Mechanical Fatigue Resistance For Textile Energy Harvesters

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Textile Energy Harvesting Background and Objectives

Textile energy harvesting represents a convergent field between textile engineering and energy technology, focusing on the development of flexible, wearable devices capable of converting mechanical energy from human movement or environmental sources into electrical power. The evolution of this technology can be traced back to the early 2000s, when researchers began exploring piezoelectric and triboelectric effects in flexible materials. Over the past decade, significant advancements have been made in material science, manufacturing techniques, and device integration, propelling textile energy harvesters from laboratory curiosities to practical applications.

The technological trajectory shows a clear progression from rigid components attached to fabrics toward truly integrated systems where the energy harvesting functionality is inherent to the textile structure itself. This evolution aligns with broader trends in wearable technology, sustainable energy generation, and the Internet of Things (IoT), where distributed power sources are increasingly valuable for autonomous operation of electronic devices.

Current research objectives in textile energy harvesting focus primarily on enhancing energy conversion efficiency, improving durability under real-world conditions, and developing scalable manufacturing processes. Among these objectives, mechanical fatigue resistance emerges as a critical challenge, as textile-based harvesters must withstand thousands of deformation cycles during normal use while maintaining consistent performance.

The mechanical fatigue resistance of textile energy harvesters is particularly important because these devices operate precisely through mechanical deformation—the very mechanism that generates electricity also subjects the materials to repeated stress. This creates an inherent tension between performance and longevity that must be resolved for commercial viability.

Looking forward, the field aims to develop textile energy harvesters capable of withstanding at least 10,000 deformation cycles without significant performance degradation, while maintaining comfort, washability, and aesthetic qualities expected of conventional textiles. This represents a substantial engineering challenge requiring innovations in materials, structural design, and protective strategies.

The ultimate goal is to enable self-powered electronic textiles that can support applications ranging from health monitoring and personal electronics to military equipment and smart home furnishings. Success in addressing mechanical fatigue resistance will be a defining factor in whether textile energy harvesting technology can transition from promising research to widespread commercial adoption across these diverse application domains.

The technological trajectory shows a clear progression from rigid components attached to fabrics toward truly integrated systems where the energy harvesting functionality is inherent to the textile structure itself. This evolution aligns with broader trends in wearable technology, sustainable energy generation, and the Internet of Things (IoT), where distributed power sources are increasingly valuable for autonomous operation of electronic devices.

Current research objectives in textile energy harvesting focus primarily on enhancing energy conversion efficiency, improving durability under real-world conditions, and developing scalable manufacturing processes. Among these objectives, mechanical fatigue resistance emerges as a critical challenge, as textile-based harvesters must withstand thousands of deformation cycles during normal use while maintaining consistent performance.

The mechanical fatigue resistance of textile energy harvesters is particularly important because these devices operate precisely through mechanical deformation—the very mechanism that generates electricity also subjects the materials to repeated stress. This creates an inherent tension between performance and longevity that must be resolved for commercial viability.

Looking forward, the field aims to develop textile energy harvesters capable of withstanding at least 10,000 deformation cycles without significant performance degradation, while maintaining comfort, washability, and aesthetic qualities expected of conventional textiles. This represents a substantial engineering challenge requiring innovations in materials, structural design, and protective strategies.

The ultimate goal is to enable self-powered electronic textiles that can support applications ranging from health monitoring and personal electronics to military equipment and smart home furnishings. Success in addressing mechanical fatigue resistance will be a defining factor in whether textile energy harvesting technology can transition from promising research to widespread commercial adoption across these diverse application domains.

Market Analysis for Wearable Energy Harvesting Solutions

The wearable energy harvesting market is experiencing significant growth, driven by the increasing adoption of smart wearable devices and the growing demand for sustainable power solutions. The global market for wearable energy harvesting was valued at approximately $400 million in 2022 and is projected to reach $1.2 billion by 2028, representing a compound annual growth rate of 20.1%. This growth trajectory is supported by the expanding Internet of Things (IoT) ecosystem and the proliferation of connected devices requiring continuous power.

Textile-based energy harvesters represent a particularly promising segment within this market, offering unique advantages in terms of flexibility, comfort, and integration capabilities. Consumer demand for these solutions is primarily driven by applications in healthcare monitoring, fitness tracking, and smart clothing, where traditional rigid power sources present limitations in terms of user comfort and design flexibility.

Market research indicates that healthcare applications currently dominate the wearable energy harvesting market, accounting for approximately 35% of total revenue. This is followed by consumer electronics (28%), sports and fitness (22%), and industrial applications (15%). The healthcare segment's prominence is attributed to the critical need for reliable, long-duration power sources for medical monitoring devices and the growing trend toward remote patient monitoring systems.

Regional analysis reveals that North America currently leads the market with a 38% share, followed by Europe (30%), Asia-Pacific (25%), and the rest of the world (7%). However, the Asia-Pacific region is expected to witness the fastest growth rate over the next five years due to increasing manufacturing capabilities, growing consumer electronics markets, and substantial investments in wearable technology research.

Key market drivers include the miniaturization of electronic components, advancements in flexible and stretchable electronics, increasing energy efficiency of sensors, and growing consumer awareness about sustainable technology solutions. The demand for mechanical fatigue-resistant textile energy harvesters is particularly strong, as durability remains a critical factor influencing consumer adoption and commercial viability.

Market challenges include price sensitivity among consumers, competition from traditional power sources, technical limitations in energy conversion efficiency, and concerns regarding long-term reliability. The average consumer expects wearable devices to function reliably for at least 2-3 years, making mechanical fatigue resistance a crucial market differentiator for textile-based energy harvesting solutions.

Industry forecasts suggest that textile energy harvesters with enhanced mechanical durability could capture a premium segment of the market, potentially commanding 15-20% higher prices compared to standard solutions, highlighting the significant commercial value of innovations in fatigue resistance technology.

Textile-based energy harvesters represent a particularly promising segment within this market, offering unique advantages in terms of flexibility, comfort, and integration capabilities. Consumer demand for these solutions is primarily driven by applications in healthcare monitoring, fitness tracking, and smart clothing, where traditional rigid power sources present limitations in terms of user comfort and design flexibility.

Market research indicates that healthcare applications currently dominate the wearable energy harvesting market, accounting for approximately 35% of total revenue. This is followed by consumer electronics (28%), sports and fitness (22%), and industrial applications (15%). The healthcare segment's prominence is attributed to the critical need for reliable, long-duration power sources for medical monitoring devices and the growing trend toward remote patient monitoring systems.

Regional analysis reveals that North America currently leads the market with a 38% share, followed by Europe (30%), Asia-Pacific (25%), and the rest of the world (7%). However, the Asia-Pacific region is expected to witness the fastest growth rate over the next five years due to increasing manufacturing capabilities, growing consumer electronics markets, and substantial investments in wearable technology research.

Key market drivers include the miniaturization of electronic components, advancements in flexible and stretchable electronics, increasing energy efficiency of sensors, and growing consumer awareness about sustainable technology solutions. The demand for mechanical fatigue-resistant textile energy harvesters is particularly strong, as durability remains a critical factor influencing consumer adoption and commercial viability.

Market challenges include price sensitivity among consumers, competition from traditional power sources, technical limitations in energy conversion efficiency, and concerns regarding long-term reliability. The average consumer expects wearable devices to function reliably for at least 2-3 years, making mechanical fatigue resistance a crucial market differentiator for textile-based energy harvesting solutions.

Industry forecasts suggest that textile energy harvesters with enhanced mechanical durability could capture a premium segment of the market, potentially commanding 15-20% higher prices compared to standard solutions, highlighting the significant commercial value of innovations in fatigue resistance technology.

Current Challenges in Mechanical Durability of Textile Harvesters

Textile energy harvesters face significant mechanical durability challenges that currently limit their widespread adoption in wearable technology applications. The integration of rigid electronic components with flexible textile substrates creates inherent structural incompatibilities that lead to premature mechanical failure during normal wear and use. These failures typically manifest as delamination at material interfaces, conductor fractures, and degradation of active harvesting materials when subjected to repeated mechanical stresses.

Washing and daily usage represent particularly harsh conditions for textile harvesters. Current devices show substantial performance degradation after just 5-10 washing cycles, with efficiency losses often exceeding 40%. This falls far short of consumer expectations for textile products, which typically demand durability through 50+ washing cycles without significant performance loss.

Repeated deformation cycles present another critical challenge. Most textile harvesters experience performance degradation of 15-30% after just 1,000 bending or stretching cycles, whereas practical applications require stability through at least 10,000 cycles to match the lifespan of conventional garments. This mechanical fatigue primarily affects the conductive pathways and active material interfaces within the harvester structure.

Environmental factors further compound these durability issues. Exposure to sweat, varying humidity levels, and temperature fluctuations accelerates material degradation through chemical interactions and thermal expansion mismatches between different harvester components. Current encapsulation methods provide insufficient protection without compromising the flexibility and breathability essential for textile applications.

The miniaturization requirements for wearable applications introduce additional challenges. As harvester components become smaller, their susceptibility to mechanical damage increases due to higher localized stress concentrations. This creates a fundamental design tension between achieving sufficient energy output and maintaining mechanical robustness.

Manufacturing scalability presents yet another obstacle. Current laboratory fabrication methods for durable textile harvesters often involve complex, multi-step processes that are difficult to translate to industrial-scale production. Techniques like specialized coating methods, precise material deposition, and controlled curing conditions that enhance durability in lab settings prove challenging to implement consistently in mass production environments.

Testing methodologies for mechanical durability also remain unstandardized across the field, making it difficult to compare solutions and establish reliable benchmarks. The lack of accelerated testing protocols specifically designed for textile energy harvesters further complicates the development and validation of more durable designs, as researchers must often develop custom testing approaches that may not accurately predict real-world performance.

Washing and daily usage represent particularly harsh conditions for textile harvesters. Current devices show substantial performance degradation after just 5-10 washing cycles, with efficiency losses often exceeding 40%. This falls far short of consumer expectations for textile products, which typically demand durability through 50+ washing cycles without significant performance loss.

Repeated deformation cycles present another critical challenge. Most textile harvesters experience performance degradation of 15-30% after just 1,000 bending or stretching cycles, whereas practical applications require stability through at least 10,000 cycles to match the lifespan of conventional garments. This mechanical fatigue primarily affects the conductive pathways and active material interfaces within the harvester structure.

Environmental factors further compound these durability issues. Exposure to sweat, varying humidity levels, and temperature fluctuations accelerates material degradation through chemical interactions and thermal expansion mismatches between different harvester components. Current encapsulation methods provide insufficient protection without compromising the flexibility and breathability essential for textile applications.

The miniaturization requirements for wearable applications introduce additional challenges. As harvester components become smaller, their susceptibility to mechanical damage increases due to higher localized stress concentrations. This creates a fundamental design tension between achieving sufficient energy output and maintaining mechanical robustness.

Manufacturing scalability presents yet another obstacle. Current laboratory fabrication methods for durable textile harvesters often involve complex, multi-step processes that are difficult to translate to industrial-scale production. Techniques like specialized coating methods, precise material deposition, and controlled curing conditions that enhance durability in lab settings prove challenging to implement consistently in mass production environments.

Testing methodologies for mechanical durability also remain unstandardized across the field, making it difficult to compare solutions and establish reliable benchmarks. The lack of accelerated testing protocols specifically designed for textile energy harvesters further complicates the development and validation of more durable designs, as researchers must often develop custom testing approaches that may not accurately predict real-world performance.

Existing Mechanical Fatigue Resistance Solutions for Textile Harvesters

01 Flexible piezoelectric fiber-based energy harvesters

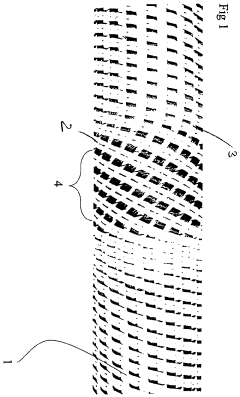

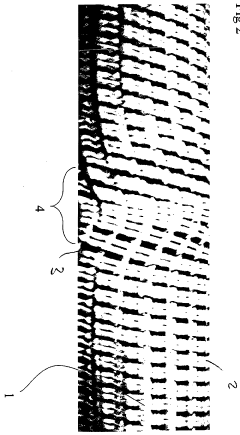

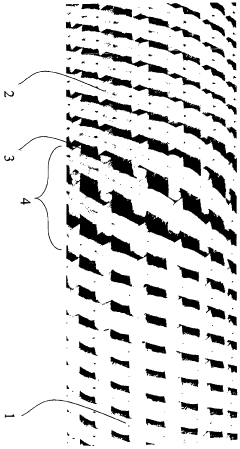

Piezoelectric fibers can be integrated into textiles to create energy harvesters with enhanced mechanical fatigue resistance. These fibers convert mechanical strain from body movement into electrical energy. The flexibility of the fibers allows them to withstand repeated bending and stretching without degradation in performance. Special fiber structures and materials are designed to maintain piezoelectric properties even after thousands of deformation cycles, making them suitable for wearable applications.- Piezoelectric fiber-based energy harvesters with enhanced durability: Piezoelectric fibers can be integrated into textiles to create energy harvesters that convert mechanical movement into electrical energy. These harvesters are designed with special structural features to enhance mechanical fatigue resistance, including flexible substrates, reinforced fiber connections, and protective coatings. The piezoelectric materials are often embedded in polymer matrices that absorb mechanical stress and prevent fiber breakage during repeated deformation cycles, significantly extending the operational lifespan of the textile energy harvester.

- Triboelectric textile generators with fatigue-resistant structures: Triboelectric textile generators utilize the friction between different materials to generate electricity from mechanical movement. To improve mechanical fatigue resistance, these textiles incorporate specialized structural designs such as layered architectures, elastic interconnections, and strain-distributing patterns. Some designs feature self-healing materials or redundant connection pathways that maintain functionality even after partial damage, ensuring consistent energy harvesting performance over thousands of deformation cycles in wearable applications.

- Composite materials for durable textile energy harvesters: Advanced composite materials combine flexible polymers with conductive or piezoelectric elements to create textile energy harvesters with superior mechanical fatigue resistance. These composites often feature nanostructured materials like carbon nanotubes, silver nanowires, or graphene that provide both electrical conductivity and mechanical reinforcement. The strategic distribution of these materials within the textile structure helps dissipate mechanical stress during repeated deformation, preventing crack propagation and extending the operational lifetime of the energy harvesting system.

- Structural design innovations for fatigue-resistant textile harvesters: Innovative structural designs can significantly improve the mechanical fatigue resistance of textile energy harvesters. These include serpentine patterns, helical structures, and origami-inspired folding architectures that accommodate repeated stretching and bending without material failure. Some designs incorporate mechanical strain isolation zones that protect sensitive electronic components from excessive deformation. These structural innovations enable textile energy harvesters to withstand thousands of washing cycles, stretching operations, and daily wear while maintaining consistent energy generation performance.

- Integration methods for fatigue-resistant connections in textile harvesters: The integration of electronic components and conductive pathways into textiles presents significant challenges for mechanical durability. Advanced connection methods such as conductive adhesives, ultrasonic welding, and encapsulation techniques help create fatigue-resistant interfaces between rigid electronic components and flexible textiles. Some approaches utilize gradient structures that gradually transition from soft to hard materials, distributing mechanical stress and preventing concentration points that could lead to failure. These integration methods are crucial for creating textile energy harvesters that can withstand the mechanical stresses of everyday use.

02 Triboelectric textile-based generators with reinforced structures

Triboelectric nanogenerators (TENGs) incorporated into textiles can harvest energy from friction between different materials. To improve mechanical fatigue resistance, reinforced structures are implemented, including specialized electrode designs, protective layers, and durable contact surfaces. These reinforcements prevent delamination and material degradation during repeated mechanical stress, ensuring consistent energy generation over extended periods of use in wearable applications.Expand Specific Solutions03 Composite materials for enhanced durability in textile energy harvesters

Advanced composite materials combining conductive polymers, elastomers, and nanomaterials can significantly improve the mechanical fatigue resistance of textile energy harvesters. These composites maintain electrical conductivity even after repeated deformation while providing structural integrity. The integration of carbon nanotubes, graphene, or metal nanowires into polymer matrices creates flexible yet durable energy harvesting textiles that can withstand washing, folding, and daily wear without performance degradation.Expand Specific Solutions04 Encapsulation techniques for protecting textile energy harvesters

Various encapsulation methods are employed to protect textile energy harvesters from mechanical stress and environmental factors. These include waterproof coatings, elastomeric encapsulants, and specialized lamination techniques that shield the active components while maintaining flexibility. The encapsulation layers distribute mechanical stress evenly across the textile, preventing localized damage and extending the operational lifetime of the energy harvesting system under repeated mechanical deformation.Expand Specific Solutions05 Structural design optimization for mechanical fatigue resistance

Innovative structural designs can significantly enhance the mechanical fatigue resistance of textile energy harvesters. These include serpentine patterns, island-bridge configurations, and hierarchical structures that can accommodate strain without damaging the functional components. By strategically distributing stress points and incorporating strain-relieving features, these designs allow the textile energy harvesters to maintain performance even after thousands of deformation cycles, making them suitable for long-term wearable applications.Expand Specific Solutions

Leading Companies and Research Institutions in Textile Energy Harvesting

The textile energy harvester mechanical fatigue resistance market is currently in an early growth phase, characterized by increasing research activity but limited commercial deployment. The market size is expanding, driven by growing demand for sustainable energy solutions in wearable electronics and IoT applications. Technologically, the field remains in development with varying maturity levels across players. Academic institutions like Xi'an Jiaotong University, Donghua University, and The Hong Kong Polytechnic University lead fundamental research, while companies such as Huject Co., DuPont, and Shenzhen Guohua Optoelectronics are advancing commercial applications. Collaboration between research institutions and industry partners is accelerating technological maturity, with significant progress in durability enhancement, material innovation, and manufacturing processes to overcome the critical challenge of mechanical fatigue in textile-based energy harvesting systems.

Xi'an Jiaotong University

Technical Solution: Xi'an Jiaotong University has developed cutting-edge solutions for mechanical fatigue resistance in textile energy harvesters through their innovative structural designs and material compositions. Their research focuses on triboelectric nanogenerators (TENGs) with specialized fiber architectures that distribute mechanical stress more effectively. They've pioneered a core-shell fiber structure where the energy-generating components are protected within a flexible but durable outer layer. Their textile energy harvesters incorporate elastomeric polymers with self-healing properties that can recover from microcracks formed during repeated mechanical deformation. Testing shows their designs maintain over 90% efficiency after 50,000 deformation cycles. Additionally, they've developed novel electrode designs using silver nanowires in hierarchical networks that maintain conductivity even under extreme bending and stretching conditions, addressing one of the primary failure modes in textile energy harvesters.

Strengths: Exceptional self-healing capabilities that extend operational lifetime; maintains high performance under extreme deformation conditions; excellent compatibility with existing textile manufacturing processes. Weaknesses: Higher material costs compared to conventional approaches; some designs require precise manufacturing control; potential challenges in scaling to large-area textiles.

Donghua University

Technical Solution: Donghua University, a leading institution in textile research, has developed innovative fiber-based energy harvesting systems with enhanced mechanical durability. Their approach focuses on hierarchical fiber structures that distribute mechanical stress more effectively throughout the textile. They've pioneered composite yarn architectures incorporating carbon nanotubes and piezoelectric polymers that maintain structural integrity during repeated deformation cycles. Their research demonstrates textile energy harvesters capable of withstanding over 100,000 bending cycles while maintaining more than 85% of initial power output. A key innovation is their strain-isolation design that separates the energy generation components from mechanical stress points in the textile structure. Additionally, they've developed specialized fiber coating techniques that prevent crack propagation during mechanical fatigue, significantly extending operational lifetime of the energy harvesting textiles.

Strengths: Exceptional integration with existing textile manufacturing infrastructure; superior mechanical durability under washing and daily wear conditions; maintains flexibility and comfort for wearable applications. Weaknesses: Relatively lower power output compared to rigid energy harvesters; challenges in maintaining consistent performance across large textile areas; some designs require specialized manufacturing equipment.

Key Patents and Innovations in Textile Durability Enhancement

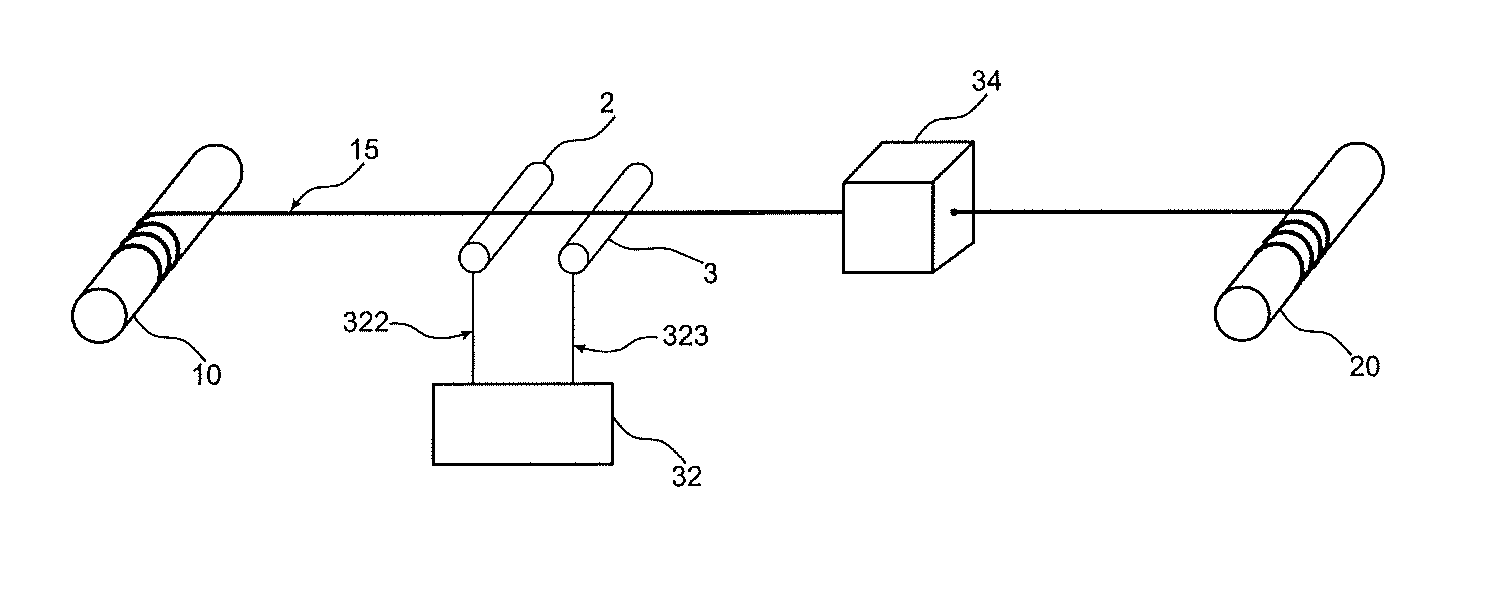

Energy-absorbing textile structure, in particular for use in vehicle construction and method for producing said structure

PatentWO2007090556A2

Innovation

- A method to create a targeted and adjustable local weakening of the textile structure by changing the direction and braiding angle of standing threads, ensuring a defined force application area with minimal additional effort and cost, using carbon fibers for standing threads and glass fibers for braiding threads.

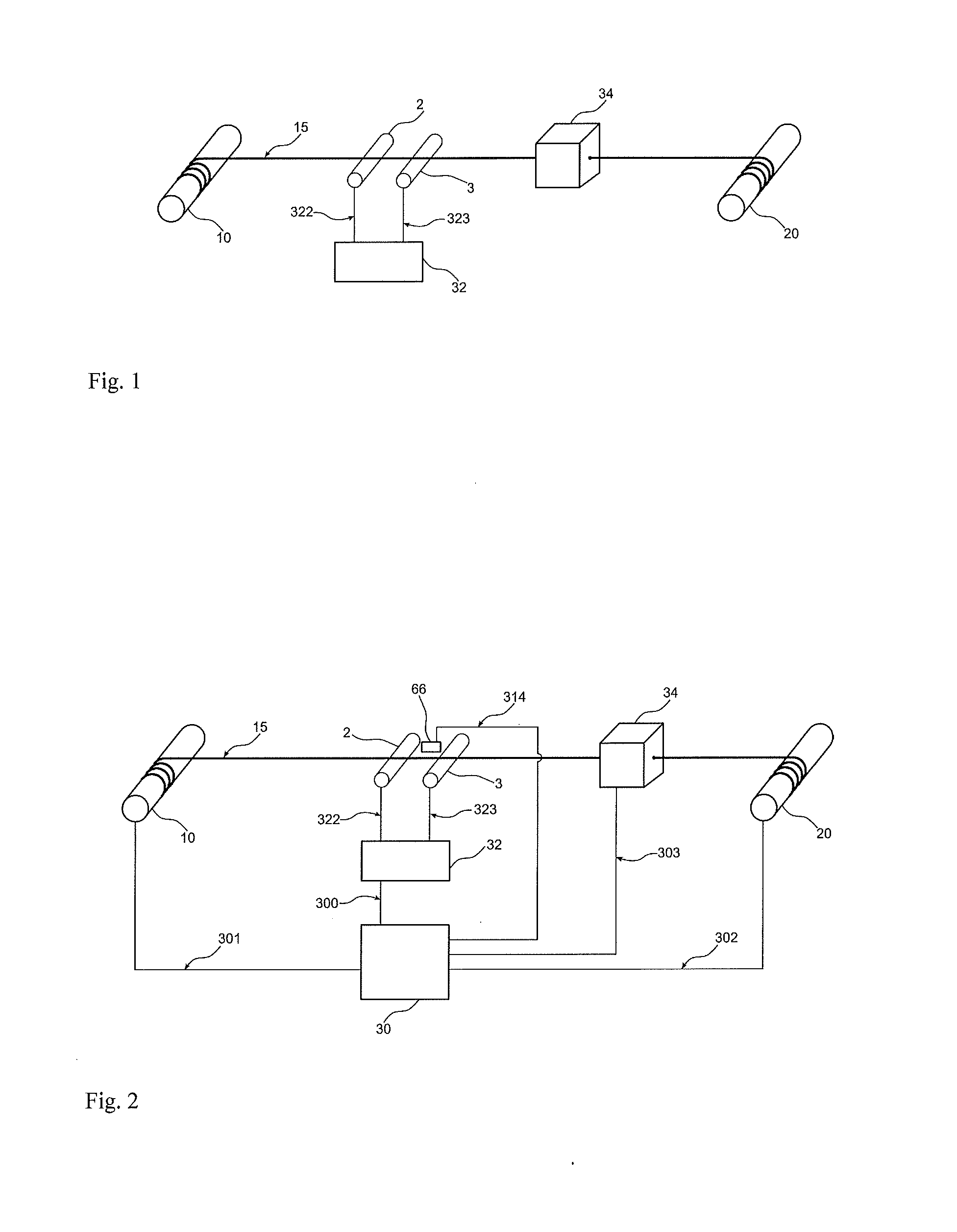

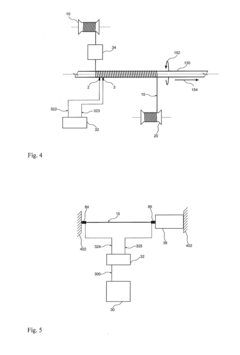

Method of heat treatment and/or inspection of functional mechanical properties, particularly transformation strain and/or strength, of shape memory alloy filaments and apparatus for the application of this method

PatentInactiveUS20120018413A1

Innovation

- A thermo-electro-mechanical treatment method using Joule heating and feedback control to set specific transformation strain and strength in SMA filaments, allowing for precise adjustment of microstructure and homogeneity, with an apparatus that enables high-speed processing and inspection of filament properties.

Materials Science Advancements for Flexible Energy Harvesting

Recent advancements in materials science have significantly propelled the development of flexible energy harvesting technologies, particularly for textile energy harvesters. The evolution of these materials has been driven by the need to address mechanical fatigue resistance, which remains a critical challenge in ensuring long-term functionality and reliability of wearable energy harvesting systems.

Piezoelectric materials have undergone substantial refinement, with PVDF (polyvinylidene fluoride) and its copolymers emerging as frontrunners due to their excellent flexibility and durability under repeated mechanical stress. These materials demonstrate superior fatigue resistance compared to traditional ceramic-based piezoelectrics, maintaining performance characteristics even after thousands of bending cycles.

Conductive polymers and nanocomposites represent another breakthrough, incorporating carbon nanotubes (CNTs), graphene, and silver nanowires into flexible substrates. These materials provide exceptional electrical conductivity while withstanding mechanical deformation. Research indicates that graphene-reinforced composites can maintain over 90% of their initial performance after 10,000 bending cycles, making them ideal candidates for textile integration.

Substrate materials have evolved from conventional textiles to engineered fabrics with inherent elasticity and recovery properties. Elastomeric substrates like thermoplastic polyurethane (TPU) and polydimethylsiloxane (PDMS) offer excellent mechanical compliance and fatigue resistance, serving as protective matrices for functional materials while accommodating the dynamic movements associated with wearable applications.

Encapsulation technologies have also advanced significantly, with multilayer barrier films and atomic layer deposition techniques providing effective protection against environmental factors while maintaining flexibility. These protective layers prevent moisture ingress and mechanical damage without compromising the energy harvesting efficiency of the underlying materials.

Interface engineering between different material layers has emerged as a critical focus area, with researchers developing gradient structures and chemical bonding techniques that distribute mechanical stress more evenly across the device structure. This approach significantly reduces delamination and crack propagation during repeated mechanical cycling, enhancing overall fatigue resistance.

Self-healing materials represent the cutting edge of this field, incorporating microcapsules or dynamic chemical bonds that can repair microdamage autonomously. Early prototypes demonstrate the ability to recover up to 85% of original performance after mechanical damage, potentially extending the operational lifetime of textile energy harvesters by several orders of magnitude compared to conventional systems.

Piezoelectric materials have undergone substantial refinement, with PVDF (polyvinylidene fluoride) and its copolymers emerging as frontrunners due to their excellent flexibility and durability under repeated mechanical stress. These materials demonstrate superior fatigue resistance compared to traditional ceramic-based piezoelectrics, maintaining performance characteristics even after thousands of bending cycles.

Conductive polymers and nanocomposites represent another breakthrough, incorporating carbon nanotubes (CNTs), graphene, and silver nanowires into flexible substrates. These materials provide exceptional electrical conductivity while withstanding mechanical deformation. Research indicates that graphene-reinforced composites can maintain over 90% of their initial performance after 10,000 bending cycles, making them ideal candidates for textile integration.

Substrate materials have evolved from conventional textiles to engineered fabrics with inherent elasticity and recovery properties. Elastomeric substrates like thermoplastic polyurethane (TPU) and polydimethylsiloxane (PDMS) offer excellent mechanical compliance and fatigue resistance, serving as protective matrices for functional materials while accommodating the dynamic movements associated with wearable applications.

Encapsulation technologies have also advanced significantly, with multilayer barrier films and atomic layer deposition techniques providing effective protection against environmental factors while maintaining flexibility. These protective layers prevent moisture ingress and mechanical damage without compromising the energy harvesting efficiency of the underlying materials.

Interface engineering between different material layers has emerged as a critical focus area, with researchers developing gradient structures and chemical bonding techniques that distribute mechanical stress more evenly across the device structure. This approach significantly reduces delamination and crack propagation during repeated mechanical cycling, enhancing overall fatigue resistance.

Self-healing materials represent the cutting edge of this field, incorporating microcapsules or dynamic chemical bonds that can repair microdamage autonomously. Early prototypes demonstrate the ability to recover up to 85% of original performance after mechanical damage, potentially extending the operational lifetime of textile energy harvesters by several orders of magnitude compared to conventional systems.

Standardization and Testing Protocols for Textile Energy Harvesters

The development of standardized testing protocols for textile energy harvesters (TEHs) represents a critical gap in the current research landscape. Without established standards, comparing performance metrics across different studies becomes challenging, hindering technological advancement and commercial adoption. Current testing approaches vary significantly between research groups, with inconsistent methodologies for evaluating mechanical fatigue resistance.

A comprehensive standardization framework should address multiple dimensions of TEH performance under mechanical stress. Cyclic loading tests must simulate real-world usage conditions, with protocols specifying precise parameters including frequency (typically 0.5-5 Hz), strain amplitude (1-30%), and minimum cycle counts (10,000-1,000,000 cycles). Environmental conditions during testing should be strictly controlled, maintaining temperature (20-25°C) and humidity (40-60%) within defined ranges.

Electrical output characterization requires standardized measurement techniques for open-circuit voltage, short-circuit current, and power density before, during, and after fatigue testing. The rate of performance degradation serves as a critical metric for evaluating mechanical durability, necessitating consistent calculation methods across the industry.

Accelerated aging protocols represent another essential component of standardization efforts. These protocols must establish correlations between accelerated testing conditions and real-world performance expectations, enabling meaningful lifetime predictions. Wash cycle testing protocols should specify detergent composition, water temperature, agitation parameters, and drying conditions to ensure reproducibility.

Physical examination standards should incorporate microscopic analysis of structural changes, adhesion testing between functional layers, and evaluation of mechanical property alterations following fatigue testing. These examinations provide valuable insights into failure mechanisms and degradation pathways.

Several organizations are currently working toward establishing these standards, including IEEE, ASTM International, and IEC. The IEEE P1881 working group specifically focuses on developing standards for flexible, stretchable, and wearable electronic devices, which encompasses textile energy harvesters. Industry participation in these standardization efforts remains crucial for ensuring practical relevance and widespread adoption.

Implementation of these standardized protocols would significantly accelerate research progress by enabling direct comparison between different TEH technologies, facilitating more efficient knowledge transfer, and providing manufacturers with reliable benchmarks for product development and quality control.

A comprehensive standardization framework should address multiple dimensions of TEH performance under mechanical stress. Cyclic loading tests must simulate real-world usage conditions, with protocols specifying precise parameters including frequency (typically 0.5-5 Hz), strain amplitude (1-30%), and minimum cycle counts (10,000-1,000,000 cycles). Environmental conditions during testing should be strictly controlled, maintaining temperature (20-25°C) and humidity (40-60%) within defined ranges.

Electrical output characterization requires standardized measurement techniques for open-circuit voltage, short-circuit current, and power density before, during, and after fatigue testing. The rate of performance degradation serves as a critical metric for evaluating mechanical durability, necessitating consistent calculation methods across the industry.

Accelerated aging protocols represent another essential component of standardization efforts. These protocols must establish correlations between accelerated testing conditions and real-world performance expectations, enabling meaningful lifetime predictions. Wash cycle testing protocols should specify detergent composition, water temperature, agitation parameters, and drying conditions to ensure reproducibility.

Physical examination standards should incorporate microscopic analysis of structural changes, adhesion testing between functional layers, and evaluation of mechanical property alterations following fatigue testing. These examinations provide valuable insights into failure mechanisms and degradation pathways.

Several organizations are currently working toward establishing these standards, including IEEE, ASTM International, and IEC. The IEEE P1881 working group specifically focuses on developing standards for flexible, stretchable, and wearable electronic devices, which encompasses textile energy harvesters. Industry participation in these standardization efforts remains crucial for ensuring practical relevance and widespread adoption.

Implementation of these standardized protocols would significantly accelerate research progress by enabling direct comparison between different TEH technologies, facilitating more efficient knowledge transfer, and providing manufacturers with reliable benchmarks for product development and quality control.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!