Field Demonstration Protocols For Wearable Energy Harvesters

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Energy Harvesting Technology Background and Objectives

Energy harvesting technology has evolved significantly over the past decades, transitioning from large-scale applications to miniaturized wearable solutions. The concept of harvesting ambient energy from the environment dates back to the early 20th century with hydroelectric power generation, but recent advancements in materials science, microelectronics, and nanotechnology have enabled the development of compact energy harvesters suitable for wearable applications.

Wearable energy harvesters represent a paradigm shift in powering portable and wearable electronics, offering the potential to eliminate or reduce the dependency on conventional batteries. These technologies convert various forms of ambient energy—such as mechanical motion, thermal gradients, solar radiation, and electromagnetic waves—into usable electrical energy to power low-power electronic devices worn on or near the human body.

The evolution of wearable energy harvesting has been driven by several technological trends, including the miniaturization of electronic components, the development of flexible and stretchable materials, improvements in energy conversion efficiency, and the growing demand for sustainable power solutions. Key milestones include the development of piezoelectric materials for mechanical energy harvesting, thermoelectric generators for thermal energy conversion, and flexible photovoltaic cells for solar energy capture.

The primary objective of field demonstration protocols for wearable energy harvesters is to establish standardized methodologies for evaluating the performance, reliability, and usability of these technologies in real-world conditions. These protocols aim to bridge the gap between laboratory testing and practical implementation by providing comprehensive frameworks for assessing energy output, efficiency, durability, and user experience across diverse environmental conditions and usage scenarios.

Additional objectives include identifying optimal deployment strategies for different wearable applications, determining the factors that influence energy harvesting performance in field conditions, and establishing benchmarks for comparing different harvesting technologies. These protocols also seek to address the challenges of integrating energy harvesters with existing wearable systems and ensuring consistent performance across varying user activities and environmental conditions.

The development of robust field demonstration protocols is crucial for accelerating the commercialization and adoption of wearable energy harvesting technologies. By providing reliable methods for validating performance claims and identifying areas for improvement, these protocols can help build confidence among potential users and investors, driving further innovation and market growth in this emerging field.

Looking forward, the technological trajectory points toward multi-modal energy harvesting systems that can simultaneously capture energy from multiple sources, adaptive harvesters that can optimize their operation based on available energy sources, and self-powered wearable systems with integrated energy management capabilities. These advancements will be essential for realizing the vision of truly autonomous wearable devices that can operate indefinitely without external power sources.

Wearable energy harvesters represent a paradigm shift in powering portable and wearable electronics, offering the potential to eliminate or reduce the dependency on conventional batteries. These technologies convert various forms of ambient energy—such as mechanical motion, thermal gradients, solar radiation, and electromagnetic waves—into usable electrical energy to power low-power electronic devices worn on or near the human body.

The evolution of wearable energy harvesting has been driven by several technological trends, including the miniaturization of electronic components, the development of flexible and stretchable materials, improvements in energy conversion efficiency, and the growing demand for sustainable power solutions. Key milestones include the development of piezoelectric materials for mechanical energy harvesting, thermoelectric generators for thermal energy conversion, and flexible photovoltaic cells for solar energy capture.

The primary objective of field demonstration protocols for wearable energy harvesters is to establish standardized methodologies for evaluating the performance, reliability, and usability of these technologies in real-world conditions. These protocols aim to bridge the gap between laboratory testing and practical implementation by providing comprehensive frameworks for assessing energy output, efficiency, durability, and user experience across diverse environmental conditions and usage scenarios.

Additional objectives include identifying optimal deployment strategies for different wearable applications, determining the factors that influence energy harvesting performance in field conditions, and establishing benchmarks for comparing different harvesting technologies. These protocols also seek to address the challenges of integrating energy harvesters with existing wearable systems and ensuring consistent performance across varying user activities and environmental conditions.

The development of robust field demonstration protocols is crucial for accelerating the commercialization and adoption of wearable energy harvesting technologies. By providing reliable methods for validating performance claims and identifying areas for improvement, these protocols can help build confidence among potential users and investors, driving further innovation and market growth in this emerging field.

Looking forward, the technological trajectory points toward multi-modal energy harvesting systems that can simultaneously capture energy from multiple sources, adaptive harvesters that can optimize their operation based on available energy sources, and self-powered wearable systems with integrated energy management capabilities. These advancements will be essential for realizing the vision of truly autonomous wearable devices that can operate indefinitely without external power sources.

Market Demand Analysis for Wearable Energy Harvesters

The wearable energy harvesting market is experiencing significant growth driven by the increasing adoption of wearable devices across multiple sectors. Current market research indicates that the global wearable technology market is expanding at a compound annual growth rate of approximately 15%, with energy harvesting solutions becoming increasingly critical to address power limitations in these devices.

Consumer demand for wearable energy harvesters stems primarily from the need for extended battery life and reduced charging frequency in everyday wearable devices. Fitness trackers, smartwatches, and health monitoring devices represent the largest segment of this market, with users expressing frustration over frequent charging requirements. Market surveys reveal that over 60% of wearable device users consider battery life a decisive factor when purchasing new devices.

The healthcare sector presents particularly strong demand potential for wearable energy harvesting technologies. Medical wearables for continuous patient monitoring require reliable, long-term power solutions, especially for implantable devices where battery replacement involves invasive procedures. The aging global population and increasing prevalence of chronic diseases are accelerating this demand, with the medical wearables segment projected to grow faster than consumer applications.

Industrial and military applications represent emerging high-value markets for wearable energy harvesters. In industrial settings, workers in remote locations or hazardous environments benefit from self-powered monitoring devices that enhance safety without requiring frequent maintenance. Military applications prioritize energy independence for field operations, driving investment in advanced harvesting technologies for soldier-worn systems.

Regional market analysis reveals varying adoption patterns, with North America and Europe leading in consumer applications while Asia-Pacific shows the fastest growth rate due to expanding manufacturing capabilities and increasing technology adoption. Developing markets demonstrate particular interest in energy harvesting solutions that can operate in areas with limited electrical infrastructure.

Consumer willingness to pay for energy harvesting features varies significantly by application. Premium pricing is more acceptable in medical and professional applications where reliability justifies higher costs, while consumer markets remain highly price-sensitive. Market research indicates that consumers would accept a 15-25% price premium for wearables with significantly reduced charging requirements.

The market trajectory suggests convergence toward integrated solutions where energy harvesting becomes a standard feature rather than a separate component. This trend is driving demand for standardized testing and demonstration protocols that can validate performance claims across different use cases and environmental conditions, allowing manufacturers to effectively communicate energy harvesting benefits to end-users and accelerate market adoption.

Consumer demand for wearable energy harvesters stems primarily from the need for extended battery life and reduced charging frequency in everyday wearable devices. Fitness trackers, smartwatches, and health monitoring devices represent the largest segment of this market, with users expressing frustration over frequent charging requirements. Market surveys reveal that over 60% of wearable device users consider battery life a decisive factor when purchasing new devices.

The healthcare sector presents particularly strong demand potential for wearable energy harvesting technologies. Medical wearables for continuous patient monitoring require reliable, long-term power solutions, especially for implantable devices where battery replacement involves invasive procedures. The aging global population and increasing prevalence of chronic diseases are accelerating this demand, with the medical wearables segment projected to grow faster than consumer applications.

Industrial and military applications represent emerging high-value markets for wearable energy harvesters. In industrial settings, workers in remote locations or hazardous environments benefit from self-powered monitoring devices that enhance safety without requiring frequent maintenance. Military applications prioritize energy independence for field operations, driving investment in advanced harvesting technologies for soldier-worn systems.

Regional market analysis reveals varying adoption patterns, with North America and Europe leading in consumer applications while Asia-Pacific shows the fastest growth rate due to expanding manufacturing capabilities and increasing technology adoption. Developing markets demonstrate particular interest in energy harvesting solutions that can operate in areas with limited electrical infrastructure.

Consumer willingness to pay for energy harvesting features varies significantly by application. Premium pricing is more acceptable in medical and professional applications where reliability justifies higher costs, while consumer markets remain highly price-sensitive. Market research indicates that consumers would accept a 15-25% price premium for wearables with significantly reduced charging requirements.

The market trajectory suggests convergence toward integrated solutions where energy harvesting becomes a standard feature rather than a separate component. This trend is driving demand for standardized testing and demonstration protocols that can validate performance claims across different use cases and environmental conditions, allowing manufacturers to effectively communicate energy harvesting benefits to end-users and accelerate market adoption.

Current State and Challenges in Field Testing

Field testing of wearable energy harvesters currently faces significant standardization challenges across the industry. Despite the growing interest in these technologies, there exists no universally accepted protocol for evaluating their performance in real-world conditions. This lack of standardization makes it difficult to compare results across different studies and impedes the translation of laboratory successes to practical applications.

Current field testing approaches vary widely between research institutions and commercial entities. Some focus primarily on power output metrics under controlled activities, while others emphasize durability or user comfort during extended wear periods. This methodological inconsistency creates barriers to meaningful benchmarking and slows industry-wide progress toward commercialization.

A major technical challenge in field testing involves accurately measuring energy output under dynamic human movements. Laboratory simulations often fail to capture the unpredictable nature of real-world activities, leading to performance discrepancies when devices transition from controlled environments to actual use cases. The development of reliable, portable measurement systems that can accurately capture performance data without interfering with normal user movement patterns remains an ongoing challenge.

Environmental factors present another significant hurdle in field testing protocols. Wearable energy harvesters must function across varying humidity levels, temperatures, and exposure conditions. Current testing methodologies inadequately address these variables, resulting in performance data that may not reflect real-world reliability or longevity.

User compliance issues further complicate field testing efforts. Test subjects may alter their behavior when aware they are testing an energy harvesting device, creating artificial usage patterns that skew performance data. Additionally, comfort and ergonomic factors that significantly impact long-term adoption are often insufficiently quantified in current testing protocols.

Geographically, field testing capabilities are unevenly distributed, with advanced facilities concentrated primarily in North America, Western Europe, and East Asia. This distribution limits access to comprehensive testing for developers in other regions and restricts the diversity of environmental and use-case scenarios being evaluated.

The regulatory landscape adds another layer of complexity, as medical-grade wearable energy harvesters must meet stringent safety and performance standards that consumer-grade devices may not. Current field testing protocols often fail to adequately distinguish between these different application categories, creating confusion regarding appropriate evaluation metrics and certification requirements.

Current field testing approaches vary widely between research institutions and commercial entities. Some focus primarily on power output metrics under controlled activities, while others emphasize durability or user comfort during extended wear periods. This methodological inconsistency creates barriers to meaningful benchmarking and slows industry-wide progress toward commercialization.

A major technical challenge in field testing involves accurately measuring energy output under dynamic human movements. Laboratory simulations often fail to capture the unpredictable nature of real-world activities, leading to performance discrepancies when devices transition from controlled environments to actual use cases. The development of reliable, portable measurement systems that can accurately capture performance data without interfering with normal user movement patterns remains an ongoing challenge.

Environmental factors present another significant hurdle in field testing protocols. Wearable energy harvesters must function across varying humidity levels, temperatures, and exposure conditions. Current testing methodologies inadequately address these variables, resulting in performance data that may not reflect real-world reliability or longevity.

User compliance issues further complicate field testing efforts. Test subjects may alter their behavior when aware they are testing an energy harvesting device, creating artificial usage patterns that skew performance data. Additionally, comfort and ergonomic factors that significantly impact long-term adoption are often insufficiently quantified in current testing protocols.

Geographically, field testing capabilities are unevenly distributed, with advanced facilities concentrated primarily in North America, Western Europe, and East Asia. This distribution limits access to comprehensive testing for developers in other regions and restricts the diversity of environmental and use-case scenarios being evaluated.

The regulatory landscape adds another layer of complexity, as medical-grade wearable energy harvesters must meet stringent safety and performance standards that consumer-grade devices may not. Current field testing protocols often fail to adequately distinguish between these different application categories, creating confusion regarding appropriate evaluation metrics and certification requirements.

Existing Field Demonstration Methodologies

01 Wearable energy harvesting systems for body motion

These systems capture energy from human body movements such as walking, running, or arm swinging. The harvested energy can power wearable devices like fitness trackers or health monitors. Field demonstration protocols for these systems typically involve testing under various movement conditions to evaluate energy generation efficiency, durability, and user comfort during normal daily activities.- Wearable energy harvesting systems for body motion: These systems capture energy from human body movements such as walking, running, or arm swinging. The harvested energy can power wearable devices, eliminating the need for frequent battery replacements. Field demonstration protocols for these systems typically involve testing under various movement conditions to evaluate energy generation efficiency, durability, and user comfort during extended wear periods.

- Testing protocols for environmental energy harvesting wearables: Field demonstration protocols for wearable devices that harvest energy from environmental sources such as solar, thermal, or RF radiation. These protocols include standardized testing in various real-world conditions to measure energy collection efficiency, storage capacity, and power output stability. The testing methodologies ensure consistent performance evaluation across different environmental conditions and usage scenarios.

- Data collection and analysis frameworks for wearable energy harvesters: Frameworks and methodologies for collecting, processing, and analyzing performance data from wearable energy harvesting devices during field demonstrations. These systems enable real-time monitoring of energy generation, storage efficiency, and device performance metrics. The protocols include standardized data formats, collection intervals, and analysis methods to ensure consistent evaluation across different testing environments.

- Integration of wearable energy harvesters with health monitoring systems: Field demonstration protocols for testing wearable energy harvesters integrated with health monitoring functionalities. These protocols evaluate both energy harvesting performance and the accuracy of health data collection. The testing methodologies assess how the energy harvesting components affect the comfort, usability, and reliability of the health monitoring features under various real-world conditions.

- Validation methods for wearable energy harvester durability and reliability: Standardized protocols for validating the long-term durability and reliability of wearable energy harvesting devices. These methods include accelerated aging tests, environmental stress testing, and extended field trials under various conditions. The protocols establish benchmarks for device longevity, performance degradation over time, and resistance to environmental factors such as moisture, temperature variations, and mechanical stress.

02 Testing protocols for environmental energy harvesting wearables

Protocols for field testing wearable devices that harvest energy from environmental sources such as solar, thermal, or RF energy. These demonstrations evaluate performance across different weather conditions, geographical locations, and times of day. The protocols typically include measurement of energy conversion efficiency, storage capacity, and operational reliability in real-world environments.Expand Specific Solutions03 Data collection and analysis frameworks for energy harvester field trials

Frameworks and methodologies for collecting, processing, and analyzing data from wearable energy harvester field demonstrations. These protocols establish standardized metrics for performance evaluation, including energy output, conversion efficiency, and reliability. They often incorporate wireless data transmission systems to monitor device performance in real-time during field testing.Expand Specific Solutions04 User experience and human factors in energy harvester demonstrations

Protocols focusing on the human aspects of wearable energy harvesters during field demonstrations, including comfort, usability, and user acceptance. These methodologies evaluate how the harvesting technology integrates with daily activities, assess user perception of the technology, and measure any impact on normal movement patterns or behavior. The protocols often include surveys, interviews, and observational studies alongside technical performance metrics.Expand Specific Solutions05 Integration and interoperability testing for wearable energy systems

Field demonstration protocols for testing how wearable energy harvesters integrate with other systems and devices. These protocols evaluate power management, energy storage solutions, and compatibility with various powered devices. They include testing for seamless operation between the harvester, power conditioning circuits, energy storage components, and the end-use application under real-world conditions.Expand Specific Solutions

Key Industry Players and Research Institutions

The wearable energy harvesting field is currently in a growth phase, with the market expected to expand significantly due to increasing demand for sustainable power solutions in wearable technology. The competitive landscape features established tech giants like QUALCOMM, Sony, and Intel alongside specialized players such as Oura Health and Wiliot. These companies are developing field demonstration protocols to validate energy harvesting technologies in real-world conditions. Technical maturity varies considerably, with companies like Philips and Boeing focusing on industrial applications, while consumer electronics firms like Xiaomi and vivo are integrating harvesters into commercial wearables. Academic-industry partnerships, exemplified by collaborations with Shanghai University and University of Michigan, are accelerating protocol standardization and technology validation methodologies.

QUALCOMM, Inc.

Technical Solution: Qualcomm's field demonstration protocol for wearable energy harvesters centers on their WiPower technology, which enables wireless charging for wearable devices through near-field magnetic resonance. Their protocol includes comprehensive testing methodologies for real-world environments, measuring energy conversion efficiency across variable distances and orientations. Qualcomm has developed standardized metrics for evaluating harvester performance under dynamic user movement conditions, with particular focus on thermal management during extended wear. Their demonstration framework incorporates automated data collection systems that monitor power generation consistency over time, environmental adaptability, and integration with their Snapdragon Wearable platforms. The protocol specifically addresses electromagnetic compatibility testing to ensure harvester operation doesn't interfere with other wireless communications, while maintaining compliance with international safety standards for wearable technology.

Strengths: Industry-leading wireless charging expertise; extensive ecosystem of compatible devices; robust testing infrastructure. Weaknesses: Solutions may be optimized primarily for their own chipsets; higher implementation costs compared to simpler harvesting technologies.

Sony Group Corp.

Technical Solution: Sony has developed a comprehensive field demonstration protocol for their flexible thermoelectric wearable energy harvesters that convert body heat into usable electricity. Their protocol features a multi-phase testing methodology beginning with controlled laboratory assessments followed by graduated real-world testing scenarios. Sony's approach includes standardized measurement procedures for power density (achieving up to 15μW/cm² at a 5°C temperature differential), conversion efficiency, and durability metrics under various environmental conditions. The protocol incorporates specialized wearable form factors designed to maximize skin contact while maintaining user comfort, with particular attention to flexibility testing that ensures functionality after 10,000+ bending cycles. Sony's demonstration framework includes long-term performance monitoring systems that track degradation patterns and energy storage integration, with specific provisions for demonstrating compatibility with their wearable product ecosystem.

Strengths: Advanced materials science expertise; integration with existing consumer electronics ecosystem; superior flexibility and comfort in design. Weaknesses: Higher production costs than competing technologies; currently limited to applications with sufficient temperature differential.

Critical Technical Standards and Testing Protocols

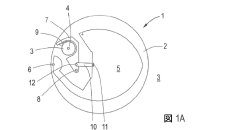

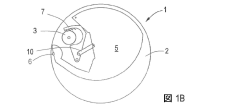

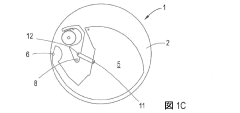

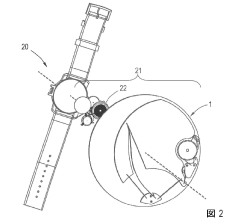

Energy harvester for wearable and/or portable device

PatentPendingJP2023107762A

Innovation

- A variable transmission ratio is implemented between the body and the transducer/reservoir, with increased ratios near extreme positions, allowing efficient energy conversion and avoiding collisions by ensuring the body does not hit endstops.

Method for estimating the time-varying energy balance of a collection of energy sinks, harvesters, and storage devices

PatentActiveUS11671817B2

Innovation

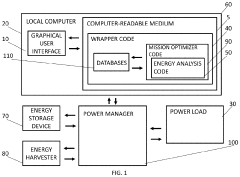

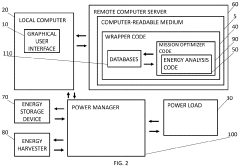

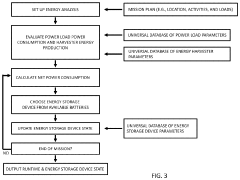

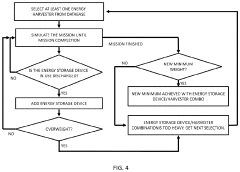

- A computer-implemented method that estimates a time-varying energy balance of a power system by analyzing mission plans, power loads, energy storage devices, and energy harvesters, using a database to support various applications and update parameters in real-time, allowing for intelligent energy management and optimization of equipment selection.

Environmental Impact and Sustainability Considerations

Wearable energy harvesters represent a significant advancement in sustainable technology, offering potential reductions in electronic waste and battery consumption. The environmental impact of these devices extends throughout their entire lifecycle, from raw material extraction to end-of-life disposal. When developing field demonstration protocols, sustainability considerations must be integrated to ensure these technologies deliver on their green promises.

The manufacturing processes for wearable energy harvesters typically involve specialized materials including piezoelectric elements, flexible substrates, and conductive components. Field demonstration protocols should include comprehensive lifecycle assessments (LCA) that quantify environmental impacts across production, use, and disposal phases. These assessments help identify opportunities for reducing carbon footprints and resource consumption during manufacturing and deployment.

Energy payback time represents a critical metric for environmental evaluation of these technologies. Field protocols must establish standardized methodologies for calculating how long a harvester must operate before generating energy equivalent to that consumed during its production. Current research indicates that well-designed harvesters can achieve energy payback periods ranging from several months to a few years, depending on usage patterns and harvesting efficiency.

The reduction of battery waste constitutes one of the most significant environmental benefits of wearable energy harvesters. Field demonstrations should quantify this benefit by measuring the extended operational time of devices and the corresponding reduction in battery replacements. Protocols should include methodologies for calculating the prevented electronic waste and toxic material mitigation resulting from decreased battery consumption.

Material selection presents another crucial sustainability consideration. Field protocols must evaluate the environmental impact of materials used in harvesters, prioritizing those with lower toxicity profiles and greater recyclability. Demonstrations should document the percentage of recyclable or biodegradable components and assess the feasibility of circular economy approaches for these devices.

End-of-life management strategies must be incorporated into field demonstration protocols. This includes evaluating disassembly procedures, identifying recoverable components, and assessing recycling pathways for specialized materials. Protocols should establish metrics for measuring recyclability rates and recovery efficiency of critical materials like rare earth elements often used in energy harvesting technologies.

Water and energy consumption during manufacturing and testing phases should be measured and reported as part of comprehensive field demonstrations. This data helps identify resource-intensive processes that could benefit from optimization. Additionally, protocols should assess the potential for harvesters to reduce overall energy consumption in larger systems by eliminating the need for battery charging infrastructure.

The manufacturing processes for wearable energy harvesters typically involve specialized materials including piezoelectric elements, flexible substrates, and conductive components. Field demonstration protocols should include comprehensive lifecycle assessments (LCA) that quantify environmental impacts across production, use, and disposal phases. These assessments help identify opportunities for reducing carbon footprints and resource consumption during manufacturing and deployment.

Energy payback time represents a critical metric for environmental evaluation of these technologies. Field protocols must establish standardized methodologies for calculating how long a harvester must operate before generating energy equivalent to that consumed during its production. Current research indicates that well-designed harvesters can achieve energy payback periods ranging from several months to a few years, depending on usage patterns and harvesting efficiency.

The reduction of battery waste constitutes one of the most significant environmental benefits of wearable energy harvesters. Field demonstrations should quantify this benefit by measuring the extended operational time of devices and the corresponding reduction in battery replacements. Protocols should include methodologies for calculating the prevented electronic waste and toxic material mitigation resulting from decreased battery consumption.

Material selection presents another crucial sustainability consideration. Field protocols must evaluate the environmental impact of materials used in harvesters, prioritizing those with lower toxicity profiles and greater recyclability. Demonstrations should document the percentage of recyclable or biodegradable components and assess the feasibility of circular economy approaches for these devices.

End-of-life management strategies must be incorporated into field demonstration protocols. This includes evaluating disassembly procedures, identifying recoverable components, and assessing recycling pathways for specialized materials. Protocols should establish metrics for measuring recyclability rates and recovery efficiency of critical materials like rare earth elements often used in energy harvesting technologies.

Water and energy consumption during manufacturing and testing phases should be measured and reported as part of comprehensive field demonstrations. This data helps identify resource-intensive processes that could benefit from optimization. Additionally, protocols should assess the potential for harvesters to reduce overall energy consumption in larger systems by eliminating the need for battery charging infrastructure.

Regulatory Framework and Compliance Requirements

The regulatory landscape for wearable energy harvesters encompasses multiple jurisdictional frameworks that manufacturers must navigate to ensure market compliance. At the international level, the International Electrotechnical Commission (IEC) has established standards such as IEC 62133 for battery safety and IEC 60601 for medical electrical equipment, which apply to wearable energy harvesting devices intended for healthcare applications. These standards define essential safety requirements, electromagnetic compatibility parameters, and performance benchmarks that must be met before commercialization.

In the United States, the Food and Drug Administration (FDA) regulates wearable energy harvesters that claim medical benefits under the Medical Device Regulations framework. Depending on their intended use and risk classification, these devices may require premarket notification (510(k)) or premarket approval (PMA). Additionally, the Federal Communications Commission (FCC) mandates compliance with electromagnetic interference standards for electronic devices, particularly relevant for harvesters utilizing wireless transmission capabilities.

The European Union implements the CE marking system, requiring conformity with the Radio Equipment Directive (RED), Electromagnetic Compatibility Directive (EMC), and potentially the Medical Device Regulation (MDR) for health-related applications. Manufacturers must prepare technical documentation, conduct risk assessments, and issue declarations of conformity before affixing the CE mark to their products.

Field demonstration protocols must incorporate verification procedures that address these regulatory requirements. This includes documented testing for electrical safety (isolation, leakage currents), biocompatibility assessment for skin-contact materials, and electromagnetic compatibility testing under real-world conditions. Protocols should establish clear acceptance criteria aligned with regulatory thresholds and include procedures for addressing non-conformities discovered during field testing.

Environmental regulations also impact wearable energy harvesters, particularly regarding material restrictions and end-of-life considerations. The Restriction of Hazardous Substances (RoHS) directive limits the use of certain hazardous materials, while the Waste Electrical and Electronic Equipment (WEEE) directive mandates recycling provisions. Field demonstration protocols should verify compliance with these environmental regulations through material composition analysis and recyclability assessments.

Data privacy regulations present additional compliance challenges for connected wearable energy harvesters. The General Data Protection Regulation (GDPR) in Europe and various state-level privacy laws in the United States impose requirements on data collection, processing, and storage. Field demonstration protocols must incorporate privacy impact assessments, data protection measures, and user consent mechanisms to ensure regulatory compliance in this domain.

In the United States, the Food and Drug Administration (FDA) regulates wearable energy harvesters that claim medical benefits under the Medical Device Regulations framework. Depending on their intended use and risk classification, these devices may require premarket notification (510(k)) or premarket approval (PMA). Additionally, the Federal Communications Commission (FCC) mandates compliance with electromagnetic interference standards for electronic devices, particularly relevant for harvesters utilizing wireless transmission capabilities.

The European Union implements the CE marking system, requiring conformity with the Radio Equipment Directive (RED), Electromagnetic Compatibility Directive (EMC), and potentially the Medical Device Regulation (MDR) for health-related applications. Manufacturers must prepare technical documentation, conduct risk assessments, and issue declarations of conformity before affixing the CE mark to their products.

Field demonstration protocols must incorporate verification procedures that address these regulatory requirements. This includes documented testing for electrical safety (isolation, leakage currents), biocompatibility assessment for skin-contact materials, and electromagnetic compatibility testing under real-world conditions. Protocols should establish clear acceptance criteria aligned with regulatory thresholds and include procedures for addressing non-conformities discovered during field testing.

Environmental regulations also impact wearable energy harvesters, particularly regarding material restrictions and end-of-life considerations. The Restriction of Hazardous Substances (RoHS) directive limits the use of certain hazardous materials, while the Waste Electrical and Electronic Equipment (WEEE) directive mandates recycling provisions. Field demonstration protocols should verify compliance with these environmental regulations through material composition analysis and recyclability assessments.

Data privacy regulations present additional compliance challenges for connected wearable energy harvesters. The General Data Protection Regulation (GDPR) in Europe and various state-level privacy laws in the United States impose requirements on data collection, processing, and storage. Field demonstration protocols must incorporate privacy impact assessments, data protection measures, and user consent mechanisms to ensure regulatory compliance in this domain.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!