizing topology-optimized designs. Automated fiber placement (AFP) and automated tape laying (ATL) technologies offer the precision necessary to place fibers along optimized load paths, though they require sophisticated programming and path planning to follow topology-optimized geometries. The equipment costs for these systems remain prohibitively high for many manufacturers, limiting widespread adoption.

3D printing of continuous fiber composites has emerged as a particularly promising approach. Technologies such as continuous fiber manufacturing (CFM) and continuous fiber 3D printing allow for fiber orientation to follow optimized load paths while creating complex geometries. However, these processes currently face limitations in terms of build volume, printing speed, and achievable fiber volume fractions compared to traditional manufacturing methods.

Hybrid manufacturing approaches combining additive and subtractive techniques show potential for overcoming some limitations. These methods can create near-net-shape preforms that are subsequently finished using conventional composite processing techniques, potentially offering a balance between geometric complexity and production efficiency.

Material considerations present additional challenges. The anisotropic nature of FRPs means that fiber orientation must be carefully controlled throughout the manufacturing process to match the optimized design. Current topology optimization algorithms often assume isotropic materials, creating a disconnect between design and manufacturing realities for composites.

Cost implications remain significant. While topology optimization theoretically reduces material usage and improves performance, the increased manufacturing complexity can offset these benefits through higher production costs. The economic viability depends heavily on production volume, with custom, low-volume applications currently representing the most feasible implementation scenarios.

Quality control and repeatability present further challenges, as complex internal structures may be difficult to inspect using conventional non-destructive testing methods. Advanced inspection techniques such as computed tomography scanning may be required to verify internal features, adding to overall production costs.

Traditional FRP manufacturing methods such as hand lay-up, compression molding, and pultrusion have inherent limitations when dealing with variable-thickness sections and intricate internal structures that topology optimization often generates. These conventional processes are optimized for relatively uniform cross-sections and consistent material distribution.

Advanced manufacturing techniques show greater promise for realizing topology-optimized designs. Automated fiber placement (AFP) and automated tape laying (ATL) technologies offer the precision necessary to place fibers along optimized load paths, though they require sophisticated programming and path planning to follow topology-optimized geometries. The equipment costs for these systems remain prohibitively high for many manufacturers, limiting widespread adoption.

3D printing of continuous fiber composites has emerged as a particularly promising approach. Technologies such as continuous fiber manufacturing (CFM) and continuous fiber 3D printing allow for fiber orientation to follow optimized load paths while creating complex geometries. However, these processes currently face limitations in terms of build volume, printing speed, and achievable fiber volume fractions compared to traditional manufacturing methods.

Hybrid manufacturing approaches combining additive and subtractive techniques show potential for overcoming some limitations. These methods can create near-net-shape preforms that are subsequently finished using conventional composite processing techniques, potentially offering a balance between geometric complexity and production efficiency.

Material considerations present additional challenges. The anisotropic nature of FRPs means that fiber orientation must be carefully controlled throughout the manufacturing process to match the optimized design. Current topology optimization algorithms often assume isotropic materials, creating a disconnect between design and manufacturing realities for composites.

Cost implications remain significant. While topology optimization theoretically reduces material usage and improves performance, the increased manufacturing complexity can offset these benefits through higher production costs. The economic viability depends heavily on production volume, with custom, low-volume applications currently representing the most feasible implementation scenarios.

Quality control and repeatability present further challenges, as complex internal structures may be difficult to inspect using conventional non-destructive testing methods. Advanced inspection techniques such as computed tomography scanning may be required to verify internal features, adding to overall production costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!