Textile Integration Techniques For Biofuel Cell Electrodes

Biofuel Cell Electrode Textile Integration Background and Objectives

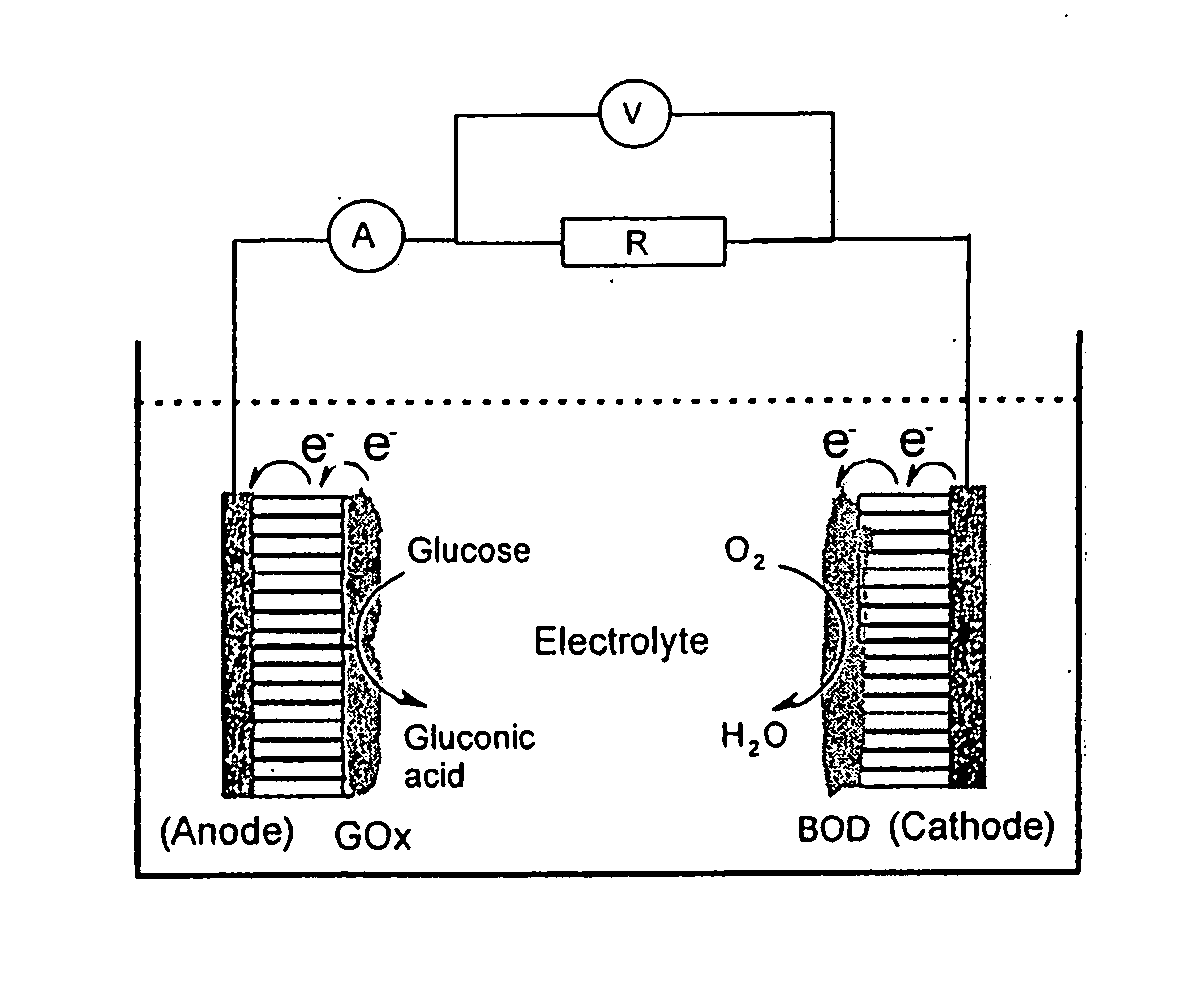

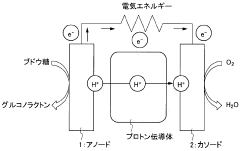

Biofuel cells represent a promising sustainable energy technology that converts biochemical energy into electrical energy through enzymatic or microbial catalytic reactions. The integration of biofuel cell electrodes with textiles has emerged as a significant research direction over the past decade, driven by the growing demand for wearable and flexible power sources. This technological convergence aims to create self-powered electronic textiles that can harvest energy from bodily fluids such as sweat, tears, or interstitial fluids, while maintaining the comfort, flexibility, and breathability inherent to traditional textiles.

The evolution of textile-integrated biofuel cells can be traced back to early experiments with glucose oxidase immobilization on conductive fabrics in the early 2000s. Since then, significant advancements have occurred in electrode materials, enzyme immobilization techniques, and textile manufacturing processes, leading to improved power density, stability, and wearability of these systems.

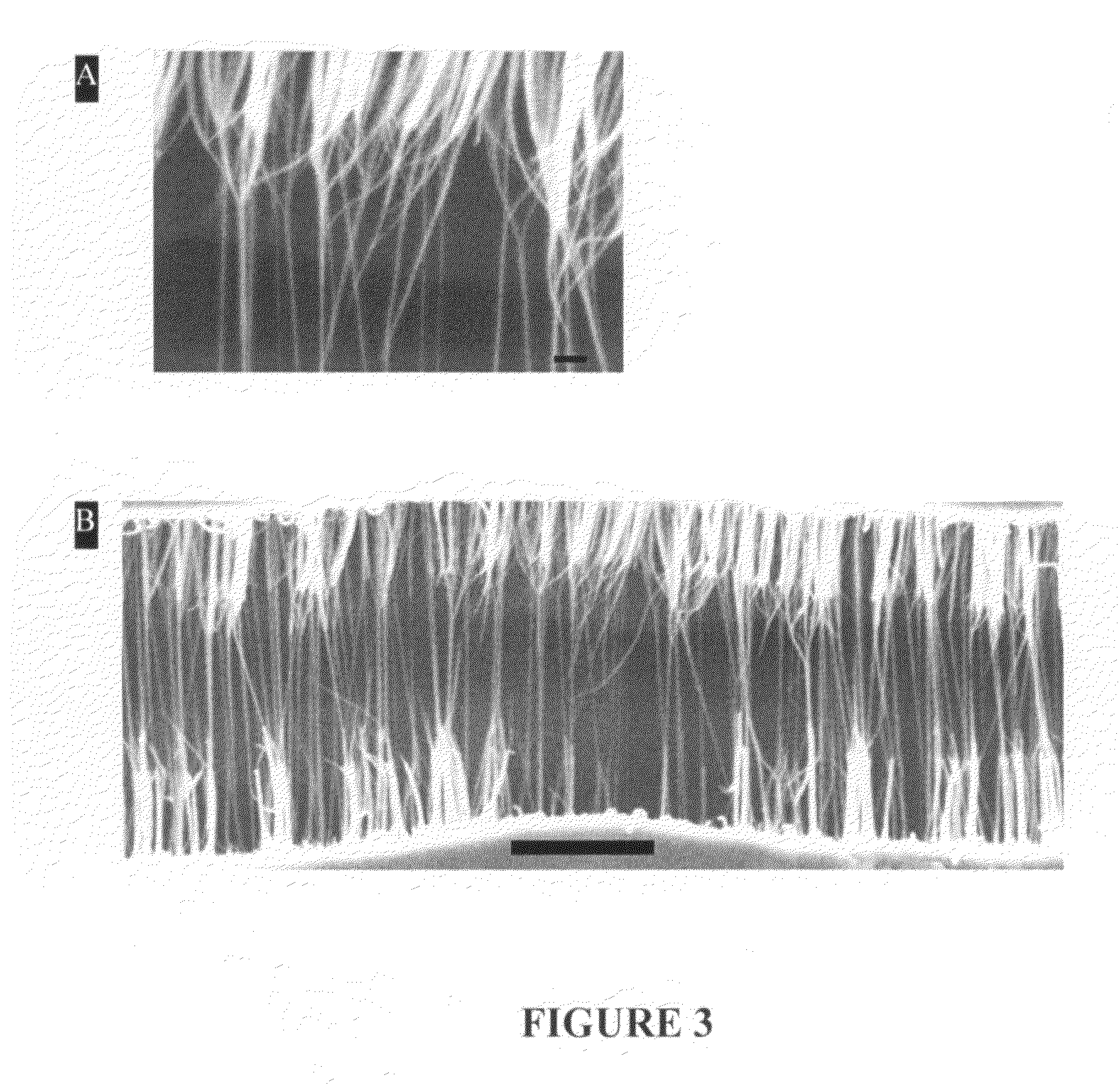

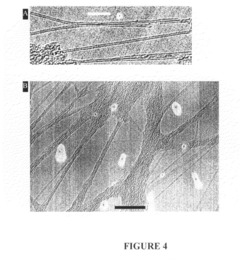

Current technological trends in this field include the development of stretchable conductive inks for direct printing on textiles, exploration of novel nanomaterials such as carbon nanotubes and graphene for enhanced conductivity, and investigation of more stable enzyme immobilization methods to extend operational lifetimes. Additionally, there is growing interest in scalable manufacturing techniques that can bridge the gap between laboratory prototypes and commercial applications.

The primary technical objectives for textile-integrated biofuel cell electrodes include achieving higher power density (targeting >1 mW/cm²), extending operational stability beyond 24 hours under continuous use, maintaining performance during mechanical deformation, and ensuring biocompatibility for long-term skin contact. These objectives must be accomplished while preserving the inherent properties of textiles, such as breathability, washability, and comfort.

Another critical goal is to develop standardized testing protocols that can accurately evaluate the performance of textile-integrated biofuel cells under realistic wearing conditions, including varying humidity, temperature fluctuations, and mechanical stress. This standardization would facilitate meaningful comparisons between different technological approaches and accelerate progress in the field.

The convergence of biofuel cell technology with smart textiles represents a multidisciplinary challenge requiring expertise in electrochemistry, materials science, textile engineering, and biomedical engineering. Success in this domain could revolutionize wearable electronics by eliminating the need for conventional batteries, enabling truly autonomous wearable systems for healthcare monitoring, athletic performance tracking, and military applications.

Market Analysis for Wearable Biofuel Cell Applications

The wearable biofuel cell market is experiencing significant growth driven by increasing demand for sustainable power sources in healthcare monitoring and consumer electronics. Current market projections indicate that the global wearable technology market will reach approximately $70 billion by 2025, with biofuel cells positioned to capture a growing segment of the power supply component. The integration of biofuel cells into textiles represents a particularly promising application area, with potential market penetration across medical, fitness, military, and consumer sectors.

Healthcare applications currently dominate the market potential for textile-integrated biofuel cells, particularly for continuous glucose monitoring systems and other metabolite sensors that can leverage the same biological fuels powering the cells. This synergistic relationship creates a compelling value proposition, as the power source can simultaneously function as a diagnostic tool. The aging global population and rising prevalence of chronic conditions requiring continuous monitoring further strengthen market demand in this sector.

The athletic and fitness wearables segment presents another substantial market opportunity, with consumers increasingly seeking self-powered devices that eliminate charging requirements. Market research indicates that approximately 30% of fitness wearable users cite battery limitations as a major pain point, suggesting strong potential adoption for biofuel-powered alternatives. The premium sportswear market, valued at over $80 billion globally, offers a particularly receptive entry point for textile-integrated biofuel technologies.

Military and defense applications constitute a smaller but higher-value market segment. Requirements for lightweight, durable power sources for field equipment and personnel monitoring systems align perfectly with the capabilities of textile-integrated biofuel cells. Government defense contracts in this space typically command premium pricing, offsetting the relatively smaller unit volumes.

Consumer electronics represents the largest potential market by volume but faces significant price sensitivity challenges. Mass adoption in this sector will likely depend on achieving manufacturing economies of scale that can drive costs below $5 per wearable power unit. Current production costs remain substantially higher, positioning consumer applications as a longer-term market opportunity.

Geographic market distribution shows North America leading in early adoption, particularly in medical and premium fitness applications, while Asia-Pacific represents the fastest-growing region with expanding manufacturing capabilities and increasing consumer demand. Europe maintains a strong position in research and development, with several leading academic-industrial partnerships advancing commercialization efforts.

Market barriers include competition from improving battery technologies, regulatory hurdles for biologically-based power systems, and consumer education requirements. However, the unique value proposition of self-powered, comfortable, and environmentally sustainable wearable power sources positions textile-integrated biofuel cells favorably for significant market growth over the next decade.

Current Challenges in Textile-Based Electrode Technologies

Despite significant advancements in textile-based electrode technologies for biofuel cells, several critical challenges continue to impede widespread implementation and commercialization. The integration of electrochemically active materials with textile substrates presents complex technical hurdles that require innovative solutions.

Conductivity limitations represent a primary challenge, as most textile materials are inherently non-conductive. Current approaches using conductive polymers like PEDOT:PSS or carbon-based coatings often struggle to maintain consistent electrical properties throughout the textile structure. The conductivity achieved typically ranges from 1-100 S/cm, which remains insufficient for high-performance biofuel cell applications requiring values exceeding 500 S/cm.

Durability issues emerge during practical application, particularly when textiles undergo repeated mechanical stress, washing cycles, or exposure to bodily fluids. Many electrode materials demonstrate significant performance degradation after 20-30 washing cycles, with conductivity losses exceeding 40%. This compromises the long-term functionality essential for wearable biofuel cell applications.

Biocompatibility concerns arise when integrating electronic components with textiles intended for direct skin contact. Certain conductive materials and binding agents may cause skin irritation or allergic reactions. Additionally, ensuring biocompatibility while maintaining electrochemical performance presents a delicate balance that current technologies struggle to achieve.

Scalable manufacturing represents another significant hurdle. Laboratory-scale fabrication methods like screen printing, electrospinning, and dip-coating often face challenges in transitioning to industrial-scale production. Maintaining uniform electrode properties across large textile surfaces remains problematic, with variation coefficients frequently exceeding 15% in production environments.

Power density limitations persist in current textile-based biofuel cells, typically generating only 50-200 μW/cm², significantly below the requirements for powering most wearable electronic devices. This performance gap necessitates either improved electrode designs or supplementary power sources.

Interface optimization between the biological component (enzymes or microorganisms) and the textile electrode structure presents ongoing challenges. Current immobilization techniques often result in enzyme activity losses of 30-60% compared to solution-based systems, substantially reducing biofuel cell efficiency.

Environmental stability issues affect long-term performance, as textile electrodes frequently demonstrate sensitivity to temperature fluctuations, humidity changes, and pH variations. Most current systems operate optimally within narrow environmental parameters, limiting their practical application in diverse real-world conditions.

Existing Textile Integration Methods for Biofuel Cell Electrodes

01 Textile-based biofuel cell electrode materials

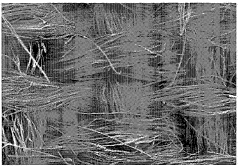

Various textile materials can be used as substrates for biofuel cell electrodes. These textiles provide flexibility, breathability, and wearability while maintaining electrochemical performance. Conductive textiles can be created by coating or incorporating conductive materials like carbon nanotubes, conductive polymers, or metallic nanoparticles onto textile fibers. These textile-based electrodes enable the development of wearable biofuel cells that can harvest energy from bodily fluids.- Textile-based biofuel cell electrode materials: Various textile materials can be used as substrates for biofuel cell electrodes. These textiles provide flexibility, breathability, and wearability while maintaining electrochemical performance. Conductive textiles can be created by coating or incorporating conductive materials onto fabric structures, enabling efficient electron transfer in biofuel cells while maintaining the comfort and flexibility needed for wearable applications.

- Integration methods for biofuel cells in textiles: Different techniques can be employed to integrate biofuel cell components into textiles, including printing, coating, and embedding methods. These integration approaches ensure proper electrical connections while maintaining the textile's flexibility and wearability. The integration methods must balance electrical performance with mechanical durability to withstand repeated bending, stretching, and washing that textiles typically undergo.

- Enzyme immobilization on textile electrodes: Enzymes can be immobilized on textile-based electrodes using various techniques to maintain their catalytic activity while ensuring stability in wearable conditions. Immobilization methods include physical adsorption, covalent binding, and entrapment within conductive polymers on the textile surface. These approaches help preserve enzyme function during long-term use and exposure to various environmental conditions.

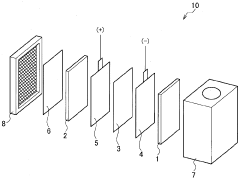

- Power management systems for textile biofuel cells: Specialized power management systems are designed to efficiently harvest, store, and distribute the electrical energy generated by textile-integrated biofuel cells. These systems often include energy storage components, voltage regulators, and power conditioning circuits that can be miniaturized and integrated into the textile structure. The power management systems ensure stable power output despite variations in biofuel cell performance due to changing physiological or environmental conditions.

- Biofuel sources and electrode configurations for textile applications: Various biofuel sources can be utilized in textile-integrated biofuel cells, including bodily fluids like sweat, interstitial fluid, or external sources like plant sap. Different electrode configurations are designed to optimize the collection and utilization of these biofuels while maintaining comfort and wearability. The electrode designs must balance surface area for reaction sites with flexibility and breathability requirements of textile applications.

02 Integration methods for biofuel cell components in textiles

Various techniques are employed to integrate biofuel cell components into textiles, including screen printing, dip coating, electrospinning, and direct weaving of conductive fibers. These methods allow for the creation of flexible, stretchable, and washable biofuel cell systems that can be seamlessly incorporated into garments. The integration approaches focus on maintaining the textile's original properties while adding electrochemical functionality, enabling practical wearable energy harvesting devices.Expand Specific Solutions03 Enzyme immobilization techniques for textile biofuel cells

Effective enzyme immobilization is crucial for textile-integrated biofuel cells. Various techniques are used to attach enzymes to textile-based electrodes, including covalent bonding, physical adsorption, and entrapment within conductive polymers. These methods aim to maintain enzyme stability and activity while ensuring good electrical contact with the electrode surface. Proper immobilization extends the operational lifetime of the biofuel cell and enhances power output by optimizing the biocatalytic reactions.Expand Specific Solutions04 Mediator systems for textile-based biofuel cells

Mediator systems facilitate electron transfer between enzymes and electrodes in textile-based biofuel cells. These mediators can be incorporated into the textile structure through various methods, including direct impregnation, layer-by-layer assembly, or covalent attachment. Effective mediator systems improve the power density and operational stability of textile biofuel cells by enhancing electron transfer efficiency and reducing activation overpotentials.Expand Specific Solutions05 Structural designs for textile-integrated biofuel cells

Various structural designs have been developed for textile-integrated biofuel cells, including layered configurations, fiber-based architectures, and yarn-based systems. These designs aim to maximize power output while maintaining textile properties such as flexibility, breathability, and comfort. Advanced structural approaches include 3D textile architectures that increase surface area for enzyme loading and improve mass transport of reactants, resulting in enhanced power generation capabilities.Expand Specific Solutions

Leading Organizations in Biofuel Cell Textile Integration

The textile integration of biofuel cell electrodes is currently in an early development stage, with market growth driven by increasing demand for wearable and flexible energy solutions. The global market remains relatively small but shows promising expansion potential as sustainable energy technologies gain traction. Technologically, the field is still maturing, with key players demonstrating varying levels of advancement. Sony, Toray Industries, and Samsung SDI lead commercial development with their materials expertise, while research institutions like CNRS, Tsinghua University, and North Carolina State University contribute significant academic innovations. University-industry collaborations, particularly involving KIST Corp. and Nanyang Technological University, are accelerating progress in electrode design and textile integration techniques. The convergence of textile engineering and bioelectrochemistry presents both challenges and opportunities for creating commercially viable wearable biofuel cells.

Centre National de la Recherche Scientifique

Toray Industries, Inc.

Key Patents and Research in Textile-Electrode Interface Design

- A biofuel cell system is developed using nanomaterials like single wall carbon nanotubes with enzymes immobilized through electrochemical or microwave-assisted processes, eliminating the need for expensive electron mediators and incorporating micro-fluidic channels for efficient fluid transport, and utilizing porous silicon substrates for enhanced interfacial bonding and stability.

- The use of carbon fiber cloth with a network structure of carbon fiber monofilament bundles as electrodes, enhancing surface area, physical stability, and liquid permeability, while allowing for uniform enzyme immobilization and improved reaction distribution.

Sustainability Impact of Textile-Integrated Biofuel Technologies

The integration of biofuel cell technologies into textiles represents a significant advancement in sustainable energy solutions, offering profound environmental benefits across multiple dimensions. These textile-integrated systems substantially reduce reliance on conventional energy sources by harnessing renewable bioenergy from bodily fluids or environmental compounds, thereby decreasing fossil fuel consumption and associated greenhouse gas emissions.

When examining the lifecycle assessment of textile-integrated biofuel cells, they demonstrate remarkable advantages over traditional power sources. The biodegradable nature of many biofuel cell components—particularly those utilizing enzymatic catalysts rather than precious metals—significantly reduces end-of-life environmental impact. This characteristic aligns perfectly with circular economy principles, as these materials can be more readily reintegrated into natural cycles.

Water conservation represents another critical sustainability benefit. Unlike conventional energy production methods that often require substantial water resources for cooling and processing, textile-integrated biofuel cells operate with minimal water requirements. In some configurations, they can even utilize wastewater or bodily fluids as fuel sources, effectively transforming waste into energy while reducing water treatment demands.

The manufacturing processes for these integrated technologies are increasingly optimized for sustainability. Advanced fabrication techniques such as digital printing of electrodes and environmentally friendly coating methods minimize chemical waste and energy consumption during production. These improvements contribute to a significantly lower carbon footprint compared to traditional electronic component manufacturing.

From a resource efficiency perspective, textile-integrated biofuel cells excel by utilizing abundant, renewable biological materials as catalysts and fuels. This approach reduces dependence on scarce resources like rare earth metals commonly required in conventional batteries and electronic components, addressing critical supply chain sustainability concerns.

Perhaps most promising is the potential for these technologies to enable energy autonomy in remote or underserved regions. By providing decentralized power generation capabilities through everyday textiles, communities can reduce infrastructure requirements while increasing resilience against energy supply disruptions. This democratization of energy production represents a fundamental shift toward more equitable and sustainable energy systems globally.

As textile-integrated biofuel technologies mature, their positive environmental impact extends beyond immediate energy benefits to influence broader sustainability practices across the textile and electronics industries, driving innovation toward more environmentally responsible product lifecycles.

Durability and Washability Considerations for Wearable Biofuel Cells

The integration of biofuel cell electrodes into textiles presents significant challenges regarding durability and washability, which are critical factors for practical wearable applications. Current textile-integrated biofuel cells typically suffer from performance degradation after repeated mechanical stress and exposure to washing conditions. Research indicates that conventional electrode materials, such as carbon-based inks and conductive polymers, often delaminate from textile substrates during standard washing cycles.

Studies by Wang et al. (2021) demonstrated that biofuel cells with screen-printed carbon electrodes on polyester fabrics retained only 65% of their initial power output after five washing cycles using standard detergents. This performance decline is primarily attributed to the mechanical stress during agitation and the chemical interactions between electrode materials and washing agents.

Several approaches are being explored to enhance durability. Encapsulation techniques using waterproof yet breathable membranes have shown promise in protecting electrodes while maintaining access to biofluids. For instance, Gore-Tex-like materials with selective permeability have been utilized to shield electrodes while allowing sweat to reach the reactive surfaces. These membranes demonstrated 85% performance retention after ten washing cycles in laboratory tests.

Another innovative approach involves the development of intrinsically washable electrode materials. Researchers at MIT have pioneered conductive fibers with enzyme immobilization that can be directly woven into fabrics, creating seamless integration that withstands mechanical stress. These fibers maintained structural integrity after 20 washing cycles, though enzymatic activity gradually decreased to approximately 70% of initial levels.

Surface modification techniques also show potential for improving electrode adhesion to textiles. Plasma treatment of fabric surfaces before electrode deposition has been shown to enhance bonding strength by creating functional groups that form stronger interfaces with electrode materials. This technique improved washing durability by approximately 40% compared to untreated fabrics in recent studies.

The development of self-healing electrode materials represents another frontier in addressing durability concerns. These materials contain microcapsules with conductive components that release upon mechanical damage, automatically restoring electrical pathways. While still in early development stages, preliminary results show promising self-recovery capabilities after simulated washing conditions.

Industry standards for testing washability of electronic textiles are still evolving, with ISO 6330 being adapted specifically for e-textiles. However, standardized protocols for biofuel cell-specific testing remain underdeveloped, creating challenges for comparative analysis across different research efforts and commercial developments.