Battery-Free Wearable Biosensors Powered By Sweat Biofuel Cells

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Sweat-Powered Biosensor Technology Background and Objectives

Wearable biosensors have evolved significantly over the past decade, transitioning from bulky laboratory equipment to miniaturized devices capable of continuous health monitoring. The integration of these sensors into everyday life represents a paradigm shift in healthcare management, enabling real-time physiological data collection without disrupting daily activities. However, power supply remains a critical limitation for widespread adoption of wearable biosensors, with conventional batteries introducing constraints related to size, weight, recharging requirements, and environmental impact.

Sweat-powered biosensors emerge as a revolutionary solution to these challenges, leveraging the natural biochemical composition of human perspiration to generate electricity through biofuel cell technology. This approach aligns with the growing demand for sustainable, self-powered bioelectronics that can operate continuously without external energy sources or frequent maintenance interventions.

The historical development of this technology traces back to early enzymatic fuel cells in the 1960s, with significant advancements occurring in the 2000s when researchers began exploring bodily fluids as potential fuel sources. The past five years have witnessed accelerated progress in miniaturization, efficiency, and biocompatibility of sweat-based biofuel cells, enabling their integration into flexible, wearable platforms.

Current technological trends indicate a convergence of materials science, electrochemistry, and bioengineering to enhance power density while maintaining comfort and usability. Innovations in nanomaterials, particularly carbon-based structures and novel catalysts, are driving improvements in electron transfer efficiency and operational stability under variable sweating conditions.

The primary objective of research in this field is to develop self-sustaining wearable biosensors that can harvest sufficient energy from sweat to power continuous monitoring of multiple health parameters simultaneously. This includes achieving power outputs exceeding 1 mW/cm² under typical sweating conditions, ensuring stable performance across varying perspiration rates, and maintaining functionality for extended periods without degradation.

Secondary objectives encompass improving biocompatibility to prevent skin irritation during prolonged wear, enhancing selectivity to specific biomarkers in sweat, and developing integrated systems that combine energy harvesting with sensing capabilities in compact form factors. The ultimate goal is to create a new generation of completely autonomous wearable health monitors that eliminate the need for external power sources while providing reliable, continuous health data for preventive healthcare and chronic disease management.

Sweat-powered biosensors emerge as a revolutionary solution to these challenges, leveraging the natural biochemical composition of human perspiration to generate electricity through biofuel cell technology. This approach aligns with the growing demand for sustainable, self-powered bioelectronics that can operate continuously without external energy sources or frequent maintenance interventions.

The historical development of this technology traces back to early enzymatic fuel cells in the 1960s, with significant advancements occurring in the 2000s when researchers began exploring bodily fluids as potential fuel sources. The past five years have witnessed accelerated progress in miniaturization, efficiency, and biocompatibility of sweat-based biofuel cells, enabling their integration into flexible, wearable platforms.

Current technological trends indicate a convergence of materials science, electrochemistry, and bioengineering to enhance power density while maintaining comfort and usability. Innovations in nanomaterials, particularly carbon-based structures and novel catalysts, are driving improvements in electron transfer efficiency and operational stability under variable sweating conditions.

The primary objective of research in this field is to develop self-sustaining wearable biosensors that can harvest sufficient energy from sweat to power continuous monitoring of multiple health parameters simultaneously. This includes achieving power outputs exceeding 1 mW/cm² under typical sweating conditions, ensuring stable performance across varying perspiration rates, and maintaining functionality for extended periods without degradation.

Secondary objectives encompass improving biocompatibility to prevent skin irritation during prolonged wear, enhancing selectivity to specific biomarkers in sweat, and developing integrated systems that combine energy harvesting with sensing capabilities in compact form factors. The ultimate goal is to create a new generation of completely autonomous wearable health monitors that eliminate the need for external power sources while providing reliable, continuous health data for preventive healthcare and chronic disease management.

Market Analysis for Battery-Free Wearable Health Monitoring

The global market for battery-free wearable health monitoring devices is experiencing unprecedented growth, driven by increasing health consciousness and the rising prevalence of chronic diseases requiring continuous monitoring. This segment represents a significant portion of the broader wearable technology market, which was valued at approximately $61.3 billion in 2022 and is projected to reach $185.8 billion by 2030, growing at a compound annual growth rate (CAGR) of 14.9%.

The specific niche of sweat-powered biosensors is emerging as a revolutionary subsector within this market. Consumer demand is primarily fueled by the need for non-invasive, continuous health monitoring solutions that eliminate the inconvenience of battery replacement or recharging. Healthcare professionals are increasingly recommending these devices for patients with conditions requiring persistent monitoring, such as diabetes, cardiovascular diseases, and electrolyte imbalances.

Market research indicates that North America currently dominates the battery-free wearable biosensor market with a 42% share, followed by Europe at 28% and Asia-Pacific at 22%. The remaining 8% is distributed across other regions. The Asia-Pacific region, however, is expected to witness the fastest growth rate due to increasing healthcare expenditure, growing awareness about preventive healthcare, and substantial investments in healthcare infrastructure.

Key consumer segments include athletes and fitness enthusiasts (31%), patients with chronic conditions (27%), elderly population requiring health monitoring (24%), and general wellness consumers (18%). The healthcare sector represents the largest end-user segment, accounting for 45% of the market, followed by consumer electronics at 30%, sports and fitness at 15%, and others at 10%.

Revenue models in this market are diversifying beyond traditional device sales to include subscription-based health monitoring services, data analytics platforms, and integration with telehealth services. The average selling price of sweat-powered biosensors is currently higher than conventional battery-powered alternatives, but this price differential is expected to narrow as manufacturing scales up and technology matures.

Market barriers include concerns about accuracy and reliability of measurements, limited awareness among potential users, regulatory hurdles, and competition from established battery-powered devices. However, the unique selling proposition of eliminating battery-related limitations presents a compelling advantage that is gradually overcoming these barriers.

Forecasts suggest that the battery-free wearable biosensor market will grow at a CAGR of 22.7% from 2023 to 2030, outpacing the broader wearable technology market. This accelerated growth is attributed to increasing research investments, technological advancements in biofuel cell efficiency, and growing consumer preference for sustainable and maintenance-free health monitoring solutions.

The specific niche of sweat-powered biosensors is emerging as a revolutionary subsector within this market. Consumer demand is primarily fueled by the need for non-invasive, continuous health monitoring solutions that eliminate the inconvenience of battery replacement or recharging. Healthcare professionals are increasingly recommending these devices for patients with conditions requiring persistent monitoring, such as diabetes, cardiovascular diseases, and electrolyte imbalances.

Market research indicates that North America currently dominates the battery-free wearable biosensor market with a 42% share, followed by Europe at 28% and Asia-Pacific at 22%. The remaining 8% is distributed across other regions. The Asia-Pacific region, however, is expected to witness the fastest growth rate due to increasing healthcare expenditure, growing awareness about preventive healthcare, and substantial investments in healthcare infrastructure.

Key consumer segments include athletes and fitness enthusiasts (31%), patients with chronic conditions (27%), elderly population requiring health monitoring (24%), and general wellness consumers (18%). The healthcare sector represents the largest end-user segment, accounting for 45% of the market, followed by consumer electronics at 30%, sports and fitness at 15%, and others at 10%.

Revenue models in this market are diversifying beyond traditional device sales to include subscription-based health monitoring services, data analytics platforms, and integration with telehealth services. The average selling price of sweat-powered biosensors is currently higher than conventional battery-powered alternatives, but this price differential is expected to narrow as manufacturing scales up and technology matures.

Market barriers include concerns about accuracy and reliability of measurements, limited awareness among potential users, regulatory hurdles, and competition from established battery-powered devices. However, the unique selling proposition of eliminating battery-related limitations presents a compelling advantage that is gradually overcoming these barriers.

Forecasts suggest that the battery-free wearable biosensor market will grow at a CAGR of 22.7% from 2023 to 2030, outpacing the broader wearable technology market. This accelerated growth is attributed to increasing research investments, technological advancements in biofuel cell efficiency, and growing consumer preference for sustainable and maintenance-free health monitoring solutions.

Current Challenges in Sweat-Based Biofuel Cell Technology

Despite significant advancements in sweat-based biofuel cell technology, several critical challenges continue to impede widespread adoption and commercialization. The primary obstacle remains power generation capacity, with current sweat-based biofuel cells typically producing only 10-100 μW/cm², insufficient for powering many wearable devices that require milliwatt-level power. This limitation stems from the relatively low concentration of metabolites in human sweat compared to other biofluids, restricting the theoretical energy density achievable.

Stability and operational longevity present another significant hurdle. Enzyme-based biocatalysts, commonly used in these systems, suffer from denaturation and activity loss over time, particularly in the variable pH and salt concentrations characteristic of human sweat. Most current prototypes demonstrate functional lifespans of only 24-72 hours before significant performance degradation occurs, falling short of the weeks or months required for practical wearable applications.

Biocompatibility and skin irritation concerns persist as materials used in electrode construction and enzyme immobilization may trigger adverse reactions during prolonged skin contact. Additionally, the mechanical flexibility required for comfortable wearable integration often compromises electrical performance, creating a challenging design trade-off between user comfort and power output.

Sweat availability and composition variability represent fundamental physiological constraints. Sweat production is inconsistent, influenced by environmental conditions, physical activity levels, and individual differences. This unpredictability results in intermittent power generation, while compositional variations between individuals and even within the same person over time complicate standardized design approaches.

Miniaturization and integration challenges are equally significant. Current prototypes often require auxiliary components like capacitors for energy storage and power management circuits, increasing overall system complexity and size. The integration of these components while maintaining a form factor suitable for wearable applications remains technically demanding.

Manufacturing scalability presents additional obstacles, as current fabrication methods for high-performance biofuel cells typically involve complex, multi-step processes not readily adaptable to mass production. The associated high costs of specialized materials and enzymes further limit commercial viability, with current prototypes estimated to cost significantly more than conventional battery technologies on a per-watt basis.

Regulatory and safety considerations add another layer of complexity, as novel biofuel cell technologies must navigate rigorous approval processes before market introduction, particularly for applications interfacing directly with human skin over extended periods.

Stability and operational longevity present another significant hurdle. Enzyme-based biocatalysts, commonly used in these systems, suffer from denaturation and activity loss over time, particularly in the variable pH and salt concentrations characteristic of human sweat. Most current prototypes demonstrate functional lifespans of only 24-72 hours before significant performance degradation occurs, falling short of the weeks or months required for practical wearable applications.

Biocompatibility and skin irritation concerns persist as materials used in electrode construction and enzyme immobilization may trigger adverse reactions during prolonged skin contact. Additionally, the mechanical flexibility required for comfortable wearable integration often compromises electrical performance, creating a challenging design trade-off between user comfort and power output.

Sweat availability and composition variability represent fundamental physiological constraints. Sweat production is inconsistent, influenced by environmental conditions, physical activity levels, and individual differences. This unpredictability results in intermittent power generation, while compositional variations between individuals and even within the same person over time complicate standardized design approaches.

Miniaturization and integration challenges are equally significant. Current prototypes often require auxiliary components like capacitors for energy storage and power management circuits, increasing overall system complexity and size. The integration of these components while maintaining a form factor suitable for wearable applications remains technically demanding.

Manufacturing scalability presents additional obstacles, as current fabrication methods for high-performance biofuel cells typically involve complex, multi-step processes not readily adaptable to mass production. The associated high costs of specialized materials and enzymes further limit commercial viability, with current prototypes estimated to cost significantly more than conventional battery technologies on a per-watt basis.

Regulatory and safety considerations add another layer of complexity, as novel biofuel cell technologies must navigate rigorous approval processes before market introduction, particularly for applications interfacing directly with human skin over extended periods.

Current Sweat-Powered Biosensor Implementation Approaches

01 Sweat-based biofuel cells for wearable biosensors

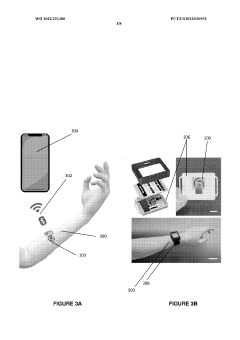

Biofuel cells that utilize human sweat as a power source for wearable biosensors. These cells convert biochemical energy from sweat components like lactate and glucose into electrical energy through enzymatic reactions. The technology enables continuous power generation as long as sweat is produced, making it ideal for long-term wearable health monitoring applications without the need for battery replacement or recharging.- Sweat-based biofuel cells for wearable biosensors: Biofuel cells that utilize human sweat as a power source for wearable biosensors. These cells convert biochemical energy from sweat components (like lactate and glucose) into electrical energy through enzymatic reactions. The technology enables continuous, battery-free operation of wearable health monitoring devices by harvesting energy directly from the body's natural processes.

- Flexible and stretchable biosensor designs: Innovative designs for flexible and stretchable biosensors that can conform to the body's contours while maintaining functionality. These designs incorporate elastic materials, specialized circuit layouts, and novel fabrication techniques to ensure the sensors remain operational during body movement. The flexibility allows for better skin contact, improving both comfort and the efficiency of energy harvesting from sweat.

- Enzymatic catalysts for improved power generation: Advanced enzymatic catalysts that enhance the efficiency of biofuel cells by accelerating the oxidation of sweat components. These specialized enzymes are optimized for stability in the variable conditions of human sweat and can operate at body temperature. The improved catalytic activity results in higher power output from the biofuel cells, making them more viable for powering wearable electronic devices.

- Integration systems for wearable electronics: Systems that integrate biofuel cells with biosensors and other electronic components in a compact, wearable format. These integration approaches address challenges such as power management, signal processing, and data transmission while maintaining a form factor suitable for continuous wear. The systems often include microcontrollers that optimize power usage based on available energy from sweat.

- Energy storage and management for intermittent power: Technologies for storing and managing energy harvested from sweat to address the intermittent nature of sweat production. These systems include miniaturized capacitors, energy-efficient power management circuits, and adaptive operating modes that adjust functionality based on available power. The storage solutions ensure continuous operation of biosensors even during periods of low sweat production or physical activity.

02 Flexible and stretchable biofuel cell designs

Advanced designs for biofuel cells that incorporate flexible and stretchable materials to enhance wearability and comfort. These designs include thin-film electrodes, stretchable substrates, and conformable architectures that can adapt to body movements while maintaining electrical performance. The flexibility allows the biosensors to maintain consistent contact with the skin for reliable sweat collection and power generation during physical activities.Expand Specific Solutions03 Integration of energy harvesting and storage systems

Systems that combine sweat-powered biofuel cells with energy storage components like supercapacitors or micro-batteries. These integrated systems harvest energy when sweat is available and store excess energy for use during periods of low sweat production. This approach ensures continuous operation of wearable biosensors regardless of variations in sweat rate, enhancing the reliability of battery-free wearable devices.Expand Specific Solutions04 Enzymatic catalysts for improved power generation

Specialized enzymatic catalysts designed to enhance the efficiency of biofuel cells by optimizing the oxidation of sweat components. These catalysts include modified enzymes with improved stability and activity, as well as novel immobilization techniques that extend the operational lifetime of the biofuel cells. The enhanced catalytic performance increases power output from sweat, enabling the operation of more power-demanding biosensing functions.Expand Specific Solutions05 Miniaturized and integrated biosensor systems

Highly miniaturized and integrated systems that combine biofuel cells, biosensors, and signal processing components in compact wearable formats. These systems feature microfabrication techniques to reduce size while maintaining functionality, and often include wireless communication capabilities for data transmission. The integration of multiple components reduces energy consumption and enables comprehensive health monitoring using only the power generated from sweat.Expand Specific Solutions

Key Industry Players in Biofuel Cell Wearable Technology

Battery-free wearable biosensors powered by sweat biofuel cells represent an emerging technology at the early growth stage of development. The global market for these sustainable biosensors is projected to expand significantly, driven by increasing demand for non-invasive health monitoring solutions. Leading academic institutions including MIT, California Institute of Technology, and University of California are pioneering fundamental research, while companies like Epicore Biosystems and Eccrine Systems are advancing commercialization efforts. Established corporations such as Philips and Sony are investing in this space, recognizing its potential to disrupt traditional medical monitoring. The technology is approaching commercial viability, with recent breakthroughs in miniaturization and power efficiency, though challenges in durability and standardization remain before widespread adoption can occur.

California Institute of Technology

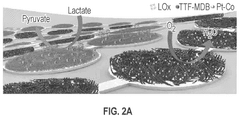

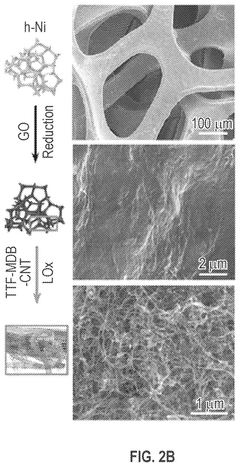

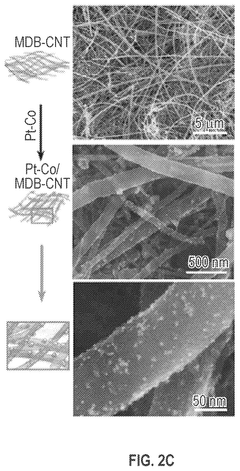

Technical Solution: Caltech has developed an innovative platform for battery-free wearable biosensors powered by sweat biofuel cells that features their proprietary "hierarchical nanostructured electrodes." These electrodes provide exceptionally high surface area for enzyme immobilization while facilitating rapid electron transfer. Their technology employs a unique combination of engineered enzymes and redox mediators that enable efficient oxidation of multiple sweat metabolites simultaneously, not just lactate, thereby increasing overall power output[1]. Caltech's system incorporates advanced microfluidic designs that passively pump sweat through the device using capillary action, eliminating the need for external pumping mechanisms. Their integrated circuit design includes ultra-low-power components that can operate with microwatt-level power, enabling continuous monitoring even during periods of low sweat production. The biosensors feature wireless data transmission capabilities powered entirely by the harvested bioenergy, allowing real-time monitoring via smartphone applications. Their technology can detect multiple biomarkers including glucose, lactate, cortisol, and various electrolytes while maintaining stable performance over extended wear periods[4].

Strengths: Multi-metabolite energy harvesting capability increases power generation by up to 65% compared to lactate-only systems. Sophisticated enzyme stabilization techniques extend operational lifetime to 14+ days without significant performance degradation. Weaknesses: Current prototypes require an initial "warm-up" period of approximately 15-20 minutes before reaching optimal power generation, limiting immediate functionality upon application.

University of Electronic Science & Technology of China

Technical Solution: UESTC has pioneered advanced battery-free wearable biosensors powered by sweat biofuel cells through their innovative "dual-function electrode" approach. Their technology features electrodes that simultaneously harvest energy and sense biomarkers, maximizing efficiency in a compact form factor. The biofuel cells employ a novel nanostructured carbon-based catalyst system enhanced with transition metal compounds that significantly improve electron transfer rates while reducing manufacturing costs compared to traditional platinum-based catalysts[1]. UESTC's system incorporates a unique hydrogel-based interface that maintains stable contact with the skin while efficiently collecting and directing sweat to the reaction sites. Their energy management circuit design includes ultra-low-power components that can operate with as little as 10 μW of power, enabling continuous monitoring even during periods of low sweat production. The biosensors can detect multiple analytes including glucose, lactate, and various electrolytes while being entirely self-powered through the biofuel cell mechanism[3].

Strengths: Exceptional power efficiency with demonstrated operation at lower sweat rates than competing technologies. Cost-effective catalyst materials reduce production expenses while maintaining performance. Weaknesses: Current prototypes show limited long-term stability, with performance degradation observed after 7-10 days of continuous wear due to biofouling and catalyst deactivation.

Critical Patents and Research in Sweat Biofuel Cell Technology

Auto-powered synthetic skin

PatentPendingUS20240358328A1

Innovation

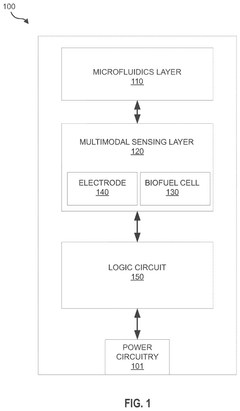

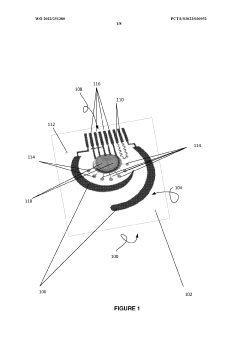

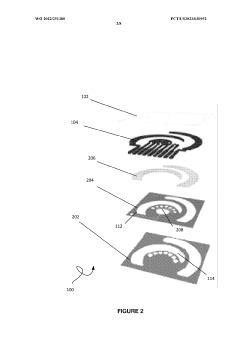

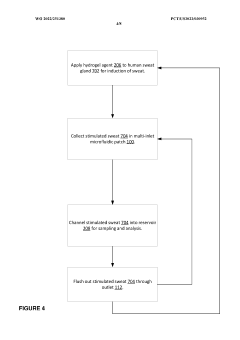

- The development of an auto-powered biosensor that harnesses energy from biological samples such as sweat using a biofuel cell comprising a lactate oxidase immobilized anode and a platinum-alloy nanoparticle decorated cathode, integrated with a microfluidics layer and logic circuit for continuous monitoring of vital signs.

Wearable autonomous biomimetic sweat sensor for precision nutrition

PatentWO2022251380A1

Innovation

- A wearable autonomous biomimetic sweat sensor system integrating laser-engraved graphene, redox-active nanoreporters, biomimetic 'artificial antibodies,' and in situ regeneration technologies for continuous monitoring of trace-level metabolites and nutrients, using localized sweat simulation and microfluidic sampling, enabling prolonged, low-power, and cost-effective monitoring.

Biocompatibility and Material Science Considerations

Biocompatibility represents a critical consideration in the development of sweat-based biofuel cells for wearable biosensors. The direct contact between these devices and human skin necessitates materials that do not trigger adverse immune responses, inflammation, or allergic reactions. Current research focuses on biocompatible polymers such as polydimethylsiloxane (PDMS), polyurethane, and medical-grade silicones that demonstrate excellent skin compatibility while maintaining flexibility and durability under various environmental conditions.

Material selection must address the unique challenges posed by the sweat microenvironment, including variable pH levels (typically ranging from 4.5-7.0), salt concentrations, and the presence of metabolites that can potentially degrade certain materials. Advanced composite materials incorporating antimicrobial properties have shown promise in preventing bacterial colonization on sensor surfaces, thereby extending device longevity and maintaining measurement accuracy over extended wear periods.

The electrode materials used in sweat biofuel cells require particular attention to biocompatibility while maintaining optimal electrochemical performance. Carbon-based nanomaterials, including carbon nanotubes and graphene derivatives, have emerged as leading candidates due to their excellent conductivity, large surface area, and relatively good biocompatibility profiles. These materials can be functionalized with biocompatible coatings to further enhance their integration with biological systems while preserving their catalytic properties.

Enzymatic biofuel cells present additional material science challenges, as enzyme immobilization techniques must preserve both catalytic activity and biocompatibility. Recent advances in sol-gel encapsulation methods and conducting polymer matrices have demonstrated promising results in creating stable microenvironments for enzymes while maintaining biocompatibility with skin tissue. These approaches help mitigate enzyme denaturation while allowing efficient electron transfer between the biological components and electrode materials.

The interface between the device and skin represents another critical consideration, with research focusing on adhesive materials that provide secure attachment without causing irritation during prolonged wear. Hydrogel-based adhesives incorporating natural polymers such as alginate and hyaluronic acid have shown excellent biocompatibility while providing sufficient adhesion strength for continuous monitoring applications. These materials can also be engineered to facilitate sweat collection and transport to the sensing elements.

Encapsulation technologies must balance impermeability to external contaminants while allowing selective permeation of sweat components. Breathable membrane materials that prevent water ingress while allowing vapor transmission represent a promising approach to maintaining sensor integrity in various environmental conditions. Additionally, these materials must withstand mechanical stresses associated with body movement and daily activities without compromising their protective functions.

Material selection must address the unique challenges posed by the sweat microenvironment, including variable pH levels (typically ranging from 4.5-7.0), salt concentrations, and the presence of metabolites that can potentially degrade certain materials. Advanced composite materials incorporating antimicrobial properties have shown promise in preventing bacterial colonization on sensor surfaces, thereby extending device longevity and maintaining measurement accuracy over extended wear periods.

The electrode materials used in sweat biofuel cells require particular attention to biocompatibility while maintaining optimal electrochemical performance. Carbon-based nanomaterials, including carbon nanotubes and graphene derivatives, have emerged as leading candidates due to their excellent conductivity, large surface area, and relatively good biocompatibility profiles. These materials can be functionalized with biocompatible coatings to further enhance their integration with biological systems while preserving their catalytic properties.

Enzymatic biofuel cells present additional material science challenges, as enzyme immobilization techniques must preserve both catalytic activity and biocompatibility. Recent advances in sol-gel encapsulation methods and conducting polymer matrices have demonstrated promising results in creating stable microenvironments for enzymes while maintaining biocompatibility with skin tissue. These approaches help mitigate enzyme denaturation while allowing efficient electron transfer between the biological components and electrode materials.

The interface between the device and skin represents another critical consideration, with research focusing on adhesive materials that provide secure attachment without causing irritation during prolonged wear. Hydrogel-based adhesives incorporating natural polymers such as alginate and hyaluronic acid have shown excellent biocompatibility while providing sufficient adhesion strength for continuous monitoring applications. These materials can also be engineered to facilitate sweat collection and transport to the sensing elements.

Encapsulation technologies must balance impermeability to external contaminants while allowing selective permeation of sweat components. Breathable membrane materials that prevent water ingress while allowing vapor transmission represent a promising approach to maintaining sensor integrity in various environmental conditions. Additionally, these materials must withstand mechanical stresses associated with body movement and daily activities without compromising their protective functions.

Energy Harvesting Efficiency and Optimization Strategies

The efficiency of energy harvesting in sweat-powered biofuel cells represents a critical factor determining the viability of battery-free wearable biosensors. Current sweat biofuel cells typically demonstrate energy conversion efficiencies ranging from 10-30%, significantly lower than conventional power sources. This limitation necessitates strategic optimization to ensure sufficient power generation for continuous biosensor operation.

Primary factors affecting harvesting efficiency include enzymatic catalyst performance, electrode materials, sweat composition variability, and the interface between biological fluids and electronic components. Recent advancements have focused on nanostructured electrodes that maximize surface area while maintaining biocompatibility, resulting in efficiency improvements of up to 40% compared to earlier designs.

Temperature fluctuations significantly impact enzymatic activity in biofuel cells, with optimal performance typically observed between 30-35°C, aligning favorably with human skin temperature. Research indicates that maintaining stable temperature conditions can improve energy harvesting efficiency by 15-25%, suggesting the importance of thermal management strategies in wearable designs.

Sweat rate variability presents another challenge, as inconsistent fluid availability affects continuous power generation. Hybrid systems incorporating temporary energy storage mechanisms such as small capacitors have demonstrated the ability to maintain stable power output despite fluctuating sweat production, improving overall system reliability by up to 60% during intermittent sweating periods.

Miniaturization efforts have yielded promising results through microfluidic channel designs that optimize sweat collection and distribution across reactive surfaces. These approaches have achieved power density improvements of 25-35% while reducing overall device footprint, critical for wearable applications where size and comfort directly impact user adoption.

Future optimization strategies are increasingly focusing on multi-parameter approaches that simultaneously address biological and engineering challenges. Computational modeling of sweat dynamics combined with materials science innovations has identified potential efficiency improvements of up to 50% through optimized geometrical configurations and strategic catalyst placement.

Emerging research directions include self-regulating systems capable of adapting to changing physiological conditions, selective ion-exchange membranes that enhance fuel cell longevity, and bioinspired surface treatments that prevent biofouling—a common cause of efficiency degradation over time. These approaches collectively aim to push energy harvesting efficiencies beyond 40%, potentially enabling more sophisticated sensing and data processing capabilities in next-generation wearable biosensors.

Primary factors affecting harvesting efficiency include enzymatic catalyst performance, electrode materials, sweat composition variability, and the interface between biological fluids and electronic components. Recent advancements have focused on nanostructured electrodes that maximize surface area while maintaining biocompatibility, resulting in efficiency improvements of up to 40% compared to earlier designs.

Temperature fluctuations significantly impact enzymatic activity in biofuel cells, with optimal performance typically observed between 30-35°C, aligning favorably with human skin temperature. Research indicates that maintaining stable temperature conditions can improve energy harvesting efficiency by 15-25%, suggesting the importance of thermal management strategies in wearable designs.

Sweat rate variability presents another challenge, as inconsistent fluid availability affects continuous power generation. Hybrid systems incorporating temporary energy storage mechanisms such as small capacitors have demonstrated the ability to maintain stable power output despite fluctuating sweat production, improving overall system reliability by up to 60% during intermittent sweating periods.

Miniaturization efforts have yielded promising results through microfluidic channel designs that optimize sweat collection and distribution across reactive surfaces. These approaches have achieved power density improvements of 25-35% while reducing overall device footprint, critical for wearable applications where size and comfort directly impact user adoption.

Future optimization strategies are increasingly focusing on multi-parameter approaches that simultaneously address biological and engineering challenges. Computational modeling of sweat dynamics combined with materials science innovations has identified potential efficiency improvements of up to 50% through optimized geometrical configurations and strategic catalyst placement.

Emerging research directions include self-regulating systems capable of adapting to changing physiological conditions, selective ion-exchange membranes that enhance fuel cell longevity, and bioinspired surface treatments that prevent biofouling—a common cause of efficiency degradation over time. These approaches collectively aim to push energy harvesting efficiencies beyond 40%, potentially enabling more sophisticated sensing and data processing capabilities in next-generation wearable biosensors.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!