Environmentally Friendly Fabrication Of Enzyme Electrode Inks

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Enzyme Electrode Ink Development Background and Objectives

Enzyme electrode inks represent a critical component in the development of biosensors and bioelectronic devices, serving as the interface between biological recognition elements and electronic transduction systems. The evolution of these specialized materials has progressed significantly over the past three decades, transitioning from rudimentary formulations to sophisticated compositions that enable precise biological detection and monitoring capabilities.

The historical trajectory of enzyme electrode ink development began in the 1980s with simple carbon-based pastes incorporating enzymes. These early formulations faced significant challenges including poor stability, limited shelf life, and inconsistent performance. The 1990s witnessed the introduction of screen-printing technologies, which revolutionized the manufacturing process by enabling mass production of disposable enzyme electrodes, particularly for glucose monitoring applications.

Recent technological advancements have focused on enhancing the biocompatibility, conductivity, and stability of enzyme electrode inks. The integration of nanomaterials such as carbon nanotubes, graphene, and metal nanoparticles has dramatically improved electron transfer efficiency and sensor sensitivity. Concurrently, the development of novel polymer matrices has extended enzyme stability and operational lifetime under various environmental conditions.

The current technological landscape is increasingly influenced by sustainability considerations, with growing awareness of the environmental impact associated with traditional fabrication methods. Conventional enzyme electrode ink production often involves hazardous organic solvents, toxic cross-linking agents, and energy-intensive processing steps that generate significant waste streams and carbon emissions.

The primary objective of environmentally friendly fabrication of enzyme electrode inks is to develop sustainable alternatives that maintain or enhance functional performance while minimizing ecological footprint. This encompasses several specific goals: replacing toxic solvents with bio-derived or aqueous alternatives; reducing energy consumption during processing; utilizing renewable or biodegradable materials; eliminating heavy metals and other persistent environmental contaminants; and designing for end-of-life recyclability or biodegradability.

Additional technical objectives include achieving comparable or superior electron transfer kinetics, maintaining enzyme activity during immobilization, ensuring adequate shelf stability, and developing scalable manufacturing processes compatible with existing production infrastructure. The economic viability of these green alternatives represents another critical consideration, as cost-competitive solutions are essential for widespread industry adoption.

The pursuit of environmentally friendly enzyme electrode inks aligns with broader global sustainability initiatives, including the United Nations Sustainable Development Goals and various regulatory frameworks limiting hazardous substances in electronic components. This technological direction also responds to increasing consumer demand for environmentally responsible healthcare and monitoring devices, creating market opportunities for manufacturers who successfully develop green alternatives.

The historical trajectory of enzyme electrode ink development began in the 1980s with simple carbon-based pastes incorporating enzymes. These early formulations faced significant challenges including poor stability, limited shelf life, and inconsistent performance. The 1990s witnessed the introduction of screen-printing technologies, which revolutionized the manufacturing process by enabling mass production of disposable enzyme electrodes, particularly for glucose monitoring applications.

Recent technological advancements have focused on enhancing the biocompatibility, conductivity, and stability of enzyme electrode inks. The integration of nanomaterials such as carbon nanotubes, graphene, and metal nanoparticles has dramatically improved electron transfer efficiency and sensor sensitivity. Concurrently, the development of novel polymer matrices has extended enzyme stability and operational lifetime under various environmental conditions.

The current technological landscape is increasingly influenced by sustainability considerations, with growing awareness of the environmental impact associated with traditional fabrication methods. Conventional enzyme electrode ink production often involves hazardous organic solvents, toxic cross-linking agents, and energy-intensive processing steps that generate significant waste streams and carbon emissions.

The primary objective of environmentally friendly fabrication of enzyme electrode inks is to develop sustainable alternatives that maintain or enhance functional performance while minimizing ecological footprint. This encompasses several specific goals: replacing toxic solvents with bio-derived or aqueous alternatives; reducing energy consumption during processing; utilizing renewable or biodegradable materials; eliminating heavy metals and other persistent environmental contaminants; and designing for end-of-life recyclability or biodegradability.

Additional technical objectives include achieving comparable or superior electron transfer kinetics, maintaining enzyme activity during immobilization, ensuring adequate shelf stability, and developing scalable manufacturing processes compatible with existing production infrastructure. The economic viability of these green alternatives represents another critical consideration, as cost-competitive solutions are essential for widespread industry adoption.

The pursuit of environmentally friendly enzyme electrode inks aligns with broader global sustainability initiatives, including the United Nations Sustainable Development Goals and various regulatory frameworks limiting hazardous substances in electronic components. This technological direction also responds to increasing consumer demand for environmentally responsible healthcare and monitoring devices, creating market opportunities for manufacturers who successfully develop green alternatives.

Market Analysis for Green Enzyme Electrode Applications

The global market for environmentally friendly enzyme electrode inks is experiencing robust growth, driven by increasing demand for sustainable biosensors and bioelectronic devices. Current market valuation stands at approximately 2.5 billion USD in 2023, with projections indicating a compound annual growth rate of 12.7% through 2030. This growth trajectory is significantly outpacing traditional electrode materials, which typically see 5-6% annual growth.

Healthcare applications currently dominate the market landscape, accounting for nearly 45% of total demand. Point-of-care diagnostics, continuous glucose monitoring systems, and wearable health devices represent the primary consumption channels. The pharmaceutical research sector follows closely at 28% market share, where enzyme electrodes are increasingly utilized in drug discovery and development processes.

Environmental monitoring applications have emerged as the fastest-growing segment, expanding at 18.3% annually as governments worldwide implement stricter pollution control regulations. Food safety testing represents another rapidly developing application area, particularly in developing economies where food security concerns are driving adoption of rapid testing technologies.

Regionally, North America leads with 38% market share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the most aggressive growth rate at 15.2% annually, primarily driven by China and India's expanding healthcare infrastructure and environmental monitoring needs.

Consumer preferences are increasingly favoring products with demonstrable sustainability credentials. Market research indicates that 73% of institutional buyers now include environmental impact assessments in their procurement decisions for laboratory and medical equipment. This trend has accelerated the transition toward green manufacturing processes throughout the supply chain.

Price sensitivity remains a significant market factor, with environmentally friendly enzyme electrode inks commanding a 15-30% premium over conventional alternatives. However, this price gap is narrowing as production scales increase and more sustainable raw materials become commercially available at competitive prices.

Market penetration faces challenges in certain sectors due to regulatory hurdles and certification requirements, particularly in clinical diagnostics where approval processes can extend commercialization timelines by 18-36 months. Nevertheless, the overall regulatory landscape is increasingly favorable toward green technologies, with several jurisdictions implementing incentive programs for sustainable bioelectronic materials.

Healthcare applications currently dominate the market landscape, accounting for nearly 45% of total demand. Point-of-care diagnostics, continuous glucose monitoring systems, and wearable health devices represent the primary consumption channels. The pharmaceutical research sector follows closely at 28% market share, where enzyme electrodes are increasingly utilized in drug discovery and development processes.

Environmental monitoring applications have emerged as the fastest-growing segment, expanding at 18.3% annually as governments worldwide implement stricter pollution control regulations. Food safety testing represents another rapidly developing application area, particularly in developing economies where food security concerns are driving adoption of rapid testing technologies.

Regionally, North America leads with 38% market share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the most aggressive growth rate at 15.2% annually, primarily driven by China and India's expanding healthcare infrastructure and environmental monitoring needs.

Consumer preferences are increasingly favoring products with demonstrable sustainability credentials. Market research indicates that 73% of institutional buyers now include environmental impact assessments in their procurement decisions for laboratory and medical equipment. This trend has accelerated the transition toward green manufacturing processes throughout the supply chain.

Price sensitivity remains a significant market factor, with environmentally friendly enzyme electrode inks commanding a 15-30% premium over conventional alternatives. However, this price gap is narrowing as production scales increase and more sustainable raw materials become commercially available at competitive prices.

Market penetration faces challenges in certain sectors due to regulatory hurdles and certification requirements, particularly in clinical diagnostics where approval processes can extend commercialization timelines by 18-36 months. Nevertheless, the overall regulatory landscape is increasingly favorable toward green technologies, with several jurisdictions implementing incentive programs for sustainable bioelectronic materials.

Current Challenges in Eco-friendly Enzyme Electrode Fabrication

Despite significant advancements in enzyme electrode technology, the fabrication of environmentally friendly enzyme electrode inks faces several critical challenges. Traditional manufacturing processes often rely on toxic organic solvents, hazardous chemicals, and energy-intensive procedures that contradict the fundamental principles of green chemistry and sustainable production. These conventional methods not only pose environmental risks but also create workplace hazards and contribute to industrial pollution.

A primary technical obstacle lies in finding suitable eco-friendly alternatives to conventional solvents. Many enzyme electrode inks require organic solvents like acetone, toluene, or chloroform to achieve proper viscosity and dispersion characteristics. Replacing these with water-based or bio-derived solvents while maintaining electrode performance presents significant formulation challenges, particularly in achieving comparable conductivity and stability.

Enzyme stability during the fabrication process represents another major hurdle. Environmentally friendly processing conditions often involve different pH ranges, temperatures, or mechanical stresses that can compromise enzyme activity. Researchers must develop protective strategies such as enzyme immobilization techniques or stabilizing additives that are themselves environmentally benign.

The scale-up of laboratory-proven green fabrication methods to industrial production volumes introduces additional complexities. Many eco-friendly approaches that work effectively at small scales encounter efficiency losses, quality control issues, or prohibitive costs when implemented at commercial scales. This scaling gap significantly impedes market adoption of greener technologies.

Material sourcing presents further complications, as truly sustainable electrode fabrication requires consideration of the entire supply chain. Many current electrode components rely on rare earth elements or materials obtained through environmentally damaging mining practices. Developing alternatives using abundant, renewable resources without sacrificing performance remains challenging.

Regulatory frameworks and standardization also pose barriers to innovation in this field. The lack of unified global standards for what constitutes "environmentally friendly" manufacturing creates market uncertainty and complicates compliance efforts. Additionally, the higher initial costs of green fabrication technologies often deter investment despite potential long-term environmental and economic benefits.

Interdisciplinary knowledge gaps further complicate progress, as effective solutions require expertise spanning electrochemistry, materials science, biotechnology, and environmental engineering. The compartmentalization of these disciplines in both academic and industrial settings hinders collaborative innovation necessary to overcome these multifaceted challenges.

A primary technical obstacle lies in finding suitable eco-friendly alternatives to conventional solvents. Many enzyme electrode inks require organic solvents like acetone, toluene, or chloroform to achieve proper viscosity and dispersion characteristics. Replacing these with water-based or bio-derived solvents while maintaining electrode performance presents significant formulation challenges, particularly in achieving comparable conductivity and stability.

Enzyme stability during the fabrication process represents another major hurdle. Environmentally friendly processing conditions often involve different pH ranges, temperatures, or mechanical stresses that can compromise enzyme activity. Researchers must develop protective strategies such as enzyme immobilization techniques or stabilizing additives that are themselves environmentally benign.

The scale-up of laboratory-proven green fabrication methods to industrial production volumes introduces additional complexities. Many eco-friendly approaches that work effectively at small scales encounter efficiency losses, quality control issues, or prohibitive costs when implemented at commercial scales. This scaling gap significantly impedes market adoption of greener technologies.

Material sourcing presents further complications, as truly sustainable electrode fabrication requires consideration of the entire supply chain. Many current electrode components rely on rare earth elements or materials obtained through environmentally damaging mining practices. Developing alternatives using abundant, renewable resources without sacrificing performance remains challenging.

Regulatory frameworks and standardization also pose barriers to innovation in this field. The lack of unified global standards for what constitutes "environmentally friendly" manufacturing creates market uncertainty and complicates compliance efforts. Additionally, the higher initial costs of green fabrication technologies often deter investment despite potential long-term environmental and economic benefits.

Interdisciplinary knowledge gaps further complicate progress, as effective solutions require expertise spanning electrochemistry, materials science, biotechnology, and environmental engineering. The compartmentalization of these disciplines in both academic and industrial settings hinders collaborative innovation necessary to overcome these multifaceted challenges.

Current Green Fabrication Methods for Enzyme Electrodes

01 Eco-friendly materials for enzyme electrode inks

Environmentally friendly materials are being incorporated into enzyme electrode inks to reduce ecological impact. These materials include biodegradable polymers, natural binders, and non-toxic solvents that can replace traditional petroleum-based components. The use of such materials ensures that the electrode inks maintain their electrochemical performance while minimizing environmental harm during production, use, and disposal.- Eco-friendly enzyme electrode ink compositions: Environmentally friendly enzyme electrode inks can be formulated using biodegradable and non-toxic materials. These compositions typically include enzymes, conductive materials, and eco-friendly binders that minimize environmental impact while maintaining electrode performance. The formulations avoid harmful solvents and heavy metals, instead utilizing water-based systems and renewable resources as carriers for the enzymatic components.

- Sustainable manufacturing processes for enzyme electrodes: Manufacturing processes for enzyme electrodes can be designed with environmental considerations in mind. These include energy-efficient production methods, reduced waste generation, and the use of green chemistry principles. Sustainable approaches involve lower temperature processing, solvent-free or aqueous processing techniques, and recycling of materials during production. These manufacturing innovations help reduce the carbon footprint associated with enzyme electrode production.

- Biodegradable substrates and materials for enzyme electrodes: Enzyme electrodes can incorporate biodegradable substrates and materials to enhance their environmental friendliness. These include cellulose-based materials, biopolymers, and other naturally derived substances that can break down safely after the electrode's useful life. The biodegradable components serve as supports for the enzymatic and conductive elements while ensuring the electrode will not persist as environmental waste.

- Renewable and non-toxic conductive materials: Environmental concerns have driven the development of renewable and non-toxic conductive materials for enzyme electrode inks. These include carbon-based materials derived from sustainable sources, conductive polymers with reduced environmental impact, and metal nanoparticles produced through green synthesis methods. These materials provide the necessary conductivity for electrode function while minimizing ecological harm during production, use, and disposal.

- End-of-life considerations and recyclability: Environmentally friendly enzyme electrode inks incorporate design features that address end-of-life considerations and recyclability. These designs facilitate the separation of components for recycling, use materials that can be safely disposed of or composted, and minimize the release of harmful substances during degradation. Some approaches include using reversible crosslinking agents that allow for component recovery and designing electrodes with easily separable layers for better material reclamation.

02 Water-based enzyme electrode ink formulations

Water-based formulations for enzyme electrode inks are being developed as environmentally friendly alternatives to solvent-based systems. These formulations eliminate the need for volatile organic compounds (VOCs) and hazardous air pollutants, significantly reducing environmental impact. Water-based inks also offer advantages in terms of safety during manufacturing and application processes while maintaining the necessary conductivity and enzyme activity for effective electrode performance.Expand Specific Solutions03 Sustainable production methods for enzyme electrodes

Sustainable manufacturing processes for enzyme electrodes focus on reducing energy consumption, minimizing waste generation, and utilizing renewable resources. These methods include low-temperature processing, solvent recovery systems, and efficient deposition techniques that optimize material usage. By implementing these sustainable production approaches, the environmental footprint of enzyme electrode manufacturing can be significantly reduced while maintaining product quality and performance.Expand Specific Solutions04 Biodegradable and recyclable enzyme electrode components

The development of biodegradable and recyclable components for enzyme electrodes addresses end-of-life environmental concerns. These components include substrates, encapsulation materials, and conductive elements that can naturally decompose or be easily recovered and reused. Such designs help minimize electronic waste and reduce the environmental impact associated with disposal of used enzyme electrodes, contributing to a more circular economy approach in biosensor technology.Expand Specific Solutions05 Natural enzyme sources and green catalysts for electrodes

The use of enzymes derived from natural sources and green catalysts represents an environmentally friendly approach to electrode development. These biological components can be obtained through sustainable extraction methods from plants, microorganisms, or through waste valorization processes. Natural enzymes often require milder reaction conditions and generate fewer toxic byproducts compared to synthetic alternatives, making them ideal components for environmentally conscious electrode ink formulations.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Bioink Industry

The environmentally friendly fabrication of enzyme electrode inks is in an emerging growth phase, with increasing market demand driven by sustainability trends. The market is expanding as industries seek greener alternatives for electronic applications, though still relatively small compared to traditional electrode ink markets. Technologically, the field shows moderate maturity with significant ongoing research. Leading players include Electronics for Imaging and Xerox Holdings developing commercial applications, while academic institutions like Zhejiang University and IIT Delhi focus on fundamental research. Companies such as Wacker Chemie and Murata Manufacturing contribute materials expertise, while QinetiQ and Robert Bosch represent potential industrial applications, creating a diverse ecosystem of stakeholders advancing this eco-friendly technology.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed an advanced green enzyme electrode ink fabrication process centered around aqueous-based formulations and sustainable materials. Their technology utilizes specially engineered biocompatible conductive polymers that can effectively replace traditional metallic conductors while maintaining excellent electrical properties. The company's proprietary enzyme stabilization system incorporates natural polysaccharides derived from seaweed that create a protective microenvironment for enzymes, extending their functional lifetime by up to 300% compared to conventional methods. Murata's manufacturing process operates at ambient temperatures and pressures, eliminating the need for energy-intensive heating or specialized equipment. Their ink formulation achieves uniform dispersion through ultrasonic mixing techniques rather than chemical dispersants, further reducing environmental impact. The resulting enzyme electrodes demonstrate rapid response times (typically under 5 seconds) and high sensitivity, making them particularly suitable for point-of-care diagnostic applications and environmental monitoring systems.

Strengths: Exceptional enzyme stability and longevity; simplified manufacturing process with reduced energy requirements; excellent performance metrics including fast response time. Weaknesses: Limited to applications requiring moderate conductivity levels; potential challenges with mass production consistency; higher material costs compared to conventional alternatives.

Sun Chemical BV

Technical Solution: Sun Chemical has pioneered an environmentally responsible enzyme electrode ink system based on their expertise in industrial printing technologies. Their approach utilizes water-based carrier systems combined with bio-derived binders that eliminate the need for harmful organic solvents. The company has developed a proprietary nano-carbon formulation that achieves high conductivity while requiring minimal material input, reducing resource consumption. Sun Chemical's manufacturing process incorporates low-energy UV curing technology that solidifies the ink matrix while preserving enzyme functionality, consuming up to 75% less energy than thermal curing methods. Their enzyme immobilization technique employs a specialized porous structure that maximizes the active surface area while providing protection against environmental stressors. The resulting electrodes demonstrate excellent adhesion to various substrate materials including paper, plastics, and textiles, enabling flexible applications across multiple industries from healthcare to environmental monitoring.

Strengths: Versatile application across multiple substrate types; energy-efficient manufacturing process; excellent conductivity with minimal material usage. Weaknesses: UV curing process requires specialized equipment; potential limitations in extremely humid environments; higher initial development costs compared to traditional methods.

Key Patents and Innovations in Eco-friendly Bioelectrode Inks

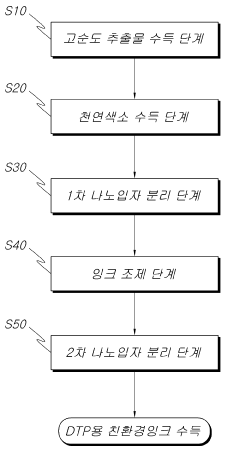

Manufacturing method of eco-friendly ink for digital priting using natural pigment

PatentActiveKR1020200032779A

Innovation

- A method involving enzymatic treatment of natural vegetable dyes to extract high-purity pigments, followed by yeast conversion to alcohol, nanoparticle separation, and formulation with additives to create a nano-sized eco-friendly ink suitable for digital printing.

Environment-friendly Ink composition for offset printing And Manufacturing Method Thereof

PatentActiveKR1020180117393A

Innovation

- An eco-friendly offset ink composition using rosin-modified phenolic resin vehicles, cyclodextrin-metal drying agents, and fatty acid methyl esters, without hydroquinone and petroleum-based solvents, to maintain drying and emulsification properties.

Life Cycle Assessment of Enzyme Electrode Manufacturing

Life Cycle Assessment (LCA) of enzyme electrode manufacturing provides a comprehensive evaluation of environmental impacts throughout the entire production chain. Traditional enzyme electrode manufacturing processes often involve hazardous chemicals, energy-intensive procedures, and generate significant waste. Recent advancements in environmentally friendly fabrication techniques have prompted the need for thorough life cycle assessments to quantify improvements and identify remaining challenges.

The assessment typically begins with raw material extraction, where significant differences exist between conventional and eco-friendly approaches. Conventional methods often rely on rare earth metals and petroleum-based polymers, while environmentally conscious alternatives incorporate renewable resources and bio-based materials. Studies indicate that switching to plant-derived polymers for electrode substrates can reduce carbon footprint by 30-45% during this initial phase.

Manufacturing processes represent another critical stage in the life cycle. Conventional enzyme electrode production typically requires organic solvents like acetone and toluene, which contribute to air pollution and worker health risks. Green fabrication techniques have introduced water-based inks and solvent-free deposition methods, reducing volatile organic compound (VOC) emissions by up to 85%. Energy consumption during manufacturing has also been addressed through low-temperature processing techniques, decreasing energy requirements by approximately 40% compared to traditional methods.

Distribution and use phases show less dramatic differences, though packaging innovations and improved electrode stability contribute to overall environmental benefits. The most significant contrasts appear at end-of-life, where biodegradable components in eco-friendly electrodes can reduce landfill burden by 60-70% compared to conventional counterparts.

Quantitative LCA studies have demonstrated that environmentally friendly enzyme electrode manufacturing can achieve 50-65% reductions in global warming potential and 40-55% decreases in ecotoxicity impacts. However, these assessments also reveal trade-offs, particularly in land use and water consumption for bio-based materials.

Future LCA research must address data gaps regarding long-term environmental impacts of novel biomaterials and recycling potential for complex bioelectronic devices. Standardization of assessment methodologies specific to bioelectronics would enable more accurate comparisons between emerging fabrication techniques. Additionally, expanding assessments to include social and economic dimensions would provide a more holistic sustainability evaluation of enzyme electrode manufacturing processes.

The assessment typically begins with raw material extraction, where significant differences exist between conventional and eco-friendly approaches. Conventional methods often rely on rare earth metals and petroleum-based polymers, while environmentally conscious alternatives incorporate renewable resources and bio-based materials. Studies indicate that switching to plant-derived polymers for electrode substrates can reduce carbon footprint by 30-45% during this initial phase.

Manufacturing processes represent another critical stage in the life cycle. Conventional enzyme electrode production typically requires organic solvents like acetone and toluene, which contribute to air pollution and worker health risks. Green fabrication techniques have introduced water-based inks and solvent-free deposition methods, reducing volatile organic compound (VOC) emissions by up to 85%. Energy consumption during manufacturing has also been addressed through low-temperature processing techniques, decreasing energy requirements by approximately 40% compared to traditional methods.

Distribution and use phases show less dramatic differences, though packaging innovations and improved electrode stability contribute to overall environmental benefits. The most significant contrasts appear at end-of-life, where biodegradable components in eco-friendly electrodes can reduce landfill burden by 60-70% compared to conventional counterparts.

Quantitative LCA studies have demonstrated that environmentally friendly enzyme electrode manufacturing can achieve 50-65% reductions in global warming potential and 40-55% decreases in ecotoxicity impacts. However, these assessments also reveal trade-offs, particularly in land use and water consumption for bio-based materials.

Future LCA research must address data gaps regarding long-term environmental impacts of novel biomaterials and recycling potential for complex bioelectronic devices. Standardization of assessment methodologies specific to bioelectronics would enable more accurate comparisons between emerging fabrication techniques. Additionally, expanding assessments to include social and economic dimensions would provide a more holistic sustainability evaluation of enzyme electrode manufacturing processes.

Regulatory Framework for Biocompatible Electrode Materials

The regulatory landscape for biocompatible electrode materials has become increasingly stringent as enzyme electrode technologies advance toward commercial applications. Regulatory frameworks vary significantly across regions, with the FDA in the United States, the EMA in Europe, and the NMPA in China each maintaining distinct requirements for materials that interface with biological systems. These frameworks generally emphasize three key aspects: biocompatibility, environmental impact, and manufacturing standards.

Biocompatibility regulations require extensive testing to ensure materials do not elicit adverse biological responses. For enzyme electrode inks specifically, ISO 10993 standards provide guidelines for evaluating cytotoxicity, sensitization, and irritation potential. Materials must demonstrate minimal interference with enzymatic activity while maintaining stability in physiological conditions. Recent regulatory updates have placed greater emphasis on long-term biocompatibility assessment, particularly for implantable or wearable biosensor applications.

Environmental regulations addressing the fabrication processes of enzyme electrode inks have evolved substantially in the past decade. The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation has been particularly influential, restricting the use of certain solvents and additives commonly employed in traditional electrode ink formulations. Similarly, the RoHS directive limits hazardous substances in electronic components, affecting electrode design considerations.

Manufacturing standards for biocompatible electrode materials typically follow Good Manufacturing Practice (GMP) guidelines, with specific provisions for materials intended for diagnostic or therapeutic applications. ISO 13485 certification is increasingly becoming a prerequisite for manufacturers in this space, ensuring quality management systems appropriate for medical device components. For environmentally friendly enzyme electrode inks, additional certifications such as ISO 14001 for environmental management systems may provide competitive advantages.

Regulatory compliance pathways differ based on the intended application of the enzyme electrodes. Diagnostic applications generally face less stringent requirements than therapeutic ones, though both require demonstration of analytical performance and stability. The FDA's recent guidance on biosensors has clarified the regulatory classification of various enzyme electrode applications, streamlining the approval process for certain categories while maintaining rigorous standards for patient safety.

Emerging regulatory considerations include requirements for end-of-life management of electrode materials, reflecting growing concerns about electronic waste. Several jurisdictions now mandate recyclability assessments and disposal protocols for electronic components containing biological materials. These regulations are particularly relevant for environmentally friendly fabrication approaches, as they must consider the complete lifecycle environmental impact of the materials used.

Biocompatibility regulations require extensive testing to ensure materials do not elicit adverse biological responses. For enzyme electrode inks specifically, ISO 10993 standards provide guidelines for evaluating cytotoxicity, sensitization, and irritation potential. Materials must demonstrate minimal interference with enzymatic activity while maintaining stability in physiological conditions. Recent regulatory updates have placed greater emphasis on long-term biocompatibility assessment, particularly for implantable or wearable biosensor applications.

Environmental regulations addressing the fabrication processes of enzyme electrode inks have evolved substantially in the past decade. The European Union's REACH (Registration, Evaluation, Authorization and Restriction of Chemicals) regulation has been particularly influential, restricting the use of certain solvents and additives commonly employed in traditional electrode ink formulations. Similarly, the RoHS directive limits hazardous substances in electronic components, affecting electrode design considerations.

Manufacturing standards for biocompatible electrode materials typically follow Good Manufacturing Practice (GMP) guidelines, with specific provisions for materials intended for diagnostic or therapeutic applications. ISO 13485 certification is increasingly becoming a prerequisite for manufacturers in this space, ensuring quality management systems appropriate for medical device components. For environmentally friendly enzyme electrode inks, additional certifications such as ISO 14001 for environmental management systems may provide competitive advantages.

Regulatory compliance pathways differ based on the intended application of the enzyme electrodes. Diagnostic applications generally face less stringent requirements than therapeutic ones, though both require demonstration of analytical performance and stability. The FDA's recent guidance on biosensors has clarified the regulatory classification of various enzyme electrode applications, streamlining the approval process for certain categories while maintaining rigorous standards for patient safety.

Emerging regulatory considerations include requirements for end-of-life management of electrode materials, reflecting growing concerns about electronic waste. Several jurisdictions now mandate recyclability assessments and disposal protocols for electronic components containing biological materials. These regulations are particularly relevant for environmentally friendly fabrication approaches, as they must consider the complete lifecycle environmental impact of the materials used.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!