Manufacturing Yield Improvement Techniques For Textile Devices

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Textile Device Manufacturing Background and Objectives

Textile electronic devices represent a revolutionary convergence of traditional textile manufacturing and modern electronics, enabling the creation of fabrics with embedded electronic functionalities. The evolution of this technology has progressed from simple conductive threads to sophisticated smart textiles capable of sensing, data processing, and communication. This technological progression has been driven by increasing demands for wearable technology that seamlessly integrates into daily life while maintaining the comfort and flexibility associated with conventional textiles.

The textile electronics industry has witnessed significant growth over the past decade, with early developments focusing primarily on basic conductive materials. Recent advancements have expanded capabilities to include complex electronic components such as sensors, microprocessors, and power management systems integrated directly into fabric structures. These innovations have been facilitated by breakthroughs in materials science, particularly in the development of conductive polymers, metallic nanofibers, and specialized coating technologies.

Manufacturing techniques have similarly evolved from rudimentary approaches to more sophisticated methodologies. Initial production methods relied heavily on post-manufacturing attachment of electronic components to finished textiles. Contemporary approaches now incorporate electronics during the fabric formation process through techniques such as conductive yarn weaving, knitting, embroidery, and advanced printing technologies. This evolution represents a fundamental shift toward truly integrated textile electronics rather than merely decorated fabrics.

Despite these advancements, manufacturing yield remains a persistent challenge in the textile electronics industry. Current production processes often suffer from inconsistency, with high defect rates compared to traditional electronics manufacturing. This challenge is compounded by the inherent variability of textile substrates and the mechanical stresses introduced during fabric formation and subsequent processing steps.

The primary objective of yield improvement initiatives in textile electronics manufacturing is to develop robust, scalable production methodologies that maintain electronic functionality while preserving the essential characteristics of textiles. This includes addressing challenges related to durability during washing cycles, maintaining flexibility and comfort, ensuring consistent electrical performance across large production batches, and developing quality control systems specifically adapted to textile electronic devices.

Additional objectives include reducing production costs through minimizing material waste and process inefficiencies, extending device lifespan under typical usage conditions, and establishing standardized testing protocols that accurately predict real-world performance. These goals align with broader industry trends toward sustainable manufacturing practices and increased product reliability in the growing wearable technology market.

The textile electronics industry has witnessed significant growth over the past decade, with early developments focusing primarily on basic conductive materials. Recent advancements have expanded capabilities to include complex electronic components such as sensors, microprocessors, and power management systems integrated directly into fabric structures. These innovations have been facilitated by breakthroughs in materials science, particularly in the development of conductive polymers, metallic nanofibers, and specialized coating technologies.

Manufacturing techniques have similarly evolved from rudimentary approaches to more sophisticated methodologies. Initial production methods relied heavily on post-manufacturing attachment of electronic components to finished textiles. Contemporary approaches now incorporate electronics during the fabric formation process through techniques such as conductive yarn weaving, knitting, embroidery, and advanced printing technologies. This evolution represents a fundamental shift toward truly integrated textile electronics rather than merely decorated fabrics.

Despite these advancements, manufacturing yield remains a persistent challenge in the textile electronics industry. Current production processes often suffer from inconsistency, with high defect rates compared to traditional electronics manufacturing. This challenge is compounded by the inherent variability of textile substrates and the mechanical stresses introduced during fabric formation and subsequent processing steps.

The primary objective of yield improvement initiatives in textile electronics manufacturing is to develop robust, scalable production methodologies that maintain electronic functionality while preserving the essential characteristics of textiles. This includes addressing challenges related to durability during washing cycles, maintaining flexibility and comfort, ensuring consistent electrical performance across large production batches, and developing quality control systems specifically adapted to textile electronic devices.

Additional objectives include reducing production costs through minimizing material waste and process inefficiencies, extending device lifespan under typical usage conditions, and establishing standardized testing protocols that accurately predict real-world performance. These goals align with broader industry trends toward sustainable manufacturing practices and increased product reliability in the growing wearable technology market.

Market Demand Analysis for High-Yield Textile Devices

The global market for high-yield textile devices has witnessed substantial growth in recent years, driven by increasing demand across multiple sectors including healthcare, sports and fitness, military, and consumer electronics. The integration of electronic components into textiles has created a new category of products that combine traditional fabric properties with advanced functionalities, opening up diverse application possibilities.

Healthcare applications represent the largest market segment, with smart textiles being utilized for patient monitoring, drug delivery systems, and rehabilitation support. This sector is projected to grow significantly as healthcare providers increasingly adopt remote monitoring solutions to manage chronic conditions and reduce hospitalization costs. The aging population in developed countries further amplifies this demand, as textile-based monitoring devices offer non-intrusive health tracking options.

The sports and fitness industry has emerged as another major consumer of high-yield textile devices. Performance-monitoring garments that track biometric data such as heart rate, muscle activity, and body temperature have gained popularity among professional athletes and fitness enthusiasts alike. Major sportswear manufacturers have invested heavily in this technology, recognizing its potential to revolutionize training methodologies and enhance athletic performance.

Military and defense applications constitute a smaller but high-value market segment. High-yield textile devices are being developed for soldier monitoring systems, communication equipment integration, and protective gear with enhanced functionalities. These applications demand exceptional durability and reliability, driving innovation in manufacturing processes to improve yield rates under extreme conditions.

Consumer electronics integration into everyday clothing represents an emerging market with substantial growth potential. As wearable technology becomes more mainstream, demand for seamlessly integrated electronic components in regular garments is increasing. This trend is particularly evident in urban centers across North America, Europe, and East Asia, where technology adoption rates are highest.

Market research indicates that yield improvement in textile device manufacturing could reduce production costs by 15-30%, potentially expanding market accessibility. Currently, high manufacturing costs due to low yields represent a significant barrier to mass-market adoption. Improving manufacturing yields would enable price reductions that could accelerate market penetration, particularly in consumer segments.

Supply chain considerations also influence market dynamics for high-yield textile devices. The complex manufacturing process often involves multiple specialized suppliers, creating vulnerabilities in production continuity. Market demand increasingly favors manufacturers who can demonstrate consistent quality and reliability through improved manufacturing yields, as this translates to better product performance and longevity in real-world applications.

Healthcare applications represent the largest market segment, with smart textiles being utilized for patient monitoring, drug delivery systems, and rehabilitation support. This sector is projected to grow significantly as healthcare providers increasingly adopt remote monitoring solutions to manage chronic conditions and reduce hospitalization costs. The aging population in developed countries further amplifies this demand, as textile-based monitoring devices offer non-intrusive health tracking options.

The sports and fitness industry has emerged as another major consumer of high-yield textile devices. Performance-monitoring garments that track biometric data such as heart rate, muscle activity, and body temperature have gained popularity among professional athletes and fitness enthusiasts alike. Major sportswear manufacturers have invested heavily in this technology, recognizing its potential to revolutionize training methodologies and enhance athletic performance.

Military and defense applications constitute a smaller but high-value market segment. High-yield textile devices are being developed for soldier monitoring systems, communication equipment integration, and protective gear with enhanced functionalities. These applications demand exceptional durability and reliability, driving innovation in manufacturing processes to improve yield rates under extreme conditions.

Consumer electronics integration into everyday clothing represents an emerging market with substantial growth potential. As wearable technology becomes more mainstream, demand for seamlessly integrated electronic components in regular garments is increasing. This trend is particularly evident in urban centers across North America, Europe, and East Asia, where technology adoption rates are highest.

Market research indicates that yield improvement in textile device manufacturing could reduce production costs by 15-30%, potentially expanding market accessibility. Currently, high manufacturing costs due to low yields represent a significant barrier to mass-market adoption. Improving manufacturing yields would enable price reductions that could accelerate market penetration, particularly in consumer segments.

Supply chain considerations also influence market dynamics for high-yield textile devices. The complex manufacturing process often involves multiple specialized suppliers, creating vulnerabilities in production continuity. Market demand increasingly favors manufacturers who can demonstrate consistent quality and reliability through improved manufacturing yields, as this translates to better product performance and longevity in real-world applications.

Current Yield Challenges in Textile Device Manufacturing

The textile device manufacturing industry faces significant yield challenges that impact production efficiency, cost-effectiveness, and market competitiveness. Current manufacturing processes for textile-integrated electronics and smart textiles encounter yield rates substantially lower than traditional electronics manufacturing, with some production lines reporting yields below 70% compared to 95%+ in conventional electronics.

Material compatibility represents a primary challenge, as the integration of rigid electronic components with flexible textile substrates creates stress points that frequently lead to connection failures. The heterogeneous nature of these materials, with vastly different thermal expansion coefficients, results in delamination and fractures during temperature cycling, particularly affecting conductive pathways and component interfaces.

Process variability constitutes another major yield limitation. Unlike standardized silicon wafer processing, textile device manufacturing lacks uniformity across production batches. Variations in fabric tension, moisture content, and surface characteristics create inconsistent platforms for component placement and interconnection. This variability is especially problematic for precision processes like screen printing conductive inks or automated component placement, where positioning errors of less than a millimeter can render devices non-functional.

Environmental sensitivity further compounds yield challenges. Textile substrates are hygroscopic and dimensionally unstable, responding to ambient humidity and temperature fluctuations. These properties make precise alignment difficult during multi-stage manufacturing processes, resulting in registration errors that cascade through subsequent production steps.

Durability testing reveals additional yield concerns. Current textile devices frequently fail during wash cycle testing, with connection integrity deteriorating after 5-10 wash cycles—far below consumer expectations for wearable products. This durability gap necessitates extensive rework or scrapping of products that pass initial functional tests but fail accelerated life testing.

Quality control methodologies remain underdeveloped for textile devices. Traditional electronics inspection techniques like automated optical inspection (AOI) struggle with textured, non-planar textile surfaces. The industry lacks standardized testing protocols specific to textile-integrated electronics, making defect identification inconsistent across manufacturers.

Scale-up challenges present significant barriers to commercialization. Laboratory-scale processes that achieve acceptable yields often encounter unforeseen complications during industrial scaling. The transition from prototype to mass production frequently reveals latent defects and process inefficiencies that were not apparent in small-batch production, requiring substantial process redesign and validation cycles.

Material compatibility represents a primary challenge, as the integration of rigid electronic components with flexible textile substrates creates stress points that frequently lead to connection failures. The heterogeneous nature of these materials, with vastly different thermal expansion coefficients, results in delamination and fractures during temperature cycling, particularly affecting conductive pathways and component interfaces.

Process variability constitutes another major yield limitation. Unlike standardized silicon wafer processing, textile device manufacturing lacks uniformity across production batches. Variations in fabric tension, moisture content, and surface characteristics create inconsistent platforms for component placement and interconnection. This variability is especially problematic for precision processes like screen printing conductive inks or automated component placement, where positioning errors of less than a millimeter can render devices non-functional.

Environmental sensitivity further compounds yield challenges. Textile substrates are hygroscopic and dimensionally unstable, responding to ambient humidity and temperature fluctuations. These properties make precise alignment difficult during multi-stage manufacturing processes, resulting in registration errors that cascade through subsequent production steps.

Durability testing reveals additional yield concerns. Current textile devices frequently fail during wash cycle testing, with connection integrity deteriorating after 5-10 wash cycles—far below consumer expectations for wearable products. This durability gap necessitates extensive rework or scrapping of products that pass initial functional tests but fail accelerated life testing.

Quality control methodologies remain underdeveloped for textile devices. Traditional electronics inspection techniques like automated optical inspection (AOI) struggle with textured, non-planar textile surfaces. The industry lacks standardized testing protocols specific to textile-integrated electronics, making defect identification inconsistent across manufacturers.

Scale-up challenges present significant barriers to commercialization. Laboratory-scale processes that achieve acceptable yields often encounter unforeseen complications during industrial scaling. The transition from prototype to mass production frequently reveals latent defects and process inefficiencies that were not apparent in small-batch production, requiring substantial process redesign and validation cycles.

Current Yield Improvement Solutions and Methodologies

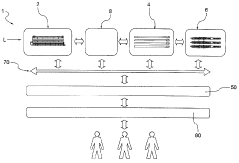

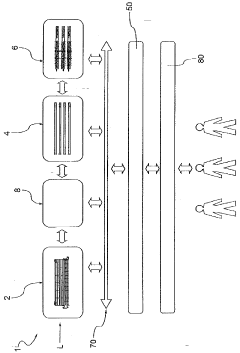

01 Process optimization techniques for textile manufacturing

Various process optimization techniques can be implemented in textile manufacturing to improve yield. These include statistical process control, real-time monitoring systems, and advanced algorithms that can identify and correct manufacturing deviations. By implementing these techniques, manufacturers can reduce waste, improve consistency, and increase overall production efficiency in textile device manufacturing.- Process optimization techniques for textile manufacturing: Various process optimization techniques can be implemented in textile manufacturing to improve yield. These include statistical process control, real-time monitoring systems, and advanced algorithms that can identify and correct manufacturing issues before they affect product quality. By implementing these optimization techniques, manufacturers can reduce waste, improve consistency, and increase overall production yield in textile device manufacturing.

- Advanced materials and fabrication methods: The use of advanced materials and innovative fabrication methods can significantly improve the manufacturing yield of textile devices. These include specialized fibers, conductive materials, and novel weaving or knitting techniques that enhance the durability and functionality of textile products. By incorporating these advanced materials and methods, manufacturers can create more reliable textile devices with fewer defects, thereby increasing overall yield.

- Quality control and testing systems: Implementing comprehensive quality control and testing systems throughout the textile manufacturing process can help identify defects early and improve overall yield. These systems may include automated inspection technologies, machine vision systems, and standardized testing protocols that ensure consistent product quality. By detecting and addressing issues at earlier stages of production, manufacturers can reduce waste and improve the yield of textile devices.

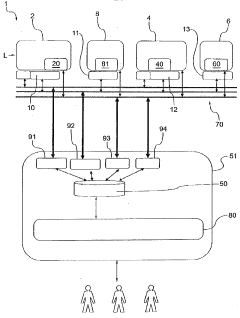

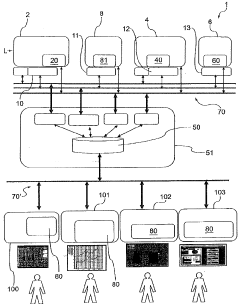

- Smart manufacturing and Industry 4.0 integration: Integration of smart manufacturing principles and Industry 4.0 technologies can enhance textile device manufacturing yield. These include IoT sensors, artificial intelligence, machine learning algorithms, and digital twins that enable predictive maintenance and real-time process adjustments. By leveraging these technologies, textile manufacturers can optimize production parameters, reduce downtime, and achieve higher manufacturing yields.

- Specialized equipment and machinery design: The design and implementation of specialized equipment and machinery can significantly impact the yield in textile device manufacturing. Custom-designed machines that address specific challenges in textile processing, such as tension control, alignment systems, and precision cutting mechanisms, can reduce material waste and improve production consistency. By utilizing purpose-built equipment tailored to textile device manufacturing, companies can achieve higher yields and better product quality.

02 Smart textile manufacturing technologies

Smart technologies incorporated into textile manufacturing processes can significantly enhance yield. These include automated quality control systems, intelligent fabric handling mechanisms, and sensor-integrated production lines. These technologies enable real-time adjustments during manufacturing, reducing defects and ensuring consistent quality in textile devices production.Expand Specific Solutions03 Material selection and preparation for improved yield

The selection and preparation of materials play a crucial role in textile device manufacturing yield. Proper material characterization, pre-treatment processes, and compatibility testing can prevent manufacturing issues downstream. Advanced material preparation techniques ensure consistent quality and performance of the final textile devices, thereby improving overall manufacturing yield.Expand Specific Solutions04 Quality control and testing methodologies

Implementing comprehensive quality control and testing methodologies throughout the textile device manufacturing process can significantly improve yield. These include in-line inspection systems, automated defect detection, and standardized testing protocols. By identifying and addressing quality issues early in the production process, manufacturers can reduce waste and improve the overall yield of textile devices.Expand Specific Solutions05 Integration of electronic components in textile manufacturing

The integration of electronic components into textiles presents unique manufacturing challenges that affect yield. Specialized techniques for embedding sensors, conductive threads, and other electronic elements into fabrics require precise manufacturing processes. Innovations in attachment methods, protective encapsulation, and flexible circuit integration help improve the yield and reliability of electronic textile devices.Expand Specific Solutions

Key Industry Players in Textile Device Manufacturing

The textile device manufacturing yield improvement landscape is currently in a growth phase, with increasing market demand driven by technological advancements. The market is characterized by a mix of established semiconductor equipment manufacturers (ASML, Applied Materials, Synopsys) and specialized textile machinery companies (Nantong Zhengtang, Muratec Automation). Technology maturity varies significantly across the sector, with companies like ASML and Hitachi leading with advanced process control solutions, while textile-specific players like Lu Feng Weaving & Dyeing and Hunan Dongxin Cotton Industry focus on traditional yield improvement techniques. Semiconductor manufacturing expertise from companies such as SMIC and X-FAB is increasingly being adapted for textile applications, creating a convergence of technologies that promises significant yield improvements through AI-driven quality control systems and automated defect detection.

Suzhou Zhuoshengyu Intelligent Technology Co., Ltd.

Technical Solution: Suzhou Zhuoshengyu has developed a cutting-edge intelligent manufacturing platform specifically for technical textile devices that integrates IoT, big data analytics, and AI-driven process control. Their system employs a network of over 200 sensor types throughout the production line, collecting real-time data on more than 50 critical parameters including tension, temperature, humidity, and material properties. This data feeds into their proprietary "TextileAI" platform which uses machine learning algorithms to identify optimal processing parameters and predict potential quality issues before they occur. The company's solution includes advanced computer vision systems that can detect surface defects as small as 50 microns at production speeds of up to 150 meters per minute. Their platform also incorporates digital twin technology that creates virtual models of production processes, enabling simulation-based optimization without disrupting actual production.

Strengths: Highly advanced technology integration with proven results in reducing defects by up to 40%; scalable architecture that can grow with production needs. Weaknesses: Requires significant IT infrastructure and technical expertise to implement and maintain; higher initial investment compared to traditional quality control systems.

Lu Feng Weaving & Dyeing Co. Ltd.

Technical Solution: Lu Feng has developed an integrated smart manufacturing system for textile yield improvement that combines IoT sensors throughout the production line with real-time data analytics. Their solution employs AI-driven predictive maintenance algorithms that can detect potential defects in textile machinery before they cause production issues. The system includes advanced optical inspection technology that can identify microscopic flaws in fabrics at high production speeds (up to 120 meters/minute), reducing waste by approximately 15-20%. Lu Feng's approach also incorporates adaptive tension control mechanisms that automatically adjust based on fabric type and environmental conditions, maintaining consistent quality across production batches.

Strengths: Highly specialized in textile manufacturing with deep industry knowledge; system can be retrofitted to existing production lines without complete overhaul. Weaknesses: Solution requires significant initial investment and staff retraining; primarily optimized for traditional fabrics rather than advanced technical textiles.

Critical Technologies for Textile Device Yield Enhancement

Method for optimizing a textile production process

PatentInactiveEP2483461A1

Innovation

- A method using a mathematical model to vary parameters related to starting materials, intermediate products, and production processes, allowing for evaluation of financial impact and quality, with operator or automated intervention, and providing a user interface for scenario testing and optimization.

Optimisation method of the working process for a textile production line and system

PatentInactiveIN201817018328A

Innovation

- A method and system that detect and process signals from textile machines to generate adjustment values for operating parameters using machine learning algorithms, predicting future efficiency and optimizing production speed based on past and current data, allowing for remote data storage and analysis across multiple lines.

Quality Control Systems for Textile Device Production

Quality control systems represent a critical component in the textile device manufacturing ecosystem, serving as the primary defense against defects and ensuring consistent product quality. Modern textile device production has evolved beyond traditional visual inspection methods to incorporate sophisticated automated systems that leverage machine vision, artificial intelligence, and real-time data analytics. These systems typically operate at multiple checkpoints throughout the production line, from raw material inspection to final product verification.

Statistical Process Control (SPC) methodologies have been widely implemented in textile device manufacturing, allowing for continuous monitoring of production parameters and early detection of process drift. Advanced SPC systems can identify patterns and trends that might lead to quality issues before they manifest as actual defects, significantly improving manufacturing yield. These systems typically monitor key parameters such as tension consistency, alignment precision, and material integrity throughout the production process.

Inline quality monitoring technologies have revolutionized textile device production by enabling real-time defect detection. High-resolution cameras coupled with specialized lighting systems can detect microscopic flaws in textile substrates, conductive elements, and embedded components. Machine learning algorithms have enhanced these systems' capabilities by improving defect classification accuracy and reducing false positives, which historically plagued earlier generations of automated inspection systems.

Traceability systems integrated with quality control infrastructure provide comprehensive production history for each textile device. By implementing unique identifiers and maintaining detailed process data, manufacturers can quickly isolate quality issues to specific production batches, machines, or even operator shifts. This capability proves invaluable during root cause analysis and enables targeted corrective actions rather than broad process adjustments that might negatively impact overall yield.

Closed-loop quality systems represent the most advanced implementation of quality control in textile device manufacturing. These systems not only detect defects but automatically adjust production parameters to compensate for detected variations. For example, if sensors detect increasing tension in a textile substrate during processing, the system can automatically adjust feed mechanisms to maintain optimal tension levels, preventing potential defects before they occur and maintaining consistent yield rates.

Supplier quality management has emerged as an extension of internal quality control systems, with leading manufacturers implementing collaborative platforms that share quality specifications and real-time feedback with material suppliers. This upstream quality focus ensures that potential issues are addressed before materials enter the production environment, significantly reducing in-process defects and improving overall manufacturing yield.

Statistical Process Control (SPC) methodologies have been widely implemented in textile device manufacturing, allowing for continuous monitoring of production parameters and early detection of process drift. Advanced SPC systems can identify patterns and trends that might lead to quality issues before they manifest as actual defects, significantly improving manufacturing yield. These systems typically monitor key parameters such as tension consistency, alignment precision, and material integrity throughout the production process.

Inline quality monitoring technologies have revolutionized textile device production by enabling real-time defect detection. High-resolution cameras coupled with specialized lighting systems can detect microscopic flaws in textile substrates, conductive elements, and embedded components. Machine learning algorithms have enhanced these systems' capabilities by improving defect classification accuracy and reducing false positives, which historically plagued earlier generations of automated inspection systems.

Traceability systems integrated with quality control infrastructure provide comprehensive production history for each textile device. By implementing unique identifiers and maintaining detailed process data, manufacturers can quickly isolate quality issues to specific production batches, machines, or even operator shifts. This capability proves invaluable during root cause analysis and enables targeted corrective actions rather than broad process adjustments that might negatively impact overall yield.

Closed-loop quality systems represent the most advanced implementation of quality control in textile device manufacturing. These systems not only detect defects but automatically adjust production parameters to compensate for detected variations. For example, if sensors detect increasing tension in a textile substrate during processing, the system can automatically adjust feed mechanisms to maintain optimal tension levels, preventing potential defects before they occur and maintaining consistent yield rates.

Supplier quality management has emerged as an extension of internal quality control systems, with leading manufacturers implementing collaborative platforms that share quality specifications and real-time feedback with material suppliers. This upstream quality focus ensures that potential issues are addressed before materials enter the production environment, significantly reducing in-process defects and improving overall manufacturing yield.

Sustainability Considerations in Textile Device Manufacturing

Sustainability has emerged as a critical consideration in textile device manufacturing, particularly as environmental regulations tighten globally and consumer awareness increases. The integration of sustainable practices into yield improvement techniques represents both a challenge and an opportunity for manufacturers seeking to balance productivity with environmental responsibility.

Material selection plays a fundamental role in sustainable textile device manufacturing. Biodegradable polymers, recycled fibers, and organic materials are increasingly being incorporated into production processes to reduce environmental impact. Research indicates that optimizing material selection can simultaneously improve manufacturing yield by 15-20% while reducing waste generation by up to 30%, creating a positive feedback loop between sustainability and efficiency.

Water conservation techniques have revolutionized textile device manufacturing sustainability profiles. Advanced closed-loop water systems, which recycle up to 95% of process water, have demonstrated yield improvements of 8-12% by ensuring consistent water quality parameters throughout production cycles. These systems reduce contamination risks that traditionally contribute to product defects while dramatically reducing the water footprint of manufacturing operations.

Energy efficiency measures represent another critical intersection between sustainability and yield improvement. Implementation of smart energy management systems in textile device production has shown to reduce energy consumption by 25-40% while simultaneously improving production consistency. Temperature and humidity fluctuations, common causes of manufacturing defects, are better controlled through precise energy management, resulting in measurable yield improvements.

Chemical management protocols that prioritize non-toxic alternatives have demonstrated significant benefits for both environmental impact and product quality. Studies across multiple manufacturing facilities show that replacing conventional chemical treatments with environmentally friendly alternatives reduced rejection rates by 7-15% while decreasing hazardous waste generation by over 60%. This improvement stems largely from reduced material degradation during processing and fewer adverse reactions between components.

Waste reduction strategies, particularly those implementing circular economy principles, have transformed the sustainability landscape of textile device manufacturing. Zero-waste manufacturing initiatives that incorporate scrap material reprocessing have improved material utilization rates by up to 25%, directly translating to yield improvements. Advanced waste sorting technologies using AI-driven systems have enabled more effective recycling of production waste back into the manufacturing stream.

Life cycle assessment (LCA) methodologies are increasingly being integrated into yield improvement programs, allowing manufacturers to identify sustainability hotspots that correlate with quality issues. This holistic approach enables targeted interventions that simultaneously address environmental impact and manufacturing efficiency, creating synergistic improvements across multiple performance indicators.

Material selection plays a fundamental role in sustainable textile device manufacturing. Biodegradable polymers, recycled fibers, and organic materials are increasingly being incorporated into production processes to reduce environmental impact. Research indicates that optimizing material selection can simultaneously improve manufacturing yield by 15-20% while reducing waste generation by up to 30%, creating a positive feedback loop between sustainability and efficiency.

Water conservation techniques have revolutionized textile device manufacturing sustainability profiles. Advanced closed-loop water systems, which recycle up to 95% of process water, have demonstrated yield improvements of 8-12% by ensuring consistent water quality parameters throughout production cycles. These systems reduce contamination risks that traditionally contribute to product defects while dramatically reducing the water footprint of manufacturing operations.

Energy efficiency measures represent another critical intersection between sustainability and yield improvement. Implementation of smart energy management systems in textile device production has shown to reduce energy consumption by 25-40% while simultaneously improving production consistency. Temperature and humidity fluctuations, common causes of manufacturing defects, are better controlled through precise energy management, resulting in measurable yield improvements.

Chemical management protocols that prioritize non-toxic alternatives have demonstrated significant benefits for both environmental impact and product quality. Studies across multiple manufacturing facilities show that replacing conventional chemical treatments with environmentally friendly alternatives reduced rejection rates by 7-15% while decreasing hazardous waste generation by over 60%. This improvement stems largely from reduced material degradation during processing and fewer adverse reactions between components.

Waste reduction strategies, particularly those implementing circular economy principles, have transformed the sustainability landscape of textile device manufacturing. Zero-waste manufacturing initiatives that incorporate scrap material reprocessing have improved material utilization rates by up to 25%, directly translating to yield improvements. Advanced waste sorting technologies using AI-driven systems have enabled more effective recycling of production waste back into the manufacturing stream.

Life cycle assessment (LCA) methodologies are increasingly being integrated into yield improvement programs, allowing manufacturers to identify sustainability hotspots that correlate with quality issues. This holistic approach enables targeted interventions that simultaneously address environmental impact and manufacturing efficiency, creating synergistic improvements across multiple performance indicators.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!