Design Guidelines For Seamless Garment Integration Of Harvesters

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Energy Harvesting Textile Background and Objectives

Energy harvesting textiles represent a convergence of traditional textile manufacturing and advanced energy technologies, emerging as a promising solution for powering wearable electronics and smart garments. The evolution of this technology can be traced back to early experiments with piezoelectric materials in the late 1990s, which demonstrated the possibility of converting mechanical energy from human movement into electrical power. Over the past two decades, the field has expanded to include various harvesting mechanisms including triboelectric, thermoelectric, and photovoltaic approaches, each offering unique advantages for different application scenarios.

The technological trajectory has been significantly influenced by parallel advancements in flexible electronics, conductive materials, and miniaturization of power management systems. Early energy harvesting textiles were bulky, rigid, and produced minimal power output, limiting their practical applications. Recent innovations have focused on developing lightweight, flexible, and washable energy harvesting components that can be seamlessly integrated into everyday garments without compromising comfort or aesthetics.

Current research trends are moving toward multi-modal energy harvesting systems that can simultaneously capture energy from different sources, such as body heat, movement, and ambient light. This approach aims to maximize energy collection efficiency and provide more consistent power output under varying environmental conditions and user activities.

The primary technical objectives for seamless garment integration of harvesters include developing fabrication methods that are compatible with existing textile manufacturing processes, ensuring durability through multiple washing cycles, maintaining user comfort, and achieving sufficient power density to support modern wearable devices. Additionally, there is a growing emphasis on sustainability, with research focusing on biodegradable or recyclable harvesting materials that align with the increasing environmental consciousness in the textile industry.

Another critical objective is standardization of testing protocols and performance metrics for energy harvesting textiles. The lack of industry-wide standards has hindered comparative analysis and slowed commercial adoption. Establishing clear benchmarks for power output, durability, and safety would accelerate development and market acceptance.

Looking forward, the field aims to achieve true textile-based energy autonomy, where garments can generate sufficient power to eliminate the need for conventional batteries in wearable devices. This vision requires significant improvements in energy conversion efficiency, storage capabilities, and power management systems specifically designed for textile integration. The ultimate goal is to create "invisible technology" where energy harvesting components are indistinguishable from conventional textile elements in terms of look, feel, and wearability.

The technological trajectory has been significantly influenced by parallel advancements in flexible electronics, conductive materials, and miniaturization of power management systems. Early energy harvesting textiles were bulky, rigid, and produced minimal power output, limiting their practical applications. Recent innovations have focused on developing lightweight, flexible, and washable energy harvesting components that can be seamlessly integrated into everyday garments without compromising comfort or aesthetics.

Current research trends are moving toward multi-modal energy harvesting systems that can simultaneously capture energy from different sources, such as body heat, movement, and ambient light. This approach aims to maximize energy collection efficiency and provide more consistent power output under varying environmental conditions and user activities.

The primary technical objectives for seamless garment integration of harvesters include developing fabrication methods that are compatible with existing textile manufacturing processes, ensuring durability through multiple washing cycles, maintaining user comfort, and achieving sufficient power density to support modern wearable devices. Additionally, there is a growing emphasis on sustainability, with research focusing on biodegradable or recyclable harvesting materials that align with the increasing environmental consciousness in the textile industry.

Another critical objective is standardization of testing protocols and performance metrics for energy harvesting textiles. The lack of industry-wide standards has hindered comparative analysis and slowed commercial adoption. Establishing clear benchmarks for power output, durability, and safety would accelerate development and market acceptance.

Looking forward, the field aims to achieve true textile-based energy autonomy, where garments can generate sufficient power to eliminate the need for conventional batteries in wearable devices. This vision requires significant improvements in energy conversion efficiency, storage capabilities, and power management systems specifically designed for textile integration. The ultimate goal is to create "invisible technology" where energy harvesting components are indistinguishable from conventional textile elements in terms of look, feel, and wearability.

Market Analysis for Wearable Energy Harvesting Solutions

The wearable energy harvesting market is experiencing significant growth, driven by increasing demand for sustainable power solutions in smart textiles and wearable electronics. Current market valuation stands at approximately 400 million USD, with projections indicating growth to reach 2.1 billion USD by 2028, representing a compound annual growth rate of 22.7%. This expansion is primarily fueled by consumer electronics, healthcare monitoring devices, and fitness tracking applications.

Consumer preferences are shifting toward unobtrusive, comfortable, and aesthetically pleasing wearable technology. Market research indicates that 78% of potential users prioritize comfort and seamless integration when considering wearable technology adoption. This creates a clear demand signal for energy harvesters that can be integrated into garments without compromising wearability or style.

The healthcare sector represents the fastest-growing segment for wearable energy harvesting solutions, with particular emphasis on remote patient monitoring systems. These applications require reliable, long-duration power sources that can operate without frequent charging or battery replacement. Energy harvesting textiles address this need by providing continuous power generation during normal daily activities.

Regional analysis shows North America currently leads market share at 38%, followed by Europe at 31% and Asia-Pacific at 24%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to expanding manufacturing capabilities and increasing technology adoption in countries like China, South Korea, and Japan.

Key market segments for seamless garment-integrated harvesters include sports and fitness apparel (36% market share), medical/healthcare garments (29%), professional/industrial workwear (18%), and consumer fashion (17%). The sports segment benefits from active movement that maximizes energy generation potential, while medical applications value reliability and consistent power output.

Consumer willingness to pay premiums for self-powering garments varies by application, with healthcare users demonstrating the highest price tolerance (up to 40% premium over standard garments), followed by professional/industrial users (25-30% premium) and consumer/fitness markets (15-20% premium).

Market barriers include manufacturing scalability challenges, durability concerns in washing conditions, and price sensitivity in consumer markets. Additionally, standardization issues across the industry create interoperability challenges that limit broader adoption. These factors must be addressed in design guidelines to ensure commercial viability of seamlessly integrated energy harvesting garments.

Consumer preferences are shifting toward unobtrusive, comfortable, and aesthetically pleasing wearable technology. Market research indicates that 78% of potential users prioritize comfort and seamless integration when considering wearable technology adoption. This creates a clear demand signal for energy harvesters that can be integrated into garments without compromising wearability or style.

The healthcare sector represents the fastest-growing segment for wearable energy harvesting solutions, with particular emphasis on remote patient monitoring systems. These applications require reliable, long-duration power sources that can operate without frequent charging or battery replacement. Energy harvesting textiles address this need by providing continuous power generation during normal daily activities.

Regional analysis shows North America currently leads market share at 38%, followed by Europe at 31% and Asia-Pacific at 24%. However, the Asia-Pacific region is expected to demonstrate the highest growth rate over the next five years due to expanding manufacturing capabilities and increasing technology adoption in countries like China, South Korea, and Japan.

Key market segments for seamless garment-integrated harvesters include sports and fitness apparel (36% market share), medical/healthcare garments (29%), professional/industrial workwear (18%), and consumer fashion (17%). The sports segment benefits from active movement that maximizes energy generation potential, while medical applications value reliability and consistent power output.

Consumer willingness to pay premiums for self-powering garments varies by application, with healthcare users demonstrating the highest price tolerance (up to 40% premium over standard garments), followed by professional/industrial users (25-30% premium) and consumer/fitness markets (15-20% premium).

Market barriers include manufacturing scalability challenges, durability concerns in washing conditions, and price sensitivity in consumer markets. Additionally, standardization issues across the industry create interoperability challenges that limit broader adoption. These factors must be addressed in design guidelines to ensure commercial viability of seamlessly integrated energy harvesting garments.

Current Challenges in Garment-Integrated Energy Harvesting

Despite significant advancements in wearable energy harvesting technologies, integrating these systems seamlessly into garments presents numerous technical challenges. The fundamental issue lies in balancing the mechanical properties of rigid or semi-rigid harvesting components with the inherent flexibility, comfort, and aesthetic requirements of everyday clothing. Traditional energy harvesters, such as piezoelectric materials, triboelectric nanogenerators, and thermoelectric modules, typically possess physical characteristics that conflict with textile properties.

Material compatibility represents a primary obstacle, as most high-performance energy harvesting materials are not naturally compatible with textiles. These materials often cannot withstand standard garment care procedures like washing, drying, and ironing. The durability gap between electronic components (designed for stable environments) and textiles (designed to endure mechanical stress and moisture) creates significant integration challenges.

Electrical interconnection systems present another major hurdle. Conventional rigid circuit boards and wiring are unsuitable for garment integration, necessitating the development of flexible, stretchable, and washable conductive pathways. Current solutions like conductive threads, inks, and elastomeric conductors still face limitations in conductivity, durability, and manufacturing scalability.

Manufacturing processes for garment-integrated harvesters remain largely experimental and labor-intensive. The textile industry's high-throughput production methods are not readily compatible with precision electronics manufacturing techniques. This manufacturing disconnect leads to high costs and limited scalability, preventing widespread commercial adoption.

User comfort and ergonomics create additional design constraints. Energy harvesters must not restrict movement, add significant weight, or create pressure points that compromise wearability. The psychological aspect of user acceptance also requires consideration, as visible or perceptible technology may reduce adoption rates in everyday clothing applications.

Power management presents unique challenges in the garment context. Energy harvesting yields are typically low and intermittent, requiring specialized power conditioning circuits that can function under variable input conditions while maintaining appropriate form factors for garment integration. Additionally, energy storage components like batteries or supercapacitors must be flexible, lightweight, and safe for body-worn applications.

Regulatory and safety considerations further complicate development efforts. Electrical components in close proximity to the body must meet stringent safety standards regarding electromagnetic emissions, thermal management, and electrical isolation. These requirements often conflict with the need for minimal, lightweight designs that can be incorporated into garments.

Material compatibility represents a primary obstacle, as most high-performance energy harvesting materials are not naturally compatible with textiles. These materials often cannot withstand standard garment care procedures like washing, drying, and ironing. The durability gap between electronic components (designed for stable environments) and textiles (designed to endure mechanical stress and moisture) creates significant integration challenges.

Electrical interconnection systems present another major hurdle. Conventional rigid circuit boards and wiring are unsuitable for garment integration, necessitating the development of flexible, stretchable, and washable conductive pathways. Current solutions like conductive threads, inks, and elastomeric conductors still face limitations in conductivity, durability, and manufacturing scalability.

Manufacturing processes for garment-integrated harvesters remain largely experimental and labor-intensive. The textile industry's high-throughput production methods are not readily compatible with precision electronics manufacturing techniques. This manufacturing disconnect leads to high costs and limited scalability, preventing widespread commercial adoption.

User comfort and ergonomics create additional design constraints. Energy harvesters must not restrict movement, add significant weight, or create pressure points that compromise wearability. The psychological aspect of user acceptance also requires consideration, as visible or perceptible technology may reduce adoption rates in everyday clothing applications.

Power management presents unique challenges in the garment context. Energy harvesting yields are typically low and intermittent, requiring specialized power conditioning circuits that can function under variable input conditions while maintaining appropriate form factors for garment integration. Additionally, energy storage components like batteries or supercapacitors must be flexible, lightweight, and safe for body-worn applications.

Regulatory and safety considerations further complicate development efforts. Electrical components in close proximity to the body must meet stringent safety standards regarding electromagnetic emissions, thermal management, and electrical isolation. These requirements often conflict with the need for minimal, lightweight designs that can be incorporated into garments.

Existing Integration Methods for Textile Energy Harvesters

01 Wearable energy harvesting systems

Energy harvesting technologies can be seamlessly integrated into wearable devices to generate power from body movements, heat, or ambient energy. These systems typically use piezoelectric, thermoelectric, or triboelectric mechanisms to convert various forms of energy into electrical power. The integration is designed to be unobtrusive, comfortable, and aesthetically pleasing while providing sufficient power for low-energy electronics and sensors in clothing, accessories, or directly on the body.- Wearable energy harvesting systems: Wearable energy harvesting systems integrate seamlessly into clothing or accessories to generate power from human movement or body heat. These systems utilize flexible materials and miniaturized components to maintain comfort while providing energy for portable electronics. The harvested energy can power health monitoring devices, smart textiles, or communication systems without requiring external charging sources, making them ideal for continuous use in daily activities.

- Structural integration of energy harvesters: Energy harvesting technologies can be seamlessly integrated into structural elements such as building materials, vehicle components, or infrastructure. These integrated systems capture ambient energy from vibrations, temperature differentials, or mechanical stress without compromising the structural integrity or aesthetic appearance. The design approach focuses on dual-functionality where the structural element serves its primary purpose while simultaneously generating electricity for low-power applications.

- Piezoelectric energy harvesting integration: Piezoelectric materials convert mechanical stress into electrical energy and can be seamlessly integrated into various applications. These materials are incorporated into floors, roadways, or moving parts to capture energy from pressure, vibration, or movement. The integration techniques focus on maximizing energy conversion efficiency while maintaining durability and functionality of the host system, enabling self-powered sensors and IoT devices in environments where battery replacement is challenging.

- Solar energy harvester integration: Solar energy harvesting technologies are designed for seamless integration into everyday objects, buildings, and vehicles. These systems utilize flexible, transparent, or aesthetically designed photovoltaic materials that can be incorporated into windows, facades, electronic device casings, or textiles. The integration approaches focus on maintaining the original functionality and appearance of the host object while adding energy generation capabilities, enabling energy autonomy for various applications.

- Energy management systems for integrated harvesters: Energy management systems are crucial for optimizing the performance of seamlessly integrated energy harvesters. These systems include power conditioning circuits, energy storage solutions, and intelligent control algorithms that efficiently collect, store, and distribute harvested energy. The management systems are designed to handle variable energy inputs from multiple harvesting sources, maximize energy utilization efficiency, and provide stable power output for connected devices despite fluctuations in environmental conditions.

02 Architectural and structural integration of energy harvesters

Energy harvesting technologies can be seamlessly incorporated into building materials, structural elements, and architectural features. These integrated systems can harvest energy from various sources including solar, wind, vibration, and thermal gradients without compromising the structural integrity or aesthetic appeal of buildings. The harvested energy can power building systems, sensors, or be fed back to the grid, contributing to energy-efficient and sustainable building designs.Expand Specific Solutions03 Vehicle-integrated energy harvesting solutions

Energy harvesters can be seamlessly integrated into various vehicle components to capture energy from vibrations, heat, solar radiation, and other sources during operation. These systems are designed to work with existing vehicle architectures without affecting performance or aesthetics. The harvested energy can supplement the vehicle's power system, reduce fuel consumption, power auxiliary systems, or charge batteries in electric vehicles, enhancing overall energy efficiency.Expand Specific Solutions04 Miniaturized and flexible energy harvesting technologies

Advanced miniaturization and flexible materials enable the seamless integration of energy harvesters into small devices or irregular surfaces. These technologies include thin-film solar cells, flexible piezoelectric materials, and microscale thermoelectric generators that can conform to various shapes and sizes. The flexibility and small form factor allow for integration into electronic devices, textiles, and IoT sensors without adding bulk or affecting functionality.Expand Specific Solutions05 Energy management systems for integrated harvesters

Sophisticated energy management systems are essential for the effective operation of seamlessly integrated energy harvesters. These systems include power conditioning circuits, energy storage solutions, and intelligent control algorithms that optimize energy capture, storage, and distribution. They ensure stable power output despite fluctuating energy sources, manage the flow between multiple harvesting technologies, and provide efficient power delivery to the connected devices or systems.Expand Specific Solutions

Leading Companies in Smart Textile Energy Harvesting

The market for seamless garment integration of harvesters is in an early growth stage, characterized by increasing innovation but limited commercial deployment. The global market size is expanding as wearable technology gains traction across industries, with projections indicating significant growth potential in the next decade. Technologically, the field remains in development with varying maturity levels among key players. Companies like Deere & Co. and CNH Industrial are leveraging their agricultural expertise to develop integrated harvesting solutions, while textile specialists such as Atsugi Co. and Utax Co. are focusing on garment integration aspects. Academic institutions like Georgia Tech Research Corp. and Zhejiang Sci-Tech University are contributing fundamental research, creating a diverse competitive landscape that spans traditional agricultural machinery manufacturers, textile companies, and technology innovators.

Atsugi Co., Ltd.

Technical Solution: Atsugi Co., Ltd., a leading Japanese textile manufacturer, has developed proprietary technology for integrating thermoelectric energy harvesters into everyday garments. Their approach focuses on utilizing body heat differentials to generate small but consistent amounts of electrical energy. Atsugi's design guidelines emphasize maintaining the garment's original comfort, stretch, and breathability while incorporating rigid thermoelectric components. Their innovation lies in creating specialized "thermal pockets" within the fabric structure that optimize heat flow while isolating the wearer from any discomfort. The company has developed specialized manufacturing techniques that allow for mass production of these enhanced textiles using modified versions of standard knitting and finishing equipment. Their guidelines address critical factors such as harvester placement optimization based on body heat mapping, washability considerations, and connection systems that withstand repeated stretching and folding. Atsugi has successfully demonstrated prototypes that can power small sensors and simple displays integrated into the garment.

Strengths: Strong manufacturing capabilities for scaling production; practical approach to maintaining garment comfort; established textile industry expertise. Weaknesses: Limited to thermoelectric harvesting methods; may generate lower power outputs compared to other harvesting technologies.

Airbus Operations SAS

Technical Solution: Airbus Operations SAS has developed advanced energy harvesting textiles primarily for aerospace applications that have significant crossover potential for consumer garments. Their technology focuses on multifunctional fabrics that combine energy harvesting with structural monitoring capabilities. Airbus has created comprehensive design guidelines for integrating piezoelectric and thermoelectric harvesters into technical textiles while maintaining flexibility and durability under extreme conditions. Their approach emphasizes modular design that allows for customization based on specific power requirements and environmental conditions. The company has pioneered specialized connection systems that maintain electrical continuity despite repeated flexing and environmental stresses. Their guidelines address critical factors such as electromagnetic compatibility, safety certification requirements, and long-term reliability testing protocols. Airbus's textile energy harvesting systems have been tested in aviation environments and demonstrate potential for adaptation to consumer wearables where reliability and performance are paramount.

Strengths: Exceptional engineering capabilities and testing resources; experience with high-reliability systems; advanced materials science expertise. Weaknesses: Primary focus on aerospace applications may limit optimization for everyday consumer garments; solutions may be over-engineered and costly for consumer applications.

Key Technical Innovations in Seamless Harvester Integration

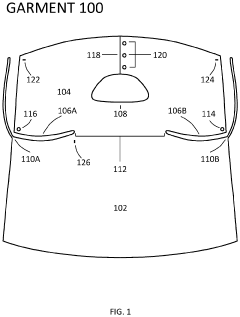

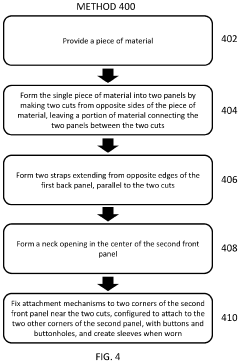

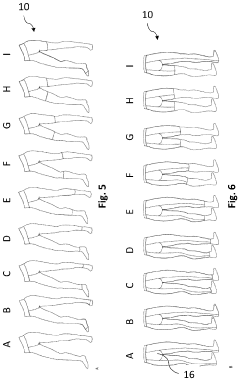

Uniwrap garment from a single seamless piece of material

PatentActiveUS10986882B2

Innovation

- A seamless garment constructed from a single piece of material, divided into two panels by cuts, with attachment mechanisms like buttons, snaps, or ties to secure it to the body, reducing complexity and production time.

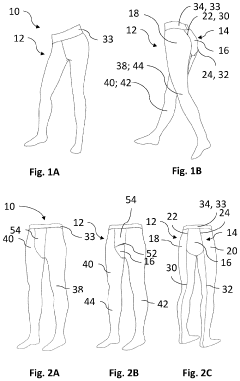

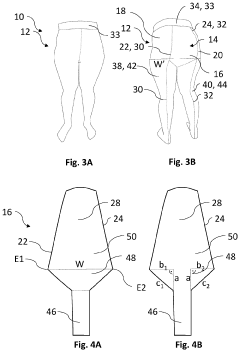

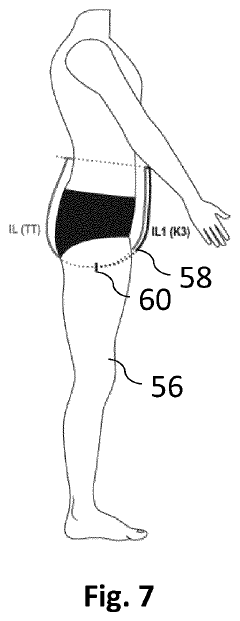

Compression garment

PatentPendingUS20240225909A1

Innovation

- A compression garment with a seamless insert covering part of both buttocks, made from knitted fabric that is adapted to the wearer's shape, eliminating seams in the intergluteal cleft area and using a combination of hydrophobic and hydrophilic yarns for enhanced comfort and compression.

Comfort and Durability Considerations for Wearable Harvesters

The integration of energy harvesting technologies into garments presents unique challenges related to user comfort and product durability. When designing wearable harvesters, the tactile experience must be prioritized to ensure user acceptance and long-term adoption. Materials that directly contact the skin should possess appropriate softness, flexibility, and breathability to prevent irritation during extended wear periods. The weight distribution of harvesting components requires careful consideration to avoid creating pressure points or restricting natural movement patterns.

Temperature regulation emerges as a critical factor in wearable comfort. Many energy harvesting technologies generate heat during operation, which must be effectively managed to prevent user discomfort, particularly in warm environments or during physical activity. Implementing thermal management solutions such as heat-dissipating materials or strategic component placement can mitigate these concerns without compromising harvesting efficiency.

Durability considerations extend beyond the harvesting technology itself to encompass the entire garment system. Repeated mechanical stress from body movement, washing cycles, and environmental exposure significantly impacts longevity. Harvesting components must withstand thousands of flexing cycles without performance degradation, particularly for technologies integrated into high-movement areas such as joints or muscle groups.

Moisture resistance represents another crucial durability factor. Perspiration, environmental humidity, and washing processes all introduce moisture challenges that can compromise electronic components. Effective encapsulation techniques using waterproof yet breathable materials can protect sensitive elements while maintaining comfort. The interface between rigid harvesting components and flexible textile substrates requires particular attention to prevent delamination or connection failures over time.

Maintenance requirements significantly influence user acceptance of wearable harvesters. Designs should accommodate standard cleaning methods without requiring specialized care procedures. Detachable harvesting modules offer one solution, allowing separate maintenance of electronic and textile components. Alternatively, fully integrated systems must incorporate washing-resistant encapsulation and connection technologies.

Long-term performance stability under various environmental conditions determines commercial viability. Temperature fluctuations, UV exposure, and chemical interactions with body oils or cleaning agents can accelerate material degradation. Accelerated aging tests simulating these conditions should inform material selection and protective strategies. The psychological comfort dimension should not be overlooked, as bulky or visibly technical components may reduce user acceptance despite adequate physical comfort.

Temperature regulation emerges as a critical factor in wearable comfort. Many energy harvesting technologies generate heat during operation, which must be effectively managed to prevent user discomfort, particularly in warm environments or during physical activity. Implementing thermal management solutions such as heat-dissipating materials or strategic component placement can mitigate these concerns without compromising harvesting efficiency.

Durability considerations extend beyond the harvesting technology itself to encompass the entire garment system. Repeated mechanical stress from body movement, washing cycles, and environmental exposure significantly impacts longevity. Harvesting components must withstand thousands of flexing cycles without performance degradation, particularly for technologies integrated into high-movement areas such as joints or muscle groups.

Moisture resistance represents another crucial durability factor. Perspiration, environmental humidity, and washing processes all introduce moisture challenges that can compromise electronic components. Effective encapsulation techniques using waterproof yet breathable materials can protect sensitive elements while maintaining comfort. The interface between rigid harvesting components and flexible textile substrates requires particular attention to prevent delamination or connection failures over time.

Maintenance requirements significantly influence user acceptance of wearable harvesters. Designs should accommodate standard cleaning methods without requiring specialized care procedures. Detachable harvesting modules offer one solution, allowing separate maintenance of electronic and textile components. Alternatively, fully integrated systems must incorporate washing-resistant encapsulation and connection technologies.

Long-term performance stability under various environmental conditions determines commercial viability. Temperature fluctuations, UV exposure, and chemical interactions with body oils or cleaning agents can accelerate material degradation. Accelerated aging tests simulating these conditions should inform material selection and protective strategies. The psychological comfort dimension should not be overlooked, as bulky or visibly technical components may reduce user acceptance despite adequate physical comfort.

Manufacturing Scalability of Integrated Energy Textiles

The scalability of manufacturing processes represents a critical factor in the commercial viability of integrated energy harvesting textiles. Current production methods for energy harvesting garments largely remain confined to laboratory settings or small-batch manufacturing, creating significant barriers to widespread adoption. The transition from prototype to mass production requires substantial process optimization to maintain consistent performance while reducing unit costs.

Traditional textile manufacturing infrastructure presents both opportunities and challenges for energy harvester integration. Existing textile production lines can potentially be modified to accommodate energy harvesting components, but such modifications require careful engineering to prevent damage to sensitive electronic elements. The integration must occur at precise stages of the manufacturing process to ensure proper functionality without compromising the textile's comfort or durability.

Material compatibility issues further complicate manufacturing scalability. Energy harvesting components often utilize materials with different physical properties than traditional textiles, creating challenges in thermal processing, adhesion, and mechanical stress distribution during manufacturing. These disparities necessitate the development of specialized equipment and processes that can handle both textile substrates and electronic components simultaneously.

Quality control represents another significant challenge in scaling production. Unlike conventional textiles where visual inspection may suffice, energy harvesting garments require functional testing of electrical properties throughout the manufacturing process. This necessitates the implementation of automated testing systems capable of rapidly assessing harvester performance without disrupting production flow.

Supply chain considerations also impact scalability. The production of integrated energy textiles requires coordination between traditional textile suppliers and electronics manufacturers, two industries with different quality standards, lead times, and production methodologies. Establishing reliable supply chains for specialized components such as conductive yarns, flexible substrates, and encapsulation materials remains challenging at scale.

Recent advancements in roll-to-roll processing techniques show promise for overcoming these scalability challenges. These continuous manufacturing methods allow for the deposition of functional materials onto textile substrates at speeds compatible with textile production. Several research institutions have demonstrated pilot-scale production using these techniques, achieving throughput rates of 5-10 meters per minute while maintaining acceptable energy harvesting performance.

Cost modeling indicates that economies of scale could reduce the production cost of energy harvesting textiles by 60-70% when moving from pilot production to full industrial scale, potentially bringing these products within competitive range of conventional textiles for specialized applications.

Traditional textile manufacturing infrastructure presents both opportunities and challenges for energy harvester integration. Existing textile production lines can potentially be modified to accommodate energy harvesting components, but such modifications require careful engineering to prevent damage to sensitive electronic elements. The integration must occur at precise stages of the manufacturing process to ensure proper functionality without compromising the textile's comfort or durability.

Material compatibility issues further complicate manufacturing scalability. Energy harvesting components often utilize materials with different physical properties than traditional textiles, creating challenges in thermal processing, adhesion, and mechanical stress distribution during manufacturing. These disparities necessitate the development of specialized equipment and processes that can handle both textile substrates and electronic components simultaneously.

Quality control represents another significant challenge in scaling production. Unlike conventional textiles where visual inspection may suffice, energy harvesting garments require functional testing of electrical properties throughout the manufacturing process. This necessitates the implementation of automated testing systems capable of rapidly assessing harvester performance without disrupting production flow.

Supply chain considerations also impact scalability. The production of integrated energy textiles requires coordination between traditional textile suppliers and electronics manufacturers, two industries with different quality standards, lead times, and production methodologies. Establishing reliable supply chains for specialized components such as conductive yarns, flexible substrates, and encapsulation materials remains challenging at scale.

Recent advancements in roll-to-roll processing techniques show promise for overcoming these scalability challenges. These continuous manufacturing methods allow for the deposition of functional materials onto textile substrates at speeds compatible with textile production. Several research institutions have demonstrated pilot-scale production using these techniques, achieving throughput rates of 5-10 meters per minute while maintaining acceptable energy harvesting performance.

Cost modeling indicates that economies of scale could reduce the production cost of energy harvesting textiles by 60-70% when moving from pilot production to full industrial scale, potentially bringing these products within competitive range of conventional textiles for specialized applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!