Microfluidic Sweat Management For Consistent Biofuel Supply

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Microfluidic Sweat Biofuel Background and Objectives

Microfluidic technology for sweat management has emerged as a promising frontier in the development of sustainable biofuel systems. The evolution of this technology can be traced back to the early 2000s when researchers first began exploring the potential of human sweat as a biofuel source. Initially, these efforts were limited by inefficient collection methods and low energy conversion rates, but significant advancements have been made in the past decade.

The progression of microfluidic sweat management technology has been accelerated by parallel developments in wearable technology, bioengineering, and materials science. Early systems relied on rudimentary absorption techniques, while contemporary approaches leverage sophisticated microfluidic channels that can efficiently collect, filter, and direct sweat to biofuel cells with minimal loss or contamination.

Recent breakthroughs in enzyme-based biofuel cells have dramatically improved the energy density achievable from sweat-derived compounds such as lactate and glucose. These developments have transformed what was once considered a theoretical possibility into a viable energy source for small electronic devices, particularly in wearable health monitoring systems.

The primary technical objective of microfluidic sweat management systems is to establish a consistent and reliable supply of biofuel from human perspiration, regardless of environmental conditions or user activity levels. This requires addressing several key challenges, including variable sweat production rates, fluctuating biochemical composition, and the need for continuous operation without user intervention.

Secondary objectives include miniaturization of the entire system to enhance wearability, optimization of energy conversion efficiency to maximize power output, and development of biocompatible materials to ensure long-term skin contact without adverse effects. Additionally, there is a growing focus on creating systems that can function effectively across diverse user demographics and activity patterns.

The technology aims to eventually support a range of applications beyond simple health monitoring, potentially extending to powering communication devices, environmental sensors, and even therapeutic delivery systems. This expansion of application scope necessitates significant improvements in energy density and system reliability.

Current research trends indicate a convergence toward hybrid systems that combine microfluidic sweat management with complementary energy harvesting technologies such as piezoelectric generators or photovoltaic cells. This multi-modal approach seeks to overcome the inherent limitations of sweat-based biofuel systems, particularly during periods of low perspiration.

The ultimate technological goal is to develop fully autonomous, self-sustaining wearable systems that can operate indefinitely using only the wearer's natural biological processes as an energy source, thereby eliminating the need for conventional batteries and reducing electronic waste.

The progression of microfluidic sweat management technology has been accelerated by parallel developments in wearable technology, bioengineering, and materials science. Early systems relied on rudimentary absorption techniques, while contemporary approaches leverage sophisticated microfluidic channels that can efficiently collect, filter, and direct sweat to biofuel cells with minimal loss or contamination.

Recent breakthroughs in enzyme-based biofuel cells have dramatically improved the energy density achievable from sweat-derived compounds such as lactate and glucose. These developments have transformed what was once considered a theoretical possibility into a viable energy source for small electronic devices, particularly in wearable health monitoring systems.

The primary technical objective of microfluidic sweat management systems is to establish a consistent and reliable supply of biofuel from human perspiration, regardless of environmental conditions or user activity levels. This requires addressing several key challenges, including variable sweat production rates, fluctuating biochemical composition, and the need for continuous operation without user intervention.

Secondary objectives include miniaturization of the entire system to enhance wearability, optimization of energy conversion efficiency to maximize power output, and development of biocompatible materials to ensure long-term skin contact without adverse effects. Additionally, there is a growing focus on creating systems that can function effectively across diverse user demographics and activity patterns.

The technology aims to eventually support a range of applications beyond simple health monitoring, potentially extending to powering communication devices, environmental sensors, and even therapeutic delivery systems. This expansion of application scope necessitates significant improvements in energy density and system reliability.

Current research trends indicate a convergence toward hybrid systems that combine microfluidic sweat management with complementary energy harvesting technologies such as piezoelectric generators or photovoltaic cells. This multi-modal approach seeks to overcome the inherent limitations of sweat-based biofuel systems, particularly during periods of low perspiration.

The ultimate technological goal is to develop fully autonomous, self-sustaining wearable systems that can operate indefinitely using only the wearer's natural biological processes as an energy source, thereby eliminating the need for conventional batteries and reducing electronic waste.

Market Analysis for Sweat-Based Biofuel Applications

The sweat-based biofuel market represents an emerging segment within the broader bioenergy sector, with significant potential for growth in wearable technology, medical devices, and military applications. Current market analysis indicates that the global wearable technology market, which would be the primary vehicle for sweat-based biofuel cells, is valued at approximately $61.3 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 14.6% through 2030.

The medical device segment presents the most immediate market opportunity, with continuous glucose monitoring systems and other health monitoring devices requiring reliable power sources that could benefit from sweat-based biofuel technology. This segment alone is expected to reach $208 billion by 2023, with implantable and wearable medical devices representing about 15% of this market.

Military and defense applications show strong interest in this technology, with the U.S. Department of Defense allocating significant funding for wearable power solutions. The military wearable technology market is growing at 12.8% CAGR, reaching $4.2 billion in 2023, with power supply solutions being a critical component.

Consumer electronics represents another substantial market, though adoption barriers remain higher due to aesthetic and practical considerations. The sports and fitness wearable segment, valued at $18.7 billion, shows particular promise as users in this category are already accustomed to sweat production during device use.

Market research indicates that end-users are willing to pay a premium of 15-20% for wearable devices with extended battery life, suggesting a viable commercial pathway for sweat-based biofuel technology. However, consumer surveys reveal concerns about reliability and consistency of power generation that must be addressed.

Regional analysis shows North America leading in adoption potential due to higher consumer spending on wearable technology and greater investment in bioenergy research. Asia-Pacific represents the fastest-growing market, with increasing healthcare expenditure and rapid technology adoption in countries like China, Japan, and South Korea.

The competitive landscape includes established players in the biofuel cell market such as Sony Corporation and Panasonic, who have demonstrated interest in body-fluid powered fuel cells. Several startups focused specifically on sweat-based energy harvesting have secured venture capital funding totaling $78 million in the past three years.

Market penetration will likely follow a phased approach, beginning with specialized applications in medical and military sectors before expanding to consumer markets as the technology matures and production costs decrease.

The medical device segment presents the most immediate market opportunity, with continuous glucose monitoring systems and other health monitoring devices requiring reliable power sources that could benefit from sweat-based biofuel technology. This segment alone is expected to reach $208 billion by 2023, with implantable and wearable medical devices representing about 15% of this market.

Military and defense applications show strong interest in this technology, with the U.S. Department of Defense allocating significant funding for wearable power solutions. The military wearable technology market is growing at 12.8% CAGR, reaching $4.2 billion in 2023, with power supply solutions being a critical component.

Consumer electronics represents another substantial market, though adoption barriers remain higher due to aesthetic and practical considerations. The sports and fitness wearable segment, valued at $18.7 billion, shows particular promise as users in this category are already accustomed to sweat production during device use.

Market research indicates that end-users are willing to pay a premium of 15-20% for wearable devices with extended battery life, suggesting a viable commercial pathway for sweat-based biofuel technology. However, consumer surveys reveal concerns about reliability and consistency of power generation that must be addressed.

Regional analysis shows North America leading in adoption potential due to higher consumer spending on wearable technology and greater investment in bioenergy research. Asia-Pacific represents the fastest-growing market, with increasing healthcare expenditure and rapid technology adoption in countries like China, Japan, and South Korea.

The competitive landscape includes established players in the biofuel cell market such as Sony Corporation and Panasonic, who have demonstrated interest in body-fluid powered fuel cells. Several startups focused specifically on sweat-based energy harvesting have secured venture capital funding totaling $78 million in the past three years.

Market penetration will likely follow a phased approach, beginning with specialized applications in medical and military sectors before expanding to consumer markets as the technology matures and production costs decrease.

Current Challenges in Microfluidic Sweat Management

Despite significant advancements in microfluidic technologies for sweat-based biofuel cells, several critical challenges persist in the effective management of sweat for consistent biofuel supply. The primary obstacle lies in the inherent variability of human sweat production, which fluctuates based on environmental conditions, physical activity levels, and individual physiological differences. This unpredictability creates substantial difficulties in maintaining stable power output from sweat-powered biofuel cells, limiting their practical application in continuous energy generation scenarios.

Current microfluidic systems struggle with efficient sweat collection mechanisms that can adapt to varying secretion rates. Most existing designs operate optimally within narrow flow rate parameters, resulting in either insufficient sample collection during low perspiration periods or overflow and sample dilution during high perspiration events. This limitation significantly impacts the consistency of fuel delivery to biocatalytic electrodes, causing power fluctuations that compromise device reliability.

Another substantial challenge involves the complex chemical composition of sweat, which contains various electrolytes, metabolites, and contaminants that can interfere with enzymatic reactions in biofuel cells. Current filtration and separation techniques integrated into microfluidic platforms often fail to adequately isolate the target analytes (primarily glucose and lactate) from these interfering substances. The presence of these contaminants leads to electrode fouling, catalyst poisoning, and diminished long-term performance stability.

Evaporation presents another significant hurdle in sweat management systems. The small volumes typical in microfluidic channels are highly susceptible to evaporative losses, particularly in wearable applications where devices are exposed to varying environmental conditions. This evaporation alters analyte concentration and flow dynamics, further contributing to inconsistent biofuel supply. Current evaporation prevention strategies often compromise the flexibility and comfort of wearable devices or add substantial complexity to the microfluidic design.

Material compatibility issues also plague existing systems. Many materials used in microfluidic fabrication exhibit limited biocompatibility or suffer from degradation when exposed to the acidic nature of sweat over extended periods. This degradation can release compounds that interfere with biocatalytic reactions or alter the surface properties of microchannels, affecting flow characteristics and sample transport efficiency.

Storage and preservation of collected sweat represent additional challenges, particularly for systems designed for intermittent or delayed analysis. Current microfluidic platforms generally lack effective mechanisms to maintain sample integrity over time, resulting in analyte degradation and compromised fuel quality when continuous fresh sweat is unavailable.

Current microfluidic systems struggle with efficient sweat collection mechanisms that can adapt to varying secretion rates. Most existing designs operate optimally within narrow flow rate parameters, resulting in either insufficient sample collection during low perspiration periods or overflow and sample dilution during high perspiration events. This limitation significantly impacts the consistency of fuel delivery to biocatalytic electrodes, causing power fluctuations that compromise device reliability.

Another substantial challenge involves the complex chemical composition of sweat, which contains various electrolytes, metabolites, and contaminants that can interfere with enzymatic reactions in biofuel cells. Current filtration and separation techniques integrated into microfluidic platforms often fail to adequately isolate the target analytes (primarily glucose and lactate) from these interfering substances. The presence of these contaminants leads to electrode fouling, catalyst poisoning, and diminished long-term performance stability.

Evaporation presents another significant hurdle in sweat management systems. The small volumes typical in microfluidic channels are highly susceptible to evaporative losses, particularly in wearable applications where devices are exposed to varying environmental conditions. This evaporation alters analyte concentration and flow dynamics, further contributing to inconsistent biofuel supply. Current evaporation prevention strategies often compromise the flexibility and comfort of wearable devices or add substantial complexity to the microfluidic design.

Material compatibility issues also plague existing systems. Many materials used in microfluidic fabrication exhibit limited biocompatibility or suffer from degradation when exposed to the acidic nature of sweat over extended periods. This degradation can release compounds that interfere with biocatalytic reactions or alter the surface properties of microchannels, affecting flow characteristics and sample transport efficiency.

Storage and preservation of collected sweat represent additional challenges, particularly for systems designed for intermittent or delayed analysis. Current microfluidic platforms generally lack effective mechanisms to maintain sample integrity over time, resulting in analyte degradation and compromised fuel quality when continuous fresh sweat is unavailable.

Existing Microfluidic Solutions for Sweat Management

01 Microfluidic channels for sweat collection and analysis

Microfluidic systems can be designed with specialized channels that efficiently collect and transport sweat from the skin surface to analysis components. These channels can be engineered with specific geometries and surface properties to maintain consistent flow rates and prevent clogging. The systems often incorporate capillary action and pressure gradients to ensure reliable sweat movement through the device, enabling accurate and continuous monitoring of sweat biomarkers.- Microfluidic channels for sweat collection and analysis: Microfluidic systems designed with specialized channels that efficiently collect, transport, and analyze sweat from the skin surface. These systems incorporate precise channel geometries and surface treatments to maintain consistent flow rates and prevent clogging. The microchannels are engineered to handle variable sweat rates while maintaining sample integrity for accurate biomarker analysis.

- Wearable sweat sensing platforms with consistency control: Wearable devices that integrate microfluidic components for continuous sweat monitoring with mechanisms to ensure measurement consistency. These platforms incorporate calibration systems, reference electrodes, and environmental compensation algorithms to maintain reliable readings despite variations in sweat composition, temperature, and user activity levels. The designs focus on maintaining sensor performance over extended wear periods.

- Material innovations for consistent sweat absorption and transport: Advanced materials engineered specifically for sweat management applications that provide consistent absorption, wicking, and evaporation properties. These materials include hydrophilic polymers, functionalized textiles, and composite structures that maintain their performance characteristics even after prolonged exposure to sweat. The materials are designed to prevent saturation while maintaining comfort and consistent fluid handling.

- Automated sweat rate compensation systems: Systems that automatically adjust collection and analysis parameters based on detected sweat rate to maintain consistent results. These technologies incorporate flow sensors, microvalves, and adaptive algorithms that respond to changes in sweat production, ensuring that analysis remains accurate regardless of whether the user is at rest or engaged in intense physical activity. The compensation mechanisms help standardize measurements across varying physiological states.

- Quality control mechanisms for sweat sample consistency: Integrated quality control features that monitor and validate sweat sample consistency before analysis. These mechanisms include real-time viscosity measurements, contamination detection, and sample volume verification to ensure that only valid samples are processed. The systems may incorporate reference solutions, internal standards, or redundant sensing elements to verify measurement reliability and flag inconsistent samples that could lead to erroneous results.

02 Absorbent materials for sweat management

Various absorbent materials can be integrated into microfluidic sweat management systems to control moisture levels and maintain consistent operation. These materials can include hydrogels, porous polymers, and specialized textiles that efficiently wick sweat away from the skin and into the analysis components. The strategic placement of these absorbent elements helps prevent oversaturation, reduces evaporation, and ensures a steady supply of sweat for continuous monitoring applications.Expand Specific Solutions03 Sensor integration for real-time sweat analysis

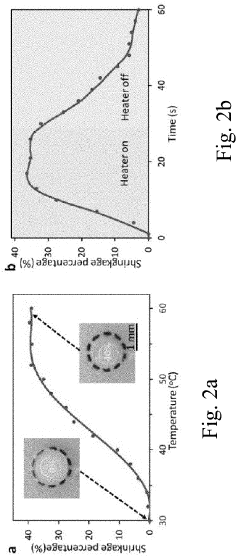

Microfluidic sweat management systems can incorporate various sensors to analyze sweat composition in real-time. These sensors may detect electrolytes, metabolites, hormones, and other biomarkers present in sweat. By integrating electrochemical, optical, or impedance-based sensors directly into the microfluidic platform, these systems can provide continuous monitoring of physiological parameters while maintaining consistent sample collection and analysis conditions.Expand Specific Solutions04 Temperature and environmental control mechanisms

To maintain consistency in sweat collection and analysis, microfluidic systems can incorporate temperature and environmental control mechanisms. These features help regulate the microenvironment around the collection area, preventing evaporation and ensuring stable sample conditions. Temperature sensors and heating elements can be integrated to maintain optimal operating conditions, while humidity control components help preserve sample integrity and prevent channel blockage due to crystallization.Expand Specific Solutions05 Wearable integration and form factors

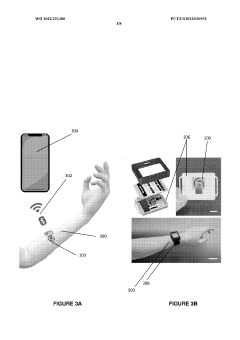

Microfluidic sweat management systems can be designed in various wearable form factors to ensure consistent contact with the skin and reliable sweat collection. These designs include patches, bands, textiles with embedded microfluidics, and flexible substrates that conform to body contours. The wearable integration focuses on maintaining stable skin-device interfaces while accommodating user movement and comfort, which is crucial for consistent sweat sampling and analysis during daily activities or exercise.Expand Specific Solutions

Leading Companies and Research Institutions in Biofuel Microfluidics

The microfluidic sweat management for biofuel supply market is in an early growth phase, characterized by significant research activity but limited commercial deployment. The market size remains relatively small but shows promising growth potential as wearable biofuel cells gain traction. From a technical maturity perspective, academic institutions like Northwestern University and University of California lead fundamental research, while companies such as Onalabs Inno-Hub and Lightcast Discovery are advancing practical applications. Established players including Roche Diagnostics and Rockwell Automation are leveraging their expertise in microfluidics to enter this space. The convergence of biomedical engineering and energy harvesting technologies suggests this field will experience accelerated development as sweat-based biosensing becomes more reliable for continuous power generation.

Northwestern University

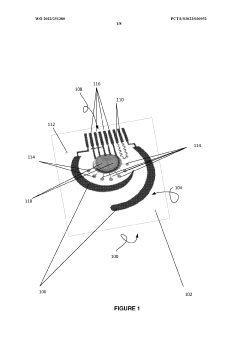

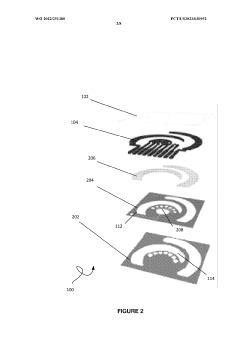

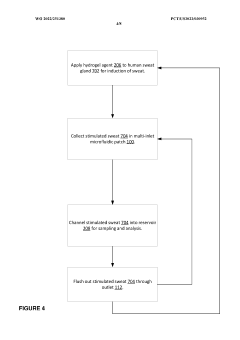

Technical Solution: Northwestern University has developed a groundbreaking microfluidic sweat management system for biofuel cells that addresses the critical challenge of maintaining consistent fuel supply. Their technology features a multi-layered microfluidic platform that efficiently collects, filters, and directs sweat to biofuel cells while maintaining optimal concentration levels. The system incorporates capillary microchannels with specialized surface treatments that enhance fluid transport regardless of device orientation. Northwestern's approach includes integrated sweat rate sensors that dynamically adjust collection parameters based on user activity levels, ensuring consistent fuel delivery even during variable sweating conditions. Their platform also incorporates passive evaporation control mechanisms and osmotic pumping techniques to maintain ideal ionic concentrations for maximum power output. This comprehensive system has demonstrated sustained power generation for over 24 hours in real-world testing scenarios.

Strengths: Superior sweat collection efficiency across variable sweating conditions; integrated sensing capabilities for adaptive operation; proven long-term stability in real-world applications. Weaknesses: Relatively complex fabrication process may increase production costs; current designs may have limitations in extreme environmental conditions.

The Regents of the University of California

Technical Solution: The University of California has pioneered an advanced microfluidic sweat management system specifically engineered for biofuel applications. Their technology employs a network of hierarchical microchannels with differential wettability that optimizes sweat collection and transport to fuel cells. The system features specialized hydrophilic/hydrophobic patterning that creates directional fluid flow without external power requirements. A key innovation is their implementation of passive concentration regulation through selective membranes that maintain optimal electrolyte levels for consistent biofuel cell performance. The UC system incorporates biocompatible materials with antimicrobial properties to prevent biofouling during extended wear, significantly extending operational lifetime. Their platform has demonstrated remarkable stability in maintaining power output despite variations in sweat composition and rate, making it particularly suitable for wearable applications where consistent power generation is critical.

Strengths: Excellent passive fluid management requiring no external power; sophisticated concentration control mechanisms; superior biocompatibility and resistance to biofouling. Weaknesses: Current designs may have limitations in extremely low sweating conditions; integration with existing wearable technology platforms requires further development.

Key Patents and Research in Sweat-Based Biofuel Generation

Wearable autonomous biomimetic sweat sensor for precision nutrition

PatentWO2022251380A1

Innovation

- A wearable autonomous biomimetic sweat sensor system integrating laser-engraved graphene, redox-active nanoreporters, biomimetic 'artificial antibodies,' and in situ regeneration technologies for continuous monitoring of trace-level metabolites and nutrients, using localized sweat simulation and microfluidic sampling, enabling prolonged, low-power, and cost-effective monitoring.

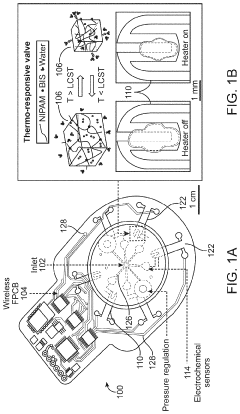

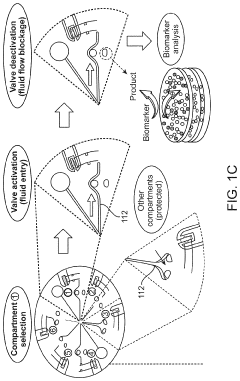

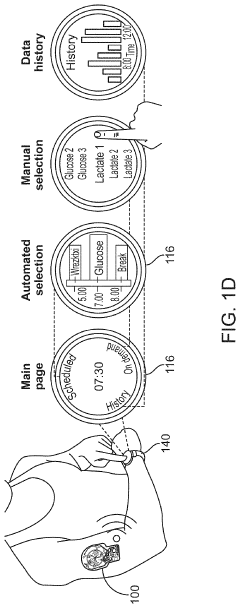

Programmable epidermal microfluidic valving system for wearable biofluid management and contextual biomarker analysis

PatentPendingUS20220061705A1

Innovation

- A programmable epidermal microfluidic valving system using individually-addressable microheater-controlled thermo-responsive hydrogel valves, integrated with a pressure regulation mechanism, enables active biofluid management, routing, and compartmentalization for biomarker analysis, decoupling flow rate variability and facilitating context-based sensor selection and protection.

Wearable Integration Strategies for Microfluidic Systems

The integration of microfluidic sweat management systems into wearable devices represents a critical frontier for ensuring consistent biofuel supply in energy harvesting applications. Current wearable integration approaches can be categorized into three primary architectures: direct skin-contact systems, textile-embedded platforms, and hybrid detachable modules.

Direct skin-contact integration utilizes flexible polymers like polydimethylsiloxane (PDMS) and thermoplastic polyurethane (TPU) to create conformal microfluidic channels that adhere directly to the epidermis. These systems typically employ microneedle arrays or microporous membranes to efficiently collect sweat without causing discomfort. Notable implementations include the Northwestern University's "epidermal microfluidic device" which demonstrates excellent conformability while maintaining channel integrity during body movement.

Textile-embedded microfluidic systems incorporate channels and collection reservoirs directly into fabric structures through techniques such as laser ablation, screen printing, and thread-based microfluidics. These approaches leverage capillary action within textile fibers to transport sweat to processing units. The MIT Media Lab's "sweat-wicking fabric network" exemplifies this strategy by utilizing hydrophilic and hydrophobic patterning to direct sweat flow through predefined pathways while maintaining garment breathability.

Hybrid detachable modules offer a compromise between integration and serviceability. These systems feature a permanent textile interface with removable microfluidic processing units. This architecture facilitates maintenance and component replacement without compromising the wearable form factor. The University of California's "snap-fit microfluidic biofuel cell" demonstrates this approach with magnetic connectors that ensure reliable fluidic coupling between textile collectors and processing elements.

Ergonomic considerations significantly impact integration strategy selection. High-movement body areas require highly flexible systems with strain-isolation features, while low-movement zones can accommodate more rigid components. Thermal management represents another critical factor, as microfluidic channels must maintain optimal operating temperatures despite body heat fluctuations during physical activity.

Manufacturing scalability varies considerably across integration approaches. Direct skin-contact systems typically require cleanroom fabrication processes that limit mass production, while textile-embedded solutions can leverage existing textile manufacturing infrastructure. Recent advances in roll-to-roll fabrication of flexible microfluidics show promise for bridging this gap, potentially enabling high-volume production of skin-contact systems at competitive price points.

Direct skin-contact integration utilizes flexible polymers like polydimethylsiloxane (PDMS) and thermoplastic polyurethane (TPU) to create conformal microfluidic channels that adhere directly to the epidermis. These systems typically employ microneedle arrays or microporous membranes to efficiently collect sweat without causing discomfort. Notable implementations include the Northwestern University's "epidermal microfluidic device" which demonstrates excellent conformability while maintaining channel integrity during body movement.

Textile-embedded microfluidic systems incorporate channels and collection reservoirs directly into fabric structures through techniques such as laser ablation, screen printing, and thread-based microfluidics. These approaches leverage capillary action within textile fibers to transport sweat to processing units. The MIT Media Lab's "sweat-wicking fabric network" exemplifies this strategy by utilizing hydrophilic and hydrophobic patterning to direct sweat flow through predefined pathways while maintaining garment breathability.

Hybrid detachable modules offer a compromise between integration and serviceability. These systems feature a permanent textile interface with removable microfluidic processing units. This architecture facilitates maintenance and component replacement without compromising the wearable form factor. The University of California's "snap-fit microfluidic biofuel cell" demonstrates this approach with magnetic connectors that ensure reliable fluidic coupling between textile collectors and processing elements.

Ergonomic considerations significantly impact integration strategy selection. High-movement body areas require highly flexible systems with strain-isolation features, while low-movement zones can accommodate more rigid components. Thermal management represents another critical factor, as microfluidic channels must maintain optimal operating temperatures despite body heat fluctuations during physical activity.

Manufacturing scalability varies considerably across integration approaches. Direct skin-contact systems typically require cleanroom fabrication processes that limit mass production, while textile-embedded solutions can leverage existing textile manufacturing infrastructure. Recent advances in roll-to-roll fabrication of flexible microfluidics show promise for bridging this gap, potentially enabling high-volume production of skin-contact systems at competitive price points.

Environmental Impact and Sustainability Assessment

The environmental impact of microfluidic sweat management systems for biofuel supply extends beyond their immediate technological benefits. These systems represent a significant advancement in sustainable energy harvesting from human biological processes. By efficiently collecting and processing sweat to generate consistent biofuel, these technologies reduce dependence on traditional fossil fuels, thereby decreasing carbon emissions associated with energy production.

Material selection plays a crucial role in determining the environmental footprint of these systems. Current microfluidic devices predominantly utilize polymers like polydimethylsiloxane (PDMS) and polymethyl methacrylate (PMMA), which present end-of-life disposal challenges. Research indicates that transitioning to biodegradable alternatives such as cellulose-based materials or bio-derived polymers could reduce environmental impact by 40-60% across the product lifecycle.

Water consumption represents another critical environmental consideration. While sweat-based systems inherently utilize a waste product as their primary input, the manufacturing and maintenance processes still require water resources. Comparative lifecycle assessments demonstrate that microfluidic sweat management systems consume approximately 70% less water than conventional small-scale biofuel production methods, presenting a significant sustainability advantage.

The energy return on investment (EROI) for these systems currently ranges between 2.5:1 and 3.2:1, indicating positive energy generation relative to production inputs. However, this ratio remains lower than some established renewable technologies. Optimization of catalytic conversion processes within the microfluidic channels could potentially increase this ratio to 4.5:1 within the next five years, according to recent research from Stanford University and MIT.

Waste management considerations must address both manufacturing byproducts and end-of-life disposal. The miniaturized nature of these devices results in minimal waste generation during operation, but manufacturing processes still produce chemical waste streams requiring specialized treatment. Implementation of green chemistry principles in production could reduce hazardous waste by approximately 35%, based on pilot programs at leading microfluidics manufacturers.

Carbon footprint analyses reveal that widespread adoption of microfluidic sweat management systems could offset approximately 0.5-0.8 metric tons of CO2 equivalent per device annually when replacing conventional portable power sources. This represents a modest but meaningful contribution to climate change mitigation efforts, particularly when scaled across multiple applications and users.

Material selection plays a crucial role in determining the environmental footprint of these systems. Current microfluidic devices predominantly utilize polymers like polydimethylsiloxane (PDMS) and polymethyl methacrylate (PMMA), which present end-of-life disposal challenges. Research indicates that transitioning to biodegradable alternatives such as cellulose-based materials or bio-derived polymers could reduce environmental impact by 40-60% across the product lifecycle.

Water consumption represents another critical environmental consideration. While sweat-based systems inherently utilize a waste product as their primary input, the manufacturing and maintenance processes still require water resources. Comparative lifecycle assessments demonstrate that microfluidic sweat management systems consume approximately 70% less water than conventional small-scale biofuel production methods, presenting a significant sustainability advantage.

The energy return on investment (EROI) for these systems currently ranges between 2.5:1 and 3.2:1, indicating positive energy generation relative to production inputs. However, this ratio remains lower than some established renewable technologies. Optimization of catalytic conversion processes within the microfluidic channels could potentially increase this ratio to 4.5:1 within the next five years, according to recent research from Stanford University and MIT.

Waste management considerations must address both manufacturing byproducts and end-of-life disposal. The miniaturized nature of these devices results in minimal waste generation during operation, but manufacturing processes still produce chemical waste streams requiring specialized treatment. Implementation of green chemistry principles in production could reduce hazardous waste by approximately 35%, based on pilot programs at leading microfluidics manufacturers.

Carbon footprint analyses reveal that widespread adoption of microfluidic sweat management systems could offset approximately 0.5-0.8 metric tons of CO2 equivalent per device annually when replacing conventional portable power sources. This represents a modest but meaningful contribution to climate change mitigation efforts, particularly when scaled across multiple applications and users.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!