Power Management Circuits For Low-Voltage Biofuel Cell Outputs

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biofuel Cell Power Management Background and Objectives

Biofuel cells represent a promising sustainable energy technology that converts biochemical energy directly into electrical energy through electrochemical reactions involving enzymes or microorganisms. The development of these cells dates back to the early 1900s, with significant advancements occurring in the late 20th century as researchers explored alternative energy sources. The evolution of biofuel cell technology has accelerated in recent decades, driven by increasing demands for renewable energy solutions and advances in bioelectrochemistry, materials science, and nanotechnology.

The fundamental challenge with biofuel cells lies in their inherently low voltage outputs, typically ranging from 0.3V to 0.8V per cell, which is insufficient for most practical applications. This limitation stems from the thermodynamic constraints of the biochemical reactions and the overpotentials required for electron transfer processes. Consequently, effective power management circuits become essential to harness and utilize the energy generated by these cells.

The technical objectives for power management circuits in biofuel cell applications are multifaceted. Primary goals include voltage boosting to usable levels (typically 1.8V-3.3V for electronic devices), efficient energy harvesting from ultra-low voltage sources (as low as 20mV), and maximizing power transfer efficiency while minimizing energy losses. Additionally, these circuits must accommodate the variable and often unpredictable nature of biofuel cell outputs, which fluctuate based on environmental conditions, substrate availability, and cell degradation over time.

Recent technological trends in this field focus on the development of ultra-low power startup circuits capable of operating at sub-threshold voltages, implementation of maximum power point tracking (MPPT) algorithms to optimize energy extraction, and integration of energy storage solutions to manage intermittent power generation. The miniaturization of these circuits is also crucial, particularly for implantable or wearable biomedical applications where biofuel cells show significant promise.

The convergence of biofuel cell technology with advanced power management circuits aims to enable self-powered bioelectronic devices, environmental sensors, and medical implants that can operate autonomously for extended periods. This represents a paradigm shift from traditional battery-powered systems to sustainable, potentially maintenance-free energy solutions. The ultimate technical goal is to develop integrated systems where biofuel cells and their associated power management circuits function seamlessly to provide reliable power for real-world applications, despite the inherent limitations of biological energy conversion processes.

The fundamental challenge with biofuel cells lies in their inherently low voltage outputs, typically ranging from 0.3V to 0.8V per cell, which is insufficient for most practical applications. This limitation stems from the thermodynamic constraints of the biochemical reactions and the overpotentials required for electron transfer processes. Consequently, effective power management circuits become essential to harness and utilize the energy generated by these cells.

The technical objectives for power management circuits in biofuel cell applications are multifaceted. Primary goals include voltage boosting to usable levels (typically 1.8V-3.3V for electronic devices), efficient energy harvesting from ultra-low voltage sources (as low as 20mV), and maximizing power transfer efficiency while minimizing energy losses. Additionally, these circuits must accommodate the variable and often unpredictable nature of biofuel cell outputs, which fluctuate based on environmental conditions, substrate availability, and cell degradation over time.

Recent technological trends in this field focus on the development of ultra-low power startup circuits capable of operating at sub-threshold voltages, implementation of maximum power point tracking (MPPT) algorithms to optimize energy extraction, and integration of energy storage solutions to manage intermittent power generation. The miniaturization of these circuits is also crucial, particularly for implantable or wearable biomedical applications where biofuel cells show significant promise.

The convergence of biofuel cell technology with advanced power management circuits aims to enable self-powered bioelectronic devices, environmental sensors, and medical implants that can operate autonomously for extended periods. This represents a paradigm shift from traditional battery-powered systems to sustainable, potentially maintenance-free energy solutions. The ultimate technical goal is to develop integrated systems where biofuel cells and their associated power management circuits function seamlessly to provide reliable power for real-world applications, despite the inherent limitations of biological energy conversion processes.

Market Analysis for Low-Voltage Biofuel Cell Applications

The biofuel cell market is experiencing significant growth driven by increasing demand for sustainable energy solutions and advancements in bioelectronics. Current market estimates value the global biofuel cell sector at approximately $1.5 billion, with projections indicating a compound annual growth rate of 9.4% through 2028. Low-voltage biofuel cells represent a rapidly expanding segment within this market, particularly for applications requiring power in the microwatt to milliwatt range.

Healthcare applications dominate the current market landscape for low-voltage biofuel cells, accounting for nearly 45% of market share. Implantable medical devices such as glucose monitors, cardiac pacemakers, and neural stimulators represent prime opportunities for biofuel cell integration. The global implantable medical device market, valued at $96.6 billion in 2022, presents substantial growth potential for biofuel cell technologies that can provide long-term, sustainable power solutions.

Environmental monitoring represents another significant application area, with market demand projected to reach $2.1 billion by 2026. Low-power sensors for water quality monitoring, soil analysis, and atmospheric condition tracking benefit from biofuel cells' ability to operate in diverse environments while harvesting energy from organic substrates present in those same environments.

Consumer electronics manufacturers are increasingly exploring biofuel cell integration for wearable devices. This market segment, valued at $61.3 billion in 2022, is expected to grow at 14.6% annually through 2027, creating substantial opportunities for low-voltage power management solutions that can extend device operation between charges.

Regional analysis reveals North America currently leads market adoption with 38% market share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 12.7% annually, driven by increasing investments in bioelectronics research and expanding healthcare infrastructure.

Key customer segments include medical device manufacturers (37%), environmental monitoring equipment producers (22%), consumer electronics companies (18%), military/defense contractors (14%), and research institutions (9%). Each segment presents unique requirements regarding power output stability, form factor constraints, and operational longevity.

Market barriers include cost considerations, with current biofuel cell solutions averaging $0.85 per milliwatt-hour compared to $0.12 for conventional batteries. Additionally, reliability concerns and limited awareness of biofuel cell capabilities among potential end-users restrict broader market penetration. However, declining production costs (decreasing at approximately 18% annually) and increasing energy density improvements are gradually addressing these limitations.

Healthcare applications dominate the current market landscape for low-voltage biofuel cells, accounting for nearly 45% of market share. Implantable medical devices such as glucose monitors, cardiac pacemakers, and neural stimulators represent prime opportunities for biofuel cell integration. The global implantable medical device market, valued at $96.6 billion in 2022, presents substantial growth potential for biofuel cell technologies that can provide long-term, sustainable power solutions.

Environmental monitoring represents another significant application area, with market demand projected to reach $2.1 billion by 2026. Low-power sensors for water quality monitoring, soil analysis, and atmospheric condition tracking benefit from biofuel cells' ability to operate in diverse environments while harvesting energy from organic substrates present in those same environments.

Consumer electronics manufacturers are increasingly exploring biofuel cell integration for wearable devices. This market segment, valued at $61.3 billion in 2022, is expected to grow at 14.6% annually through 2027, creating substantial opportunities for low-voltage power management solutions that can extend device operation between charges.

Regional analysis reveals North America currently leads market adoption with 38% market share, followed by Europe (31%) and Asia-Pacific (24%). However, the Asia-Pacific region is demonstrating the fastest growth rate at 12.7% annually, driven by increasing investments in bioelectronics research and expanding healthcare infrastructure.

Key customer segments include medical device manufacturers (37%), environmental monitoring equipment producers (22%), consumer electronics companies (18%), military/defense contractors (14%), and research institutions (9%). Each segment presents unique requirements regarding power output stability, form factor constraints, and operational longevity.

Market barriers include cost considerations, with current biofuel cell solutions averaging $0.85 per milliwatt-hour compared to $0.12 for conventional batteries. Additionally, reliability concerns and limited awareness of biofuel cell capabilities among potential end-users restrict broader market penetration. However, declining production costs (decreasing at approximately 18% annually) and increasing energy density improvements are gradually addressing these limitations.

Current Challenges in Low-Voltage Power Management Circuits

Despite significant advancements in biofuel cell technology, power management circuits for low-voltage biofuel cell outputs face several critical challenges that impede their widespread adoption. The primary obstacle remains the inherently low output voltage of biofuel cells, typically ranging from 0.3V to 0.7V, which falls significantly below the minimum operating threshold of most conventional electronic systems requiring 1.8-3.3V.

Voltage boosting presents a fundamental challenge, as traditional DC-DC converters require minimum input voltages of 0.7-1.0V to function efficiently. When dealing with sub-0.7V inputs, conventional boost converters suffer from severely degraded efficiency, often below 30%, rendering them impractical for biofuel cell applications. This efficiency bottleneck creates a paradoxical situation where the energy harvesting system consumes more power than it can effectively deliver.

Start-up issues compound these difficulties, as most power management circuits require external energy to initialize operation. Without sufficient initial voltage, the system enters a deadlock situation where energy cannot be harvested because the management circuit cannot start. This "cold-start" problem remains one of the most significant barriers to autonomous biofuel cell systems.

The variable and unpredictable nature of biofuel cell outputs presents another layer of complexity. Unlike conventional power sources with stable characteristics, biofuel cells exhibit significant output fluctuations based on environmental conditions, substrate availability, and biocatalyst activity. Power management circuits must therefore incorporate adaptive mechanisms to handle these variations without compromising overall system efficiency.

Miniaturization requirements pose additional challenges, particularly for implantable or wearable biomedical applications. The power management circuit must maintain high efficiency while occupying minimal volume and utilizing biocompatible materials. This constraint limits the selection of components and topologies that can be employed, often forcing compromises between performance and size.

Long-term stability issues also plague current designs. Biofuel cells typically experience performance degradation over time due to biocatalyst deactivation or fouling. Power management circuits must adapt to this gradual decline in input power while maintaining stable output characteristics, a requirement that few existing solutions adequately address.

Integration with energy storage elements introduces further complications. Most applications require some form of energy buffering through capacitors or microbatteries, but efficiently charging these storage elements from sub-0.7V sources while minimizing leakage and self-discharge remains problematic with current circuit technologies.

Voltage boosting presents a fundamental challenge, as traditional DC-DC converters require minimum input voltages of 0.7-1.0V to function efficiently. When dealing with sub-0.7V inputs, conventional boost converters suffer from severely degraded efficiency, often below 30%, rendering them impractical for biofuel cell applications. This efficiency bottleneck creates a paradoxical situation where the energy harvesting system consumes more power than it can effectively deliver.

Start-up issues compound these difficulties, as most power management circuits require external energy to initialize operation. Without sufficient initial voltage, the system enters a deadlock situation where energy cannot be harvested because the management circuit cannot start. This "cold-start" problem remains one of the most significant barriers to autonomous biofuel cell systems.

The variable and unpredictable nature of biofuel cell outputs presents another layer of complexity. Unlike conventional power sources with stable characteristics, biofuel cells exhibit significant output fluctuations based on environmental conditions, substrate availability, and biocatalyst activity. Power management circuits must therefore incorporate adaptive mechanisms to handle these variations without compromising overall system efficiency.

Miniaturization requirements pose additional challenges, particularly for implantable or wearable biomedical applications. The power management circuit must maintain high efficiency while occupying minimal volume and utilizing biocompatible materials. This constraint limits the selection of components and topologies that can be employed, often forcing compromises between performance and size.

Long-term stability issues also plague current designs. Biofuel cells typically experience performance degradation over time due to biocatalyst deactivation or fouling. Power management circuits must adapt to this gradual decline in input power while maintaining stable output characteristics, a requirement that few existing solutions adequately address.

Integration with energy storage elements introduces further complications. Most applications require some form of energy buffering through capacitors or microbatteries, but efficiently charging these storage elements from sub-0.7V sources while minimizing leakage and self-discharge remains problematic with current circuit technologies.

Existing Circuit Solutions for Low-Voltage Energy Harvesting

01 Voltage regulation in power management circuits

Power management circuits employ various voltage regulation techniques to maintain stable output voltages despite input fluctuations or load changes. These circuits include feedback mechanisms that continuously monitor output voltage and adjust control parameters to ensure stability. Advanced voltage regulators incorporate features like dynamic voltage scaling to optimize power consumption based on system requirements, improving overall energy efficiency while maintaining reliable operation.- Voltage regulation and conversion techniques: Power management circuits employ various voltage regulation and conversion techniques to maintain stable output voltages despite input fluctuations. These circuits include buck converters, boost converters, and buck-boost converters that efficiently transform voltage levels according to system requirements. Advanced regulation techniques incorporate feedback mechanisms to continuously monitor and adjust output voltages, ensuring optimal performance across varying load conditions.

- Dynamic voltage scaling for power optimization: Dynamic voltage scaling techniques allow power management circuits to adjust voltage levels based on processing demands, significantly reducing power consumption during periods of low activity. These systems continuously monitor workload requirements and intelligently scale voltage supplies to match actual needs, balancing performance with energy efficiency. Implementation includes predictive algorithms that anticipate processing needs and prepare voltage adjustments in advance, minimizing performance impacts while maximizing power savings.

- Multi-phase power management architectures: Multi-phase power management architectures distribute power delivery across multiple phases, reducing stress on individual components while improving overall efficiency and response times. These designs enable better thermal management by spreading heat generation across multiple circuit elements. Advanced implementations include phase shedding capabilities that dynamically adjust the number of active phases based on current load requirements, optimizing efficiency across the entire operating range.

- Intelligent power distribution and management systems: Intelligent power distribution systems incorporate microcontroller-based management to optimize voltage delivery across complex electronic systems. These circuits feature real-time monitoring of multiple voltage rails with automated adjustment capabilities to maintain system stability. Advanced implementations include fault detection, protection mechanisms, and communication interfaces that enable system-level power optimization strategies. These systems can prioritize power delivery to critical components during constrained power availability scenarios.

- Energy harvesting and storage integration: Power management circuits with integrated energy harvesting capabilities capture energy from ambient sources and efficiently convert it to usable voltage levels. These systems incorporate specialized voltage conditioning circuits to handle the variable nature of harvested energy sources. Advanced implementations include intelligent storage management that optimizes charging and discharging cycles of batteries or supercapacitors while maintaining appropriate voltage levels for connected devices. This approach extends operational life in battery-powered applications and enables self-sustaining operation in certain scenarios.

02 Power efficiency optimization techniques

Various techniques are implemented in power management circuits to optimize efficiency across different load conditions. These include adaptive switching frequency control, which adjusts the operating frequency based on load demands, and advanced power stage designs that minimize switching and conduction losses. Some implementations utilize multi-phase operation for heavy loads while reducing active phases during light loads, significantly improving efficiency across the entire operating range.Expand Specific Solutions03 Battery management and charging systems

Power management circuits for battery systems incorporate sophisticated charging algorithms and protection mechanisms. These circuits monitor battery voltage, current, and temperature to optimize charging profiles while preventing overcharging or deep discharge conditions. Advanced implementations feature cell balancing for multi-cell batteries and adaptive charging rates based on battery health and environmental conditions, extending battery lifespan while ensuring safe operation.Expand Specific Solutions04 Integrated power management solutions

Integrated power management circuits combine multiple power functions into single-chip solutions, including voltage regulators, power sequencing, and system monitoring. These highly integrated designs reduce component count and board space while improving system reliability. Many implementations include digital interfaces for configuration and monitoring, enabling dynamic adjustment of power parameters based on system requirements and facilitating advanced power saving modes.Expand Specific Solutions05 Power conversion architectures

Various power conversion architectures are employed in power management circuits, including buck, boost, and buck-boost topologies. Each architecture offers specific advantages for different voltage conversion requirements and efficiency targets. Advanced implementations utilize hybrid conversion techniques that dynamically switch between different topologies based on input/output voltage relationships, optimizing efficiency across wide operating ranges while maintaining precise voltage regulation.Expand Specific Solutions

Leading Companies in Biofuel Cell Power Management Industry

The power management circuit market for low-voltage biofuel cells is in an early growth phase, characterized by increasing research activity but limited commercial deployment. The global market size remains relatively small but is expanding as renewable energy applications gain traction. From a technical maturity perspective, companies like Texas Instruments and ROHM lead in developing specialized low-power management ICs, while automotive manufacturers including Toyota, Nissan, and BYD are investing in biofuel cell integration for electric vehicles. Research institutions such as CNRS and National University of Singapore collaborate with industry players to overcome challenges in voltage boosting and energy harvesting from sub-volt biofuel cell outputs. The competitive landscape features both established semiconductor companies and emerging specialized firms like Pragma Industries focusing on biofuel cell-specific power management solutions.

Texas Instruments Incorporated

Technical Solution: Texas Instruments has developed a sophisticated power management solution for low-voltage biofuel cells centered around their BQ25570 integrated circuit. This ultra-low-power harvester efficiently captures energy from inputs as low as 100mV, making it ideal for biofuel cell applications that typically generate 0.3-0.7V. The system employs a proprietary "boost charger" with maximum power point tracking (MPPT) that dynamically adjusts to extract optimal energy from biofuel cells despite their variable output characteristics. TI's solution incorporates a nanopower management module that consumes less than 500nA quiescent current, maximizing energy conservation. The architecture includes a programmable voltage supervisor that ensures system stability even with the fluctuating outputs common in biofuel cells. Their implementation features dual-path power management that can simultaneously power a system while charging an energy storage device, enabling continuous operation of critical biomedical sensors or implantable devices.

Strengths: Industry-leading low quiescent current maximizes energy harvesting efficiency; highly configurable solution adaptable to various biofuel cell types; extensive development ecosystem with evaluation modules and design tools. Weaknesses: Requires external components for complete solution implementation; more complex configuration compared to single-purpose alternatives.

National University of Singapore

Technical Solution: The National University of Singapore has developed an innovative power management circuit specifically designed for enzymatic and microbial biofuel cells operating at ultra-low voltages. Their solution features a self-starting boost converter capable of operating from voltages as low as 0.18V, addressing the fundamental challenge of biofuel cells that typically generate 0.2-0.5V. The architecture employs a novel oscillator design that requires minimal startup energy, enabling operation from severely depleted biofuel cells. NUS's implementation incorporates a dynamic impedance matching network that continuously adjusts to maximize power transfer from the biofuel cell despite variations in its internal resistance due to biological factors. Their system includes a hierarchical power management approach that prioritizes critical functions during energy-limited scenarios. The circuit features an ultra-efficient charge pump with specialized timing control that achieves over 80% conversion efficiency even at sub-0.3V inputs, significantly higher than conventional designs operating in this voltage range.

Strengths: Industry-leading low voltage operation capability; highly optimized for the specific characteristics of biofuel cells; innovative circuit techniques that advance the state-of-the-art. Weaknesses: Currently at research prototype stage rather than commercial product; requires specialized expertise to implement in practical applications.

Key Technologies in Voltage Boosting and Energy Storage

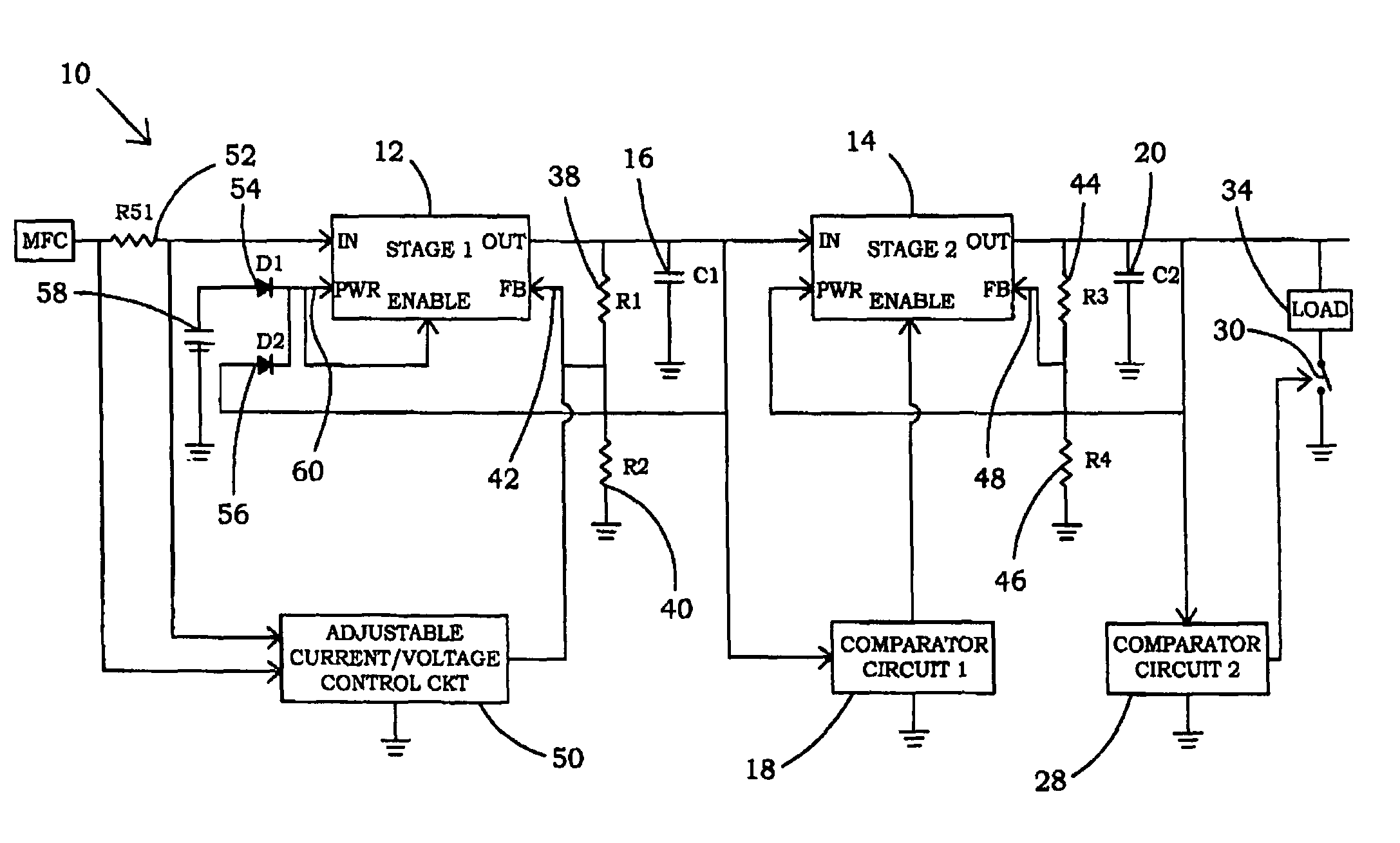

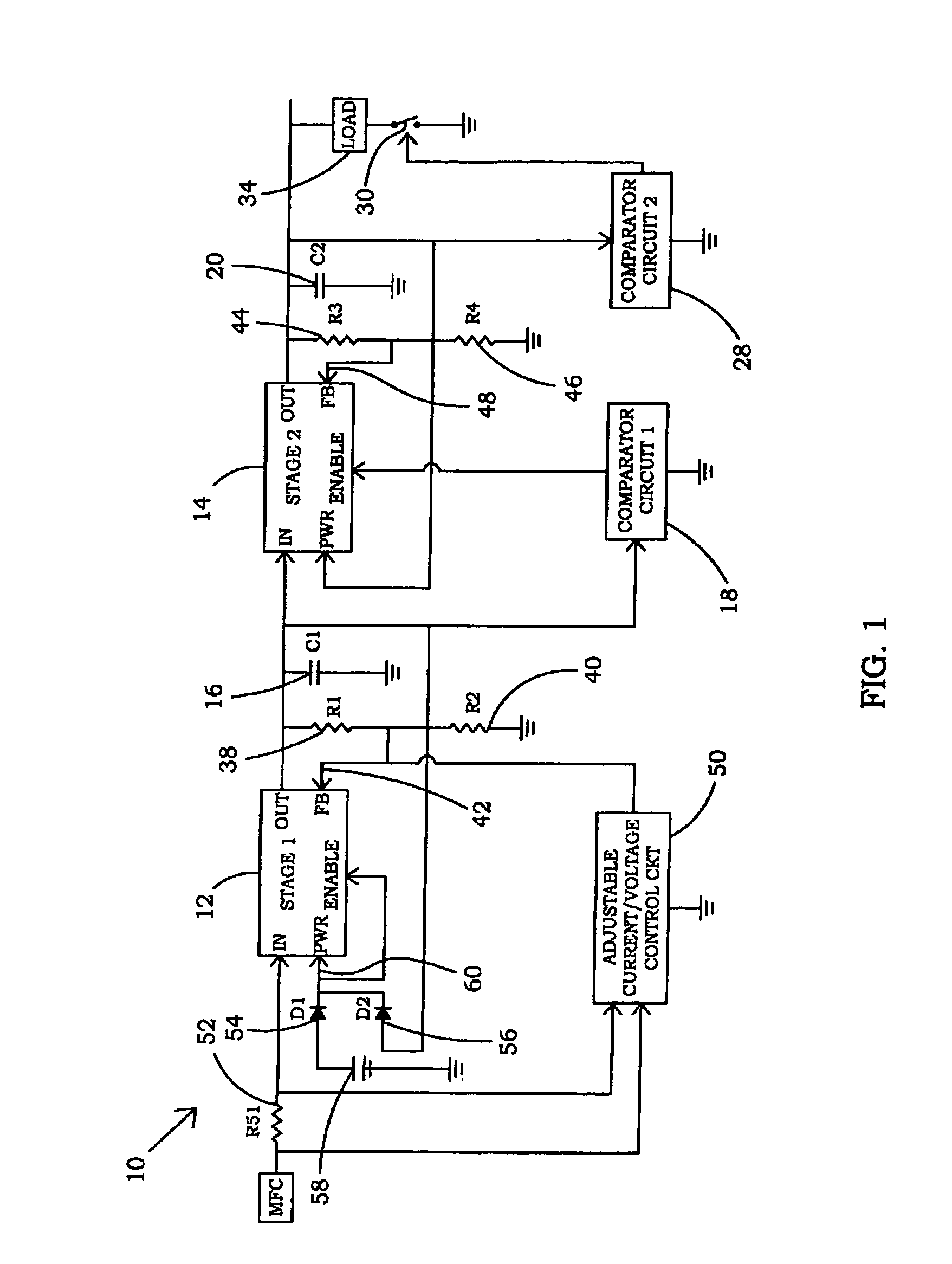

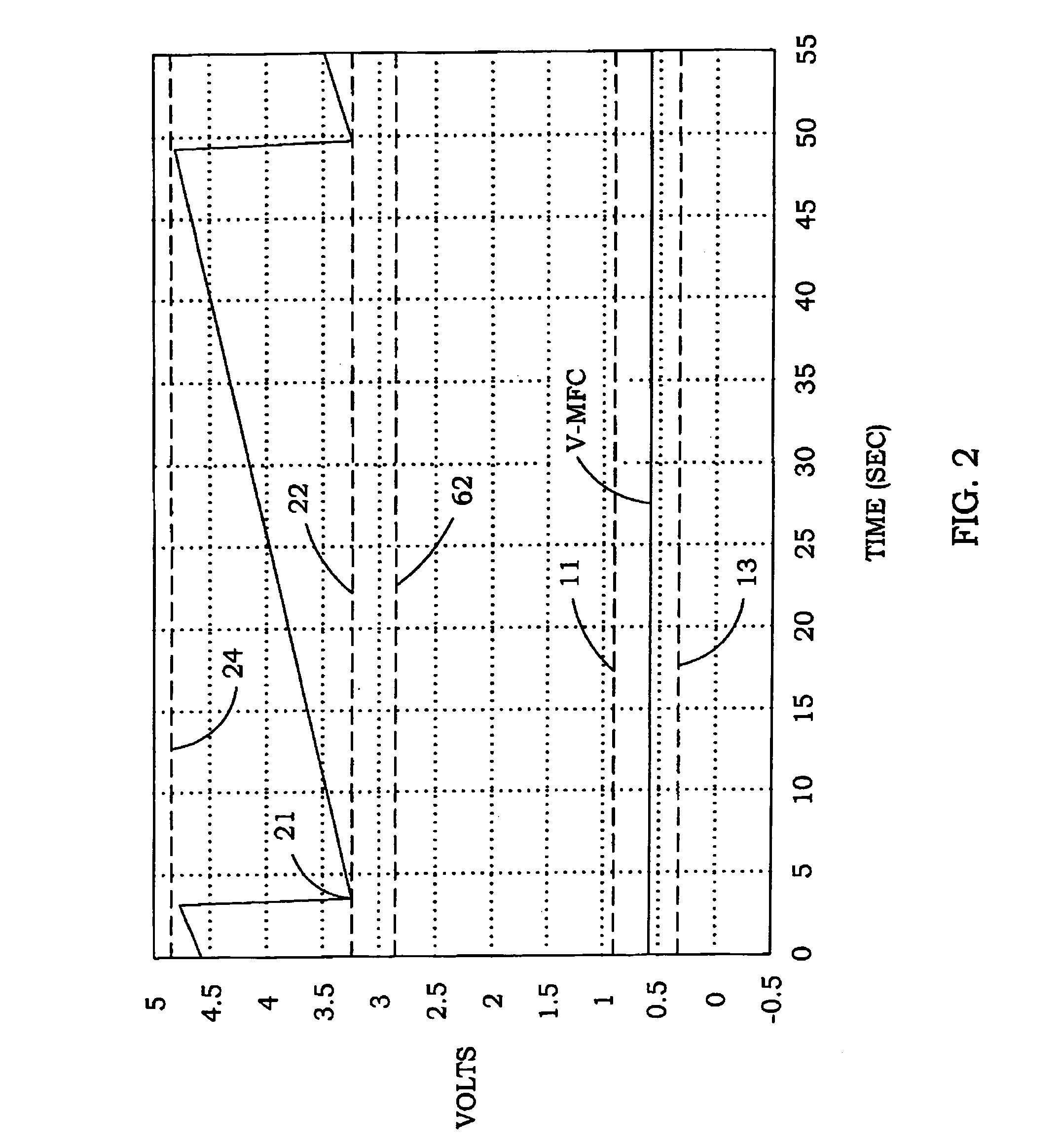

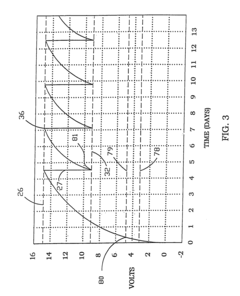

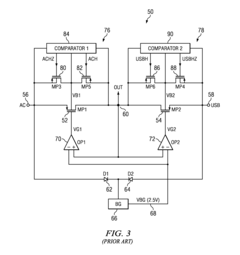

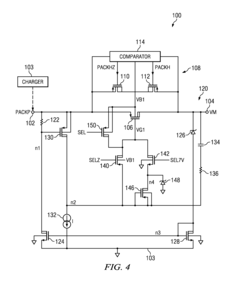

Power conditioner for microbial fuel cells

PatentInactiveUS8232761B1

Innovation

- A two-stage energy conversion and storage system that includes a first power converter stage with an integrated converter circuit and output storage device, and a second stage that boosts the voltage output to levels compatible with electronic devices, using comparator circuits to manage power distribution and storage, allowing for self-powered operation and efficient energy harvesting from MFCs.

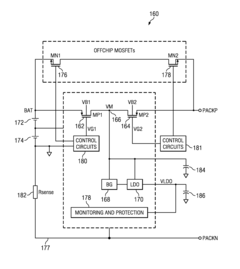

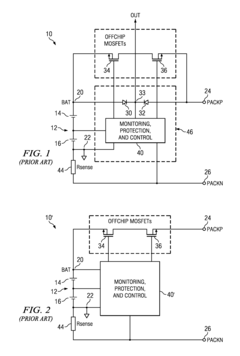

Low-voltage dual-power-path management architecture for rechargeable battery monitoring solutions

PatentActiveUS20120112686A1

Innovation

- A dual-power-path management circuit architecture that uses switch-type MOSFETs and a low-drop-out regulator (LDO) with capacitors to enable operation from zero volts, allowing charging and protection of batteries across a wide voltage range, including zero volts, and includes control circuits to manage power paths between battery and charger inputs, ensuring system stability during brown-out or short events.

Sustainability Impact of Biofuel Cell Power Management

The integration of biofuel cell power management systems represents a significant advancement in sustainable energy technology, offering substantial environmental benefits compared to conventional power sources. Biofuel cells harness energy from renewable biological materials, creating electricity through bioelectrochemical reactions that produce minimal waste and toxic byproducts. This fundamental characteristic positions them as environmentally superior alternatives to traditional batteries containing heavy metals and other hazardous components.

When examining the complete lifecycle of biofuel cell power management systems, their sustainability advantages become even more apparent. The raw materials required for biofuel cells often include renewable biological components that can be sourced through sustainable agricultural practices or even from waste streams. This circular approach significantly reduces the environmental footprint associated with resource extraction and processing that plagues conventional battery production.

Carbon emissions represent another critical sustainability metric where biofuel cell systems demonstrate considerable advantages. The operation of these cells typically involves carbon-neutral or carbon-negative processes, as the biological materials used often capture carbon during their growth phase. Advanced power management circuits optimize energy extraction efficiency, further enhancing this environmental benefit by maximizing the usable energy derived from each unit of biological material.

The end-of-life considerations for biofuel cell systems also contribute to their sustainability profile. Unlike conventional batteries that require specialized disposal procedures and recycling infrastructure, many biofuel cell components are biodegradable or can be more easily recycled. This characteristic substantially reduces the long-term environmental burden associated with electronic waste management.

In healthcare applications specifically, the sustainability benefits are particularly noteworthy. Implantable or wearable medical devices powered by biofuel cells with efficient power management circuits can operate for extended periods without battery replacement, reducing medical waste and the need for invasive replacement procedures. This translates to both environmental and patient benefits, exemplifying the dual advantages of this technology.

Looking forward, the continued development of more efficient power management circuits for low-voltage biofuel cells promises to further enhance their sustainability impact. Innovations that increase energy conversion efficiency, reduce material requirements, and extend operational lifespans will collectively strengthen the environmental case for widespread adoption of this technology across multiple sectors, from medical devices to environmental monitoring systems and beyond.

When examining the complete lifecycle of biofuel cell power management systems, their sustainability advantages become even more apparent. The raw materials required for biofuel cells often include renewable biological components that can be sourced through sustainable agricultural practices or even from waste streams. This circular approach significantly reduces the environmental footprint associated with resource extraction and processing that plagues conventional battery production.

Carbon emissions represent another critical sustainability metric where biofuel cell systems demonstrate considerable advantages. The operation of these cells typically involves carbon-neutral or carbon-negative processes, as the biological materials used often capture carbon during their growth phase. Advanced power management circuits optimize energy extraction efficiency, further enhancing this environmental benefit by maximizing the usable energy derived from each unit of biological material.

The end-of-life considerations for biofuel cell systems also contribute to their sustainability profile. Unlike conventional batteries that require specialized disposal procedures and recycling infrastructure, many biofuel cell components are biodegradable or can be more easily recycled. This characteristic substantially reduces the long-term environmental burden associated with electronic waste management.

In healthcare applications specifically, the sustainability benefits are particularly noteworthy. Implantable or wearable medical devices powered by biofuel cells with efficient power management circuits can operate for extended periods without battery replacement, reducing medical waste and the need for invasive replacement procedures. This translates to both environmental and patient benefits, exemplifying the dual advantages of this technology.

Looking forward, the continued development of more efficient power management circuits for low-voltage biofuel cells promises to further enhance their sustainability impact. Innovations that increase energy conversion efficiency, reduce material requirements, and extend operational lifespans will collectively strengthen the environmental case for widespread adoption of this technology across multiple sectors, from medical devices to environmental monitoring systems and beyond.

Standardization and Testing Protocols for Biofuel Cell Circuits

Standardization and testing protocols for biofuel cell circuits represent a critical foundation for advancing power management solutions in this emerging field. Currently, the lack of universally accepted protocols hampers meaningful comparison between different circuit designs and impedes industry-wide progress. Establishing standardized testing methodologies would enable researchers and manufacturers to evaluate performance metrics consistently across various biofuel cell power management systems.

The primary parameters requiring standardization include voltage conversion efficiency, power density measurements, operational stability under varying loads, and response times to fluctuating biofuel cell outputs. These metrics must be measured under controlled environmental conditions, as temperature, humidity, and substrate concentration significantly impact biofuel cell performance and consequently affect power management circuit evaluation.

International organizations such as IEEE and IEC have begun preliminary work on developing standards specific to biofuel cell applications, though these efforts remain in nascent stages. The IEEE P2830 working group has recently initiated discussions on standardization frameworks for bioelectronic systems, which could potentially encompass biofuel cell power management circuits.

Testing protocols should incorporate both static and dynamic evaluation methods. Static testing would assess circuit performance under constant load conditions, while dynamic protocols would evaluate response to varying loads and intermittent biofuel cell outputs—a scenario more representative of real-world applications. Accelerated aging tests are equally important to predict long-term reliability, particularly for implantable or environmental monitoring applications where maintenance access is limited.

Round-robin testing among multiple laboratories would strengthen protocol validation and ensure reproducibility across different testing environments. Several academic institutions, including Imperial College London and University of California San Diego, have proposed preliminary testing frameworks that could serve as foundations for industry-wide standards.

Certification processes based on these standardized protocols would facilitate market entry for new technologies and build consumer confidence. A tiered certification system could accommodate different application domains, recognizing that medical implants require more stringent reliability standards than environmental sensors or consumer electronics.

The development of open-source reference designs and testing platforms would accelerate adoption of standardized protocols, allowing smaller research groups and companies to participate in advancement of the field without prohibitive equipment investments.

The primary parameters requiring standardization include voltage conversion efficiency, power density measurements, operational stability under varying loads, and response times to fluctuating biofuel cell outputs. These metrics must be measured under controlled environmental conditions, as temperature, humidity, and substrate concentration significantly impact biofuel cell performance and consequently affect power management circuit evaluation.

International organizations such as IEEE and IEC have begun preliminary work on developing standards specific to biofuel cell applications, though these efforts remain in nascent stages. The IEEE P2830 working group has recently initiated discussions on standardization frameworks for bioelectronic systems, which could potentially encompass biofuel cell power management circuits.

Testing protocols should incorporate both static and dynamic evaluation methods. Static testing would assess circuit performance under constant load conditions, while dynamic protocols would evaluate response to varying loads and intermittent biofuel cell outputs—a scenario more representative of real-world applications. Accelerated aging tests are equally important to predict long-term reliability, particularly for implantable or environmental monitoring applications where maintenance access is limited.

Round-robin testing among multiple laboratories would strengthen protocol validation and ensure reproducibility across different testing environments. Several academic institutions, including Imperial College London and University of California San Diego, have proposed preliminary testing frameworks that could serve as foundations for industry-wide standards.

Certification processes based on these standardized protocols would facilitate market entry for new technologies and build consumer confidence. A tiered certification system could accommodate different application domains, recognizing that medical implants require more stringent reliability standards than environmental sensors or consumer electronics.

The development of open-source reference designs and testing platforms would accelerate adoption of standardized protocols, allowing smaller research groups and companies to participate in advancement of the field without prohibitive equipment investments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!