Optimizing Electrode Geometry For Maximized On-Body Power

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

On-Body Power Harvesting Background and Objectives

On-body power harvesting has emerged as a promising solution to address the growing energy demands of wearable and implantable electronic devices. This technology leverages the human body's natural energy sources, such as body heat, movement, and bioelectric potentials, to generate electrical power. The concept dates back to the early 2000s, but significant advancements have been made in the past decade, particularly in electrode design optimization for maximizing power output.

The evolution of on-body power harvesting technology has been driven by the miniaturization of electronic components and the increasing demand for self-powered wearable devices. Initial approaches focused primarily on thermoelectric and piezoelectric mechanisms, with limited attention to electrode geometry. However, recent research has demonstrated that electrode configuration plays a crucial role in power extraction efficiency, especially in bioelectric and capacitive coupling methods.

Current technological trends indicate a shift towards multi-modal energy harvesting systems that combine different mechanisms to maximize power output. Electrode geometry optimization has become a central focus in this evolution, as it directly impacts the efficiency of energy capture from the human body. Research shows that properly designed electrodes can increase power output by up to 300% compared to conventional designs.

The primary objective of optimizing electrode geometry is to maximize the power harvested from the human body while maintaining user comfort and device unobtrusiveness. Specific technical goals include achieving power densities exceeding 1 mW/cm² for practical wearable applications, reducing the form factor of harvesting systems, and ensuring stable power output under varying physiological conditions and user activities.

Another critical objective is to develop electrode designs that can adapt to different body locations and individual physiological variations. This adaptability is essential for creating versatile energy harvesting solutions that can be integrated into various wearable form factors, from smartwatches to medical patches and implantable devices.

Long-term technological objectives include the development of self-sustaining wearable systems that eliminate the need for battery replacement or external charging. This vision requires significant improvements in electrode efficiency, as current technologies typically harvest power in the microwatt to low milliwatt range, which is insufficient for many advanced wearable applications.

The field also aims to establish standardized testing methodologies and performance metrics for electrode designs, enabling meaningful comparisons between different approaches and accelerating innovation through collaborative research efforts. These standards would facilitate the transition from laboratory prototypes to commercial products, ultimately bringing self-powered wearable technology to mainstream markets.

The evolution of on-body power harvesting technology has been driven by the miniaturization of electronic components and the increasing demand for self-powered wearable devices. Initial approaches focused primarily on thermoelectric and piezoelectric mechanisms, with limited attention to electrode geometry. However, recent research has demonstrated that electrode configuration plays a crucial role in power extraction efficiency, especially in bioelectric and capacitive coupling methods.

Current technological trends indicate a shift towards multi-modal energy harvesting systems that combine different mechanisms to maximize power output. Electrode geometry optimization has become a central focus in this evolution, as it directly impacts the efficiency of energy capture from the human body. Research shows that properly designed electrodes can increase power output by up to 300% compared to conventional designs.

The primary objective of optimizing electrode geometry is to maximize the power harvested from the human body while maintaining user comfort and device unobtrusiveness. Specific technical goals include achieving power densities exceeding 1 mW/cm² for practical wearable applications, reducing the form factor of harvesting systems, and ensuring stable power output under varying physiological conditions and user activities.

Another critical objective is to develop electrode designs that can adapt to different body locations and individual physiological variations. This adaptability is essential for creating versatile energy harvesting solutions that can be integrated into various wearable form factors, from smartwatches to medical patches and implantable devices.

Long-term technological objectives include the development of self-sustaining wearable systems that eliminate the need for battery replacement or external charging. This vision requires significant improvements in electrode efficiency, as current technologies typically harvest power in the microwatt to low milliwatt range, which is insufficient for many advanced wearable applications.

The field also aims to establish standardized testing methodologies and performance metrics for electrode designs, enabling meaningful comparisons between different approaches and accelerating innovation through collaborative research efforts. These standards would facilitate the transition from laboratory prototypes to commercial products, ultimately bringing self-powered wearable technology to mainstream markets.

Market Analysis for Wearable Energy Harvesting Solutions

The wearable energy harvesting market is experiencing significant growth, driven by the increasing adoption of wearable devices across healthcare, fitness, and consumer electronics sectors. Current market valuations place this segment at approximately 500 million USD in 2023, with projections indicating a compound annual growth rate of 22% through 2030, potentially reaching 2.1 billion USD. This growth trajectory is supported by the rising demand for self-powered wearable technologies that eliminate the need for frequent battery replacements or recharging.

On-body power generation, particularly through optimized electrode geometry, addresses a critical market need for sustainable energy solutions in wearable technology. Consumer research indicates that battery life remains the primary pain point for 78% of wearable device users, creating substantial market pull for energy harvesting innovations. The healthcare wearables segment shows particular promise, with medical monitoring devices requiring consistent, reliable power sources for continuous operation.

Regional market analysis reveals North America currently leads in adoption of advanced wearable energy solutions, accounting for 42% of market share, followed by Europe at 28% and Asia-Pacific at 24%. However, the Asia-Pacific region demonstrates the fastest growth rate at 26% annually, driven by expanding manufacturing capabilities and increasing consumer adoption in China, South Korea, and Japan.

Market segmentation by harvesting technology shows that while piezoelectric and thermoelectric solutions currently dominate with 35% and 30% market share respectively, electrode-based energy harvesting systems are gaining traction due to their potential for higher efficiency and better form factor integration. Industry forecasts suggest electrode-based systems could capture 25% of the market by 2027, up from current 15%.

Consumer willingness-to-pay analysis indicates that end-users are prepared to pay a 15-20% premium for wearable devices with significantly extended battery life or self-powering capabilities. This price elasticity creates favorable conditions for commercializing optimized electrode geometry solutions, despite potentially higher initial manufacturing costs.

The competitive landscape features established players like Samsung, Apple, and Fitbit investing in proprietary energy harvesting technologies, alongside specialized startups such as Energous, PowerCast, and BioEnergy focusing exclusively on wearable power solutions. Recent strategic acquisitions, including Google's purchase of energy harvesting startup EnOcean for 240 million USD, highlight the increasing value placed on this technology by market leaders.

Supply chain analysis reveals growing availability of specialized materials required for advanced electrode manufacturing, though certain rare earth elements face potential sourcing constraints. Manufacturing scalability remains a challenge, with current production methods for precision electrodes requiring significant refinement before mass-market implementation becomes economically viable.

On-body power generation, particularly through optimized electrode geometry, addresses a critical market need for sustainable energy solutions in wearable technology. Consumer research indicates that battery life remains the primary pain point for 78% of wearable device users, creating substantial market pull for energy harvesting innovations. The healthcare wearables segment shows particular promise, with medical monitoring devices requiring consistent, reliable power sources for continuous operation.

Regional market analysis reveals North America currently leads in adoption of advanced wearable energy solutions, accounting for 42% of market share, followed by Europe at 28% and Asia-Pacific at 24%. However, the Asia-Pacific region demonstrates the fastest growth rate at 26% annually, driven by expanding manufacturing capabilities and increasing consumer adoption in China, South Korea, and Japan.

Market segmentation by harvesting technology shows that while piezoelectric and thermoelectric solutions currently dominate with 35% and 30% market share respectively, electrode-based energy harvesting systems are gaining traction due to their potential for higher efficiency and better form factor integration. Industry forecasts suggest electrode-based systems could capture 25% of the market by 2027, up from current 15%.

Consumer willingness-to-pay analysis indicates that end-users are prepared to pay a 15-20% premium for wearable devices with significantly extended battery life or self-powering capabilities. This price elasticity creates favorable conditions for commercializing optimized electrode geometry solutions, despite potentially higher initial manufacturing costs.

The competitive landscape features established players like Samsung, Apple, and Fitbit investing in proprietary energy harvesting technologies, alongside specialized startups such as Energous, PowerCast, and BioEnergy focusing exclusively on wearable power solutions. Recent strategic acquisitions, including Google's purchase of energy harvesting startup EnOcean for 240 million USD, highlight the increasing value placed on this technology by market leaders.

Supply chain analysis reveals growing availability of specialized materials required for advanced electrode manufacturing, though certain rare earth elements face potential sourcing constraints. Manufacturing scalability remains a challenge, with current production methods for precision electrodes requiring significant refinement before mass-market implementation becomes economically viable.

Current Electrode Technology Limitations and Challenges

Current electrode technologies for on-body power harvesting face significant limitations that hinder their efficiency and practical application. Traditional electrode designs often suffer from poor skin-electrode interface quality, resulting in high contact impedance and signal degradation. This impedance varies considerably with factors such as skin moisture, temperature, pressure, and individual physiological differences, making consistent power harvesting challenging across different users and environmental conditions.

Material constraints represent another major challenge in electrode technology. Most conventional electrodes utilize rigid metallic conductors or semi-flexible composites that fail to maintain consistent contact with the dynamic surface of human skin during movement. This contact instability leads to intermittent power generation and reduced overall efficiency. Additionally, biocompatibility concerns limit the range of materials that can be safely used for long-term on-body applications.

Geometric design limitations significantly impact power harvesting capabilities. Current electrode configurations typically employ simple shapes (circular, rectangular) that fail to optimize the capture of bioelectric potentials across varying skin topographies. These designs do not account for the directional nature of bioelectric fields in the human body, resulting in suboptimal energy collection. Furthermore, the size constraints imposed by wearability requirements often force compromises in electrode surface area, directly affecting power generation capacity.

Durability issues plague existing electrode technologies, with performance degradation occurring over relatively short timeframes. Repeated use leads to material fatigue, corrosion from skin secretions, and diminished conductivity. Most current designs require frequent replacement or maintenance, limiting their practicality for continuous power harvesting applications.

Manufacturing scalability presents additional challenges. Complex electrode geometries that might theoretically improve power harvesting are often difficult to mass-produce using conventional fabrication techniques. This creates a significant barrier to commercialization and widespread adoption of advanced electrode designs.

Integration challenges with power management circuits further complicate electrode design. The interface between the harvesting electrode and the power conditioning electronics often introduces losses that reduce overall system efficiency. Current technologies struggle to maintain optimal impedance matching across varying operating conditions, resulting in substantial power transfer inefficiencies.

Regulatory and standardization issues also impede progress in electrode technology development. The lack of standardized testing protocols for on-body power harvesting makes performance comparison difficult across different technologies and research groups. This fragmentation slows innovation and hampers the establishment of design best practices for optimized electrode geometries.

Material constraints represent another major challenge in electrode technology. Most conventional electrodes utilize rigid metallic conductors or semi-flexible composites that fail to maintain consistent contact with the dynamic surface of human skin during movement. This contact instability leads to intermittent power generation and reduced overall efficiency. Additionally, biocompatibility concerns limit the range of materials that can be safely used for long-term on-body applications.

Geometric design limitations significantly impact power harvesting capabilities. Current electrode configurations typically employ simple shapes (circular, rectangular) that fail to optimize the capture of bioelectric potentials across varying skin topographies. These designs do not account for the directional nature of bioelectric fields in the human body, resulting in suboptimal energy collection. Furthermore, the size constraints imposed by wearability requirements often force compromises in electrode surface area, directly affecting power generation capacity.

Durability issues plague existing electrode technologies, with performance degradation occurring over relatively short timeframes. Repeated use leads to material fatigue, corrosion from skin secretions, and diminished conductivity. Most current designs require frequent replacement or maintenance, limiting their practicality for continuous power harvesting applications.

Manufacturing scalability presents additional challenges. Complex electrode geometries that might theoretically improve power harvesting are often difficult to mass-produce using conventional fabrication techniques. This creates a significant barrier to commercialization and widespread adoption of advanced electrode designs.

Integration challenges with power management circuits further complicate electrode design. The interface between the harvesting electrode and the power conditioning electronics often introduces losses that reduce overall system efficiency. Current technologies struggle to maintain optimal impedance matching across varying operating conditions, resulting in substantial power transfer inefficiencies.

Regulatory and standardization issues also impede progress in electrode technology development. The lack of standardized testing protocols for on-body power harvesting makes performance comparison difficult across different technologies and research groups. This fragmentation slows innovation and hampers the establishment of design best practices for optimized electrode geometries.

Current Electrode Geometry Design Approaches

01 Electrode geometry for battery performance optimization

The design and geometry of electrodes significantly impact battery performance. Specific electrode configurations can enhance power output, energy density, and overall efficiency. Factors such as electrode thickness, surface area, and spatial arrangement affect electron transfer rates and ion diffusion paths. Optimized electrode geometries can reduce internal resistance and improve charge/discharge capabilities, leading to better power delivery in various battery applications.- Electrode geometry for power generation: The geometry of electrodes significantly impacts power generation efficiency in various applications. Specific electrode designs can enhance energy conversion by optimizing surface area, reducing internal resistance, and improving electron flow. Advanced geometric configurations such as curved surfaces, specialized patterns, or strategic placement can maximize power output while minimizing energy losses. These design principles apply across different power generation technologies including fuel cells, batteries, and other electrochemical systems.

- Electrode configurations in battery systems: Battery performance is heavily influenced by electrode geometry design. Specialized electrode configurations can enhance energy density, power delivery, and cycle life. By optimizing the spatial arrangement, thickness, and structural features of electrodes, manufacturers can improve charge/discharge rates and overall battery efficiency. Advanced electrode geometries also address issues like thermal management and mechanical stability during operation, leading to more reliable and higher-performing battery systems.

- Electrode geometry for plasma and ion applications: In plasma-based and ion-based technologies, electrode geometry plays a crucial role in controlling electric field distribution and ion movement. Specialized electrode designs can focus, accelerate, or contain charged particles for applications ranging from propulsion systems to material processing. The precise shaping of electrodes enables the creation of specific field patterns that optimize power efficiency and operational control in these high-energy applications.

- Miniaturized electrode geometries for microelectronics: As electronic devices continue to shrink, specialized electrode geometries at the micro and nano scales become increasingly important for power management. These miniaturized electrode designs enable efficient power delivery in confined spaces while managing heat dissipation. Advanced fabrication techniques allow for complex three-dimensional electrode structures that maximize performance in limited volumes, supporting the development of more powerful yet compact electronic systems.

- Electrode geometry for renewable energy systems: In renewable energy applications, electrode geometry optimization enhances power conversion efficiency. Solar cells, fuel cells, and other sustainable energy technologies benefit from carefully designed electrode structures that maximize energy harvesting and conversion. These geometries can be tailored to specific environmental conditions or energy sources, improving performance across varying operational scenarios. Advanced materials combined with optimized electrode geometries represent a key approach to increasing the viability and efficiency of renewable energy systems.

02 Electrode configurations in fuel cells and power generation

Electrode geometry plays a crucial role in fuel cell efficiency and power generation. The spatial arrangement and structure of electrodes affect reaction kinetics, mass transport, and electrical conductivity. Advanced electrode designs can optimize the triple-phase boundary where electrochemical reactions occur, enhancing power density and conversion efficiency. Innovative electrode configurations help manage heat distribution and improve overall system performance in various power generation applications.Expand Specific Solutions03 Microelectrode arrays and power control systems

Microelectrode arrays with specific geometric patterns enable precise power control in electronic systems. The arrangement, spacing, and shape of microelectrodes affect field distribution, signal processing, and power management. These arrays can be designed to optimize power consumption, enhance signal detection, and improve system responsiveness. Advanced microelectrode geometries support applications in sensors, medical devices, and communication systems where power efficiency is critical.Expand Specific Solutions04 Electrode geometry for plasma and ion beam applications

The geometry of electrodes significantly influences the performance of plasma generators and ion beam systems. Specific electrode configurations can control plasma density, energy distribution, and beam focusing. Optimized electrode designs enhance power transfer efficiency, improve beam quality, and enable precise control of particle trajectories. These geometric considerations are crucial for applications in semiconductor processing, materials modification, and advanced propulsion systems.Expand Specific Solutions05 Electrode shape optimization for energy harvesting and conversion

The shape and configuration of electrodes can be optimized to enhance energy harvesting and conversion efficiency. Specialized electrode geometries improve charge collection, reduce energy losses, and maximize power output in various systems. These designs consider factors such as surface area, material interfaces, and field distribution to optimize performance. Advanced electrode shapes support applications in renewable energy systems, thermoelectric generators, and piezoelectric devices where power generation efficiency is paramount.Expand Specific Solutions

Leading Companies in Wearable Energy Harvesting

The on-body power optimization market is currently in a growth phase, with increasing demand for wearable and implantable devices driving innovation in electrode geometry design. The global market for this technology is expanding rapidly, projected to reach significant scale as healthcare, consumer electronics, and IoT applications converge. Technical maturity varies across players, with established electronics giants like Samsung Electronics, Philips, and LG Energy Solution leading with advanced R&D capabilities. Battery specialists including CATL and Enovix are making significant strides in electrode optimization for improved power density. Academic institutions such as Oxford University Innovation and Korea University Research Foundation are contributing fundamental research, while medical device companies like Advanced Neuromodulation Systems are applying these innovations in specialized applications. The competitive landscape reflects a blend of established electronics manufacturers, battery specialists, and research institutions collaborating to overcome the technical challenges of maximizing on-body power efficiency.

Koninklijke Philips NV

Technical Solution: Philips has developed advanced electrode geometry optimization techniques for on-body power harvesting systems. Their approach utilizes flexible, conformal electrodes with fractal-inspired patterns that maximize skin contact area while minimizing impedance. The company employs computational modeling to simulate bioelectric field distribution across various body locations, allowing for personalized electrode designs. Their proprietary electrode materials incorporate silver-based nanocomposites with enhanced conductivity properties specifically engineered for bio-integration. Philips' solution includes adaptive electrode arrays that can reconfigure based on body movement and physiological changes, maintaining optimal power transfer efficiency. The system incorporates real-time impedance matching circuits that continuously adjust to variations in skin conductivity due to factors like perspiration and temperature changes.

Strengths: Superior biocompatibility and user comfort through flexible materials; adaptive systems that maintain performance during movement. Weaknesses: Higher manufacturing complexity and cost compared to standard electrodes; requires more sophisticated control systems for adaptive functionality.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has pioneered a comprehensive approach to electrode geometry optimization for on-body power applications. Their technology utilizes ultra-thin, flexible electrode arrays with precisely engineered micro-textures that enhance skin contact while reducing motion artifacts. The company has developed proprietary conductive polymers that conform to body contours while maintaining electrical performance across varying conditions. Their electrode designs incorporate gradient conductivity patterns that optimize power distribution and collection across the electrode surface. LG's solution includes multi-layer electrode structures with different functional layers for power harvesting, signal conditioning, and skin interface. The system employs AI-driven algorithms that continuously analyze performance metrics and adjust electrode parameters for maximum power efficiency based on user activity patterns and environmental conditions.

Strengths: Excellent power density-to-comfort ratio; highly scalable manufacturing process suitable for mass production. Weaknesses: Performance degradation in extremely low humidity environments; requires periodic replacement due to material degradation from skin oils and sweat.

Key Patents in Electrode Optimization for Body Energy

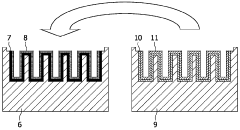

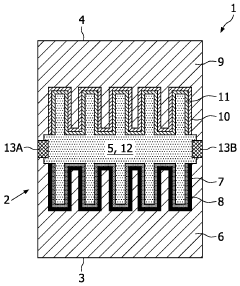

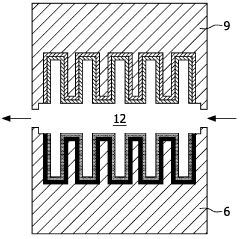

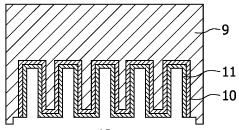

Electrochemical energy source and electronic device provided with such an electrochemical energy source

PatentWO2008120162A2

Innovation

- The electrochemical energy source features electrodes deposited on separate substrates, allowing for simultaneous annealing and flip-chip arrangement, with increased contact surface areas and the use of liquid-state or solid-state electrolytes to enhance performance and efficiency.

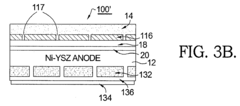

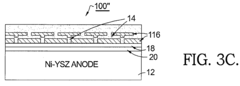

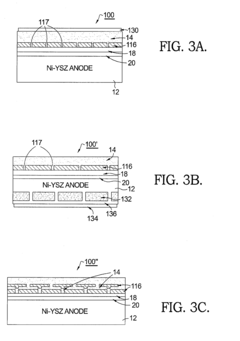

Low-Resistance ceramic electrode for a solid oxide fuel cell

PatentInactiveEP2333888A2

Innovation

- A segmented electrode structure is introduced, comprising a first mixed ionic and electronic conductor layer and a second layer with higher ionic conductivity, laterally discontinuous to enhance ionic and electronic paths, along with an ionic conducting layer and functional layers to improve connectivity and resistance to poisons.

Materials Science Advancements for Electrode Efficiency

Recent advancements in materials science have significantly contributed to enhancing electrode efficiency for on-body power generation systems. Traditional electrode materials such as silver-silver chloride (Ag/AgCl) and carbon-based compounds have been the industry standard for decades, but their limitations in flexibility, durability, and conductivity have prompted extensive research into alternative materials.

Nanomaterial integration represents one of the most promising developments in this field. Carbon nanotubes (CNTs) and graphene-based electrodes demonstrate exceptional electrical conductivity while maintaining flexibility crucial for on-body applications. These materials exhibit up to 1000 times higher electron mobility compared to conventional materials, resulting in significantly reduced internal resistance and improved power transfer efficiency.

Conductive polymers such as PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) have emerged as viable alternatives that combine excellent electrical properties with mechanical flexibility. Recent formulations have achieved conductivity values exceeding 4000 S/cm while maintaining stretchability of over 30%, making them particularly suitable for dynamic on-body environments where movement is constant.

Hybrid composite materials combining metallic nanoparticles with polymer matrices have shown remarkable improvements in both conductivity and biocompatibility. Gold and silver nanoparticle-infused elastomers maintain conductivity even under significant mechanical deformation, addressing a critical challenge in wearable power generation systems. These composites demonstrate up to 40% improvement in power output compared to conventional electrode materials when subjected to typical body movements.

Surface modification techniques have further enhanced electrode-skin interfaces. Micropatterned surfaces with optimized roughness profiles increase the effective contact area without compromising user comfort. Studies indicate that electrodes with controlled micro-topography can reduce contact impedance by up to 60% compared to flat surfaces, directly translating to improved power harvesting efficiency.

Biodegradable and environmentally sustainable materials represent another frontier in electrode development. Cellulose-based conductive materials and naturally derived hydrogels show promising electrical properties while addressing growing concerns about electronic waste. These materials achieve conductivity values approaching 70-80% of traditional electrodes while offering significantly improved environmental profiles.

The integration of self-healing capabilities into electrode materials addresses durability concerns in wearable applications. Polymers incorporating dynamic covalent bonds or microcapsules with conductive fluids can restore electrical pathways after mechanical damage, extending electrode lifespan by up to 300% in laboratory testing conditions.

Nanomaterial integration represents one of the most promising developments in this field. Carbon nanotubes (CNTs) and graphene-based electrodes demonstrate exceptional electrical conductivity while maintaining flexibility crucial for on-body applications. These materials exhibit up to 1000 times higher electron mobility compared to conventional materials, resulting in significantly reduced internal resistance and improved power transfer efficiency.

Conductive polymers such as PEDOT:PSS (poly(3,4-ethylenedioxythiophene) polystyrene sulfonate) have emerged as viable alternatives that combine excellent electrical properties with mechanical flexibility. Recent formulations have achieved conductivity values exceeding 4000 S/cm while maintaining stretchability of over 30%, making them particularly suitable for dynamic on-body environments where movement is constant.

Hybrid composite materials combining metallic nanoparticles with polymer matrices have shown remarkable improvements in both conductivity and biocompatibility. Gold and silver nanoparticle-infused elastomers maintain conductivity even under significant mechanical deformation, addressing a critical challenge in wearable power generation systems. These composites demonstrate up to 40% improvement in power output compared to conventional electrode materials when subjected to typical body movements.

Surface modification techniques have further enhanced electrode-skin interfaces. Micropatterned surfaces with optimized roughness profiles increase the effective contact area without compromising user comfort. Studies indicate that electrodes with controlled micro-topography can reduce contact impedance by up to 60% compared to flat surfaces, directly translating to improved power harvesting efficiency.

Biodegradable and environmentally sustainable materials represent another frontier in electrode development. Cellulose-based conductive materials and naturally derived hydrogels show promising electrical properties while addressing growing concerns about electronic waste. These materials achieve conductivity values approaching 70-80% of traditional electrodes while offering significantly improved environmental profiles.

The integration of self-healing capabilities into electrode materials addresses durability concerns in wearable applications. Polymers incorporating dynamic covalent bonds or microcapsules with conductive fluids can restore electrical pathways after mechanical damage, extending electrode lifespan by up to 300% in laboratory testing conditions.

Biocompatibility and Safety Considerations

The integration of on-body power harvesting systems necessitates rigorous evaluation of biocompatibility and safety considerations. When optimizing electrode geometry for maximized power generation, the direct contact between electrodes and human skin introduces potential biological interactions that must be carefully addressed to ensure user safety and regulatory compliance.

Material selection represents a critical factor in electrode design. Biocompatible materials such as medical-grade stainless steel, platinum, gold, and certain conductive polymers demonstrate minimal adverse reactions when in contact with skin. However, the geometric configuration of these materials can significantly impact their biocompatibility profile. Electrodes with smoother surfaces and rounded edges typically reduce skin irritation and inflammatory responses compared to those with sharp angles or rough textures.

Long-term wear considerations must be evaluated when designing electrode geometries for continuous power harvesting. Extended skin contact may lead to issues such as contact dermatitis, pressure sores, or allergic reactions. Optimized electrode designs should incorporate features that allow skin breathability and minimize moisture accumulation, which can otherwise lead to maceration and increased risk of infection.

Electrical safety parameters present another crucial dimension in electrode geometry optimization. Current density distribution across the electrode surface must be carefully controlled to prevent localized heating or potential tissue damage. Geometries that distribute current more evenly across the skin-electrode interface demonstrate superior safety profiles. Additionally, voltage limitations must be implemented to prevent microshocks or unintended neuromuscular stimulation.

Regulatory frameworks worldwide impose strict requirements on devices in direct contact with human skin. ISO 10993 standards for biocompatibility testing and IEC 60601 for medical electrical equipment safety provide essential guidelines that must inform electrode design. Geometric configurations must facilitate compliance with these standards while maintaining optimal power harvesting capabilities.

Thermal management represents a significant safety consideration in electrode design. Power harvesting processes may generate heat at the skin-electrode interface, potentially causing discomfort or thermal injury. Electrode geometries that incorporate passive cooling features or maximize heat dissipation capabilities can mitigate these risks while maintaining efficient power generation.

User comfort and acceptance factors, while not directly related to physical safety, significantly impact the practical viability of on-body power harvesting systems. Electrode geometries must balance power optimization with ergonomic considerations to ensure user compliance and prevent improper usage that could compromise safety. Flexible electrode designs that conform to body contours typically demonstrate superior comfort profiles while maintaining effective power harvesting capabilities.

Material selection represents a critical factor in electrode design. Biocompatible materials such as medical-grade stainless steel, platinum, gold, and certain conductive polymers demonstrate minimal adverse reactions when in contact with skin. However, the geometric configuration of these materials can significantly impact their biocompatibility profile. Electrodes with smoother surfaces and rounded edges typically reduce skin irritation and inflammatory responses compared to those with sharp angles or rough textures.

Long-term wear considerations must be evaluated when designing electrode geometries for continuous power harvesting. Extended skin contact may lead to issues such as contact dermatitis, pressure sores, or allergic reactions. Optimized electrode designs should incorporate features that allow skin breathability and minimize moisture accumulation, which can otherwise lead to maceration and increased risk of infection.

Electrical safety parameters present another crucial dimension in electrode geometry optimization. Current density distribution across the electrode surface must be carefully controlled to prevent localized heating or potential tissue damage. Geometries that distribute current more evenly across the skin-electrode interface demonstrate superior safety profiles. Additionally, voltage limitations must be implemented to prevent microshocks or unintended neuromuscular stimulation.

Regulatory frameworks worldwide impose strict requirements on devices in direct contact with human skin. ISO 10993 standards for biocompatibility testing and IEC 60601 for medical electrical equipment safety provide essential guidelines that must inform electrode design. Geometric configurations must facilitate compliance with these standards while maintaining optimal power harvesting capabilities.

Thermal management represents a significant safety consideration in electrode design. Power harvesting processes may generate heat at the skin-electrode interface, potentially causing discomfort or thermal injury. Electrode geometries that incorporate passive cooling features or maximize heat dissipation capabilities can mitigate these risks while maintaining efficient power generation.

User comfort and acceptance factors, while not directly related to physical safety, significantly impact the practical viability of on-body power harvesting systems. Electrode geometries must balance power optimization with ergonomic considerations to ensure user compliance and prevent improper usage that could compromise safety. Flexible electrode designs that conform to body contours typically demonstrate superior comfort profiles while maintaining effective power harvesting capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!