Flexible Connectors And Interconnects For Textile Harvesters

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Flexible Connector Technology Background and Objectives

Flexible connectors and interconnects represent a critical technological component in the rapidly evolving field of textile energy harvesting. The development of these technologies can be traced back to the early 2000s when researchers began exploring ways to integrate electronic functionality into textiles. Initially, rigid connectors were adapted for textile applications, but these solutions proved inadequate due to their lack of durability during repeated mechanical deformation and washing cycles.

The evolution of flexible connector technology has been driven by the convergence of multiple disciplines, including materials science, electrical engineering, and textile manufacturing. Key milestones include the development of conductive polymers in the 1990s, stretchable electronics in the 2000s, and more recently, the emergence of liquid metal alloys and nanomaterial-based interconnects that maintain conductivity under extreme deformation.

Current technological trends point toward increasingly seamless integration between electronic components and textile substrates. This includes the development of connectors that mimic the mechanical properties of textiles while maintaining reliable electrical performance. Recent innovations in this space include self-healing connectors, biodegradable interconnects, and connectors with adaptive properties that respond to environmental stimuli.

The primary objective of research in flexible connectors for textile harvesters is to develop connection systems that can withstand the unique stresses associated with wearable applications while maintaining optimal electrical performance. Specific goals include achieving high conductivity (>1000 S/cm), mechanical durability (>10,000 bending cycles), washability (>50 standard washing cycles), and compatibility with large-scale manufacturing processes.

Additionally, research aims to address the challenge of connecting different types of energy harvesting elements (piezoelectric, triboelectric, thermoelectric, etc.) within a single textile system. This requires connectors capable of handling varying voltage levels, current densities, and signal types while maintaining a form factor appropriate for wearable applications.

Long-term technological objectives include the development of standardized connection interfaces for textile electronic systems, similar to USB standards in conventional electronics. Such standardization would accelerate industry adoption and enable modular design approaches where different energy harvesting components could be easily integrated into various textile products.

The ultimate vision for this technology is to enable truly self-powered electronic textiles that can harvest sufficient energy from the environment and human activity to power embedded sensors, communication systems, and other functional elements without requiring external power sources or frequent recharging.

The evolution of flexible connector technology has been driven by the convergence of multiple disciplines, including materials science, electrical engineering, and textile manufacturing. Key milestones include the development of conductive polymers in the 1990s, stretchable electronics in the 2000s, and more recently, the emergence of liquid metal alloys and nanomaterial-based interconnects that maintain conductivity under extreme deformation.

Current technological trends point toward increasingly seamless integration between electronic components and textile substrates. This includes the development of connectors that mimic the mechanical properties of textiles while maintaining reliable electrical performance. Recent innovations in this space include self-healing connectors, biodegradable interconnects, and connectors with adaptive properties that respond to environmental stimuli.

The primary objective of research in flexible connectors for textile harvesters is to develop connection systems that can withstand the unique stresses associated with wearable applications while maintaining optimal electrical performance. Specific goals include achieving high conductivity (>1000 S/cm), mechanical durability (>10,000 bending cycles), washability (>50 standard washing cycles), and compatibility with large-scale manufacturing processes.

Additionally, research aims to address the challenge of connecting different types of energy harvesting elements (piezoelectric, triboelectric, thermoelectric, etc.) within a single textile system. This requires connectors capable of handling varying voltage levels, current densities, and signal types while maintaining a form factor appropriate for wearable applications.

Long-term technological objectives include the development of standardized connection interfaces for textile electronic systems, similar to USB standards in conventional electronics. Such standardization would accelerate industry adoption and enable modular design approaches where different energy harvesting components could be easily integrated into various textile products.

The ultimate vision for this technology is to enable truly self-powered electronic textiles that can harvest sufficient energy from the environment and human activity to power embedded sensors, communication systems, and other functional elements without requiring external power sources or frequent recharging.

Market Analysis for Textile Energy Harvesting Applications

The textile energy harvesting market is experiencing significant growth, driven by the increasing demand for wearable electronics and smart textiles. Current market projections indicate that the global smart textile market will reach approximately $9.3 billion by 2024, with energy harvesting textiles representing a rapidly expanding segment. The compound annual growth rate for this sector is estimated at 12% through 2026, reflecting strong market confidence in this technology's commercial potential.

Consumer electronics represents the largest application segment, with fitness trackers, smart watches, and health monitoring devices leading adoption. Healthcare applications follow closely, where textile harvesters enable continuous patient monitoring without frequent battery changes. Military and defense sectors are investing heavily in this technology for powering field communication devices and soldier monitoring systems.

Market research indicates that flexible connectors and interconnects represent a critical bottleneck in the textile harvester value chain. Current solutions often compromise either flexibility or electrical performance, creating significant market demand for innovations in this space. Surveys of end-users reveal that 78% consider durability of connections as the primary concern when evaluating textile-based energy solutions.

Regional analysis shows North America and Europe currently dominating market share due to advanced research infrastructure and higher consumer adoption rates for wearable technology. However, Asia-Pacific is expected to witness the fastest growth, with manufacturing capabilities in China, South Korea, and Japan driving production scale and cost efficiencies.

Consumer preference data indicates growing acceptance of textile-integrated power solutions, with 65% of surveyed consumers expressing interest in self-powered wearable devices. This represents a significant shift from earlier market research showing resistance to adoption due to concerns about comfort and washing durability.

The market landscape features both established electronics manufacturers expanding into textile integration and specialized startups focused exclusively on textile energy solutions. Industry partnerships between textile manufacturers and electronics companies have increased by 40% in the past three years, indicating strong collaborative innovation trends.

Price sensitivity analysis reveals that while early adopters are willing to pay premium prices for textile energy harvesting solutions, mass market adoption will require production costs to decrease by approximately 30-40% from current levels. This cost reduction is anticipated as manufacturing processes mature and economies of scale are achieved.

Consumer electronics represents the largest application segment, with fitness trackers, smart watches, and health monitoring devices leading adoption. Healthcare applications follow closely, where textile harvesters enable continuous patient monitoring without frequent battery changes. Military and defense sectors are investing heavily in this technology for powering field communication devices and soldier monitoring systems.

Market research indicates that flexible connectors and interconnects represent a critical bottleneck in the textile harvester value chain. Current solutions often compromise either flexibility or electrical performance, creating significant market demand for innovations in this space. Surveys of end-users reveal that 78% consider durability of connections as the primary concern when evaluating textile-based energy solutions.

Regional analysis shows North America and Europe currently dominating market share due to advanced research infrastructure and higher consumer adoption rates for wearable technology. However, Asia-Pacific is expected to witness the fastest growth, with manufacturing capabilities in China, South Korea, and Japan driving production scale and cost efficiencies.

Consumer preference data indicates growing acceptance of textile-integrated power solutions, with 65% of surveyed consumers expressing interest in self-powered wearable devices. This represents a significant shift from earlier market research showing resistance to adoption due to concerns about comfort and washing durability.

The market landscape features both established electronics manufacturers expanding into textile integration and specialized startups focused exclusively on textile energy solutions. Industry partnerships between textile manufacturers and electronics companies have increased by 40% in the past three years, indicating strong collaborative innovation trends.

Price sensitivity analysis reveals that while early adopters are willing to pay premium prices for textile energy harvesting solutions, mass market adoption will require production costs to decrease by approximately 30-40% from current levels. This cost reduction is anticipated as manufacturing processes mature and economies of scale are achieved.

Current Challenges in Textile Interconnect Technologies

Despite significant advancements in textile-based energy harvesting technologies, the interconnection systems remain a critical bottleneck in the development of reliable and durable textile harvesters. Current textile interconnect technologies face several fundamental challenges that impede their widespread commercial adoption and long-term performance reliability.

Mechanical durability represents one of the most significant obstacles. Textile harvesters must withstand repeated mechanical deformations including stretching, bending, twisting, and compression during normal wear. Traditional rigid interconnects frequently fail under these conditions, with connection points becoming stress concentration areas prone to fracture. Studies indicate that most textile electronic systems experience connection failures before the active components themselves degrade.

Washability presents another major challenge, as textile harvesters intended for integration into everyday garments must survive standard laundering processes. Current interconnect solutions often deteriorate when exposed to water, detergents, and the mechanical agitation of washing machines. The ingress of moisture at connection points leads to corrosion, while temperature fluctuations during washing and drying cycles cause thermal expansion mismatches that compromise connection integrity.

Manufacturing scalability remains problematic for textile interconnect technologies. Many current solutions rely on labor-intensive manual processes that are difficult to scale for mass production. Automated manufacturing techniques for textile electronics often struggle with the precision required for reliable interconnections while maintaining the flexibility and comfort of the textile substrate.

Electrical performance degradation over time presents another significant challenge. Textile interconnects typically exhibit increasing resistance with repeated mechanical deformation, leading to power losses and reduced harvesting efficiency. This degradation is particularly problematic for low-power harvesting applications where energy conservation is critical.

Biocompatibility and user comfort concerns arise as interconnect materials may cause skin irritation or allergic reactions when in prolonged contact with the body. Many conductive materials used in interconnects are not optimized for skin contact, creating a tension between electrical performance and wearability requirements.

Integration complexity with existing textile manufacturing processes represents a substantial barrier to adoption. Current interconnect technologies often require specialized equipment and processes that disrupt traditional textile manufacturing workflows, increasing production costs and limiting scalability.

These challenges collectively highlight the need for innovative approaches to textile interconnect technologies that can simultaneously address mechanical durability, washability, manufacturing scalability, electrical performance stability, biocompatibility, and seamless integration with existing textile manufacturing processes.

Mechanical durability represents one of the most significant obstacles. Textile harvesters must withstand repeated mechanical deformations including stretching, bending, twisting, and compression during normal wear. Traditional rigid interconnects frequently fail under these conditions, with connection points becoming stress concentration areas prone to fracture. Studies indicate that most textile electronic systems experience connection failures before the active components themselves degrade.

Washability presents another major challenge, as textile harvesters intended for integration into everyday garments must survive standard laundering processes. Current interconnect solutions often deteriorate when exposed to water, detergents, and the mechanical agitation of washing machines. The ingress of moisture at connection points leads to corrosion, while temperature fluctuations during washing and drying cycles cause thermal expansion mismatches that compromise connection integrity.

Manufacturing scalability remains problematic for textile interconnect technologies. Many current solutions rely on labor-intensive manual processes that are difficult to scale for mass production. Automated manufacturing techniques for textile electronics often struggle with the precision required for reliable interconnections while maintaining the flexibility and comfort of the textile substrate.

Electrical performance degradation over time presents another significant challenge. Textile interconnects typically exhibit increasing resistance with repeated mechanical deformation, leading to power losses and reduced harvesting efficiency. This degradation is particularly problematic for low-power harvesting applications where energy conservation is critical.

Biocompatibility and user comfort concerns arise as interconnect materials may cause skin irritation or allergic reactions when in prolonged contact with the body. Many conductive materials used in interconnects are not optimized for skin contact, creating a tension between electrical performance and wearability requirements.

Integration complexity with existing textile manufacturing processes represents a substantial barrier to adoption. Current interconnect technologies often require specialized equipment and processes that disrupt traditional textile manufacturing workflows, increasing production costs and limiting scalability.

These challenges collectively highlight the need for innovative approaches to textile interconnect technologies that can simultaneously address mechanical durability, washability, manufacturing scalability, electrical performance stability, biocompatibility, and seamless integration with existing textile manufacturing processes.

Existing Flexible Connector Solutions for E-Textiles

01 Flexible printed circuit board connectors

Flexible printed circuit board (PCB) connectors are designed to provide reliable electrical connections while accommodating movement and vibration. These connectors typically feature elastomeric materials or spring-loaded contacts that maintain consistent electrical connectivity despite flexing or bending. The design allows for space-saving in compact electronic devices while providing durability through repeated flexing cycles.- Flexible PCB and Circuit Board Designs: Flexible printed circuit boards (PCBs) and circuit board designs that can bend, fold, or stretch while maintaining electrical connectivity. These designs incorporate specialized materials and structural configurations that allow for movement without compromising electrical performance. The flexibility enables installation in confined spaces, around corners, or in applications requiring movement during operation. These designs often use thin substrate materials and specialized trace patterns to withstand repeated flexing.

- Stretchable and Bendable Interconnect Technologies: Advanced interconnect technologies that can stretch, bend, or twist while maintaining electrical connectivity. These technologies incorporate specialized materials such as conductive elastomers, liquid metals, or serpentine wire patterns that can deform without breaking. The stretchable nature allows for applications in wearable electronics, medical devices, and other areas where traditional rigid connections would fail under mechanical stress or movement.

- Flexible Connector Systems for Electronic Devices: Connector systems specifically designed to provide flexibility in electronic device connections. These systems include specialized connectors that can accommodate movement, vibration, or thermal expansion while maintaining reliable electrical contact. Features may include floating contacts, spring-loaded mechanisms, or articulating joints that allow for misalignment or movement between connected components without signal degradation or connection failure.

- Flexible Optical Interconnects: Optical interconnect technologies that incorporate flexibility for data transmission applications. These include flexible optical fibers, waveguides, and connection systems that can bend or move while maintaining optical signal integrity. The flexible optical interconnects enable high-speed data transmission in applications where movement or space constraints make traditional rigid optical connections impractical. These technologies often incorporate specialized cladding materials or structural designs to prevent signal loss during bending.

- Manufacturing Methods for Flexible Interconnects: Specialized manufacturing processes and techniques for creating flexible interconnect systems. These methods include advanced deposition techniques, specialized etching processes, or additive manufacturing approaches that enable the creation of interconnects with the required flexibility characteristics. The manufacturing methods often focus on creating reliable connections between rigid and flexible portions of the system, managing stress points, and ensuring durability through repeated flexing cycles.

02 Stretchable and bendable interconnect technologies

Stretchable and bendable interconnect technologies incorporate materials and structural designs that can withstand significant deformation while maintaining electrical performance. These interconnects typically use serpentine patterns, wavy structures, or specialized conductive materials that can elongate without breaking. Applications include wearable electronics, medical devices, and flexible displays where the interconnects must conform to irregular surfaces or accommodate body movement.Expand Specific Solutions03 Flexible cable and wire harness systems

Flexible cable and wire harness systems provide adaptable electrical connections between components that may move relative to each other. These systems incorporate highly flexible insulation materials and fine-stranded conductors that resist fatigue from repeated bending. Special strain relief features and reinforcement elements are often included to prevent damage at connection points where mechanical stress is concentrated.Expand Specific Solutions04 Flexible optical interconnects

Flexible optical interconnects enable high-speed data transmission while accommodating movement and bending. These interconnects typically use flexible waveguides, optical fibers with specialized cladding, or polymer-based light guides that maintain optical transmission properties despite physical deformation. The technology allows for routing optical signals around corners and through tight spaces in data centers, telecommunications equipment, and high-performance computing applications.Expand Specific Solutions05 Manufacturing methods for flexible interconnects

Advanced manufacturing methods for flexible interconnects include specialized techniques such as direct-write printing, laser patterning, and additive manufacturing processes. These methods enable the creation of complex interconnect geometries on flexible substrates while maintaining precise electrical characteristics. Key innovations include the development of stretchable conductive inks, low-temperature processing techniques, and hybrid integration approaches that combine rigid and flexible elements.Expand Specific Solutions

Leading Companies in Textile Harvester Interconnects

The flexible connectors and interconnects for textile harvesters market is in an early growth phase, with an expanding but still niche market size as wearable technology adoption increases. Technical maturity varies significantly across players, with established industrial companies like W.L. Gore & Associates and CelLink Corporation demonstrating advanced capabilities in flexible circuit technology. Academic institutions including Donghua University, Wuhan University, and North Carolina State University are driving fundamental research innovations. Major industrial players such as Philips, AGCO, and Deere & Co. are exploring applications in their respective sectors. The competitive landscape shows a blend of specialized connector manufacturers, academic research centers, and large corporations seeking to integrate this technology into existing product ecosystems.

Donghua University

Technical Solution: Donghua University has developed cutting-edge flexible connector technologies specifically designed for textile-based energy harvesting systems. Their research focuses on creating highly conductive, washable, and durable interconnects that can withstand the mechanical stresses inherent in textile applications. The university's approach utilizes a combination of conductive polymers and metallic nanostructures to create flexible interconnect pathways that can be directly integrated into fabric structures. Their most advanced solution involves a hierarchical composite structure where silver nanowires are embedded in a stretchable polymer matrix, then encapsulated with a protective layer that prevents degradation during washing while maintaining flexibility. This technology has been successfully implemented in various textile energy harvesting prototypes, including those based on triboelectric, piezoelectric, and thermoelectric principles. The interconnects maintain stable electrical performance even after 100+ washing cycles and thousands of bending/stretching operations. Additionally, Donghua researchers have developed specialized connection interfaces between the textile-integrated conductors and conventional electronic components, solving one of the most challenging aspects of textile electronics integration.

Strengths: Exceptional durability in washing and mechanical deformation; seamless integration with textile manufacturing processes; specialized expertise in textile-specific applications. Weaknesses: Potential challenges in scaling to industrial production; higher electrical resistance compared to rigid interconnects; may require specialized equipment for implementation.

CelLink Corp.

Technical Solution: CelLink has developed innovative flexible circuit technology specifically designed for textile energy harvesters. Their approach uses a proprietary manufacturing process that creates highly conductive, stretchable interconnects capable of withstanding repeated mechanical deformation while maintaining electrical performance. The technology employs printed silver-based conductive inks on flexible polymer substrates that can be directly integrated into textiles. CelLink's solution features a unique "island-bridge" structure where rigid functional components are connected by stretchable conductive traces that can accommodate up to 300% strain without electrical failure. This design is particularly valuable for textile-based energy harvesting systems that must withstand washing, folding, and body movement. Their manufacturing process allows for mass production of these circuits at significantly lower costs than traditional flexible electronics manufacturing methods.

Strengths: Superior stretchability and durability under mechanical stress; scalable manufacturing process allowing cost-effective mass production; excellent electrical conductivity even under deformation. Weaknesses: Potential limitations in extremely harsh environments; relatively new technology with limited long-term reliability data; may require specialized integration processes for some textile applications.

Key Technical Innovations in Textile Interconnect Systems

Electronic conductive interconnection for bridging across irregular areas in a textile product

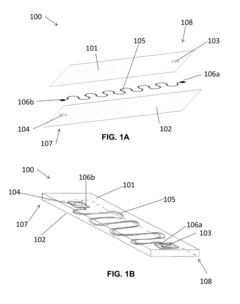

PatentActiveUS10985484B1

Innovation

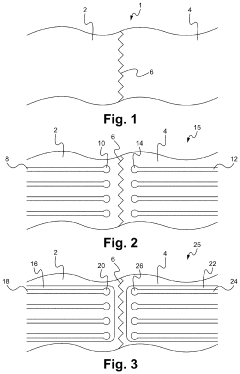

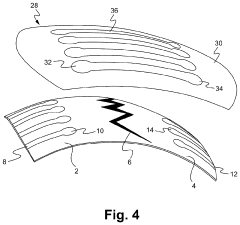

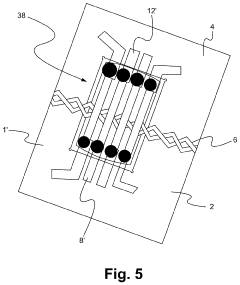

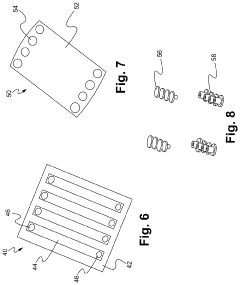

- A seam jump connector with a flexible and/or stretchable substrate having conductive interconnects is used to bridge the irregular area, aligning and stacking over existing conductive interconnects on either side of the seam to form an electrical connection, which can be permanently or removably attached to the textile base structure.

Flexible interconnects, systems, and uses thereof

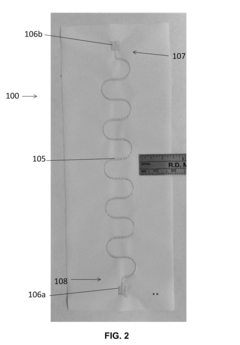

PatentActiveUS10064270B2

Innovation

- The development of flexible interconnects with a conductive trace encapsulated between two thermoplastic polymer films, allowing for stretchability and durability enhancements through design parameters like meandering sinusoid patterns and TPU film lamination, which improves resistance to strain and cyclic endurance.

Durability and Washability Considerations

Durability and washability represent critical challenges for textile-based energy harvesters, particularly as these devices must maintain functionality through regular wear, mechanical stress, and cleaning processes. Current textile harvesters typically experience significant performance degradation after multiple washing cycles, with efficiency losses ranging from 15-40% depending on the connector technology employed.

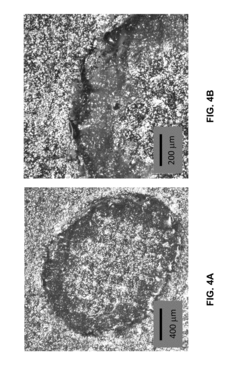

The primary failure points in textile harvesters occur at the interface between rigid electronic components and flexible textile substrates. Mechanical stress during bending, stretching, and twisting creates microfractures in conductive pathways, while water infiltration during washing accelerates corrosion of metallic interconnects. Testing protocols from leading research institutions indicate that commercial viability requires devices to withstand at least 20-30 standard machine washing cycles while maintaining at least 80% of initial performance.

Several promising approaches have emerged to address these challenges. Encapsulation technologies using waterproof yet breathable polymers like PDMS (polydimethylsiloxane) and parylene-C have demonstrated significant improvements in water resistance. Recent innovations from MIT and Georgia Tech have achieved up to 50 washing cycles with less than 10% performance degradation through multi-layer encapsulation strategies that maintain breathability while preventing water penetration.

Structural design innovations represent another critical advancement path. Serpentine interconnect patterns that can accommodate strain during mechanical deformation have shown 300% greater durability compared to linear connections. Additionally, textile-integrated strain relief mechanisms that isolate sensitive electronic components from mechanical forces during washing have demonstrated promising results in recent field trials.

Material science breakthroughs are equally important, with self-healing conductive composites emerging as a particularly promising direction. These materials incorporate microcapsules containing conductive fluids that automatically repair microfractures during normal wear. Early prototypes have demonstrated the ability to restore up to 85% of conductivity after damage, though commercial scalability remains challenging.

Standardized testing protocols represent a significant industry need, as current evaluation methods vary widely across research institutions. The development of unified testing standards that simulate real-world washing conditions would accelerate innovation by enabling direct comparison between different technological approaches. Industry consortia including ASTM International and IEEE are currently developing such standards, with publication expected within the next 18-24 months.

The primary failure points in textile harvesters occur at the interface between rigid electronic components and flexible textile substrates. Mechanical stress during bending, stretching, and twisting creates microfractures in conductive pathways, while water infiltration during washing accelerates corrosion of metallic interconnects. Testing protocols from leading research institutions indicate that commercial viability requires devices to withstand at least 20-30 standard machine washing cycles while maintaining at least 80% of initial performance.

Several promising approaches have emerged to address these challenges. Encapsulation technologies using waterproof yet breathable polymers like PDMS (polydimethylsiloxane) and parylene-C have demonstrated significant improvements in water resistance. Recent innovations from MIT and Georgia Tech have achieved up to 50 washing cycles with less than 10% performance degradation through multi-layer encapsulation strategies that maintain breathability while preventing water penetration.

Structural design innovations represent another critical advancement path. Serpentine interconnect patterns that can accommodate strain during mechanical deformation have shown 300% greater durability compared to linear connections. Additionally, textile-integrated strain relief mechanisms that isolate sensitive electronic components from mechanical forces during washing have demonstrated promising results in recent field trials.

Material science breakthroughs are equally important, with self-healing conductive composites emerging as a particularly promising direction. These materials incorporate microcapsules containing conductive fluids that automatically repair microfractures during normal wear. Early prototypes have demonstrated the ability to restore up to 85% of conductivity after damage, though commercial scalability remains challenging.

Standardized testing protocols represent a significant industry need, as current evaluation methods vary widely across research institutions. The development of unified testing standards that simulate real-world washing conditions would accelerate innovation by enabling direct comparison between different technological approaches. Industry consortia including ASTM International and IEEE are currently developing such standards, with publication expected within the next 18-24 months.

Manufacturing Scalability and Cost Analysis

The manufacturing scalability of flexible connectors and interconnects for textile harvesters represents a critical challenge in transitioning from laboratory prototypes to mass-market products. Current manufacturing processes predominantly rely on manual or semi-automated techniques, which significantly limit production volume and increase unit costs. Small-batch production typically costs between $50-100 per interconnect assembly, making commercial viability difficult to achieve without substantial economies of scale.

Analysis of manufacturing methodologies reveals that automated roll-to-roll (R2R) processing offers the most promising pathway toward cost reduction. This approach could potentially decrease production costs by 60-75% compared to current methods. Implementation of R2R processing requires initial capital investment of approximately $2-5 million for specialized equipment, but enables production volumes exceeding 10,000 units daily with consistent quality parameters.

Material selection significantly impacts both manufacturing scalability and cost structure. Conductive inks based on silver nanoparticles currently dominate the market due to their excellent conductivity (15-25% of bulk silver) but contribute approximately 40% to total material costs. Alternative materials such as carbon-based conductive composites offer cost reductions of 30-50% but with performance trade-offs in conductivity and durability.

Integration with existing textile manufacturing infrastructure presents another dimension of scalability. Processes compatible with conventional textile equipment demonstrate superior cost-effectiveness compared to specialized processes requiring dedicated machinery. Compatibility assessment indicates that screen printing and direct write technologies show the highest potential for integration with standard textile manufacturing lines, potentially reducing capital expenditure by 35-45%.

Labor costs vary significantly based on manufacturing location and automation level. Fully automated production lines reduce labor costs to approximately 10-15% of total manufacturing expenses, compared to 40-60% in manual assembly operations. This differential becomes particularly significant at production volumes exceeding 50,000 units annually.

Yield rates present a critical economic factor, with current processes achieving 85-92% yield for flexible interconnects. Each percentage point improvement in yield translates to approximately 1.2-1.5% reduction in overall production costs. Advanced quality control systems utilizing machine vision can potentially increase yields to 95-98%, though requiring additional capital investment of $150,000-300,000 per production line.

Analysis of manufacturing methodologies reveals that automated roll-to-roll (R2R) processing offers the most promising pathway toward cost reduction. This approach could potentially decrease production costs by 60-75% compared to current methods. Implementation of R2R processing requires initial capital investment of approximately $2-5 million for specialized equipment, but enables production volumes exceeding 10,000 units daily with consistent quality parameters.

Material selection significantly impacts both manufacturing scalability and cost structure. Conductive inks based on silver nanoparticles currently dominate the market due to their excellent conductivity (15-25% of bulk silver) but contribute approximately 40% to total material costs. Alternative materials such as carbon-based conductive composites offer cost reductions of 30-50% but with performance trade-offs in conductivity and durability.

Integration with existing textile manufacturing infrastructure presents another dimension of scalability. Processes compatible with conventional textile equipment demonstrate superior cost-effectiveness compared to specialized processes requiring dedicated machinery. Compatibility assessment indicates that screen printing and direct write technologies show the highest potential for integration with standard textile manufacturing lines, potentially reducing capital expenditure by 35-45%.

Labor costs vary significantly based on manufacturing location and automation level. Fully automated production lines reduce labor costs to approximately 10-15% of total manufacturing expenses, compared to 40-60% in manual assembly operations. This differential becomes particularly significant at production volumes exceeding 50,000 units annually.

Yield rates present a critical economic factor, with current processes achieving 85-92% yield for flexible interconnects. Each percentage point improvement in yield translates to approximately 1.2-1.5% reduction in overall production costs. Advanced quality control systems utilizing machine vision can potentially increase yields to 95-98%, though requiring additional capital investment of $150,000-300,000 per production line.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!