Encapsulation Materials To Protect Enzymes From Environmental Stress

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Enzyme Encapsulation Background and Objectives

Enzyme encapsulation technology has evolved significantly over the past three decades, transitioning from rudimentary immobilization techniques to sophisticated micro and nano-encapsulation systems. This evolution has been driven by the increasing recognition of enzymes' potential in various industrial applications, including food processing, pharmaceuticals, biofuels, and environmental remediation. The fundamental challenge has always been maintaining enzymatic activity under non-optimal conditions, as enzymes are inherently sensitive to environmental factors such as temperature, pH, oxidative stress, and mechanical forces.

The development trajectory shows a clear shift from simple physical adsorption methods to complex multi-material encapsulation systems designed to provide protective microenvironments. Early approaches focused primarily on immobilization for reusability, while contemporary research emphasizes creating biomimetic environments that not only protect enzymes but also enhance their catalytic efficiency and specificity.

Current technological objectives in enzyme encapsulation research center on developing materials that can simultaneously address multiple environmental stressors while maintaining optimal enzyme functionality. These materials must provide effective barriers against thermal fluctuations, pH variations, proteolytic degradation, and oxidative damage, without impeding substrate accessibility or product release. Additionally, there is growing interest in stimuli-responsive encapsulation systems that can adapt to changing environmental conditions or release enzymes in response to specific triggers.

The field is increasingly moving toward biocompatible and sustainable encapsulation materials, reflecting broader trends in green chemistry and bioengineering. Natural polymers such as alginate, chitosan, and cellulose derivatives are being explored alongside synthetic materials like polyethylene glycol (PEG) and poly(lactic-co-glycolic acid) (PLGA). Hybrid organic-inorganic materials, including silica-based matrices and metal-organic frameworks (MOFs), represent another promising direction due to their tunable properties and structural versatility.

A significant objective is to develop scalable and cost-effective encapsulation technologies that can transition from laboratory demonstrations to industrial applications. This requires addressing challenges related to mass transfer limitations, mechanical stability during processing, and long-term storage stability. The ultimate goal is to create encapsulation systems that not only protect enzymes from environmental stress but also enhance their performance, extending their operational lifetime and expanding their application range across diverse industrial sectors.

Recent advances in nanomaterials science, polymer chemistry, and biomimetic design principles have opened new avenues for innovation in this field, suggesting that the next generation of enzyme encapsulation materials will likely incorporate multiple protective mechanisms within unified, multifunctional architectures tailored to specific enzymatic systems and their intended applications.

The development trajectory shows a clear shift from simple physical adsorption methods to complex multi-material encapsulation systems designed to provide protective microenvironments. Early approaches focused primarily on immobilization for reusability, while contemporary research emphasizes creating biomimetic environments that not only protect enzymes but also enhance their catalytic efficiency and specificity.

Current technological objectives in enzyme encapsulation research center on developing materials that can simultaneously address multiple environmental stressors while maintaining optimal enzyme functionality. These materials must provide effective barriers against thermal fluctuations, pH variations, proteolytic degradation, and oxidative damage, without impeding substrate accessibility or product release. Additionally, there is growing interest in stimuli-responsive encapsulation systems that can adapt to changing environmental conditions or release enzymes in response to specific triggers.

The field is increasingly moving toward biocompatible and sustainable encapsulation materials, reflecting broader trends in green chemistry and bioengineering. Natural polymers such as alginate, chitosan, and cellulose derivatives are being explored alongside synthetic materials like polyethylene glycol (PEG) and poly(lactic-co-glycolic acid) (PLGA). Hybrid organic-inorganic materials, including silica-based matrices and metal-organic frameworks (MOFs), represent another promising direction due to their tunable properties and structural versatility.

A significant objective is to develop scalable and cost-effective encapsulation technologies that can transition from laboratory demonstrations to industrial applications. This requires addressing challenges related to mass transfer limitations, mechanical stability during processing, and long-term storage stability. The ultimate goal is to create encapsulation systems that not only protect enzymes from environmental stress but also enhance their performance, extending their operational lifetime and expanding their application range across diverse industrial sectors.

Recent advances in nanomaterials science, polymer chemistry, and biomimetic design principles have opened new avenues for innovation in this field, suggesting that the next generation of enzyme encapsulation materials will likely incorporate multiple protective mechanisms within unified, multifunctional architectures tailored to specific enzymatic systems and their intended applications.

Market Analysis for Enzyme Protection Technologies

The global enzyme market has been experiencing robust growth, with a market value reaching $10.5 billion in 2022 and projected to expand at a CAGR of 7.2% through 2030. Within this broader market, enzyme protection technologies represent a critical segment, as enzymes' functionality and stability are highly susceptible to environmental factors including temperature fluctuations, pH changes, oxidative stress, and mechanical forces.

The industrial enzyme sector, comprising food and beverage, detergents, biofuels, animal feed, and pharmaceuticals, dominates the demand for enzyme protection technologies. Food and beverage applications currently lead with approximately 35% market share, driven by increasing consumer preference for natural ingredients and clean-label products. The pharmaceutical and biotechnology sectors follow closely, showing the fastest growth rate at 8.5% annually due to expanding biopharmaceutical production and enzyme-based therapeutics.

Regionally, North America and Europe currently hold the largest market shares at 32% and 28% respectively, attributed to their advanced biotechnology infrastructure and stringent regulations promoting sustainable industrial processes. However, the Asia-Pacific region is emerging as the fastest-growing market with a 9.3% annual growth rate, fueled by rapid industrialization in China and India, expanding food processing sectors, and increasing investments in biotechnology research.

Market dynamics are increasingly influenced by sustainability concerns, with industries seeking enzyme stabilization technologies that extend enzyme shelf-life and reduce waste. This trend has created a premium market segment for green encapsulation materials derived from natural polymers, biodegradable substances, and renewable resources, growing at 10.2% annually.

Customer segmentation reveals distinct needs across industries: food manufacturers prioritize food-grade, allergen-free protection materials; pharmaceutical companies demand high-purity, biocompatible encapsulants with controlled release properties; while industrial enzyme users focus on cost-effectiveness and performance under harsh processing conditions.

The competitive landscape features established players like DuPont, BASF, and Novozymes controlling approximately 45% of the market share, alongside emerging specialized companies offering innovative encapsulation technologies. Strategic partnerships between enzyme producers and material science companies are increasingly common, creating integrated solutions that address specific industry challenges.

Market barriers include high R&D costs for novel encapsulation materials, regulatory hurdles particularly for food and pharmaceutical applications, and technical challenges in maintaining enzyme activity during encapsulation processes. Despite these challenges, the enzyme protection technologies market is expected to reach $3.8 billion by 2028, driven by expanding applications in emerging economies and growing demand for sustainable industrial processes.

The industrial enzyme sector, comprising food and beverage, detergents, biofuels, animal feed, and pharmaceuticals, dominates the demand for enzyme protection technologies. Food and beverage applications currently lead with approximately 35% market share, driven by increasing consumer preference for natural ingredients and clean-label products. The pharmaceutical and biotechnology sectors follow closely, showing the fastest growth rate at 8.5% annually due to expanding biopharmaceutical production and enzyme-based therapeutics.

Regionally, North America and Europe currently hold the largest market shares at 32% and 28% respectively, attributed to their advanced biotechnology infrastructure and stringent regulations promoting sustainable industrial processes. However, the Asia-Pacific region is emerging as the fastest-growing market with a 9.3% annual growth rate, fueled by rapid industrialization in China and India, expanding food processing sectors, and increasing investments in biotechnology research.

Market dynamics are increasingly influenced by sustainability concerns, with industries seeking enzyme stabilization technologies that extend enzyme shelf-life and reduce waste. This trend has created a premium market segment for green encapsulation materials derived from natural polymers, biodegradable substances, and renewable resources, growing at 10.2% annually.

Customer segmentation reveals distinct needs across industries: food manufacturers prioritize food-grade, allergen-free protection materials; pharmaceutical companies demand high-purity, biocompatible encapsulants with controlled release properties; while industrial enzyme users focus on cost-effectiveness and performance under harsh processing conditions.

The competitive landscape features established players like DuPont, BASF, and Novozymes controlling approximately 45% of the market share, alongside emerging specialized companies offering innovative encapsulation technologies. Strategic partnerships between enzyme producers and material science companies are increasingly common, creating integrated solutions that address specific industry challenges.

Market barriers include high R&D costs for novel encapsulation materials, regulatory hurdles particularly for food and pharmaceutical applications, and technical challenges in maintaining enzyme activity during encapsulation processes. Despite these challenges, the enzyme protection technologies market is expected to reach $3.8 billion by 2028, driven by expanding applications in emerging economies and growing demand for sustainable industrial processes.

Current Challenges in Enzyme Stabilization

Despite significant advancements in enzyme technology, several critical challenges persist in stabilizing enzymes against environmental stressors. Temperature fluctuations remain one of the most formidable obstacles, as most enzymes exhibit optimal activity within narrow temperature ranges. Exposure to temperatures outside these ranges often leads to denaturation, where the enzyme's three-dimensional structure unfolds, resulting in permanent activity loss. This thermal instability severely limits industrial applications requiring high-temperature processing or long-term storage.

pH variation presents another significant challenge, as enzymes typically function optimally within specific pH ranges. Industrial processes frequently involve pH shifts that can disrupt ionic interactions within enzyme structures, altering their catalytic efficiency. The development of encapsulation materials that can maintain a consistent microenvironment pH regardless of external conditions remains technically demanding.

Oxidative stress poses a particularly insidious threat to enzyme stability. Reactive oxygen species can attack amino acid residues critical for catalytic function, irreversibly damaging the enzyme. Current encapsulation technologies struggle to incorporate effective antioxidant properties without compromising other essential characteristics such as permeability and mechanical strength.

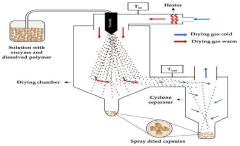

Mechanical stress during industrial processing represents another substantial challenge. Shear forces during mixing, pumping, or spray drying can denature enzymes by physically disrupting their structure. Existing encapsulation materials often fail to provide sufficient mechanical protection while maintaining necessary diffusion properties for substrates and products.

Water activity fluctuations significantly impact enzyme stability, as both excessive hydration and dehydration can compromise functionality. Creating encapsulation materials that maintain optimal water activity levels while allowing selective permeability remains technically challenging. This is particularly problematic in applications involving freeze-drying or processes with varying humidity conditions.

Proteolytic degradation by endogenous or exogenous proteases presents another obstacle, especially in complex biological environments. Current encapsulation strategies often cannot fully prevent protease access while maintaining substrate accessibility to the encapsulated enzyme.

Additionally, the challenge of balancing protection with functionality persists across all encapsulation approaches. Materials that provide excellent environmental protection often restrict substrate access or product release, reducing overall catalytic efficiency. Conversely, highly permeable materials may offer insufficient protection against environmental stressors.

Finally, scalability and cost-effectiveness remain significant hurdles. Many promising encapsulation technologies demonstrate excellent performance in laboratory settings but face substantial challenges in scaling to industrial production volumes while maintaining economic viability.

pH variation presents another significant challenge, as enzymes typically function optimally within specific pH ranges. Industrial processes frequently involve pH shifts that can disrupt ionic interactions within enzyme structures, altering their catalytic efficiency. The development of encapsulation materials that can maintain a consistent microenvironment pH regardless of external conditions remains technically demanding.

Oxidative stress poses a particularly insidious threat to enzyme stability. Reactive oxygen species can attack amino acid residues critical for catalytic function, irreversibly damaging the enzyme. Current encapsulation technologies struggle to incorporate effective antioxidant properties without compromising other essential characteristics such as permeability and mechanical strength.

Mechanical stress during industrial processing represents another substantial challenge. Shear forces during mixing, pumping, or spray drying can denature enzymes by physically disrupting their structure. Existing encapsulation materials often fail to provide sufficient mechanical protection while maintaining necessary diffusion properties for substrates and products.

Water activity fluctuations significantly impact enzyme stability, as both excessive hydration and dehydration can compromise functionality. Creating encapsulation materials that maintain optimal water activity levels while allowing selective permeability remains technically challenging. This is particularly problematic in applications involving freeze-drying or processes with varying humidity conditions.

Proteolytic degradation by endogenous or exogenous proteases presents another obstacle, especially in complex biological environments. Current encapsulation strategies often cannot fully prevent protease access while maintaining substrate accessibility to the encapsulated enzyme.

Additionally, the challenge of balancing protection with functionality persists across all encapsulation approaches. Materials that provide excellent environmental protection often restrict substrate access or product release, reducing overall catalytic efficiency. Conversely, highly permeable materials may offer insufficient protection against environmental stressors.

Finally, scalability and cost-effectiveness remain significant hurdles. Many promising encapsulation technologies demonstrate excellent performance in laboratory settings but face substantial challenges in scaling to industrial production volumes while maintaining economic viability.

Current Encapsulation Material Solutions

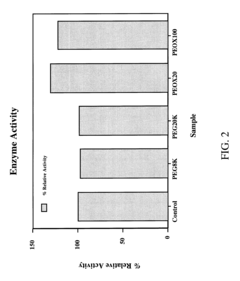

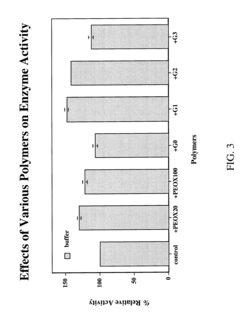

01 Polymer-based encapsulation materials

Various polymers can be used as encapsulation materials to protect enzymes from environmental stress. These polymers form a protective barrier around the enzymes, shielding them from harsh conditions such as extreme pH, temperature fluctuations, and oxidative stress. Common polymers used include polyethylene glycol (PEG), polylactic acid (PLA), and chitosan. These materials can be formulated to create microcapsules or microspheres that provide controlled release of enzymes while maintaining their stability and activity.- Polymer-based encapsulation materials: Various polymers can be used as encapsulation materials to protect enzymes from environmental stress. These polymers form a protective barrier around the enzymes, shielding them from harsh conditions such as extreme pH, temperature fluctuations, and oxidative stress. Common polymers used include polyethylene glycol, polylactic acid, and chitosan. These materials can be formulated into microspheres, nanoparticles, or hydrogels to provide effective enzyme protection while maintaining enzymatic activity.

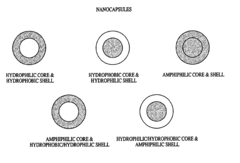

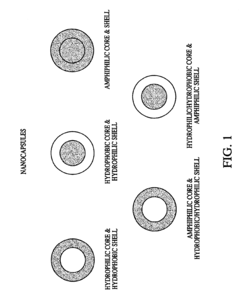

- Liposomal and lipid-based encapsulation systems: Liposomes and lipid-based systems offer effective protection for enzymes against environmental stressors. These systems consist of phospholipid bilayers that mimic cell membranes, creating a biocompatible environment for enzymes. The lipid barrier protects enzymes from proteolytic degradation, pH changes, and oxidative damage. Additionally, these systems can be modified with surface ligands to enhance targeting and stability, making them versatile for various applications in biotechnology, pharmaceuticals, and food industries.

- Sol-gel and silica-based encapsulation techniques: Sol-gel technology and silica-based materials provide robust protection for enzymes against environmental stress. These materials form a porous network around enzymes, allowing substrate diffusion while preventing enzyme leakage. The silica matrix shields enzymes from thermal denaturation, pH fluctuations, and mechanical stress. The encapsulation process can be conducted under mild conditions, preserving enzyme activity. These materials offer excellent stability and can be tailored to specific applications by modifying pore size, surface chemistry, and matrix composition.

- Protein and peptide-based protective matrices: Proteins and peptides can serve as natural encapsulation materials for enzyme protection. These biomolecules form protective matrices through self-assembly or crosslinking mechanisms. Protein-based encapsulation offers biocompatibility and biodegradability while providing effective protection against environmental stressors. Common protein materials include albumin, gelatin, and engineered peptides with specific protective properties. These systems can maintain enzyme activity in harsh conditions and can be designed to respond to specific environmental triggers for controlled enzyme release.

- Composite and hybrid encapsulation systems: Composite and hybrid encapsulation systems combine multiple materials to enhance enzyme protection against environmental stress. These systems integrate the advantages of different materials, such as the mechanical strength of inorganic components with the biocompatibility of organic polymers. Examples include polymer-clay nanocomposites, metal-organic frameworks, and core-shell structures with multiple protective layers. These hybrid systems provide superior protection against multiple stressors simultaneously, including temperature extremes, mechanical forces, chemical degradation, and microbial attack.

02 Liposomal and lipid-based encapsulation systems

Liposomes and lipid-based systems offer effective protection for enzymes against environmental stressors. These systems consist of phospholipid bilayers that mimic natural cell membranes, providing a biocompatible environment for enzymes. The lipid bilayers can be engineered to have specific permeability properties, allowing for controlled interaction with the external environment while protecting the encapsulated enzymes from degradation. These systems are particularly useful for enzymes that are sensitive to oxidation or require a hydrophobic environment to maintain their activity.Expand Specific Solutions03 Inorganic material-based encapsulation

Inorganic materials such as silica, clay minerals, and metal oxides can be used to encapsulate enzymes for protection against environmental stress. These materials form rigid structures that shield enzymes from physical and chemical degradation. Sol-gel processes are commonly used to create porous silica matrices that immobilize enzymes while allowing substrates to diffuse in and products to diffuse out. The inorganic encapsulation materials provide excellent thermal stability and mechanical strength, making them suitable for applications in harsh industrial conditions.Expand Specific Solutions04 Hydrogel-based enzyme encapsulation

Hydrogels are three-dimensional networks of hydrophilic polymers that can absorb large amounts of water while maintaining their structure. They provide a favorable microenvironment for enzymes, protecting them from denaturation and aggregation. The high water content of hydrogels allows for efficient diffusion of substrates and products, while the polymer network prevents enzyme leakage. Various natural and synthetic polymers, such as alginate, gelatin, and polyacrylamide, can be used to form hydrogels for enzyme encapsulation. These systems can be designed to respond to environmental stimuli such as pH, temperature, or ionic strength.Expand Specific Solutions05 Composite and hybrid encapsulation materials

Composite and hybrid materials combine the advantages of different encapsulation systems to provide enhanced protection for enzymes. These materials may include polymer-inorganic hybrids, multilayered structures, or core-shell particles. By integrating multiple components, these systems can address various environmental stressors simultaneously. For example, a composite material might include a hydrophobic core to protect enzymes from water, surrounded by a pH-responsive polymer layer that controls substrate access. These sophisticated encapsulation systems can be tailored to specific enzyme requirements and application conditions.Expand Specific Solutions

Leading Companies in Enzyme Protection Industry

The enzyme encapsulation materials market is currently in a growth phase, characterized by increasing demand for enzyme stabilization technologies across various industries. The global market size for enzyme encapsulation is expanding rapidly, driven by applications in pharmaceuticals, food processing, and agriculture. Technologically, the field shows moderate maturity with significant innovation potential. Leading players include INOFEA AG with their patented enzzen® platform, Unilever leveraging encapsulation for consumer products, and AgroSpheres developing novel delivery technologies for agricultural applications. Academic institutions like University of Alabama and Nanyang Technological University contribute fundamental research, while established corporations such as Henkel, Siemens, and Texas Instruments explore industrial applications. The competitive landscape features specialized biotech firms developing proprietary technologies alongside diversified corporations integrating enzyme protection into their product portfolios.

INOFEA AG

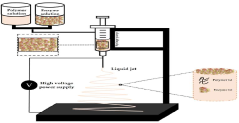

Technical Solution: INOFEA AG has developed a proprietary enzyme encapsulation platform called enzzen®, which uses a unique combination of polymers to create nanoscale protective shells around enzymes. This technology creates enzyme particles with diameters of 100-500 nm that shield enzymes from harsh environmental conditions including extreme pH, temperature fluctuations, and organic solvents. The enzzen® platform employs a controlled polymerization process that forms covalent bonds with the enzyme surface, creating a porous shell that allows substrate diffusion while preventing enzyme leakage. This encapsulation method has been demonstrated to extend enzyme half-life by up to 100 times compared to free enzymes and maintain activity across broader pH and temperature ranges. INOFEA's approach also enables enzyme immobilization on various surfaces, facilitating enzyme recovery and reuse in industrial processes.

Strengths: Superior protection against multiple stressors simultaneously; significantly extended enzyme lifetime; maintained catalytic activity; enables enzyme recycling. Weaknesses: Potential diffusion limitations for larger substrates; may require customization for specific enzyme classes; higher production costs compared to simpler stabilization methods.

Battelle Memorial Institute

Technical Solution: Battelle Memorial Institute has developed a sophisticated enzyme encapsulation platform called EnzMatrix™ that utilizes advanced biomaterials and microfluidic fabrication techniques. This technology creates precisely controlled microenvironments for enzymes using combinations of natural and synthetic polymers, including modified chitosan, alginate derivatives, and proprietary synthetic hydrogels. The EnzMatrix™ system employs a microfluidic droplet generation process that produces uniform microcapsules (20-200 μm) with tailored internal structures optimized for specific enzyme classes. These capsules incorporate multiple protective mechanisms, including oxygen scavengers for oxidation-sensitive enzymes, water activity modulators for hydrolytic enzymes, and metal chelators for metalloenzymes. The technology has been particularly successful in protecting enzymes used in environmental remediation applications, where harsh field conditions often lead to rapid enzyme deactivation. Field tests have demonstrated that lipases and dehalogenases encapsulated using the EnzMatrix™ platform maintain over 75% activity after exposure to soil contaminants and temperature fluctuations for 60 days, compared to complete deactivation of free enzymes within 7 days.

Strengths: Highly customizable protection strategies for different enzyme classes; precise control over microenvironment conditions; demonstrated effectiveness in extreme environmental conditions; scalable manufacturing process. Weaknesses: Higher production complexity and costs; requires specialized equipment for manufacturing; may have limitations in applications requiring rapid enzyme action due to diffusion barriers.

Key Patents in Enzyme Protection Technologies

Encapsulation methodologies and applications of polymeric materials for the protection of enzymes

PatentPendingIN202341008570A

Innovation

- The use of semi-synthetic polymers like chitosan and alginate for encapsulating enzymes, which form hybrid gels with enhanced mechanical strength and biocompatibility, allowing for controlled release and high encapsulation efficiency through methods like ionic gelation, spray drying, and nanoprecipitation, while characterizing microparticle properties for optimal performance.

Enhancing protein activity through nanoencapsulation

PatentInactiveUS6716450B1

Innovation

- Development of nanocapsules with sizes ranging from 10 to 500 nm, made through a simple and inexpensive physical nanoencapsulation strategy, which encapsulates proteins and enzymes, providing stability in extreme conditions and controlled release, using covalently linked, hyper-branched polymers with surface functionalization for enhanced solubility and reactivity.

Sustainability Aspects of Encapsulation Materials

The sustainability of encapsulation materials for enzyme protection represents a critical consideration in modern biotechnological applications. As industries increasingly adopt enzymatic processes for their efficiency and specificity, the environmental impact of protective materials cannot be overlooked. Traditional encapsulation materials often derive from petroleum-based polymers, raising significant concerns regarding biodegradability and ecological footprint throughout their lifecycle.

Recent advances have focused on developing bio-based alternatives that maintain protective efficacy while reducing environmental impact. Materials such as alginate, chitosan, cellulose derivatives, and other polysaccharides demonstrate promising capabilities for enzyme encapsulation while offering inherent biodegradability. These materials decompose naturally in environmental conditions without generating toxic residues, significantly reducing waste accumulation compared to synthetic counterparts.

The energy consumption associated with encapsulation material production represents another crucial sustainability factor. Conventional synthetic polymers typically require energy-intensive manufacturing processes, contributing substantially to carbon emissions. In contrast, bio-based encapsulation materials generally require less energy during production, with some estimates suggesting 30-50% lower carbon footprints compared to petroleum-derived alternatives.

Water usage and pollution present additional sustainability challenges. The production of certain synthetic encapsulation materials involves substantial water consumption and may generate contaminated effluents requiring specialized treatment. Bio-based alternatives typically demonstrate more favorable water utilization profiles, though processing methods must be carefully optimized to maintain this advantage at industrial scales.

Circular economy principles are increasingly being applied to encapsulation material development. Research into recyclable or reusable encapsulation systems shows promise for reducing material consumption while maintaining enzyme protection. Some innovative approaches incorporate waste streams from agricultural or food processing industries as raw materials for encapsulation, creating value-added applications for materials that would otherwise be discarded.

Regulatory frameworks worldwide are evolving to encourage sustainable practices in industrial biotechnology. Several jurisdictions have implemented or proposed restrictions on non-biodegradable microplastics and similar materials, potentially affecting certain encapsulation technologies. Forward-thinking companies are proactively transitioning to more sustainable alternatives, recognizing both environmental benefits and potential regulatory advantages.

The economic viability of sustainable encapsulation materials remains a critical consideration for widespread adoption. While production costs for bio-based materials have historically exceeded those of synthetic alternatives, economies of scale and technological improvements are gradually narrowing this gap, making environmentally responsible choices increasingly competitive in commercial applications.

Recent advances have focused on developing bio-based alternatives that maintain protective efficacy while reducing environmental impact. Materials such as alginate, chitosan, cellulose derivatives, and other polysaccharides demonstrate promising capabilities for enzyme encapsulation while offering inherent biodegradability. These materials decompose naturally in environmental conditions without generating toxic residues, significantly reducing waste accumulation compared to synthetic counterparts.

The energy consumption associated with encapsulation material production represents another crucial sustainability factor. Conventional synthetic polymers typically require energy-intensive manufacturing processes, contributing substantially to carbon emissions. In contrast, bio-based encapsulation materials generally require less energy during production, with some estimates suggesting 30-50% lower carbon footprints compared to petroleum-derived alternatives.

Water usage and pollution present additional sustainability challenges. The production of certain synthetic encapsulation materials involves substantial water consumption and may generate contaminated effluents requiring specialized treatment. Bio-based alternatives typically demonstrate more favorable water utilization profiles, though processing methods must be carefully optimized to maintain this advantage at industrial scales.

Circular economy principles are increasingly being applied to encapsulation material development. Research into recyclable or reusable encapsulation systems shows promise for reducing material consumption while maintaining enzyme protection. Some innovative approaches incorporate waste streams from agricultural or food processing industries as raw materials for encapsulation, creating value-added applications for materials that would otherwise be discarded.

Regulatory frameworks worldwide are evolving to encourage sustainable practices in industrial biotechnology. Several jurisdictions have implemented or proposed restrictions on non-biodegradable microplastics and similar materials, potentially affecting certain encapsulation technologies. Forward-thinking companies are proactively transitioning to more sustainable alternatives, recognizing both environmental benefits and potential regulatory advantages.

The economic viability of sustainable encapsulation materials remains a critical consideration for widespread adoption. While production costs for bio-based materials have historically exceeded those of synthetic alternatives, economies of scale and technological improvements are gradually narrowing this gap, making environmentally responsible choices increasingly competitive in commercial applications.

Regulatory Framework for Enzyme Products

The regulatory landscape for enzyme products, particularly those utilizing encapsulation technologies for environmental stress protection, is complex and varies significantly across global markets. In the United States, the FDA regulates enzymes differently based on their intended use - as food additives under 21 CFR Parts 170-199, as dietary supplements under DSHEA, or as industrial enzymes under TSCA when used in non-food applications. The EPA may also have jurisdiction when enzymes are incorporated into environmental applications such as bioremediation solutions.

European regulations present a more stringent framework through the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation, which requires comprehensive safety data for enzymes used in industrial applications. Additionally, the European Food Safety Authority (EFSA) evaluates enzymes intended for food applications under Regulation (EC) No 1332/2008, with specific attention to novel encapsulation materials that may require separate safety assessments.

Japan's regulatory system operates through the Ministry of Health, Labour and Welfare, which has established specific guidelines for enzyme products, particularly focusing on stability and safety aspects of encapsulation technologies. The Japanese framework emphasizes long-term stability testing under various environmental conditions, which directly relates to the effectiveness of encapsulation materials.

Emerging markets such as China and India are rapidly developing their regulatory frameworks, with China's National Medical Products Administration (NMPA) implementing new guidelines specifically addressing novel delivery systems including enzyme encapsulation technologies. These regulations increasingly focus on biodegradability and environmental impact of encapsulation materials.

International harmonization efforts are underway through organizations like the International Conference on Harmonisation (ICH) and ISO technical committees, which are developing standardized testing protocols for encapsulated enzyme products. These include stability testing under various environmental stressors (temperature, pH, humidity) and guidelines for characterizing encapsulation material interactions with both enzymes and the environment.

Regulatory compliance for encapsulated enzyme products requires extensive documentation including manufacturing process validation, stability studies demonstrating protection against environmental stressors, and safety assessments of both the enzyme and encapsulation materials. Many jurisdictions now require environmental impact assessments, particularly for novel synthetic encapsulation materials that may persist in the environment.

Recent regulatory trends indicate increasing scrutiny of synthetic polymers used in encapsulation, with preference for bio-based, biodegradable alternatives. This shift presents both challenges and opportunities for researchers developing new encapsulation materials, as regulatory approval pathways for novel biomaterials may be expedited if they demonstrate improved environmental profiles compared to conventional options.

European regulations present a more stringent framework through the REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation, which requires comprehensive safety data for enzymes used in industrial applications. Additionally, the European Food Safety Authority (EFSA) evaluates enzymes intended for food applications under Regulation (EC) No 1332/2008, with specific attention to novel encapsulation materials that may require separate safety assessments.

Japan's regulatory system operates through the Ministry of Health, Labour and Welfare, which has established specific guidelines for enzyme products, particularly focusing on stability and safety aspects of encapsulation technologies. The Japanese framework emphasizes long-term stability testing under various environmental conditions, which directly relates to the effectiveness of encapsulation materials.

Emerging markets such as China and India are rapidly developing their regulatory frameworks, with China's National Medical Products Administration (NMPA) implementing new guidelines specifically addressing novel delivery systems including enzyme encapsulation technologies. These regulations increasingly focus on biodegradability and environmental impact of encapsulation materials.

International harmonization efforts are underway through organizations like the International Conference on Harmonisation (ICH) and ISO technical committees, which are developing standardized testing protocols for encapsulated enzyme products. These include stability testing under various environmental stressors (temperature, pH, humidity) and guidelines for characterizing encapsulation material interactions with both enzymes and the environment.

Regulatory compliance for encapsulated enzyme products requires extensive documentation including manufacturing process validation, stability studies demonstrating protection against environmental stressors, and safety assessments of both the enzyme and encapsulation materials. Many jurisdictions now require environmental impact assessments, particularly for novel synthetic encapsulation materials that may persist in the environment.

Recent regulatory trends indicate increasing scrutiny of synthetic polymers used in encapsulation, with preference for bio-based, biodegradable alternatives. This shift presents both challenges and opportunities for researchers developing new encapsulation materials, as regulatory approval pathways for novel biomaterials may be expedited if they demonstrate improved environmental profiles compared to conventional options.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!