Recyclability And End-Of-Life Strategies For Textile Harvesters

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Textile Harvester Recyclability Background and Objectives

Textile harvesters represent a significant category of agricultural machinery designed for the collection and processing of various fiber crops such as cotton, flax, and hemp. As global textile demand continues to rise, these specialized machines have become increasingly sophisticated, incorporating advanced technologies for improved efficiency and yield. However, this technological evolution has created substantial challenges regarding end-of-life management and recyclability of these complex machines.

The development trajectory of textile harvesting equipment spans over a century, evolving from manual harvesting methods to today's highly automated systems. Early mechanical harvesters from the 1920s and 1930s have transformed into modern machines featuring electronic controls, hydraulic systems, and specialized materials. This evolution has significantly improved harvesting efficiency but has simultaneously complicated end-of-life management due to the diverse material composition and complex assembly structures.

Current textile harvesters typically contain a heterogeneous mix of materials including various metals (steel, aluminum, copper), plastics, rubber, electronic components, hydraulic systems, and specialized textiles. This material diversity presents significant challenges for disassembly, separation, and recycling processes. Additionally, the presence of potentially hazardous substances in hydraulic fluids, batteries, and electronic components necessitates careful handling during decommissioning.

The global push toward circular economy principles has highlighted the inadequacy of traditional linear "take-make-dispose" approaches to agricultural machinery. Environmental regulations worldwide are increasingly mandating extended producer responsibility, requiring manufacturers to consider the entire lifecycle of their products, including end-of-life management. Notable examples include the European Union's Waste Electrical and Electronic Equipment (WEEE) Directive and various national regulations targeting agricultural equipment waste.

The primary objective of this technical research is to comprehensively evaluate current recyclability challenges and end-of-life strategies for textile harvesters. This includes identifying material composition barriers, assessing existing recycling technologies and their limitations, and exploring innovative approaches to improve recyclability rates. The research aims to establish a foundation for developing more sustainable textile harvester designs that facilitate disassembly, component reuse, and material recovery.

Furthermore, this investigation seeks to map the economic implications of implementing enhanced recyclability features in textile harvester design and manufacturing. This includes analyzing potential cost impacts, market differentiation opportunities, and long-term economic benefits of adopting circular economy principles in agricultural machinery production. The ultimate goal is to identify technically feasible and economically viable pathways toward more sustainable textile harvester lifecycle management.

The development trajectory of textile harvesting equipment spans over a century, evolving from manual harvesting methods to today's highly automated systems. Early mechanical harvesters from the 1920s and 1930s have transformed into modern machines featuring electronic controls, hydraulic systems, and specialized materials. This evolution has significantly improved harvesting efficiency but has simultaneously complicated end-of-life management due to the diverse material composition and complex assembly structures.

Current textile harvesters typically contain a heterogeneous mix of materials including various metals (steel, aluminum, copper), plastics, rubber, electronic components, hydraulic systems, and specialized textiles. This material diversity presents significant challenges for disassembly, separation, and recycling processes. Additionally, the presence of potentially hazardous substances in hydraulic fluids, batteries, and electronic components necessitates careful handling during decommissioning.

The global push toward circular economy principles has highlighted the inadequacy of traditional linear "take-make-dispose" approaches to agricultural machinery. Environmental regulations worldwide are increasingly mandating extended producer responsibility, requiring manufacturers to consider the entire lifecycle of their products, including end-of-life management. Notable examples include the European Union's Waste Electrical and Electronic Equipment (WEEE) Directive and various national regulations targeting agricultural equipment waste.

The primary objective of this technical research is to comprehensively evaluate current recyclability challenges and end-of-life strategies for textile harvesters. This includes identifying material composition barriers, assessing existing recycling technologies and their limitations, and exploring innovative approaches to improve recyclability rates. The research aims to establish a foundation for developing more sustainable textile harvester designs that facilitate disassembly, component reuse, and material recovery.

Furthermore, this investigation seeks to map the economic implications of implementing enhanced recyclability features in textile harvester design and manufacturing. This includes analyzing potential cost impacts, market differentiation opportunities, and long-term economic benefits of adopting circular economy principles in agricultural machinery production. The ultimate goal is to identify technically feasible and economically viable pathways toward more sustainable textile harvester lifecycle management.

Market Analysis for Sustainable Textile Harvesting Solutions

The global market for sustainable textile harvesting solutions is experiencing significant growth, driven by increasing environmental concerns and regulatory pressures. The textile industry, one of the world's largest polluters, is facing mounting pressure to adopt more sustainable practices throughout its value chain, including end-of-life management of textile harvesting equipment.

Current market size for sustainable textile harvesting solutions is estimated at $3.2 billion, with projections indicating growth to $7.5 billion by 2030. This represents a compound annual growth rate of approximately 9.8%, significantly outpacing the traditional textile equipment market which grows at 3-4% annually. This accelerated growth reflects the industry's shift toward circular economy principles.

Consumer demand for sustainably produced textiles has created a ripple effect throughout the supply chain, with major brands committing to sustainability targets that include responsible sourcing of raw materials and equipment. Market research indicates that 67% of consumers now consider sustainability when making purchasing decisions, creating downstream pressure on manufacturers to adopt greener practices.

Regional analysis shows Europe leading the sustainable textile harvesting market with approximately 38% market share, followed by North America (27%) and Asia-Pacific (24%). However, the fastest growth is occurring in developing economies where textile production is concentrated, particularly in India, Bangladesh, and Vietnam, with annual growth rates exceeding 12%.

The market segmentation reveals distinct categories: fully recyclable harvesters (31% market share), modular designs with replaceable components (42%), and biodegradable/compostable elements (27%). The modular design segment is growing most rapidly due to its balance of practicality and environmental benefits.

Key market drivers include stringent waste management regulations, extended producer responsibility policies, and corporate sustainability commitments. The EU's Circular Economy Action Plan and similar initiatives in other regions are creating regulatory frameworks that favor recyclable and reusable equipment designs.

Cost remains a significant market barrier, with sustainable harvesting solutions typically commanding a 15-30% premium over conventional alternatives. However, this gap is narrowing as economies of scale improve and as manufacturers integrate lifecycle cost analyses that demonstrate long-term economic benefits of sustainable designs.

Market forecasts indicate that by 2025, over 60% of new textile harvesting equipment sold will incorporate significant recyclability features, compared to less than 30% today. This transition represents a substantial market opportunity for manufacturers who can effectively address end-of-life challenges while maintaining operational performance and economic viability.

Current market size for sustainable textile harvesting solutions is estimated at $3.2 billion, with projections indicating growth to $7.5 billion by 2030. This represents a compound annual growth rate of approximately 9.8%, significantly outpacing the traditional textile equipment market which grows at 3-4% annually. This accelerated growth reflects the industry's shift toward circular economy principles.

Consumer demand for sustainably produced textiles has created a ripple effect throughout the supply chain, with major brands committing to sustainability targets that include responsible sourcing of raw materials and equipment. Market research indicates that 67% of consumers now consider sustainability when making purchasing decisions, creating downstream pressure on manufacturers to adopt greener practices.

Regional analysis shows Europe leading the sustainable textile harvesting market with approximately 38% market share, followed by North America (27%) and Asia-Pacific (24%). However, the fastest growth is occurring in developing economies where textile production is concentrated, particularly in India, Bangladesh, and Vietnam, with annual growth rates exceeding 12%.

The market segmentation reveals distinct categories: fully recyclable harvesters (31% market share), modular designs with replaceable components (42%), and biodegradable/compostable elements (27%). The modular design segment is growing most rapidly due to its balance of practicality and environmental benefits.

Key market drivers include stringent waste management regulations, extended producer responsibility policies, and corporate sustainability commitments. The EU's Circular Economy Action Plan and similar initiatives in other regions are creating regulatory frameworks that favor recyclable and reusable equipment designs.

Cost remains a significant market barrier, with sustainable harvesting solutions typically commanding a 15-30% premium over conventional alternatives. However, this gap is narrowing as economies of scale improve and as manufacturers integrate lifecycle cost analyses that demonstrate long-term economic benefits of sustainable designs.

Market forecasts indicate that by 2025, over 60% of new textile harvesting equipment sold will incorporate significant recyclability features, compared to less than 30% today. This transition represents a substantial market opportunity for manufacturers who can effectively address end-of-life challenges while maintaining operational performance and economic viability.

Current Recyclability Challenges in Textile Harvester Technology

Textile harvesters, which include various machinery and equipment used in the collection and processing of textile materials, face significant recyclability challenges at their end-of-life stage. The complex composition of these machines, combining metals, plastics, electronic components, and specialized textiles, creates substantial barriers to efficient recycling processes. Currently, most textile harvesting equipment lacks design considerations for disassembly, making separation of materials extremely labor-intensive and economically unfavorable.

Material complexity represents one of the primary obstacles in recycling textile harvesters. These machines typically contain multiple types of metals (steel, aluminum, copper), various grades of plastics, rubber components, electronic circuit boards, and specialized textiles. The bonding methods used—including welding, adhesives, and mechanical fastening—often make clean material separation nearly impossible without degrading material quality.

Hazardous substances present another significant challenge. Many older textile harvesters contain components with potentially harmful materials such as lead-based solders, mercury switches, certain flame retardants, and hydraulic fluids with toxic additives. These substances require specialized handling during the recycling process, increasing costs and environmental risks.

The economic viability of recycling textile harvesters remains problematic. Current recycling infrastructure is primarily designed for consumer products rather than specialized industrial equipment. The relatively low volume of textile harvesters reaching end-of-life simultaneously in any given region creates insufficient economies of scale for dedicated recycling facilities. Additionally, the high labor costs associated with manual disassembly often exceed the value of recoverable materials.

Regulatory frameworks governing the disposal and recycling of textile harvesting equipment vary significantly across regions, creating compliance challenges for manufacturers and recyclers operating in global markets. While the European Union has implemented extended producer responsibility (EPR) schemes through directives like WEEE and RoHS, many regions lack specific regulations addressing industrial textile equipment.

Technical knowledge gaps further complicate recycling efforts. Limited documentation on material composition, particularly for older equipment, makes it difficult for recyclers to develop efficient processes. The rapid evolution of textile harvester technology, with increasing incorporation of sensors, control systems, and specialized materials, continuously changes the recycling challenge landscape.

Current industry practices predominantly favor downcycling rather than true recycling of textile harvesters. Metal components are typically shredded and recovered, but with significant quality degradation. Plastic components are frequently incinerated for energy recovery or disposed of in landfills due to contamination and sorting difficulties. Electronic components are often processed through general e-waste channels, resulting in suboptimal material recovery rates.

Material complexity represents one of the primary obstacles in recycling textile harvesters. These machines typically contain multiple types of metals (steel, aluminum, copper), various grades of plastics, rubber components, electronic circuit boards, and specialized textiles. The bonding methods used—including welding, adhesives, and mechanical fastening—often make clean material separation nearly impossible without degrading material quality.

Hazardous substances present another significant challenge. Many older textile harvesters contain components with potentially harmful materials such as lead-based solders, mercury switches, certain flame retardants, and hydraulic fluids with toxic additives. These substances require specialized handling during the recycling process, increasing costs and environmental risks.

The economic viability of recycling textile harvesters remains problematic. Current recycling infrastructure is primarily designed for consumer products rather than specialized industrial equipment. The relatively low volume of textile harvesters reaching end-of-life simultaneously in any given region creates insufficient economies of scale for dedicated recycling facilities. Additionally, the high labor costs associated with manual disassembly often exceed the value of recoverable materials.

Regulatory frameworks governing the disposal and recycling of textile harvesting equipment vary significantly across regions, creating compliance challenges for manufacturers and recyclers operating in global markets. While the European Union has implemented extended producer responsibility (EPR) schemes through directives like WEEE and RoHS, many regions lack specific regulations addressing industrial textile equipment.

Technical knowledge gaps further complicate recycling efforts. Limited documentation on material composition, particularly for older equipment, makes it difficult for recyclers to develop efficient processes. The rapid evolution of textile harvester technology, with increasing incorporation of sensors, control systems, and specialized materials, continuously changes the recycling challenge landscape.

Current industry practices predominantly favor downcycling rather than true recycling of textile harvesters. Metal components are typically shredded and recovered, but with significant quality degradation. Plastic components are frequently incinerated for energy recovery or disposed of in landfills due to contamination and sorting difficulties. Electronic components are often processed through general e-waste channels, resulting in suboptimal material recovery rates.

Existing End-of-Life Strategies for Textile Harvesting Equipment

01 Recyclable textile harvester components

Textile harvesters can be designed with recyclable components to reduce environmental impact. These designs incorporate materials that can be easily separated, processed, and reused at the end of their lifecycle. The recyclable components may include structural elements, collection mechanisms, and processing parts that are specifically engineered to be disassembled and reclaimed through established recycling channels.- Recyclable textile energy harvesting systems: Energy harvesting textiles can be designed with recyclability in mind, incorporating materials and components that can be easily separated and reprocessed at end-of-life. These systems typically use conductive fibers, piezoelectric elements, or other energy-generating materials integrated into fabric structures in ways that allow for disassembly. The recyclable design approaches focus on modular construction, compatible material selection, and connection methods that facilitate separation without compromising energy harvesting efficiency during use.

- Biodegradable materials for textile harvesters: Biodegradable materials are increasingly being incorporated into textile energy harvesters to improve their environmental profile. These materials include natural fibers, biopolymers, and eco-friendly conductive elements that can break down naturally at the end of their useful life. The biodegradable components are engineered to maintain necessary electrical and mechanical properties during use while offering a sustainable disposal option. This approach reduces environmental impact while still enabling effective energy harvesting functionality in textile applications.

- Modular design for component recovery: Modular design approaches for textile harvesters enable easier disassembly and component recovery at end-of-life. By creating systems with detachable energy harvesting elements, power management circuits, and storage components, valuable materials can be recovered and reused. These designs typically feature standardized connections, removable electronic modules, and strategic material placement that allows for selective recovery of high-value components while facilitating the recycling of the textile substrate separately.

- Automated recycling processes for e-textiles: Specialized automated recycling processes have been developed specifically for electronic textiles including energy harvesters. These systems can identify, sort, and separate the various components of textile harvesters using techniques such as optical recognition, mechanical separation, and chemical processing. The automated approaches enable efficient recovery of valuable materials like conductive metals, semiconductor components, and specialized polymers while minimizing manual labor and improving the economic viability of textile harvester recycling.

- Circular economy approaches for textile harvesters: Circular economy principles are being applied to textile harvester design and manufacturing to maximize resource efficiency and minimize waste. These approaches include designing for disassembly, using recycled materials in production, establishing take-back programs, and developing closed-loop manufacturing systems. By considering the entire lifecycle of textile harvesters from material sourcing through disposal, manufacturers can create more sustainable products that retain value through multiple use cycles and reduce environmental impact.

02 Biodegradable materials in textile harvesting systems

Incorporating biodegradable materials in textile harvesting equipment enhances environmental sustainability. These materials naturally decompose after their useful life, reducing landfill waste and environmental contamination. Biodegradable components can include collection bags, filters, and non-structural elements that maintain performance during operation but break down safely when disposed of, creating a more environmentally responsible harvesting solution.Expand Specific Solutions03 Energy harvesting integration with textile recycling

Advanced textile harvesters incorporate energy harvesting technologies that work in conjunction with recycling processes. These systems capture and convert mechanical energy from the harvesting operation into electrical power, which can then be used to power sorting mechanisms or preprocessing of recyclable materials. This integration creates a more sustainable closed-loop system where the harvesting process generates part of the energy needed for subsequent recycling operations.Expand Specific Solutions04 Modular design for improved recyclability

Modular design approaches in textile harvesters facilitate easier recycling by allowing components to be replaced, upgraded, or recycled individually. This design philosophy enables damaged parts to be replaced without discarding the entire system and simplifies end-of-life disassembly. Modular components are typically designed with compatible materials that can be efficiently sorted during recycling processes, extending the overall lifecycle of the harvesting equipment.Expand Specific Solutions05 Automated sorting systems for harvested textile recycling

Automated systems for sorting harvested textiles enhance the efficiency and effectiveness of recycling processes. These systems employ sensors, machine vision, and artificial intelligence to identify and categorize different types of textile materials based on composition, color, and condition. By accurately sorting materials at the harvesting stage, downstream recycling processes become more efficient, resulting in higher quality recycled materials and reduced processing costs.Expand Specific Solutions

Leading Manufacturers and Stakeholders in Sustainable Harvesting

The textile recycling and end-of-life management sector is currently in a growth phase, with an estimated market size of $5-7 billion globally and projected to reach $10 billion by 2027. Companies like Evrnu and Circ are pioneering chemical recycling technologies that can process blended textiles, while academic institutions such as Aalto University and Sichuan University are advancing fundamental research. The competitive landscape shows varying levels of technological maturity: established players like Deere & Co. focus on mechanical harvesting solutions, while specialized firms like Fibe and Neogenix develop innovative fiber recovery processes. Regional clusters are forming in North America, Europe, and Asia, with Chinese companies like Hubei Grerial and Zhejiang Yana Textile rapidly scaling up operations to meet increasing regulatory and consumer demands for sustainable textile solutions.

Evrnu, Inc.

Technical Solution: Evrnu has developed NuCycl™, a revolutionary technology that breaks down post-consumer textile waste at the molecular level and regenerates it into pristine new fiber. Their process can transform discarded cotton garments into high-performance materials that match or exceed the quality of virgin fibers. The technology employs a solvent-based dissolution process that separates cotton from contaminants and polyester, allowing for the recovery of both materials. Evrnu's system can process blended textiles, addressing a significant challenge in textile recycling. Their closed-loop system recaptures and reuses chemicals, minimizing environmental impact while producing fibers that can be recycled multiple times without quality degradation.

Strengths: Ability to process mixed fiber waste that traditional recycling cannot handle; produces high-quality fiber suitable for premium applications; closed-loop chemical system with minimal environmental impact. Weaknesses: Energy-intensive process; requires sophisticated sorting of input materials; higher cost compared to virgin material production.

Circ LLC

Technical Solution: Circ has pioneered a hydrothermal process called SelFrag that separates and recovers both polyester and cotton from blended textiles. Their technology uses targeted pressure and temperature conditions to break down textile waste into constituent polymers without degrading their quality. The process employs environmentally friendly solvents that can be recaptured and reused, creating a closed-loop system. Circ's innovation addresses the critical challenge of recycling poly-cotton blends, which constitute approximately 80% of textile waste. The recovered materials maintain their original quality, allowing them to be reintroduced into the textile supply chain for manufacturing new garments rather than being downcycled into lower-value applications. Circ has partnered with major fashion brands to implement their technology at commercial scale.

Strengths: Effectively separates polyester and natural fibers from blended textiles; maintains polymer quality for true circular recycling; scalable process with commercial partnerships already in place. Weaknesses: Requires significant water usage; energy-intensive separation process; depends on consistent waste stream quality.

Key Innovations in Recyclable Materials for Agricultural Machinery

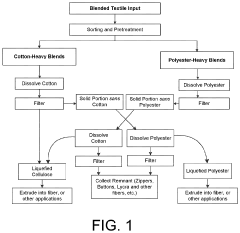

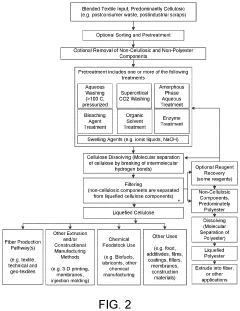

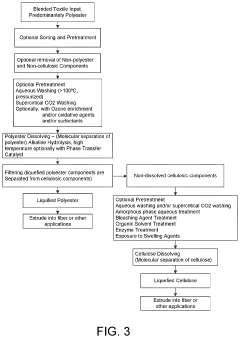

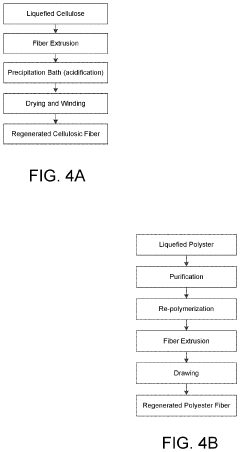

Methods and systems for processing mixed textile feedstock, isolating constituent molecules, and regenerating cellulosic and polyester fibers

PatentPendingUS20230124761A1

Innovation

- A multi-stage process involving pretreatment and pulping/dissolution stages to isolate cellulose and polyester polymers from mixed textile feedstocks, allowing for the production of regenerated fibers with improved properties, utilizing techniques such as high temperature aqueous washing, supercritical CO2 treatment, and enzymatic processes to minimize environmental impact.

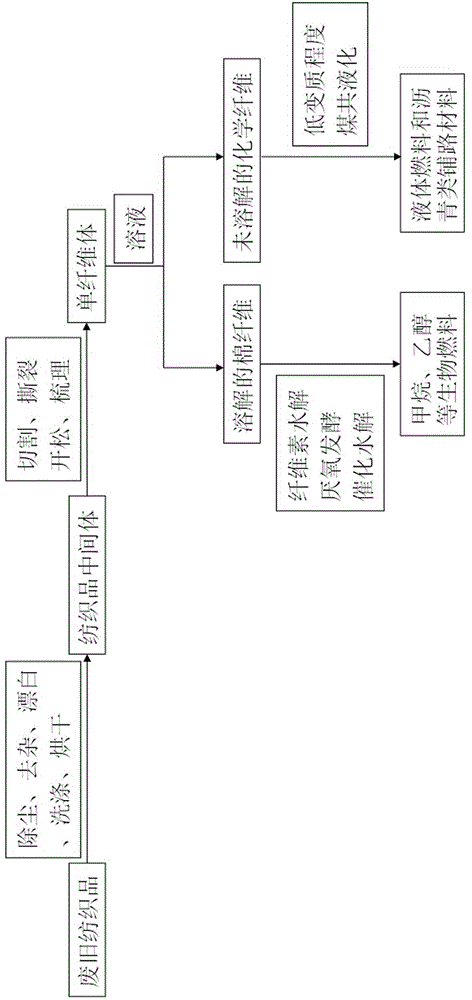

Method for producing fuel and road asphalt modifier by utilizing waste and old textiles

PatentActiveCN104531234A

Innovation

- Single fiber bodies are obtained by preprocessing waste textiles, which are converted into biofuels using alkaline solutions or biodegradation methods, and liquid fuels and road asphalt modifiers are produced through co-liquefaction to reduce dependence on petroleum and coal and reduce environmental pollution.

Environmental Impact Assessment of Textile Harvester Lifecycle

The lifecycle environmental impact of textile harvesters represents a critical dimension in evaluating their overall sustainability. Current assessment methodologies reveal that these specialized agricultural machines generate significant environmental footprints across their production, operation, maintenance, and disposal phases. Life Cycle Assessment (LCA) studies indicate that the manufacturing stage accounts for approximately 35-40% of total environmental impact, primarily due to resource-intensive metal fabrication and electronic component production.

During the operational phase, textile harvesters contribute to environmental degradation through fuel consumption, generating an estimated 15-20 tons of CO2 equivalent emissions annually per machine. This is compounded by soil compaction issues that can reduce agricultural land productivity by up to 15% in heavily trafficked areas, creating long-term ecosystem disruption that extends beyond the immediate harvest period.

Maintenance activities introduce additional environmental concerns through the consumption of lubricants, replacement parts, and cleaning agents. Research indicates that improper disposal of maintenance waste can lead to localized soil and water contamination, with hydraulic fluid leakage representing a particularly significant risk factor in agricultural settings.

The end-of-life phase presents perhaps the most complex environmental challenges. Current disposal practices for decommissioned textile harvesters result in only 60-65% of materials being effectively recycled, with the remainder typically directed to landfills. This represents a substantial loss of valuable materials including high-grade steel, aluminum, copper, and increasingly, electronic components containing rare earth elements.

Water consumption across the lifecycle presents another significant impact vector, with manufacturing processes requiring between 50,000-75,000 liters per machine. This water footprint is particularly concerning in water-stressed regions where manufacturing facilities are often located.

Emerging research suggests that implementing circular economy principles could reduce the overall environmental impact by 30-40% through design modifications that facilitate component reuse and material recovery. Several leading manufacturers have begun incorporating Design for Environment (DfE) principles, resulting in machines with improved disassembly characteristics and reduced toxic material content.

Comparative analyses between conventional and eco-designed textile harvesters demonstrate that environmentally optimized machines can achieve similar performance metrics while reducing lifecycle greenhouse gas emissions by 25-30% and resource depletion by up to 35%. These improvements primarily stem from material substitution, weight reduction strategies, and increased use of recycled content in non-critical components.

During the operational phase, textile harvesters contribute to environmental degradation through fuel consumption, generating an estimated 15-20 tons of CO2 equivalent emissions annually per machine. This is compounded by soil compaction issues that can reduce agricultural land productivity by up to 15% in heavily trafficked areas, creating long-term ecosystem disruption that extends beyond the immediate harvest period.

Maintenance activities introduce additional environmental concerns through the consumption of lubricants, replacement parts, and cleaning agents. Research indicates that improper disposal of maintenance waste can lead to localized soil and water contamination, with hydraulic fluid leakage representing a particularly significant risk factor in agricultural settings.

The end-of-life phase presents perhaps the most complex environmental challenges. Current disposal practices for decommissioned textile harvesters result in only 60-65% of materials being effectively recycled, with the remainder typically directed to landfills. This represents a substantial loss of valuable materials including high-grade steel, aluminum, copper, and increasingly, electronic components containing rare earth elements.

Water consumption across the lifecycle presents another significant impact vector, with manufacturing processes requiring between 50,000-75,000 liters per machine. This water footprint is particularly concerning in water-stressed regions where manufacturing facilities are often located.

Emerging research suggests that implementing circular economy principles could reduce the overall environmental impact by 30-40% through design modifications that facilitate component reuse and material recovery. Several leading manufacturers have begun incorporating Design for Environment (DfE) principles, resulting in machines with improved disassembly characteristics and reduced toxic material content.

Comparative analyses between conventional and eco-designed textile harvesters demonstrate that environmentally optimized machines can achieve similar performance metrics while reducing lifecycle greenhouse gas emissions by 25-30% and resource depletion by up to 35%. These improvements primarily stem from material substitution, weight reduction strategies, and increased use of recycled content in non-critical components.

Policy Framework for Agricultural Equipment Waste Management

The regulatory landscape governing agricultural equipment waste management varies significantly across regions, creating a complex environment for textile harvester end-of-life management. In the European Union, the Waste Electrical and Electronic Equipment (WEEE) Directive provides a comprehensive framework that increasingly encompasses agricultural machinery, requiring manufacturers to establish collection and recycling systems. This producer responsibility approach has proven effective in increasing recycling rates and reducing landfill disposal of complex equipment.

In contrast, the United States relies on a patchwork of state-level regulations, with only California and a few other states implementing mandatory recycling programs for agricultural equipment. The lack of federal standardization creates challenges for manufacturers operating across multiple states and may contribute to inconsistent recycling practices for textile harvesters.

Emerging economies present a different scenario, where informal recycling sectors often handle agricultural equipment disposal. Countries like India and Brazil are developing regulatory frameworks that balance environmental protection with economic realities, though enforcement remains challenging. China has recently strengthened its waste management policies, implementing extended producer responsibility systems that specifically address agricultural machinery.

Financial incentives play a crucial role in effective policy implementation. Tax benefits for equipment trade-ins, subsidies for recycling infrastructure, and penalties for improper disposal have demonstrated positive impacts in various jurisdictions. The EU's circular economy package includes financial mechanisms that have successfully increased the recovery of valuable materials from agricultural equipment by approximately 35% over the past decade.

Certification standards represent another important policy tool. The development of industry-specific standards for textile harvester recycling, such as those promoted by the International Organization for Standardization (ISO), provides clear guidelines for environmentally sound management practices. These standards facilitate international harmonization and create market incentives for responsible end-of-life management.

Looking forward, policy innovation is needed to address the unique challenges of textile harvesters, which contain a complex mix of materials including textiles, metals, electronics, and hydraulic systems. Policies that promote design for disassembly, material identification, and specialized recycling technologies will be essential for improving recyclability rates. Additionally, collaborative approaches involving manufacturers, farmers, recyclers, and policymakers show promise in creating holistic solutions that balance environmental, economic, and practical considerations.

In contrast, the United States relies on a patchwork of state-level regulations, with only California and a few other states implementing mandatory recycling programs for agricultural equipment. The lack of federal standardization creates challenges for manufacturers operating across multiple states and may contribute to inconsistent recycling practices for textile harvesters.

Emerging economies present a different scenario, where informal recycling sectors often handle agricultural equipment disposal. Countries like India and Brazil are developing regulatory frameworks that balance environmental protection with economic realities, though enforcement remains challenging. China has recently strengthened its waste management policies, implementing extended producer responsibility systems that specifically address agricultural machinery.

Financial incentives play a crucial role in effective policy implementation. Tax benefits for equipment trade-ins, subsidies for recycling infrastructure, and penalties for improper disposal have demonstrated positive impacts in various jurisdictions. The EU's circular economy package includes financial mechanisms that have successfully increased the recovery of valuable materials from agricultural equipment by approximately 35% over the past decade.

Certification standards represent another important policy tool. The development of industry-specific standards for textile harvester recycling, such as those promoted by the International Organization for Standardization (ISO), provides clear guidelines for environmentally sound management practices. These standards facilitate international harmonization and create market incentives for responsible end-of-life management.

Looking forward, policy innovation is needed to address the unique challenges of textile harvesters, which contain a complex mix of materials including textiles, metals, electronics, and hydraulic systems. Policies that promote design for disassembly, material identification, and specialized recycling technologies will be essential for improving recyclability rates. Additionally, collaborative approaches involving manufacturers, farmers, recyclers, and policymakers show promise in creating holistic solutions that balance environmental, economic, and practical considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!