Interfacing Biofuel Cell Outputs With IoT Sensor Nodes

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Biofuel Cell-IoT Integration Background and Objectives

Biofuel cells represent a promising sustainable energy technology that has evolved significantly over the past two decades. These electrochemical devices convert biochemical energy into electrical energy through enzymatic or microbial catalytic reactions, offering unique advantages for powering small electronic devices. The integration of biofuel cells with Internet of Things (IoT) sensor nodes presents a compelling opportunity to address the growing energy demands of distributed sensing networks while advancing sustainability goals.

The historical trajectory of biofuel cell development began with rudimentary designs in the early 2000s, progressing through significant improvements in power density, operational stability, and miniaturization. Recent advancements in materials science, particularly in electrode design and enzyme immobilization techniques, have dramatically enhanced the performance metrics of these bioelectrochemical systems, making them increasingly viable for practical applications.

Concurrently, IoT technology has experienced exponential growth, with billions of connected devices deployed globally. These devices typically rely on conventional batteries, creating substantial environmental challenges related to disposal and resource depletion. The convergence of biofuel cell technology with IoT sensor nodes represents a natural technological evolution, potentially enabling self-powered sensing systems that can operate autonomously in diverse environments.

The primary objective of this technological integration is to develop reliable, sustainable power solutions for IoT sensor nodes that can harvest energy from readily available biological substrates in their deployment environment. This approach aims to overcome the fundamental limitations of battery-powered IoT devices, particularly in remote or inaccessible locations where battery replacement is impractical or impossible.

Secondary objectives include optimizing the power management interfaces between biofuel cells and IoT hardware, addressing voltage and current matching challenges, and developing robust energy harvesting circuits capable of accommodating the variable output characteristics inherent to biofuel cells. Additionally, this integration seeks to extend the operational lifespan of IoT sensor nodes while reducing their environmental footprint.

The technological trajectory suggests continued improvements in biofuel cell energy density, stability, and biocompatibility, alongside advancements in ultra-low-power IoT components and energy-efficient communication protocols. These parallel developments are expected to enhance the viability of biofuel cell-powered IoT systems across diverse application domains, including environmental monitoring, agricultural sensing, healthcare diagnostics, and industrial process control.

As this integration matures, it promises to enable new classes of self-sustaining IoT applications that were previously infeasible due to energy constraints, potentially transforming how we deploy and maintain distributed sensing networks in the coming decade.

The historical trajectory of biofuel cell development began with rudimentary designs in the early 2000s, progressing through significant improvements in power density, operational stability, and miniaturization. Recent advancements in materials science, particularly in electrode design and enzyme immobilization techniques, have dramatically enhanced the performance metrics of these bioelectrochemical systems, making them increasingly viable for practical applications.

Concurrently, IoT technology has experienced exponential growth, with billions of connected devices deployed globally. These devices typically rely on conventional batteries, creating substantial environmental challenges related to disposal and resource depletion. The convergence of biofuel cell technology with IoT sensor nodes represents a natural technological evolution, potentially enabling self-powered sensing systems that can operate autonomously in diverse environments.

The primary objective of this technological integration is to develop reliable, sustainable power solutions for IoT sensor nodes that can harvest energy from readily available biological substrates in their deployment environment. This approach aims to overcome the fundamental limitations of battery-powered IoT devices, particularly in remote or inaccessible locations where battery replacement is impractical or impossible.

Secondary objectives include optimizing the power management interfaces between biofuel cells and IoT hardware, addressing voltage and current matching challenges, and developing robust energy harvesting circuits capable of accommodating the variable output characteristics inherent to biofuel cells. Additionally, this integration seeks to extend the operational lifespan of IoT sensor nodes while reducing their environmental footprint.

The technological trajectory suggests continued improvements in biofuel cell energy density, stability, and biocompatibility, alongside advancements in ultra-low-power IoT components and energy-efficient communication protocols. These parallel developments are expected to enhance the viability of biofuel cell-powered IoT systems across diverse application domains, including environmental monitoring, agricultural sensing, healthcare diagnostics, and industrial process control.

As this integration matures, it promises to enable new classes of self-sustaining IoT applications that were previously infeasible due to energy constraints, potentially transforming how we deploy and maintain distributed sensing networks in the coming decade.

Market Analysis for Biofuel-Powered IoT Applications

The biofuel cell-powered IoT sensor market is experiencing significant growth driven by the convergence of sustainable energy solutions and expanding IoT applications. Current market projections indicate that the global IoT sensor market will reach approximately $30 billion by 2025, with energy-autonomous sensors representing a rapidly growing segment. Within this context, biofuel cell integration presents a compelling value proposition for specific applications where traditional power sources are impractical.

Healthcare monitoring represents the largest current market opportunity, with continuous glucose monitoring systems being the most mature application. These systems leverage glucose-powered biofuel cells to enable self-powered operation, eliminating battery replacement needs in implantable or wearable devices. This segment is growing at nearly 15% annually, driven by increasing diabetes prevalence and demand for continuous health monitoring solutions.

Environmental monitoring constitutes another substantial market, particularly for remote deployment scenarios where conventional power infrastructure is unavailable. Applications include agricultural monitoring, water quality assessment, and wildlife tracking, with market growth exceeding 20% annually as climate change concerns drive increased environmental surveillance requirements.

Industrial IoT represents a developing market with significant potential, particularly in hazardous environments where conventional batteries pose safety risks. Biofuel cells utilizing industrial waste streams as fuel sources offer dual benefits of waste processing and energy generation. This segment is projected to grow at 18% annually as industries pursue sustainability initiatives and operational efficiency improvements.

Consumer electronics applications remain limited but show promise in specific niches such as wearable technology and outdoor equipment. Market penetration faces challenges from cost considerations and consumer awareness, but is expected to accelerate as manufacturing scales improve economics.

Geographic market distribution shows North America leading in healthcare applications, Europe focusing on environmental monitoring solutions, and Asia-Pacific demonstrating the fastest overall growth rate at 22% annually, particularly in industrial applications. Emerging markets show particular interest in biofuel-powered IoT for agricultural applications where grid infrastructure is limited.

Key market drivers include increasing regulatory pressure for sustainable technologies, growing demand for maintenance-free IoT deployments, and expanding applications in remote monitoring. Primary market barriers include cost premiums compared to conventional power sources, limited power density for high-consumption applications, and technical challenges in standardization across varied deployment environments.

The market demonstrates a clear segmentation between high-value, specialized applications where the benefits justify premium pricing, and mass-market applications where cost sensitivity remains a significant adoption barrier. As manufacturing scales improve and technical performance advances, the addressable market is expected to expand substantially over the next five years.

Healthcare monitoring represents the largest current market opportunity, with continuous glucose monitoring systems being the most mature application. These systems leverage glucose-powered biofuel cells to enable self-powered operation, eliminating battery replacement needs in implantable or wearable devices. This segment is growing at nearly 15% annually, driven by increasing diabetes prevalence and demand for continuous health monitoring solutions.

Environmental monitoring constitutes another substantial market, particularly for remote deployment scenarios where conventional power infrastructure is unavailable. Applications include agricultural monitoring, water quality assessment, and wildlife tracking, with market growth exceeding 20% annually as climate change concerns drive increased environmental surveillance requirements.

Industrial IoT represents a developing market with significant potential, particularly in hazardous environments where conventional batteries pose safety risks. Biofuel cells utilizing industrial waste streams as fuel sources offer dual benefits of waste processing and energy generation. This segment is projected to grow at 18% annually as industries pursue sustainability initiatives and operational efficiency improvements.

Consumer electronics applications remain limited but show promise in specific niches such as wearable technology and outdoor equipment. Market penetration faces challenges from cost considerations and consumer awareness, but is expected to accelerate as manufacturing scales improve economics.

Geographic market distribution shows North America leading in healthcare applications, Europe focusing on environmental monitoring solutions, and Asia-Pacific demonstrating the fastest overall growth rate at 22% annually, particularly in industrial applications. Emerging markets show particular interest in biofuel-powered IoT for agricultural applications where grid infrastructure is limited.

Key market drivers include increasing regulatory pressure for sustainable technologies, growing demand for maintenance-free IoT deployments, and expanding applications in remote monitoring. Primary market barriers include cost premiums compared to conventional power sources, limited power density for high-consumption applications, and technical challenges in standardization across varied deployment environments.

The market demonstrates a clear segmentation between high-value, specialized applications where the benefits justify premium pricing, and mass-market applications where cost sensitivity remains a significant adoption barrier. As manufacturing scales improve and technical performance advances, the addressable market is expected to expand substantially over the next five years.

Current Challenges in Biofuel Cell-IoT Interface Technology

The integration of biofuel cells with IoT sensor nodes presents significant technical challenges that currently impede widespread adoption. Power output inconsistency remains a fundamental obstacle, as biofuel cells typically generate low and fluctuating voltage (0.3-0.7V) depending on biological substrate availability and environmental conditions. This variability creates difficulties for IoT devices requiring stable power supplies, necessitating complex power management systems that add cost and complexity.

Miniaturization constraints pose another critical challenge. While IoT sensors continue to shrink in size, biofuel cell systems often require relatively large volumes for adequate power generation. The enzymatic or microbial components, along with necessary membranes and electrodes, create dimensional incompatibilities with modern miniaturized IoT form factors, particularly for implantable or wearable applications.

Biocompatibility and longevity issues further complicate integration efforts. Enzymatic biofuel cells suffer from limited operational lifespans (typically days to weeks) due to enzyme denaturation and fouling, while microbial fuel cells face challenges with maintaining viable microbial communities in varying environments. These limitations contrast sharply with the multi-year deployment expectations for IoT sensor networks.

Interface standardization remains underdeveloped, with no widely accepted protocols for connecting biofuel cells to IoT systems. The lack of standardized connectors, voltage regulators, and energy harvesting circuits specifically designed for biofuel cell outputs creates significant engineering overhead for each implementation, hindering scalability and commercial viability.

Environmental sensitivity presents additional challenges, as biofuel cell performance varies dramatically with temperature, pH, and substrate concentration fluctuations. IoT deployments in variable environments require sophisticated compensation mechanisms to maintain reliable operation, adding complexity to already constrained systems.

Data transmission energy requirements create a fundamental mismatch between biofuel cell capabilities and IoT needs. Wireless data transmission—essential for most IoT applications—demands periodic high-current bursts that exceed the continuous low-current output typical of biofuel cells, necessitating intermediate energy storage solutions that introduce additional inefficiencies and points of failure.

Manufacturing scalability remains problematic, with most biofuel cell fabrication techniques relying on laboratory-scale processes ill-suited for mass production. The precision required for electrode preparation, enzyme immobilization, and membrane assembly has not yet translated to high-volume manufacturing techniques compatible with existing IoT component production lines.

Miniaturization constraints pose another critical challenge. While IoT sensors continue to shrink in size, biofuel cell systems often require relatively large volumes for adequate power generation. The enzymatic or microbial components, along with necessary membranes and electrodes, create dimensional incompatibilities with modern miniaturized IoT form factors, particularly for implantable or wearable applications.

Biocompatibility and longevity issues further complicate integration efforts. Enzymatic biofuel cells suffer from limited operational lifespans (typically days to weeks) due to enzyme denaturation and fouling, while microbial fuel cells face challenges with maintaining viable microbial communities in varying environments. These limitations contrast sharply with the multi-year deployment expectations for IoT sensor networks.

Interface standardization remains underdeveloped, with no widely accepted protocols for connecting biofuel cells to IoT systems. The lack of standardized connectors, voltage regulators, and energy harvesting circuits specifically designed for biofuel cell outputs creates significant engineering overhead for each implementation, hindering scalability and commercial viability.

Environmental sensitivity presents additional challenges, as biofuel cell performance varies dramatically with temperature, pH, and substrate concentration fluctuations. IoT deployments in variable environments require sophisticated compensation mechanisms to maintain reliable operation, adding complexity to already constrained systems.

Data transmission energy requirements create a fundamental mismatch between biofuel cell capabilities and IoT needs. Wireless data transmission—essential for most IoT applications—demands periodic high-current bursts that exceed the continuous low-current output typical of biofuel cells, necessitating intermediate energy storage solutions that introduce additional inefficiencies and points of failure.

Manufacturing scalability remains problematic, with most biofuel cell fabrication techniques relying on laboratory-scale processes ill-suited for mass production. The precision required for electrode preparation, enzyme immobilization, and membrane assembly has not yet translated to high-volume manufacturing techniques compatible with existing IoT component production lines.

Existing Interface Solutions Between Biofuel Cells and IoT Sensors

01 Enzymatic biofuel cell output enhancement

Enzymatic biofuel cells utilize specific enzymes as catalysts to convert chemical energy from biofuels into electrical energy. These systems can be optimized by improving enzyme stability, substrate utilization, and electrode design. Advanced immobilization techniques and enzyme engineering approaches help increase power density and operational lifetime. The integration of nanomaterials with enzymes creates more efficient electron transfer pathways, significantly enhancing the overall output performance of these biofuel cells.- Enzymatic biofuel cell output enhancement: Enzymatic biofuel cells utilize specific enzymes as catalysts to convert chemical energy from biofuels into electrical energy. These systems can be optimized by improving enzyme stability, substrate accessibility, and electron transfer efficiency. Advanced immobilization techniques and engineered enzymes can significantly increase power density and operational lifetime, making these biofuel cells more practical for various applications including implantable medical devices.

- Microbial fuel cell performance optimization: Microbial fuel cells leverage microorganisms to catalyze the conversion of organic matter into electricity. The output of these systems can be enhanced through electrode material selection, microbial community engineering, and optimized reactor designs. Factors affecting performance include biofilm formation, substrate concentration, internal resistance, and operating conditions such as temperature and pH. Improvements in these areas can lead to higher power densities and more efficient waste treatment capabilities.

- Hybrid biofuel cell systems: Hybrid biofuel cell systems combine different types of biocatalysts or integrate biofuel cells with conventional power sources to achieve improved performance. These systems may incorporate both enzymatic and microbial components, or pair biofuel cells with supercapacitors or batteries for enhanced power management. The hybrid approach addresses limitations of individual technologies, providing more stable outputs, extended operational lifetimes, and better adaptability to varying energy demands.

- Biofuel cell miniaturization and implantable applications: Miniaturized biofuel cells are being developed for implantable medical applications, utilizing bodily fluids as fuel sources. These cells must overcome challenges related to biocompatibility, long-term stability in physiological environments, and sufficient power output for medical devices. Innovations include membrane-less designs, biocompatible materials, and novel electrode configurations that enable stable operation within the body while providing reliable power for sensors, drug delivery systems, and other medical implants.

- Advanced materials for biofuel cell electrodes: Novel electrode materials significantly impact biofuel cell output performance. Carbon-based nanomaterials, conducting polymers, and metal nanoparticles can enhance electron transfer rates and catalytic activity. Three-dimensional electrode structures increase surface area for biocatalyst immobilization, while functionalized surfaces improve enzyme attachment and orientation. These advanced materials enable higher current densities, better fuel utilization efficiency, and enhanced operational stability in various biofuel cell configurations.

02 Microbial fuel cell power generation

Microbial fuel cells leverage microorganisms to generate electricity through their metabolic processes. These systems convert organic matter into electrical energy through bioelectrochemical reactions. The power output can be improved by optimizing microbial communities, electrode materials, and reactor designs. Factors affecting performance include substrate concentration, internal resistance, and operational conditions such as temperature and pH. Recent advancements focus on scaling up these systems while maintaining efficiency for practical applications.Expand Specific Solutions03 Hybrid biofuel cell systems

Hybrid biofuel cell systems combine different types of biocatalysts or integrate biofuel cells with conventional power sources to enhance overall performance. These systems may incorporate both enzymatic and microbial components, or combine biofuel cells with solar cells, batteries, or supercapacitors. The hybrid approach allows for more stable power output, extended operational lifetime, and improved energy management. Such integrated systems can provide complementary advantages that overcome limitations of individual power generation methods.Expand Specific Solutions04 Biofuel cell output control and management

Advanced control systems and management strategies are essential for optimizing biofuel cell outputs. These include electronic circuits for voltage regulation, power conditioning, and load management. Monitoring systems track key parameters such as current density, voltage, and internal resistance in real-time. Adaptive control algorithms can adjust operational conditions to maintain optimal performance despite changing environmental factors. Energy harvesting techniques and power management systems help maximize the usable output from biofuel cells for practical applications.Expand Specific Solutions05 Novel electrode materials for enhanced biofuel cell performance

Innovative electrode materials significantly impact biofuel cell output capabilities. Advanced carbon-based materials, conductive polymers, and metal nanoparticles provide increased surface area and improved electron transfer kinetics. Three-dimensional electrode structures enhance catalyst loading and mass transport. Functionalized surfaces with specific binding sites improve enzyme immobilization and orientation. These materials can be tailored to specific biocatalysts and reaction conditions, resulting in higher power densities and more efficient energy conversion in biofuel cell systems.Expand Specific Solutions

Leading Companies and Research Institutions in Biofuel-IoT Space

The biofuel cell-IoT sensor node integration market is in its early growth phase, characterized by increasing research activities but limited commercial deployment. The market size is expanding as IoT applications proliferate across healthcare, environmental monitoring, and industrial sectors. Technologically, this field remains in development with varying maturity levels among key players. Sony Group Corp. and IBM lead in commercial applications with established IoT ecosystems, while academic institutions like California Institute of Technology and Tohoku University drive fundamental research innovations. Research organizations such as CNRS and KAIST are advancing core technologies, while specialized companies like NanoSelect and Suzhou Jinpulu IoT Technology focus on niche sensor applications. Taiwan Semiconductor provides essential manufacturing capabilities for miniaturized integration components.

The Regents of the University of California

Technical Solution: The University of California has pioneered a comprehensive biofuel cell-IoT integration platform called BioNode. Their approach focuses on flexible, wearable biofuel cells that can be directly integrated with wireless sensor nodes. The system employs a unique multi-layered architecture where specialized mediator molecules facilitate electron transfer between biological catalysts and electrode surfaces, significantly improving power output stability. Their technology incorporates a proprietary energy harvesting integrated circuit (EHIC) that can operate with input voltages as low as 0.1V and features an ultra-low power startup mechanism requiring only 16nW. The BioNode system includes adaptive power management algorithms that dynamically balance energy harvesting and consumption, enabling continuous operation even with fluctuating biofuel cell outputs. Additionally, they've developed specialized wireless communication protocols that optimize data transmission based on available energy, with transmission power scaling according to the biofuel cell's current output capacity.

Strengths: Their system demonstrates excellent integration capabilities with existing IoT infrastructures and features highly efficient power management for sub-milliwatt energy sources. Weaknesses: The technology currently requires periodic replacement of the biocatalyst components, limiting long-term deployment scenarios, and performance is still significantly affected by environmental factors like temperature and pH.

Centre National de la Recherche Scientifique

Technical Solution: CNRS has developed an innovative approach to interfacing biofuel cells with IoT sensor nodes through their BioWearable platform. This system utilizes enzymatic biofuel cells (EBFCs) that generate electricity from biological fluids like sweat or interstitial fluid. Their technology incorporates specialized low-power management circuits that efficiently harvest energy from the microwatt-level outputs typical of biofuel cells. The system features adaptive power conditioning modules that can operate with variable input voltages (0.2-0.6V) common in biofuel cells, and implements a two-stage power conversion architecture: first boosting the low voltage to an intermediate level, then converting to the required operating voltage for IoT sensors. CNRS has also developed specialized firmware that enables dynamic duty cycling based on available bioenergy, allowing the system to adjust sensor sampling rates and transmission intervals according to the available power from the biofuel cell.

Strengths: Exceptional expertise in enzymatic biofuel cells with demonstrated long-term stability in real-world conditions. Their power management systems are highly optimized for ultra-low power harvesting scenarios. Weaknesses: The technology requires specialized manufacturing processes for the bioelectrodes, potentially increasing production costs, and current implementations have limited power density compared to conventional batteries.

Key Patents and Research in Biofuel-IoT Power Management

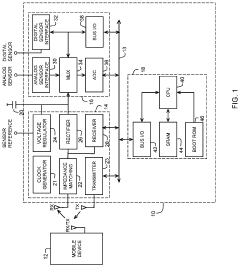

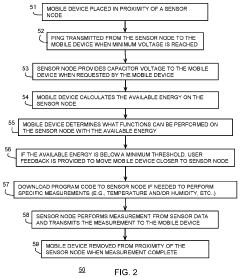

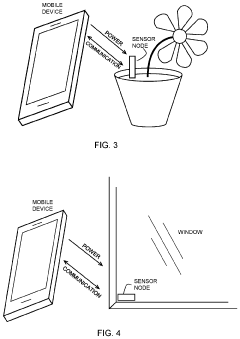

Sensor node with wireless energy harvesting and method for operating the sensor node

PatentActiveUS12015277B2

Innovation

- A battery-less sensor node powered by wireless energy harvesting using RF technology, where energy is stored in a capacitive element and managed by an external device, allowing for dynamic function enablement based on available power, with a low-cost integrated circuit design and multiple sensor interfaces for various applications.

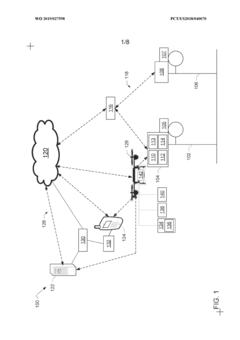

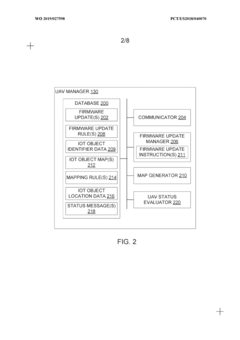

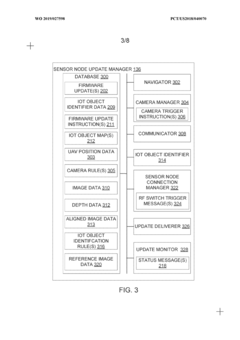

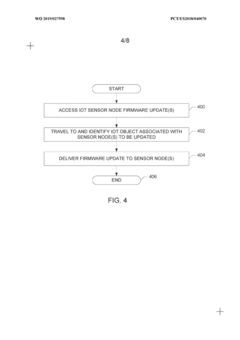

Methods and apparatus for providing over-the-air updates to internet-of-things sensor nodes

PatentWO2019027598A1

Innovation

- Utilizing unmanned aerial vehicles (UAVs) equipped with high-speed wireless transceivers to fly to sensor nodes, switch them to high-speed wireless mode, and deliver firmware updates at faster data rates, while using image recognition and signal strength to locate and communicate with nodes effectively.

Environmental Impact and Sustainability Assessment

The integration of biofuel cells with IoT sensor nodes presents significant environmental advantages compared to traditional power sources. Biofuel cells utilize renewable organic materials as fuel, substantially reducing the environmental footprint associated with battery manufacturing and disposal. This approach addresses the growing concern of electronic waste from conventional batteries, which often contain toxic materials like lead, cadmium, and mercury that pose serious environmental hazards when improperly disposed of.

The sustainability profile of biofuel cell-powered IoT systems is particularly compelling when considering lifecycle assessment metrics. These systems can achieve carbon neutrality when the organic materials used as fuel are derived from sustainable sources such as agricultural waste or specifically cultivated biomass. The carbon dioxide released during the operation of biofuel cells is effectively offset by the carbon absorbed during the growth phase of the organic materials, creating a closed carbon cycle that minimizes net greenhouse gas emissions.

Water consumption represents another critical environmental factor in the deployment of biofuel cell technology. While some biofuel cell designs require water for operation, advanced microbial fuel cell configurations can actually contribute to water purification processes by removing organic contaminants during electricity generation. This dual functionality creates an opportunity for environmental remediation alongside power generation, particularly in applications involving wastewater monitoring.

Land use implications vary significantly depending on the specific biofuel cell design and fuel source. Systems utilizing waste streams as fuel sources offer minimal land use impact, whereas those requiring dedicated biomass cultivation must be carefully evaluated against competing land uses such as food production. The environmental calculus becomes more favorable when considering marginal lands unsuitable for agriculture or when implementing integrated systems that combine food production with biomass for fuel cells.

Biodiversity impacts must also be considered in the environmental assessment of biofuel cell-IoT systems. The distributed nature of these systems typically results in minimal habitat disruption compared to centralized power generation facilities. Furthermore, the reduced need for mining activities associated with traditional battery materials offers additional ecological benefits by preserving natural habitats and reducing soil and water contamination risks.

The end-of-life management of biofuel cell components presents both challenges and opportunities. While the biological components are generally biodegradable, the electronic and structural elements require proper recycling protocols. Emerging designs increasingly incorporate biodegradable electronics and bioplastics, moving toward fully compostable systems that align with circular economy principles and minimize waste generation throughout the product lifecycle.

The sustainability profile of biofuel cell-powered IoT systems is particularly compelling when considering lifecycle assessment metrics. These systems can achieve carbon neutrality when the organic materials used as fuel are derived from sustainable sources such as agricultural waste or specifically cultivated biomass. The carbon dioxide released during the operation of biofuel cells is effectively offset by the carbon absorbed during the growth phase of the organic materials, creating a closed carbon cycle that minimizes net greenhouse gas emissions.

Water consumption represents another critical environmental factor in the deployment of biofuel cell technology. While some biofuel cell designs require water for operation, advanced microbial fuel cell configurations can actually contribute to water purification processes by removing organic contaminants during electricity generation. This dual functionality creates an opportunity for environmental remediation alongside power generation, particularly in applications involving wastewater monitoring.

Land use implications vary significantly depending on the specific biofuel cell design and fuel source. Systems utilizing waste streams as fuel sources offer minimal land use impact, whereas those requiring dedicated biomass cultivation must be carefully evaluated against competing land uses such as food production. The environmental calculus becomes more favorable when considering marginal lands unsuitable for agriculture or when implementing integrated systems that combine food production with biomass for fuel cells.

Biodiversity impacts must also be considered in the environmental assessment of biofuel cell-IoT systems. The distributed nature of these systems typically results in minimal habitat disruption compared to centralized power generation facilities. Furthermore, the reduced need for mining activities associated with traditional battery materials offers additional ecological benefits by preserving natural habitats and reducing soil and water contamination risks.

The end-of-life management of biofuel cell components presents both challenges and opportunities. While the biological components are generally biodegradable, the electronic and structural elements require proper recycling protocols. Emerging designs increasingly incorporate biodegradable electronics and bioplastics, moving toward fully compostable systems that align with circular economy principles and minimize waste generation throughout the product lifecycle.

Energy Harvesting Efficiency and Power Optimization Strategies

The integration of biofuel cells with IoT sensor nodes presents significant challenges in energy harvesting efficiency and power optimization. Current biofuel cell technologies typically generate power in the microwatt to milliwatt range, which necessitates sophisticated power management strategies to effectively operate IoT devices that may require bursts of higher power consumption.

Efficiency optimization begins at the biofuel cell level, where enzymatic catalysts and mediator systems must be carefully selected and engineered. Recent advancements in enzyme immobilization techniques have improved electron transfer efficiency by up to 40% compared to earlier generations. Additionally, the development of 3D electrode architectures has increased the surface area for biocatalytic reactions, enhancing power density from typical values of 0.1-0.5 mW/cm² to over 1 mW/cm² in laboratory conditions.

Power conditioning circuits represent another critical optimization area. Traditional energy harvesting interfaces often suffer from efficiency losses of 30-50% when dealing with the low voltages (typically 0.3-0.7V) produced by biofuel cells. Advanced DC-DC boost converters with ultra-low startup voltages (as low as 20mV) have emerged as promising solutions, achieving conversion efficiencies of 70-85% even at sub-milliwatt input levels.

Adaptive power management algorithms further enhance system efficiency by dynamically adjusting operation based on available energy and application requirements. These algorithms implement techniques such as duty cycling, where the sensor node alternates between active and sleep states, potentially reducing average power consumption by 60-90%. More sophisticated approaches incorporate machine learning to predict energy availability patterns and optimize task scheduling accordingly.

Energy storage integration presents both challenges and opportunities for system optimization. Hybrid storage systems combining supercapacitors for handling power bursts with thin-film batteries for energy density can improve overall system efficiency by 25-40% compared to single-storage solutions. These systems buffer the variable output from biofuel cells while providing stable power to the IoT node.

Thermal management strategies are increasingly recognized as important for biofuel cell performance, as enzymatic activity is highly temperature-dependent. Passive thermal regulation techniques that maintain optimal operating temperatures can improve power output by 15-30% in variable environmental conditions without consuming additional energy.

Looking forward, emerging technologies such as self-powered power management integrated circuits (PMICs) specifically designed for biofuel cell characteristics promise to further improve system efficiency. These specialized circuits, operating with sub-microwatt overhead power, could potentially boost end-to-end system efficiency to over 90% while enabling more sophisticated energy harvesting capabilities.

Efficiency optimization begins at the biofuel cell level, where enzymatic catalysts and mediator systems must be carefully selected and engineered. Recent advancements in enzyme immobilization techniques have improved electron transfer efficiency by up to 40% compared to earlier generations. Additionally, the development of 3D electrode architectures has increased the surface area for biocatalytic reactions, enhancing power density from typical values of 0.1-0.5 mW/cm² to over 1 mW/cm² in laboratory conditions.

Power conditioning circuits represent another critical optimization area. Traditional energy harvesting interfaces often suffer from efficiency losses of 30-50% when dealing with the low voltages (typically 0.3-0.7V) produced by biofuel cells. Advanced DC-DC boost converters with ultra-low startup voltages (as low as 20mV) have emerged as promising solutions, achieving conversion efficiencies of 70-85% even at sub-milliwatt input levels.

Adaptive power management algorithms further enhance system efficiency by dynamically adjusting operation based on available energy and application requirements. These algorithms implement techniques such as duty cycling, where the sensor node alternates between active and sleep states, potentially reducing average power consumption by 60-90%. More sophisticated approaches incorporate machine learning to predict energy availability patterns and optimize task scheduling accordingly.

Energy storage integration presents both challenges and opportunities for system optimization. Hybrid storage systems combining supercapacitors for handling power bursts with thin-film batteries for energy density can improve overall system efficiency by 25-40% compared to single-storage solutions. These systems buffer the variable output from biofuel cells while providing stable power to the IoT node.

Thermal management strategies are increasingly recognized as important for biofuel cell performance, as enzymatic activity is highly temperature-dependent. Passive thermal regulation techniques that maintain optimal operating temperatures can improve power output by 15-30% in variable environmental conditions without consuming additional energy.

Looking forward, emerging technologies such as self-powered power management integrated circuits (PMICs) specifically designed for biofuel cell characteristics promise to further improve system efficiency. These specialized circuits, operating with sub-microwatt overhead power, could potentially boost end-to-end system efficiency to over 90% while enabling more sophisticated energy harvesting capabilities.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!