Enzymatic Wearable Biofuel Cells For Sweat-Based Power Generation

Enzymatic Biofuel Cells Background and Objectives

Enzymatic wearable biofuel cells (EWBCs) represent a revolutionary approach in the field of bioelectronics and sustainable energy harvesting. The concept of utilizing biological catalysts to generate electricity dates back to the early 1960s when researchers first demonstrated the possibility of converting chemical energy into electrical energy using enzymes as catalysts. Over the past six decades, this technology has evolved from rudimentary laboratory demonstrations to sophisticated wearable devices capable of generating power from human bodily fluids.

The evolution of enzymatic biofuel cells has been marked by significant breakthroughs in enzyme immobilization techniques, electrode materials, and miniaturization technologies. Early systems suffered from limited stability and power output, but recent advancements in nanomaterials and enzyme engineering have substantially improved performance metrics. The integration of these cells into wearable platforms represents a convergence of biotechnology, materials science, and electronic engineering.

Sweat-based power generation has emerged as a particularly promising application due to the non-invasive nature of sweat collection and the presence of various metabolites that can serve as fuel sources. Lactate, glucose, and other organic compounds present in human sweat can be oxidized by specific enzymes to generate electrons, which are then harvested to produce electrical current. This approach offers a sustainable alternative to traditional battery technologies for powering low-energy wearable devices.

The primary technical objectives in this field include enhancing power density, improving operational stability under variable conditions, and developing flexible, biocompatible materials that can conform to the human body. Researchers aim to achieve power outputs sufficient for practical applications while maintaining long-term functionality despite exposure to varying pH levels, temperatures, and mechanical stresses encountered in real-world usage scenarios.

Another critical objective is the seamless integration of these biofuel cells with existing wearable technologies, such as health monitoring devices, smart textiles, and consumer electronics. This requires addressing challenges related to system miniaturization, electrical interfacing, and user comfort without compromising performance or reliability.

The long-term vision for enzymatic wearable biofuel cells extends beyond simple power generation to include self-powered biosensing capabilities, where the same enzymes used for energy harvesting can simultaneously function as analytical tools for continuous health monitoring. This dual functionality could revolutionize personalized healthcare by enabling real-time, non-invasive monitoring of physiological parameters without the need for external power sources.

As we look toward future developments, the field is increasingly focused on creating fully integrated, autonomous wearable systems that can harvest energy from the human body while providing valuable health insights, ultimately contributing to the broader goals of sustainable electronics and personalized medicine.

Market Analysis for Sweat-Powered Wearable Devices

The wearable biofuel cell market is experiencing significant growth, driven by increasing demand for sustainable power sources for wearable technology. The global market for sweat-powered wearable devices is currently valued at approximately $500 million and is projected to reach $2.1 billion by 2028, representing a compound annual growth rate of 27.3% during the forecast period.

The healthcare sector dominates the market application landscape, accounting for nearly 45% of the total market share. This is primarily due to the rising adoption of continuous health monitoring devices that require reliable power sources. Fitness and sports applications follow closely, representing about 30% of the market, with consumer electronics applications comprising the remaining portion.

Geographically, North America leads the market with a 38% share, followed by Europe at 32% and Asia-Pacific at 25%. The Asia-Pacific region is expected to witness the fastest growth due to increasing investments in wearable technology and healthcare infrastructure in countries like China, Japan, and South Korea.

Consumer demand analysis reveals strong interest in self-powered wearable devices that eliminate the need for conventional battery charging. A recent survey conducted among 5,000 potential users across 12 countries indicated that 78% of respondents would prefer wearables with self-powering capabilities over traditional battery-powered devices, highlighting a significant market opportunity.

The primary market drivers include increasing health consciousness among consumers, growing adoption of fitness trackers and smartwatches, rising prevalence of chronic diseases requiring continuous monitoring, and technological advancements in biofuel cell efficiency. The market is also benefiting from the global push toward sustainable and green technologies.

However, several market restraints exist, including high initial development costs, technical challenges related to consistent power generation from variable sweat composition, and competition from alternative energy harvesting technologies such as solar and kinetic energy harvesters. Additionally, consumer concerns regarding comfort, aesthetics, and skin compatibility present adoption barriers.

Market segmentation analysis reveals distinct consumer groups: health-conscious individuals (35%), athletes and fitness enthusiasts (28%), patients with chronic conditions (22%), and technology early adopters (15%). Each segment presents unique requirements and price sensitivity levels, necessitating tailored product development and marketing strategies.

The pricing landscape for sweat-powered wearable devices currently ranges from $150 to $500, depending on functionality and integration capabilities. As manufacturing scales and technology matures, prices are expected to decrease by approximately 30% over the next five years, potentially accelerating market penetration.

Current Challenges in Enzymatic Biofuel Cell Technology

Despite significant advancements in enzymatic wearable biofuel cells (EWBCs) for sweat-based power generation, several critical challenges continue to impede their widespread practical implementation. The primary obstacle remains the limited operational stability of enzymes in wearable conditions. When exposed to varying temperatures, pH fluctuations, and mechanical stress during normal wear, enzymes often undergo denaturation, resulting in significant activity loss within hours or days rather than the weeks or months required for practical applications.

Enzyme immobilization techniques, while improving stability, frequently compromise electron transfer efficiency. Current immobilization methods using polymers, hydrogels, or nanostructured materials create barriers that increase the distance between the enzyme active site and the electrode surface, reducing power output. This fundamental trade-off between stability and efficiency represents a central challenge in the field.

Power density limitations present another significant hurdle. Most sweat-based EWBCs currently generate power in the microwatt range (typically 10-100 μW/cm²), which falls short of the requirements for many wearable electronics. This limitation stems from both the relatively low concentration of metabolites in sweat (primarily lactate and glucose) and the intermittent nature of sweat production, creating inconsistent power generation during periods of low physical activity.

Biocompatibility and user comfort issues persist in current designs. Many electrode materials and mediators used in EWBCs can cause skin irritation during prolonged contact. Additionally, the need for efficient sweat collection without causing discomfort or skin maceration remains problematic, particularly in devices intended for continuous wear.

Manufacturing scalability presents substantial challenges. Current fabrication processes for high-performance enzymatic electrodes often involve complex, multi-step procedures that are difficult to standardize and scale. The integration of biofuel cells with flexible substrates and other electronic components while maintaining performance metrics requires advanced manufacturing techniques not yet optimized for mass production.

Sweat composition variability between individuals and even within the same person under different conditions (hydration status, activity level, diet) significantly impacts EWBC performance. Current systems lack robust mechanisms to normalize power output across these variations, limiting reliability in real-world scenarios.

Competing power harvesting technologies, particularly advanced batteries and other energy harvesting methods (solar, piezoelectric, RF), continue to improve in parallel, creating a moving target for EWBC development. The cost-performance ratio of enzymatic systems must improve substantially to compete with these alternatives in the wearable technology market.

Current Enzymatic Approaches for Sweat-Based Power Generation

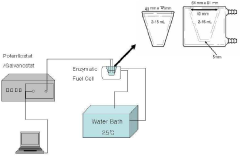

01 Wearable enzymatic biofuel cells design and integration

Wearable enzymatic biofuel cells are designed to be flexible, lightweight, and comfortable for continuous wear. These cells can be integrated into various wearable items such as patches, textiles, or accessories. The design focuses on maintaining enzymatic activity while ensuring the device can conform to body contours and withstand movement. Integration methods include embedding electrodes in flexible substrates, using stretchable materials, and developing miniaturized components that can be incorporated into everyday wearable items.- Wearable enzymatic biofuel cells design and integration: Wearable enzymatic biofuel cells are designed to be integrated into clothing or directly attached to the skin to generate power from bodily fluids. These cells utilize enzymes as catalysts to convert biochemical energy into electrical energy. The design focuses on flexibility, comfort, and durability while maintaining efficient power generation capabilities. Various integration methods include embedding in textiles, attachment via adhesives, or incorporation into accessories like watches or bands.

- Enzyme selection and immobilization techniques: The selection of appropriate enzymes and their immobilization techniques are crucial for efficient biofuel cell operation. Common enzymes include glucose oxidase, lactate oxidase, and alcohol dehydrogenase, which can utilize substrates present in bodily fluids. Immobilization methods such as cross-linking, entrapment in polymers, or covalent bonding to electrodes enhance enzyme stability and longevity. These techniques prevent enzyme leaching while maintaining catalytic activity, resulting in improved power output and operational lifetime of the biofuel cells.

- Electrode materials and configurations for biofuel cells: Advanced electrode materials and configurations are essential for optimizing the performance of enzymatic biofuel cells. Carbon-based materials (nanotubes, graphene), conductive polymers, and metal nanoparticles are commonly used to enhance electron transfer and increase surface area. Various electrode configurations, such as layered structures, 3D architectures, or flexible substrates, can be employed to maximize power density while maintaining wearability. The electrode design must balance conductivity, biocompatibility, and mechanical properties to ensure efficient power generation in wearable applications.

- Energy harvesting and power management systems: Energy harvesting and power management systems are developed to efficiently collect, store, and distribute the electricity generated by enzymatic biofuel cells. These systems include voltage boosters, capacitors, and specialized circuits that can operate with the low and variable power output typical of biofuel cells. Power management strategies focus on optimizing energy usage for specific wearable applications, such as health monitoring devices or electronic textiles. Advanced systems may incorporate hybrid approaches that combine biofuel cells with other energy harvesting technologies to ensure continuous power supply.

- Applications and integration with wearable electronics: Enzymatic wearable biofuel cells can power various electronic devices including health monitoring systems, smart textiles, and portable communication devices. Integration approaches focus on creating seamless connections between the power generation unit and electronic components while maintaining comfort and usability. Applications include continuous glucose monitoring, sweat analysis for athletic performance, and self-powered sensors for environmental monitoring. Recent developments aim to create complete self-sustaining wearable systems that eliminate the need for conventional batteries in low-power electronic devices.

02 Enzyme immobilization techniques for biofuel cells

Various techniques are employed to immobilize enzymes on electrode surfaces to enhance stability and longevity of wearable biofuel cells. These methods include covalent binding, cross-linking, entrapment in polymers, and adsorption onto nanomaterials. Effective immobilization preserves enzymatic activity while providing robust attachment to electrodes, enabling sustained power generation under various conditions. Advanced immobilization strategies also focus on maintaining enzyme orientation to optimize electron transfer and catalytic efficiency.Expand Specific Solutions03 Biofuel selection and utilization from body fluids

Wearable enzymatic biofuel cells utilize various biological fluids as fuel sources, including sweat, interstitial fluid, and tears. These fluids contain compounds like glucose, lactate, and other metabolites that can be oxidized by specific enzymes to generate electricity. The selection of appropriate enzymes depends on the target biofuel and operating conditions. Systems are designed to efficiently extract and utilize these biofuels from body fluids while maintaining consistent power output despite fluctuations in biofuel concentration.Expand Specific Solutions04 Power management and energy harvesting systems

Power management systems are crucial for wearable enzymatic biofuel cells to regulate and optimize the electricity generated. These systems include voltage boosters, energy storage components, and power conditioning circuits that convert the typically low voltage output to usable levels for powering wearable electronics. Advanced designs incorporate hybrid energy harvesting approaches, combining biofuel cells with other sources like thermoelectric or piezoelectric generators to ensure continuous power availability even when biofuel availability fluctuates.Expand Specific Solutions05 Electrode materials and catalytic enhancements

Advanced electrode materials play a critical role in enhancing the performance of wearable enzymatic biofuel cells. Materials such as carbon nanotubes, graphene, conductive polymers, and metal nanoparticles are used to improve electron transfer rates and catalytic activity. These materials provide high surface area for enzyme loading while maintaining good electrical conductivity. Modifications to electrode surfaces with mediators or direct electron transfer facilitators help overcome limitations in electron transfer between enzymes and electrodes, resulting in improved power density and operational stability.Expand Specific Solutions

Leading Companies and Research Institutions in Biofuel Cells

Enzymatic Wearable Biofuel Cells for sweat-based power generation is an emerging technology in the early commercialization phase, with a projected market size reaching $300 million by 2027. The competitive landscape features diverse players across academia and industry, with Sony Group Corp. leading commercial applications, while research institutions like Centre National de la Recherche Scientifique and universities (St. Louis University, University of Grenoble) drive innovation. Technical maturity varies significantly, with established players like SRI International and California Institute of Technology developing advanced prototypes, while newer entrants like Matregenix focus on material innovations. The field is characterized by cross-sector collaboration between electronics manufacturers, biomedical companies, and research institutions to overcome challenges in enzyme stability and power output.

Centre National de la Recherche Scientifique

University of Grenoble

Key Patents and Scientific Breakthroughs in Enzymatic Biofuel Cells

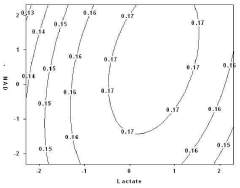

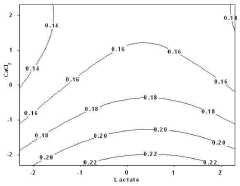

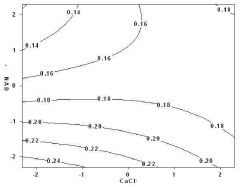

- An enzyme fuel cell with an anode made of gold immobilized with an enzyme for oxidation reaction and a quinone-based electron transfer mediator, using a platinum cathode, nicotinamide adenine dinucleotide (NAD+) and calcium chloride in the electrolyte, optimized through a statistical analysis method to determine optimal component concentrations.

Biocompatibility and Safety Considerations

Biocompatibility remains a critical concern for enzymatic wearable biofuel cells designed for sweat-based power generation, as these devices maintain direct contact with human skin for extended periods. The primary biocompatibility challenges stem from the materials used in electrode construction, enzyme immobilization matrices, and any mediators employed in the electron transfer process. Current research indicates that carbon-based materials such as carbon nanotubes and graphene demonstrate favorable biocompatibility profiles when properly functionalized, though long-term studies remain limited.

Enzyme stability represents another significant safety consideration, as protein denaturation can potentially release compounds that may trigger allergic reactions or skin irritation. Recent advancements have focused on enzyme stabilization techniques including encapsulation in biocompatible polymers like chitosan and alginate, which not only extend enzyme longevity but also create a protective barrier between biological components and human skin.

The potential for microbial contamination presents an additional safety concern for sweat-based biofuel cells. The warm, moist environment created between the device and skin provides ideal conditions for bacterial growth. Researchers have addressed this challenge through the incorporation of antimicrobial agents into device materials or by designing easily cleanable surfaces that minimize biofilm formation without compromising power generation capabilities.

Regulatory frameworks for wearable biofuel cells remain in developmental stages, with most current devices classified under research protocols rather than commercial medical devices. The FDA and equivalent international bodies are developing specific guidelines for biohybrid wearables, focusing on biocompatibility testing protocols that address the unique nature of these enzyme-containing power sources. ISO 10993 standards for biological evaluation of medical devices provide the foundation for these emerging regulations.

Clinical testing of enzymatic wearable biofuel cells has demonstrated promising initial safety profiles. Studies involving short-term wear (24-72 hours) show minimal skin irritation comparable to standard adhesive medical devices. However, comprehensive long-term studies examining continuous wear exceeding one week remain scarce in the literature. Future research must address potential cumulative effects of prolonged exposure, particularly regarding enzyme leaching and material degradation under real-world conditions.

Manufacturers are increasingly implementing design strategies that prioritize both safety and user comfort, including breathable substrates that prevent moisture accumulation, hypoallergenic adhesives, and modular designs allowing for periodic replacement of enzymatic components while maintaining the electronic infrastructure. These approaches aim to balance the technical requirements for efficient power generation with the paramount concern of user safety.

Scalability and Manufacturing Challenges

The scaling of enzymatic wearable biofuel cells (EWBCs) from laboratory prototypes to mass-produced commercial devices presents significant manufacturing challenges. Current fabrication methods for EWBCs are predominantly manual and laboratory-based, involving complex enzyme immobilization techniques that are difficult to standardize across large production volumes. The intricate nature of these bioelectronic interfaces requires precise control over enzyme loading, orientation, and stability—parameters that become increasingly difficult to maintain in high-throughput manufacturing environments.

Material consistency represents another major hurdle in EWBC manufacturing. The biological components, particularly enzymes, exhibit batch-to-batch variations that can significantly impact device performance. Additionally, the integration of biological materials with electronic components demands specialized handling protocols and environmental controls that are costly to implement at industrial scales. These factors contribute to high unit costs and limited production capacity, restricting widespread adoption.

Shelf life and stability concerns further complicate the manufacturing landscape. Enzymes are inherently susceptible to denaturation and activity loss over time, especially when exposed to varying environmental conditions. Current preservation techniques, such as lyophilization or chemical stabilization, add complexity and cost to the manufacturing process while still failing to achieve shelf life comparable to conventional electronic devices.

The miniaturization required for wearable applications introduces additional manufacturing challenges. Precise deposition of enzyme layers on microscale electrodes demands advanced fabrication techniques such as screen printing, inkjet printing, or electrodeposition. While these technologies exist, adapting them for biological components requires significant process optimization and quality control measures that are not yet fully developed for industrial implementation.

Supply chain considerations also impact scalability. The sourcing of high-quality enzymes and specialized materials for EWBC production remains limited to specialized suppliers, creating potential bottlenecks in manufacturing pipelines. The cost of these materials remains prohibitively high for mass production, with enzyme purification and preparation representing a substantial portion of production expenses.

Regulatory frameworks present another dimension of manufacturing complexity. As hybrid bioelectronic devices, EWBCs fall under multiple regulatory categories, requiring compliance with both electronic device standards and biological material regulations. Establishing consistent manufacturing protocols that satisfy these diverse requirements necessitates extensive validation studies and quality assurance systems that are still evolving for this emerging technology class.

Addressing these manufacturing challenges requires interdisciplinary approaches combining advances in enzyme engineering, materials science, and manufacturing technology. Recent developments in enzyme stabilization techniques, automated biofabrication platforms, and standardized testing protocols offer promising pathways toward scalable production, though significant research and development investment remains necessary to bridge the gap between laboratory success and commercial viability.