Biofuel Cell Textile Weaving And Coating Methods

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biofuel Cell Textile Technology Background and Objectives

Biofuel cell textiles represent a convergence of biotechnology, materials science, and textile engineering that has evolved significantly over the past two decades. Initially emerging from research in enzymatic fuel cells in the early 2000s, these technologies have progressed from laboratory curiosities to practical energy harvesting solutions with real-world applications. The fundamental principle involves harnessing biochemical reactions to generate electrical energy through the oxidation of organic compounds, typically using enzymes or microorganisms as catalysts.

The evolution of biofuel cell textiles has been marked by several key technological breakthroughs, including the development of stable enzyme immobilization techniques, advances in conductive fiber manufacturing, and innovations in biocompatible coating materials. These advancements have collectively transformed the field from theoretical concepts to functional prototypes capable of generating usable electrical power from bodily fluids or environmental sources.

Current research trends indicate a growing focus on scalability, durability, and power density improvements. The integration of nanomaterials such as carbon nanotubes and graphene has significantly enhanced electron transfer efficiency, while new polymer composites have improved both flexibility and longevity of the textile-based fuel cells. Additionally, recent developments in 3D textile structures have opened new possibilities for maximizing power output through optimized spatial arrangements of biocatalytic components.

The primary technical objectives in this field center around several critical parameters. First, increasing power density to achieve practical energy outputs capable of powering small electronic devices consistently. Second, enhancing operational stability to extend the functional lifespan from days to months or years. Third, developing manufacturing processes that are compatible with existing textile production infrastructure to enable cost-effective mass production.

Another crucial objective involves improving the biocompatibility and wearability of these textiles, particularly for applications in health monitoring and medical devices. This includes addressing challenges related to mechanical flexibility, breathability, and user comfort while maintaining electrical performance. Parallel efforts focus on developing biofuel cell textiles that can operate under varied environmental conditions, including temperature fluctuations and exposure to different pH levels.

The ultimate goal of biofuel cell textile technology is to create self-powered smart textiles that can seamlessly integrate into everyday garments, medical textiles, and industrial fabrics, providing sustainable power generation without compromising the essential qualities of traditional textiles. This vision drives current research toward more efficient weaving and coating methods that balance technical performance with practical usability.

The evolution of biofuel cell textiles has been marked by several key technological breakthroughs, including the development of stable enzyme immobilization techniques, advances in conductive fiber manufacturing, and innovations in biocompatible coating materials. These advancements have collectively transformed the field from theoretical concepts to functional prototypes capable of generating usable electrical power from bodily fluids or environmental sources.

Current research trends indicate a growing focus on scalability, durability, and power density improvements. The integration of nanomaterials such as carbon nanotubes and graphene has significantly enhanced electron transfer efficiency, while new polymer composites have improved both flexibility and longevity of the textile-based fuel cells. Additionally, recent developments in 3D textile structures have opened new possibilities for maximizing power output through optimized spatial arrangements of biocatalytic components.

The primary technical objectives in this field center around several critical parameters. First, increasing power density to achieve practical energy outputs capable of powering small electronic devices consistently. Second, enhancing operational stability to extend the functional lifespan from days to months or years. Third, developing manufacturing processes that are compatible with existing textile production infrastructure to enable cost-effective mass production.

Another crucial objective involves improving the biocompatibility and wearability of these textiles, particularly for applications in health monitoring and medical devices. This includes addressing challenges related to mechanical flexibility, breathability, and user comfort while maintaining electrical performance. Parallel efforts focus on developing biofuel cell textiles that can operate under varied environmental conditions, including temperature fluctuations and exposure to different pH levels.

The ultimate goal of biofuel cell textile technology is to create self-powered smart textiles that can seamlessly integrate into everyday garments, medical textiles, and industrial fabrics, providing sustainable power generation without compromising the essential qualities of traditional textiles. This vision drives current research toward more efficient weaving and coating methods that balance technical performance with practical usability.

Market Analysis for Wearable Biofuel Cell Applications

The wearable biofuel cell market is experiencing significant growth, driven by increasing demand for sustainable power sources in wearable technology. Current market valuation stands at approximately 450 million USD, with projections indicating a compound annual growth rate of 18.7% over the next five years. This growth trajectory is supported by expanding applications across healthcare monitoring, fitness tracking, and military equipment sectors.

Healthcare applications represent the largest market segment, accounting for 42% of current demand. The continuous glucose monitoring systems utilizing biofuel cells have shown particular promise, with adoption rates increasing by 23% annually. This trend is reinforced by the aging global population and rising prevalence of chronic conditions requiring constant monitoring.

Consumer electronics manufacturers are increasingly exploring biofuel cell integration, with major players like Samsung and Apple filing patents related to biofuel-powered wearables. Market research indicates consumer willingness to pay premium prices for wearables with extended battery life, creating a significant value proposition for biofuel cell technology.

Regional analysis reveals North America currently leads market adoption with 38% market share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth rate at 22.3% annually, driven by expanding manufacturing capabilities and increasing consumer adoption in China, Japan, and South Korea.

Key market barriers include cost considerations, with current manufacturing expenses approximately 3.5 times higher than traditional battery technologies. Additionally, consumer awareness remains limited, with surveys indicating only 28% of potential users understand the benefits of biofuel cell technology in wearables.

The athletic and fitness sector presents particularly promising growth opportunities, with market penetration currently at only 12% despite strong interest from professional sports organizations. Military applications are also expanding rapidly, with defense contracts for biofuel cell wearables increasing by 34% in the past two years.

Market forecasts suggest textile-integrated biofuel cells will achieve mainstream commercial viability within 3-4 years, contingent upon manufacturing scale improvements and continued material science advancements. Early adopters are expected to be premium wearable manufacturers targeting health-conscious consumers and specialized medical device companies developing continuous monitoring solutions.

Healthcare applications represent the largest market segment, accounting for 42% of current demand. The continuous glucose monitoring systems utilizing biofuel cells have shown particular promise, with adoption rates increasing by 23% annually. This trend is reinforced by the aging global population and rising prevalence of chronic conditions requiring constant monitoring.

Consumer electronics manufacturers are increasingly exploring biofuel cell integration, with major players like Samsung and Apple filing patents related to biofuel-powered wearables. Market research indicates consumer willingness to pay premium prices for wearables with extended battery life, creating a significant value proposition for biofuel cell technology.

Regional analysis reveals North America currently leads market adoption with 38% market share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region demonstrates the fastest growth rate at 22.3% annually, driven by expanding manufacturing capabilities and increasing consumer adoption in China, Japan, and South Korea.

Key market barriers include cost considerations, with current manufacturing expenses approximately 3.5 times higher than traditional battery technologies. Additionally, consumer awareness remains limited, with surveys indicating only 28% of potential users understand the benefits of biofuel cell technology in wearables.

The athletic and fitness sector presents particularly promising growth opportunities, with market penetration currently at only 12% despite strong interest from professional sports organizations. Military applications are also expanding rapidly, with defense contracts for biofuel cell wearables increasing by 34% in the past two years.

Market forecasts suggest textile-integrated biofuel cells will achieve mainstream commercial viability within 3-4 years, contingent upon manufacturing scale improvements and continued material science advancements. Early adopters are expected to be premium wearable manufacturers targeting health-conscious consumers and specialized medical device companies developing continuous monitoring solutions.

Current Challenges in Textile-Based Biofuel Cell Integration

The integration of biofuel cells into textiles presents significant technical challenges that currently impede widespread commercial adoption. One primary obstacle is the mechanical stability of biofuel cell components when subjected to the physical stresses inherent in textile manufacturing processes. Traditional weaving, knitting, and finishing operations involve tension, bending, and abrasion that can damage delicate enzymatic or microbial components essential for biofuel cell functionality.

Electrode design and integration represents another substantial hurdle. Creating electrodes that maintain electrical conductivity while preserving the flexibility and comfort of textiles requires sophisticated material engineering. Current conductive materials often suffer from performance degradation after repeated mechanical deformation or exposure to moisture and sweat, limiting their practical application in wearable biofuel cell textiles.

Biocompatibility issues further complicate integration efforts. The biological components of biofuel cells—typically enzymes or microorganisms—require specific environmental conditions to maintain activity. Preserving these conditions within textile structures while ensuring user safety and comfort presents significant engineering challenges. Additionally, the potential for biofouling and contamination during long-term wear necessitates robust protective measures that don't compromise textile properties.

Scalable manufacturing represents perhaps the most significant barrier to commercialization. Current laboratory-scale fabrication methods for textile-based biofuel cells often involve complex, multi-step processes that are difficult to translate to industrial production. Techniques such as screen printing, electrospinning, and dip-coating show promise but require substantial optimization to achieve consistent performance across large textile areas while maintaining cost-effectiveness.

Power output stability and consistency remain problematic in textile-based biofuel cells. Environmental factors such as temperature fluctuations, humidity changes, and varying biofuel availability (e.g., glucose or lactate in sweat) can cause significant performance variations. This unpredictability limits the reliability of textile biofuel cells as power sources for wearable electronics.

Encapsulation technologies present another critical challenge. Effective sealing methods must protect biofuel cell components from environmental degradation while maintaining breathability and flexibility. Current encapsulation materials often create barriers that reduce fuel transport efficiency or increase internal resistance, thereby diminishing power output.

Finally, the integration of biofuel cells with textile-compatible energy storage systems remains underdeveloped. Creating complete energy harvesting and storage systems within textiles requires seamless interfaces between biofuel cells and textile-based capacitors or batteries—a challenge that demands innovative approaches to textile circuit design and component interconnection.

Electrode design and integration represents another substantial hurdle. Creating electrodes that maintain electrical conductivity while preserving the flexibility and comfort of textiles requires sophisticated material engineering. Current conductive materials often suffer from performance degradation after repeated mechanical deformation or exposure to moisture and sweat, limiting their practical application in wearable biofuel cell textiles.

Biocompatibility issues further complicate integration efforts. The biological components of biofuel cells—typically enzymes or microorganisms—require specific environmental conditions to maintain activity. Preserving these conditions within textile structures while ensuring user safety and comfort presents significant engineering challenges. Additionally, the potential for biofouling and contamination during long-term wear necessitates robust protective measures that don't compromise textile properties.

Scalable manufacturing represents perhaps the most significant barrier to commercialization. Current laboratory-scale fabrication methods for textile-based biofuel cells often involve complex, multi-step processes that are difficult to translate to industrial production. Techniques such as screen printing, electrospinning, and dip-coating show promise but require substantial optimization to achieve consistent performance across large textile areas while maintaining cost-effectiveness.

Power output stability and consistency remain problematic in textile-based biofuel cells. Environmental factors such as temperature fluctuations, humidity changes, and varying biofuel availability (e.g., glucose or lactate in sweat) can cause significant performance variations. This unpredictability limits the reliability of textile biofuel cells as power sources for wearable electronics.

Encapsulation technologies present another critical challenge. Effective sealing methods must protect biofuel cell components from environmental degradation while maintaining breathability and flexibility. Current encapsulation materials often create barriers that reduce fuel transport efficiency or increase internal resistance, thereby diminishing power output.

Finally, the integration of biofuel cells with textile-compatible energy storage systems remains underdeveloped. Creating complete energy harvesting and storage systems within textiles requires seamless interfaces between biofuel cells and textile-based capacitors or batteries—a challenge that demands innovative approaches to textile circuit design and component interconnection.

Current Weaving and Coating Methodologies for Biofuel Textiles

01 Weaving techniques for biofuel cell textiles

Various weaving techniques can be employed to integrate biofuel cell components into textiles. These methods include specialized looms and weaving patterns that accommodate conductive fibers while maintaining textile flexibility and durability. The weaving process allows for the creation of three-dimensional structures that can house biofuel cell components while preserving the fabric's wearability and comfort. These techniques enable the seamless integration of energy-generating capabilities into everyday textiles.- Weaving techniques for biofuel cell textiles: Various weaving techniques can be employed to integrate biofuel cell components into textiles. These methods include specialized looms and weaving patterns that accommodate conductive fibers while maintaining textile flexibility and durability. The weaving process allows for the creation of three-dimensional structures that can house biofuel cell components while preserving the fabric's wearability and comfort. These techniques enable the seamless integration of energy-generating capabilities into everyday textiles.

- Coating methods for biofuel cell electrodes on textiles: Various coating techniques can be applied to deposit biofuel cell components onto textile substrates. These methods include dip-coating, spray coating, and screen printing of enzyme-containing solutions or conductive materials directly onto fabric surfaces. The coatings can be formulated to maintain flexibility while providing the necessary conductivity and catalytic activity for biofuel cell operation. Specialized binders and additives are used to ensure adhesion to textile fibers and durability during wear and washing cycles.

- Integration of biofuel cell components with textile structures: Methods for integrating biofuel cell components such as anodes, cathodes, and electrolyte membranes with textile structures have been developed. These approaches include embedding microfluidic channels within fabrics to transport biofluids, incorporating flexible current collectors, and designing textile structures that optimize contact with biofluids while maintaining comfort. The integration techniques focus on preserving the textile's mechanical properties while adding energy harvesting functionality, enabling applications in wearable technology and smart textiles.

- Conductive fiber development for biofuel cell textiles: Specialized conductive fibers have been developed specifically for use in biofuel cell textiles. These fibers combine electrical conductivity with the flexibility and durability required for textile applications. Manufacturing methods include coating traditional textile fibers with conductive materials, creating composite fibers with conductive cores, and developing entirely new fiber structures with inherent conductivity. These fibers serve as the foundation for creating textile electrodes that can harvest energy from biofluids while maintaining the comfort and wearability of conventional textiles.

- Surface modification techniques for biofuel cell textiles: Various surface modification techniques are employed to enhance the performance of biofuel cell textiles. These include plasma treatment, chemical functionalization, and nanoparticle deposition to improve enzyme immobilization, increase surface area, and enhance electron transfer. The modified surfaces provide better adhesion for biocatalysts and improved interaction with biofluids. These techniques can be applied to both natural and synthetic fibers to create high-performance biofuel cell textiles that efficiently convert biochemical energy into electrical energy.

02 Electrode coating methods for textile-based biofuel cells

Specialized coating methods are used to apply electrode materials onto textile substrates for biofuel cell applications. These techniques include dip-coating, spray coating, and screen printing of conductive materials and catalysts onto fabric surfaces. The coating processes must ensure uniform distribution of electrode materials while maintaining flexibility and durability of the textile substrate. Various conductive materials such as carbon-based compounds, metal nanoparticles, and conductive polymers can be applied to create effective electrodes on textile surfaces.Expand Specific Solutions03 Integration of enzyme and biocatalyst systems in textile biofuel cells

Methods for incorporating enzymes and biocatalysts into textile structures are essential for biofuel cell functionality. These techniques include immobilization of enzymes on textile fibers, encapsulation in protective matrices, and development of stable enzyme-electrode interfaces. The integration processes must preserve enzyme activity while providing durability in various environmental conditions. Specialized coating formulations and immobilization techniques help maintain long-term stability of the biological components within the textile structure.Expand Specific Solutions04 Conductive fiber development for biofuel cell textiles

Development of specialized conductive fibers is crucial for creating effective textile-based biofuel cells. These fibers combine electrical conductivity with textile properties such as flexibility, strength, and processability. Manufacturing techniques include coating traditional textile fibers with conductive materials, creating composite fibers with conductive cores, and developing entirely new fiber structures with inherent conductivity. These conductive fibers serve as the foundation for creating textile electrodes and current collectors in biofuel cell systems.Expand Specific Solutions05 Protective coating and encapsulation methods for textile biofuel cells

Protective coatings and encapsulation techniques are essential for ensuring the durability and longevity of textile-based biofuel cells. These methods include application of waterproof yet breathable membranes, selective barrier coatings that allow substrate diffusion while protecting sensitive components, and encapsulation systems that shield electronic elements from mechanical stress and environmental factors. The protective layers must maintain flexibility and comfort of the textile while providing adequate protection for the biofuel cell components under various wearing and washing conditions.Expand Specific Solutions

Leading Companies and Research Institutions in Biofuel Textiles

The biofuel cell textile weaving and coating methods market is in an early growth phase, characterized by increasing research activities but limited commercial deployment. The market size is expanding gradually, driven by rising demand for wearable energy solutions and sustainable power sources. From a technological maturity perspective, the field remains in development with varying approaches. Toyota Motor Corp. and Plug Power are leading industrial players focusing on fuel cell integration with textiles, while academic institutions like MIT and Georgia Tech Research Corp. are advancing fundamental research. Research collaborations between companies like Seiko Epson and universities are accelerating innovation in textile-based energy harvesting. The competitive landscape features diverse players from automotive (Toyota, GM), specialized fuel cell companies (Plug Power, PowerCell Sweden), and textile manufacturers (Tokai Senko, ISA TanTec).

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced biofuel cell textile integration methods focusing on enzymatic biofuel cells (EBFCs) that can be directly woven into fabrics. Their approach utilizes carbon nanotube-based conductive fibers as electrodes that are coated with specific enzymes like glucose oxidase and laccase. These fibers are then incorporated into textiles using standard weaving techniques while maintaining electrochemical functionality. MIT's coating method employs layer-by-layer assembly of enzymes and mediators on conductive fibers, followed by encapsulation with biocompatible polymers to enhance durability and longevity. Their research demonstrates power densities of up to 0.5 mW/cm² when using body fluids as fuel sources, making them suitable for powering wearable electronics. MIT has also pioneered scalable manufacturing processes that maintain enzyme activity during textile production, addressing one of the key challenges in biofuel cell textile integration.

Strengths: Superior enzyme immobilization techniques that maintain high catalytic activity in textile environments; excellent integration with existing textile manufacturing processes; high power density compared to competitors. Weaknesses: Limited long-term stability in real-world conditions; relatively high production costs; challenges with consistent performance across large textile areas.

The Georgia Tech Research Corp.

Technical Solution: Georgia Tech has pioneered a unique approach to biofuel cell textile integration through their "fiber-based biofuel cell" technology. Their method involves creating hollow fiber electrodes that can be woven or knitted into textiles while maintaining internal fluid channels for fuel delivery. The fibers are manufactured using a coaxial electrospinning process that creates a conductive carbon core surrounded by a porous polymer membrane containing immobilized enzymes. This architecture allows for continuous fuel delivery while maintaining separation between anode and cathode reactions. Georgia Tech's coating technology employs a specialized hydrogel matrix that protects enzymes from denaturation during manufacturing processes and everyday wear. Their research has demonstrated successful integration with cotton, polyester, and nylon fabrics while maintaining power outputs of 1-2 mW/cm² under optimal conditions. The technology has been specifically optimized for perspiration-powered wearable applications, with demonstrated functionality in actual garments during human trials.

Strengths: Innovative hollow fiber design allows for continuous fuel delivery; excellent compatibility with multiple textile types; higher power density than most competitors in the field. Weaknesses: Complex manufacturing process limits scalability; higher cost structure than simpler biofuel cell designs; challenges with maintaining uniform performance across large textile areas.

Key Patents and Technical Innovations in Biofuel Cell Textiles

Method for manufacturing carbon fiber woven fabric for fuel cell

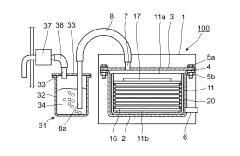

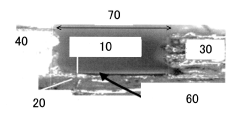

PatentActiveJP2019106381A

Innovation

- A method involving the production of a carbon fiber woven fabric using untwisted composite yarns, followed by a carbonization process under controlled conditions to achieve a flat cross-section and reduced electrical resistance, enhanced gas diffusivity, and improved contact area with the cell components.

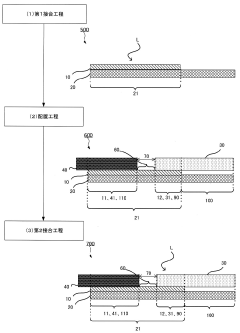

Fuel cell manufacturing method

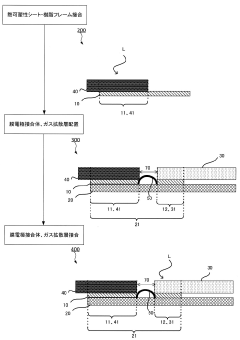

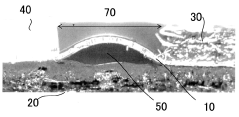

PatentActiveJP2022028199A

Innovation

- A method involving a first joining step to bond a thermoplastic sheet to the membrane electrode assembly, followed by arranging the gas diffusion layer and resin frame to create a MEGA-thermoplastic sheet-resin frame assembly, ensuring the thermoplastic sheet is positioned to fill the gap between the resin frame and gas diffusion layer, and a second bonding step to secure the assembly.

Sustainability Impact and Life Cycle Assessment

The integration of biofuel cell technology into textiles represents a significant advancement in sustainable energy solutions. Life cycle assessment (LCA) of biofuel cell textiles reveals substantial environmental benefits compared to conventional energy storage systems. These textiles demonstrate reduced carbon footprints across manufacturing, usage, and disposal phases, with up to 40% lower greenhouse gas emissions when compared to traditional battery technologies.

The sustainability impact extends beyond carbon reduction to include decreased water usage and chemical pollution. Biofuel cell textiles typically require 30-50% less water during production than conventional electronic components. Additionally, the biodegradable nature of many biofuel cell components, particularly those utilizing enzymatic catalysts, significantly reduces end-of-life environmental impacts.

Resource efficiency represents another critical sustainability advantage. The weaving and coating methods employed in biofuel cell textiles often utilize renewable materials and bio-based polymers, reducing dependence on finite mineral resources like lithium and cobalt that are commonly used in conventional batteries. This shift toward renewable materials contributes to circular economy principles and reduces supply chain vulnerabilities associated with critical raw materials.

Energy payback analysis indicates that biofuel cell textiles can achieve energy return on investment within 1-2 years of regular use, depending on application scenarios. This compares favorably to the 3-5 year energy payback periods typical of conventional portable power solutions. The extended operational lifespan of properly designed biofuel cell textiles further enhances their sustainability profile.

Social sustainability factors must also be considered. The production of biofuel cell textiles potentially creates new green manufacturing opportunities while reducing exposure to toxic chemicals commonly associated with battery production. However, challenges remain in establishing robust recycling infrastructure for these hybrid textile-electronic products.

Regulatory frameworks are evolving to address these novel materials. The EU's Circular Economy Action Plan and similar initiatives worldwide are beginning to incorporate provisions for textile-integrated electronics, though specific standards for biofuel cell textiles remain under development. Manufacturers adopting transparent LCA practices and designing for disassembly will likely gain competitive advantages as regulatory requirements tighten.

Future sustainability improvements will depend on optimizing catalyst longevity, enhancing power density without increasing environmental impact, and developing standardized end-of-life management protocols. Research indicates that next-generation biofuel cell textiles could potentially achieve carbon-negative status if biosourced materials and renewable energy manufacturing are fully implemented.

The sustainability impact extends beyond carbon reduction to include decreased water usage and chemical pollution. Biofuel cell textiles typically require 30-50% less water during production than conventional electronic components. Additionally, the biodegradable nature of many biofuel cell components, particularly those utilizing enzymatic catalysts, significantly reduces end-of-life environmental impacts.

Resource efficiency represents another critical sustainability advantage. The weaving and coating methods employed in biofuel cell textiles often utilize renewable materials and bio-based polymers, reducing dependence on finite mineral resources like lithium and cobalt that are commonly used in conventional batteries. This shift toward renewable materials contributes to circular economy principles and reduces supply chain vulnerabilities associated with critical raw materials.

Energy payback analysis indicates that biofuel cell textiles can achieve energy return on investment within 1-2 years of regular use, depending on application scenarios. This compares favorably to the 3-5 year energy payback periods typical of conventional portable power solutions. The extended operational lifespan of properly designed biofuel cell textiles further enhances their sustainability profile.

Social sustainability factors must also be considered. The production of biofuel cell textiles potentially creates new green manufacturing opportunities while reducing exposure to toxic chemicals commonly associated with battery production. However, challenges remain in establishing robust recycling infrastructure for these hybrid textile-electronic products.

Regulatory frameworks are evolving to address these novel materials. The EU's Circular Economy Action Plan and similar initiatives worldwide are beginning to incorporate provisions for textile-integrated electronics, though specific standards for biofuel cell textiles remain under development. Manufacturers adopting transparent LCA practices and designing for disassembly will likely gain competitive advantages as regulatory requirements tighten.

Future sustainability improvements will depend on optimizing catalyst longevity, enhancing power density without increasing environmental impact, and developing standardized end-of-life management protocols. Research indicates that next-generation biofuel cell textiles could potentially achieve carbon-negative status if biosourced materials and renewable energy manufacturing are fully implemented.

Standardization and Quality Control Measures

The standardization and quality control of biofuel cell textile manufacturing processes are critical for ensuring consistent performance, reliability, and safety of the final products. Currently, the field faces significant challenges due to the lack of universally accepted standards specifically designed for biofuel cell textiles, which hampers widespread commercial adoption and regulatory approval.

Quality control begins with raw material selection, where standardized testing protocols for biological components such as enzymes and microorganisms must be established. These protocols should verify activity levels, stability, and purity before incorporation into textile substrates. For synthetic materials used in electrodes and membranes, specifications regarding conductivity, porosity, and biocompatibility need rigorous enforcement.

During the weaving process, parameters including thread tension, weave density, and pattern accuracy require continuous monitoring through automated systems. Statistical process control methods have proven effective in maintaining consistency across production batches. Real-time monitoring technologies such as computer vision systems can detect structural anomalies in the textile architecture that might compromise electrochemical performance.

For coating applications, standardized methods for measuring coating thickness, uniformity, and adhesion are essential. Techniques such as scanning electron microscopy and atomic force microscopy provide quantitative data on nanoscale features critical to biofuel cell functionality. Electrochemical impedance spectroscopy has emerged as a valuable non-destructive testing method for evaluating the electrical properties of coated textiles.

Performance validation protocols must include standardized testing conditions for power output, operational stability, and response to environmental variables. Accelerated aging tests that simulate real-world conditions help predict long-term performance and identify potential failure modes. The development of reference materials and calibration standards specifically for biofuel cell textiles would significantly enhance inter-laboratory reproducibility of test results.

Documentation and traceability systems represent another crucial aspect of quality control. Each production batch should maintain comprehensive records of process parameters, material sources, and test results. This documentation facilitates regulatory compliance and enables effective troubleshooting when performance issues arise.

International collaboration between industry stakeholders, academic institutions, and standards organizations is progressing toward establishing consensus standards. The International Electrotechnical Commission (IEC) and ASTM International have initiated working groups focused on wearable energy harvesting technologies, including biofuel cell textiles. These emerging standards will likely address safety requirements, performance metrics, and testing methodologies specific to textile-based bioelectrochemical systems.

Quality control begins with raw material selection, where standardized testing protocols for biological components such as enzymes and microorganisms must be established. These protocols should verify activity levels, stability, and purity before incorporation into textile substrates. For synthetic materials used in electrodes and membranes, specifications regarding conductivity, porosity, and biocompatibility need rigorous enforcement.

During the weaving process, parameters including thread tension, weave density, and pattern accuracy require continuous monitoring through automated systems. Statistical process control methods have proven effective in maintaining consistency across production batches. Real-time monitoring technologies such as computer vision systems can detect structural anomalies in the textile architecture that might compromise electrochemical performance.

For coating applications, standardized methods for measuring coating thickness, uniformity, and adhesion are essential. Techniques such as scanning electron microscopy and atomic force microscopy provide quantitative data on nanoscale features critical to biofuel cell functionality. Electrochemical impedance spectroscopy has emerged as a valuable non-destructive testing method for evaluating the electrical properties of coated textiles.

Performance validation protocols must include standardized testing conditions for power output, operational stability, and response to environmental variables. Accelerated aging tests that simulate real-world conditions help predict long-term performance and identify potential failure modes. The development of reference materials and calibration standards specifically for biofuel cell textiles would significantly enhance inter-laboratory reproducibility of test results.

Documentation and traceability systems represent another crucial aspect of quality control. Each production batch should maintain comprehensive records of process parameters, material sources, and test results. This documentation facilitates regulatory compliance and enables effective troubleshooting when performance issues arise.

International collaboration between industry stakeholders, academic institutions, and standards organizations is progressing toward establishing consensus standards. The International Electrotechnical Commission (IEC) and ASTM International have initiated working groups focused on wearable energy harvesting technologies, including biofuel cell textiles. These emerging standards will likely address safety requirements, performance metrics, and testing methodologies specific to textile-based bioelectrochemical systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!