Best Practices for Zirconia Ceramic Manufacturing

Zirconia Ceramic Evolution and Objectives

Zirconia ceramics have undergone significant evolution since their introduction in the 1960s. Initially developed for high-temperature applications, these materials have found widespread use in various industries due to their exceptional mechanical properties and biocompatibility. The evolution of zirconia ceramics has been driven by the need for improved performance, reliability, and cost-effectiveness in manufacturing processes.

The primary objective in zirconia ceramic manufacturing is to produce high-quality, consistent materials with optimal mechanical and physical properties. This includes achieving high strength, toughness, and wear resistance while maintaining dimensional stability and biocompatibility. Manufacturers aim to develop efficient production methods that minimize defects, reduce costs, and increase yield.

One of the key evolutionary trends in zirconia ceramic manufacturing has been the development of advanced powder processing techniques. These methods have enabled the production of finer, more uniform powders, leading to improved sintering characteristics and enhanced final properties. Innovations in sintering technologies, such as hot isostatic pressing (HIP) and spark plasma sintering (SPS), have also contributed to the advancement of zirconia ceramic manufacturing.

Another significant objective in the field has been the enhancement of zirconia's phase stability. The transformation toughening mechanism, which gives zirconia its exceptional mechanical properties, relies on the controlled transformation of tetragonal to monoclinic phase. Researchers and manufacturers have focused on optimizing the composition and microstructure to maximize this beneficial transformation while preventing undesirable aging effects.

The pursuit of improved surface finishing techniques has been another crucial aspect of zirconia ceramic evolution. As applications in dental and medical fields expanded, the need for smoother, more aesthetically pleasing surfaces became paramount. This led to the development of advanced polishing methods and surface treatments that enhance both the functional and visual qualities of zirconia ceramics.

In recent years, the integration of digital technologies in zirconia ceramic manufacturing has become a primary objective. Computer-aided design and manufacturing (CAD/CAM) systems have revolutionized the production of custom components, particularly in the dental industry. This digital approach allows for greater precision, reproducibility, and efficiency in the manufacturing process.

Looking forward, the objectives in zirconia ceramic manufacturing continue to evolve. Current focus areas include the development of novel compositions with enhanced properties, such as increased translucency for dental applications or improved thermal shock resistance for industrial uses. Additionally, there is a growing emphasis on sustainable manufacturing practices, including the reduction of energy consumption and waste in the production process.

Market Analysis for Zirconia Ceramics

The global market for zirconia ceramics has been experiencing steady growth, driven by increasing demand across various industries such as healthcare, electronics, and aerospace. The market size for zirconia ceramics was valued at approximately $1.2 billion in 2020 and is projected to reach $1.8 billion by 2026, growing at a CAGR of around 6.5% during the forecast period.

The healthcare sector remains the largest consumer of zirconia ceramics, particularly in dental applications. The rising prevalence of dental disorders, coupled with growing aesthetic consciousness among consumers, has led to a surge in demand for zirconia-based dental implants and prosthetics. This segment is expected to maintain its dominant position in the market, accounting for over 40% of the total market share.

The electronics industry is emerging as a significant growth driver for zirconia ceramics. With the increasing miniaturization of electronic components and the need for high-performance materials, zirconia ceramics are finding applications in semiconductor manufacturing, sensors, and fuel cells. This sector is anticipated to witness the fastest growth rate, with a CAGR exceeding 8% over the next five years.

Geographically, Asia-Pacific holds the largest market share, accounting for approximately 35% of the global zirconia ceramics market. The region's dominance is attributed to the rapid industrialization in countries like China and India, coupled with increasing investments in healthcare infrastructure. North America and Europe follow closely, with strong demand from the medical and aerospace sectors.

The market landscape is characterized by intense competition among key players such as Saint-Gobain, Tosoh Corporation, and Kyocera Corporation. These companies are focusing on research and development activities to enhance product properties and expand their application scope. Mergers, acquisitions, and strategic partnerships are common strategies employed to strengthen market positions and gain technological advantages.

Despite the positive outlook, the zirconia ceramics market faces challenges such as high production costs and complex manufacturing processes. These factors can potentially hinder market growth, especially in price-sensitive regions. However, ongoing technological advancements in manufacturing techniques, such as additive manufacturing and precision machining, are expected to alleviate some of these challenges and open up new opportunities for market expansion.

Zirconia Manufacturing Challenges

Zirconia ceramic manufacturing faces several significant challenges that impact product quality, production efficiency, and overall cost-effectiveness. One of the primary hurdles is achieving consistent material properties throughout the manufacturing process. The transformation toughening mechanism, which gives zirconia its exceptional strength, is highly sensitive to processing conditions. Variations in temperature, pressure, or composition during sintering can lead to uneven phase distribution and compromised mechanical properties.

Another major challenge lies in the precise control of grain size and porosity. The final microstructure of zirconia ceramics directly influences their performance characteristics, including strength, toughness, and wear resistance. Manufacturers must carefully balance sintering parameters to achieve the desired grain size while minimizing porosity. This delicate balance is often difficult to maintain across large production volumes, leading to potential inconsistencies in product quality.

The selection and preparation of raw materials also present significant challenges. High-purity zirconia powders are essential for producing high-quality ceramics, but they can be expensive and may vary in quality between batches. Ensuring consistent particle size distribution and chemical composition of the starting powders is crucial for achieving reproducible results in the final product. Additionally, the incorporation of stabilizing agents, such as yttria, must be precisely controlled to maintain the desired crystal structure and properties.

Machining and finishing of zirconia ceramics pose another set of challenges. The material's inherent hardness and brittleness make it difficult to shape and polish without introducing surface defects or residual stresses. Conventional machining techniques often result in micro-cracks or chipping, which can significantly reduce the strength and reliability of the final product. Advanced machining methods, such as computer-controlled grinding and ultrasonic machining, are often required but can substantially increase production costs.

Environmental considerations also play a role in zirconia manufacturing challenges. The high-temperature sintering process consumes significant energy, contributing to both environmental impact and production costs. Manufacturers are under increasing pressure to develop more energy-efficient sintering techniques without compromising product quality. Additionally, the handling and disposal of zirconia powders and waste materials require careful management to minimize environmental and health risks.

Lastly, the complexity of zirconia's phase transformations during thermal cycling presents challenges in ensuring long-term stability and reliability of the final products. This is particularly critical in applications such as dental implants or high-temperature components, where the material may be subjected to repeated thermal and mechanical stresses. Manufacturers must develop strategies to mitigate the risk of spontaneous phase transformations that could lead to premature failure or degradation of the ceramic components.

Current Zirconia Production Methods

01 Composition and properties of zirconia ceramics

Zirconia ceramics are advanced materials known for their high strength, toughness, and thermal stability. They are composed of zirconium dioxide (ZrO2) and can be stabilized with various additives to enhance their properties. These ceramics exhibit excellent wear resistance and biocompatibility, making them suitable for a wide range of applications.- Composition and properties of zirconia ceramics: Zirconia ceramics are advanced materials known for their high strength, toughness, and thermal stability. They are composed primarily of zirconium dioxide (ZrO2) and can be stabilized with various additives to enhance their properties. These ceramics exhibit excellent wear resistance and biocompatibility, making them suitable for a wide range of applications.

- Manufacturing processes for zirconia ceramics: Various manufacturing processes are employed to produce zirconia ceramics, including sintering, hot isostatic pressing, and injection molding. These processes involve careful control of temperature, pressure, and particle size to achieve desired microstructures and properties. Advanced techniques such as spark plasma sintering may be used to produce high-density zirconia ceramics with improved mechanical properties.

- Applications of zirconia ceramics in dentistry: Zirconia ceramics are widely used in dental applications due to their excellent biocompatibility, aesthetics, and mechanical properties. They are used for dental crowns, bridges, implants, and other prosthetic devices. The material's translucency and color can be adjusted to match natural teeth, while its strength and durability ensure long-lasting restorations.

- Zirconia ceramics in industrial applications: Zirconia ceramics find extensive use in various industrial applications due to their exceptional properties. They are used in cutting tools, wear-resistant components, thermal barrier coatings, and high-temperature applications such as fuel cells and oxygen sensors. The material's chemical inertness and thermal stability make it suitable for aggressive environments.

- Surface modification and coating of zirconia ceramics: Surface modification and coating techniques are employed to enhance the properties of zirconia ceramics. These methods can improve wear resistance, reduce friction, enhance biocompatibility, or provide specific surface functionalities. Techniques such as plasma spraying, chemical vapor deposition, and sol-gel processes are used to apply coatings or modify the surface of zirconia ceramics for various applications.

02 Manufacturing processes for zirconia ceramics

Various manufacturing processes are employed to produce zirconia ceramics, including sintering, hot isostatic pressing, and injection molding. These processes involve careful control of temperature, pressure, and particle size to achieve desired microstructures and properties. Advanced techniques such as spark plasma sintering may be used to produce fully dense zirconia ceramics with enhanced mechanical properties.Expand Specific Solutions03 Applications of zirconia ceramics in dentistry

Zirconia ceramics are widely used in dental applications due to their excellent biocompatibility, aesthetics, and mechanical properties. They are used for dental crowns, bridges, implants, and other prosthetic devices. The material's natural tooth-like appearance and durability make it an ideal choice for restorative dentistry.Expand Specific Solutions04 Zirconia ceramics in industrial applications

Zirconia ceramics find extensive use in various industrial applications due to their exceptional properties. They are used in cutting tools, wear-resistant components, thermal barrier coatings, and high-temperature applications such as fuel cells and oxygen sensors. The material's chemical inertness and thermal stability make it suitable for harsh operating environments.Expand Specific Solutions05 Innovations in zirconia ceramic technology

Ongoing research and development in zirconia ceramics focus on improving their properties and expanding their applications. This includes developing new compositions, enhancing toughness and strength, improving processing techniques, and exploring novel applications such as in aerospace and energy sectors. Recent innovations also involve the development of nanostructured zirconia ceramics with superior mechanical and functional properties.Expand Specific Solutions

Key Zirconia Ceramic Manufacturers

The zirconia ceramic manufacturing industry is in a mature growth phase, characterized by a diverse competitive landscape with established players and emerging innovators. The global market size for zirconia ceramics is projected to reach $2.5 billion by 2027, driven by increasing demand in dental, medical, and industrial applications. Technological maturity varies across different manufacturing processes, with companies like Kyocera Corp., Ivoclar Vivadent AG, and NGK Insulators, Ltd. leading in advanced manufacturing techniques. Emerging players such as CENOTEC Co., Ltd. and Aidite Technology Co., Ltd. are focusing on innovative approaches to improve material properties and production efficiency. Research institutions like the Korea Institute of Ceramic Engineering & Technology and Shandong University of Technology are contributing to the advancement of zirconia ceramic manufacturing technologies, fostering industry-academia collaborations for continuous improvement in best practices.

Kyocera Corp.

Ivoclar Vivadent AG

Innovative Zirconia Sintering Techniques

- A zirconia-based ceramic bead composition comprising specific proportions of ZrO2, HfO2, SiO2, CeO2, Al2O3, CaO, and additives like Fe2O3, MgO, La2O3, TiO2, ZnO, with a manufacturing process involving suspension preparation, granulation, heat treatment, and sintering to enhance wear resistance and hardness.

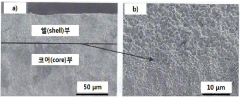

- Applying Tri-Calcium Phosphate (TCP, Ca3(PO4)2) to zirconia powder molded bodies and sintering at a faster temperature rise rate of at least 1°C/min to 6°C/min, resulting in a zirconia sintered body with a tetragonal core and monoclinic shell.

Quality Control in Zirconia Production

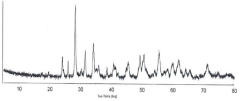

Quality control is a critical aspect of zirconia ceramic manufacturing, ensuring the production of high-quality, reliable components. Effective quality control measures begin with raw material inspection, where the purity and particle size distribution of zirconia powder are rigorously evaluated. Advanced techniques such as X-ray diffraction and particle size analysis are employed to verify the powder's composition and physical properties.

Throughout the manufacturing process, strict monitoring of temperature and pressure conditions is essential. Precision control systems are implemented to maintain optimal sintering temperatures, typically ranging from 1400°C to 1500°C, to achieve desired densification and mechanical properties. Atmosphere control within the sintering furnace is equally crucial, with inert gases often used to prevent unwanted reactions or contamination.

Post-sintering, a comprehensive suite of non-destructive testing methods is applied to assess the structural integrity and dimensional accuracy of zirconia components. These include ultrasonic testing for internal defect detection, X-ray computed tomography for 3D visualization of internal structures, and coordinate measuring machines for precise dimensional verification.

Surface finish and aesthetics are paramount in many zirconia applications, particularly in dental and biomedical fields. Advanced optical inspection systems and profilometers are utilized to evaluate surface roughness and identify any imperfections. For dental applications, color matching and translucency assessments are conducted using spectrophotometers to ensure consistency with natural tooth appearance.

Mechanical property testing forms a cornerstone of zirconia quality control. Standardized procedures for measuring flexural strength, fracture toughness, and hardness are routinely performed on sample specimens. These tests not only verify compliance with industry standards but also provide valuable data for continuous process improvement.

Traceability is a key component of modern quality control systems in zirconia production. Each batch of raw material and finished product is assigned a unique identifier, allowing for comprehensive tracking throughout the manufacturing process. This system facilitates rapid identification and isolation of any quality issues, minimizing potential impacts on downstream processes or end-users.

Statistical process control (SPC) techniques are widely adopted to monitor and analyze production data in real-time. By establishing control limits and tracking key performance indicators, manufacturers can quickly identify trends or deviations that may impact product quality. This proactive approach enables timely interventions and adjustments to maintain consistent, high-quality output.

Environmental Impact of Zirconia Manufacturing

The manufacturing of zirconia ceramics has significant environmental implications that require careful consideration and management. The production process involves energy-intensive steps and the use of various chemicals, which can contribute to environmental pollution if not properly controlled. One of the primary environmental concerns is the high energy consumption during sintering, which typically occurs at temperatures exceeding 1400°C. This energy-intensive process contributes to greenhouse gas emissions, particularly when fossil fuels are used as the energy source.

Raw material extraction and processing also pose environmental challenges. Mining zirconium ores can lead to habitat destruction, soil erosion, and water pollution if not conducted responsibly. The refining of zirconium compounds often involves chemical processes that generate waste products and emissions that must be carefully managed to prevent environmental contamination.

Water usage is another critical environmental factor in zirconia manufacturing. The production process requires substantial amounts of water for various stages, including material preparation and cleaning. Proper water management and recycling systems are essential to minimize water consumption and reduce the strain on local water resources.

The use of additives and binders in zirconia ceramic production can introduce potential environmental hazards. Some of these substances may be toxic or harmful if released into the environment. Implementing proper handling, storage, and disposal protocols is crucial to prevent soil and water contamination.

Dust generation during grinding and machining processes is a significant concern for both worker health and environmental impact. Fine zirconia particles can become airborne, potentially affecting air quality and posing respiratory risks. Advanced dust collection and filtration systems are necessary to mitigate these issues.

Waste management is a critical aspect of environmental stewardship in zirconia manufacturing. The production process generates various types of waste, including rejected parts, grinding sludge, and packaging materials. Implementing effective recycling and waste reduction strategies can significantly decrease the environmental footprint of zirconia production.

To address these environmental challenges, many manufacturers are adopting cleaner production techniques and investing in more efficient technologies. This includes the use of renewable energy sources, implementation of closed-loop water systems, and development of low-temperature sintering methods. Additionally, life cycle assessments are increasingly being employed to evaluate and minimize the overall environmental impact of zirconia ceramic products from raw material extraction to end-of-life disposal.