Catalyst Poisoning Mechanisms in Electrolyzers and How to Mitigate Them

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrolyzer Catalyst Poisoning Background

Electrolyzers play a crucial role in the production of hydrogen through water splitting, a process that is gaining importance in the transition to clean energy systems. However, one of the major challenges faced in electrolyzer technology is catalyst poisoning, which significantly impacts the efficiency and longevity of these devices.

Catalyst poisoning in electrolyzers refers to the degradation of catalyst performance due to the adsorption of impurities or the formation of unwanted compounds on the catalyst surface. This phenomenon can occur on both the anode and cathode sides of the electrolyzer, affecting different types of catalysts used in various electrolyzer technologies, such as polymer electrolyte membrane (PEM) electrolyzers, alkaline electrolyzers, and solid oxide electrolyzers.

The history of catalyst poisoning research in electrolyzers dates back to the early development of water electrolysis technology. As the field progressed, researchers identified various mechanisms contributing to catalyst deactivation, including chemical poisoning, physical blockage, and electrochemical degradation.

Chemical poisoning typically involves the strong adsorption of contaminants onto active catalyst sites, preventing reactant molecules from accessing these sites. Common chemical poisons include sulfur compounds, carbon monoxide, and certain metal ions. Physical blockage, on the other hand, occurs when larger particles or precipitates accumulate on the catalyst surface, reducing the available active area.

Electrochemical degradation is a more complex process that can involve the dissolution of catalyst materials, structural changes in the catalyst surface, or the formation of oxide layers that hinder catalytic activity. This type of degradation is often associated with potential cycling and prolonged operation under harsh conditions.

The impact of catalyst poisoning on electrolyzer performance is significant. It leads to increased overpotentials, reduced current densities, and ultimately, decreased hydrogen production efficiency. Moreover, catalyst poisoning can accelerate the overall degradation of the electrolyzer system, shortening its operational lifespan and increasing maintenance costs.

Understanding the mechanisms of catalyst poisoning is crucial for developing effective mitigation strategies. These strategies may include improving catalyst design to enhance poison resistance, implementing advanced purification techniques for feed water and reactant gases, and developing regeneration protocols to restore catalyst activity.

As research in this field continues to evolve, new analytical techniques and in-situ characterization methods are being employed to gain deeper insights into the poisoning processes at the molecular level. This knowledge is essential for the development of next-generation electrolyzers with improved durability and performance, which are critical for the large-scale implementation of hydrogen-based energy systems.

Catalyst poisoning in electrolyzers refers to the degradation of catalyst performance due to the adsorption of impurities or the formation of unwanted compounds on the catalyst surface. This phenomenon can occur on both the anode and cathode sides of the electrolyzer, affecting different types of catalysts used in various electrolyzer technologies, such as polymer electrolyte membrane (PEM) electrolyzers, alkaline electrolyzers, and solid oxide electrolyzers.

The history of catalyst poisoning research in electrolyzers dates back to the early development of water electrolysis technology. As the field progressed, researchers identified various mechanisms contributing to catalyst deactivation, including chemical poisoning, physical blockage, and electrochemical degradation.

Chemical poisoning typically involves the strong adsorption of contaminants onto active catalyst sites, preventing reactant molecules from accessing these sites. Common chemical poisons include sulfur compounds, carbon monoxide, and certain metal ions. Physical blockage, on the other hand, occurs when larger particles or precipitates accumulate on the catalyst surface, reducing the available active area.

Electrochemical degradation is a more complex process that can involve the dissolution of catalyst materials, structural changes in the catalyst surface, or the formation of oxide layers that hinder catalytic activity. This type of degradation is often associated with potential cycling and prolonged operation under harsh conditions.

The impact of catalyst poisoning on electrolyzer performance is significant. It leads to increased overpotentials, reduced current densities, and ultimately, decreased hydrogen production efficiency. Moreover, catalyst poisoning can accelerate the overall degradation of the electrolyzer system, shortening its operational lifespan and increasing maintenance costs.

Understanding the mechanisms of catalyst poisoning is crucial for developing effective mitigation strategies. These strategies may include improving catalyst design to enhance poison resistance, implementing advanced purification techniques for feed water and reactant gases, and developing regeneration protocols to restore catalyst activity.

As research in this field continues to evolve, new analytical techniques and in-situ characterization methods are being employed to gain deeper insights into the poisoning processes at the molecular level. This knowledge is essential for the development of next-generation electrolyzers with improved durability and performance, which are critical for the large-scale implementation of hydrogen-based energy systems.

Market Demand for Efficient Electrolyzers

The market demand for efficient electrolyzers has been steadily increasing in recent years, driven by the global push towards clean energy solutions and the growing hydrogen economy. As countries and industries strive to reduce carbon emissions and achieve sustainability goals, the need for high-performance electrolyzers has become more pronounced.

The electrolyzer market is expected to experience significant growth in the coming years, with projections indicating a compound annual growth rate (CAGR) of over 20% through 2030. This growth is primarily fueled by the increasing adoption of hydrogen as a clean energy carrier in various sectors, including transportation, industry, and power generation.

One of the key drivers of market demand is the automotive industry's shift towards fuel cell electric vehicles (FCEVs). As major automakers invest in hydrogen-powered vehicles, the demand for efficient electrolyzers to produce green hydrogen is rising. This trend is particularly evident in countries like Japan, South Korea, and Germany, where governments are actively promoting FCEV adoption.

The industrial sector is another significant contributor to the growing demand for efficient electrolyzers. Industries such as steel production, chemical manufacturing, and refining are exploring ways to decarbonize their processes using green hydrogen. This shift is creating a substantial market for large-scale electrolyzers capable of producing hydrogen at competitive costs.

In the power generation sector, there is an increasing interest in using electrolyzers for energy storage and grid balancing. As renewable energy sources like wind and solar become more prevalent, the need for efficient energy storage solutions grows. Electrolyzers can convert excess renewable energy into hydrogen, which can be stored and later used to generate electricity during periods of high demand or low renewable energy production.

The maritime industry is also emerging as a potential market for efficient electrolyzers. With stricter emissions regulations on the horizon, shipping companies are exploring alternative fuels, including hydrogen. This trend is driving demand for electrolyzers that can produce hydrogen at ports and marine facilities.

Despite the growing market demand, challenges remain in the widespread adoption of electrolyzers. Cost reduction is a critical factor, as the current capital and operational expenses of electrolyzers can be prohibitive for some applications. Improving the efficiency and durability of electrolyzers, particularly in addressing issues like catalyst poisoning, is crucial to meeting market demands and accelerating adoption across various sectors.

The electrolyzer market is expected to experience significant growth in the coming years, with projections indicating a compound annual growth rate (CAGR) of over 20% through 2030. This growth is primarily fueled by the increasing adoption of hydrogen as a clean energy carrier in various sectors, including transportation, industry, and power generation.

One of the key drivers of market demand is the automotive industry's shift towards fuel cell electric vehicles (FCEVs). As major automakers invest in hydrogen-powered vehicles, the demand for efficient electrolyzers to produce green hydrogen is rising. This trend is particularly evident in countries like Japan, South Korea, and Germany, where governments are actively promoting FCEV adoption.

The industrial sector is another significant contributor to the growing demand for efficient electrolyzers. Industries such as steel production, chemical manufacturing, and refining are exploring ways to decarbonize their processes using green hydrogen. This shift is creating a substantial market for large-scale electrolyzers capable of producing hydrogen at competitive costs.

In the power generation sector, there is an increasing interest in using electrolyzers for energy storage and grid balancing. As renewable energy sources like wind and solar become more prevalent, the need for efficient energy storage solutions grows. Electrolyzers can convert excess renewable energy into hydrogen, which can be stored and later used to generate electricity during periods of high demand or low renewable energy production.

The maritime industry is also emerging as a potential market for efficient electrolyzers. With stricter emissions regulations on the horizon, shipping companies are exploring alternative fuels, including hydrogen. This trend is driving demand for electrolyzers that can produce hydrogen at ports and marine facilities.

Despite the growing market demand, challenges remain in the widespread adoption of electrolyzers. Cost reduction is a critical factor, as the current capital and operational expenses of electrolyzers can be prohibitive for some applications. Improving the efficiency and durability of electrolyzers, particularly in addressing issues like catalyst poisoning, is crucial to meeting market demands and accelerating adoption across various sectors.

Current Challenges in Catalyst Longevity

Catalyst longevity remains a critical challenge in the development and operation of electrolyzers. The primary issue stems from catalyst poisoning mechanisms, which significantly reduce the efficiency and lifespan of these essential components. One of the most prevalent challenges is the adsorption of impurities onto the catalyst surface, leading to a decrease in active sites and overall catalytic activity.

Contaminants such as sulfur compounds, carbon monoxide, and metal ions present in feedwater or generated during the electrolysis process can irreversibly bind to catalyst surfaces. This binding not only blocks active sites but can also alter the electronic structure of the catalyst, further diminishing its effectiveness. The accumulation of these impurities over time results in a gradual decline in electrolyzer performance and increased energy consumption to maintain desired hydrogen production rates.

Another significant challenge is catalyst degradation due to repeated oxidation and reduction cycles. This is particularly problematic in proton exchange membrane (PEM) electrolyzers, where catalysts are subjected to high potentials and acidic environments. The cycling can lead to dissolution of catalyst particles, agglomeration, and detachment from support materials, all of which contribute to a loss of active surface area and reduced catalytic activity.

Catalyst stability in alkaline environments poses a unique set of challenges. While alkaline electrolyzers offer the advantage of using non-noble metal catalysts, these materials are often susceptible to corrosion and structural changes in highly basic conditions. The dissolution and reprecipitation of catalyst materials can lead to changes in morphology and composition, affecting long-term stability and performance.

The development of catalyst supports that maintain high surface area and conductivity over extended periods is another ongoing challenge. Carbon-based supports, commonly used in PEM electrolyzers, are prone to corrosion at high potentials, leading to catalyst detachment and loss. Alternative support materials must balance stability, conductivity, and surface area to ensure optimal catalyst dispersion and longevity.

Addressing these challenges requires a multifaceted approach, combining advances in materials science, electrochemistry, and engineering. Strategies such as developing poison-resistant catalyst formulations, implementing more effective purification systems for feedwater, and designing novel catalyst structures that mitigate degradation mechanisms are all active areas of research. The ultimate goal is to create catalysts that maintain high activity and selectivity over thousands of hours of operation, significantly reducing the operational costs and improving the economic viability of hydrogen production through electrolysis.

Contaminants such as sulfur compounds, carbon monoxide, and metal ions present in feedwater or generated during the electrolysis process can irreversibly bind to catalyst surfaces. This binding not only blocks active sites but can also alter the electronic structure of the catalyst, further diminishing its effectiveness. The accumulation of these impurities over time results in a gradual decline in electrolyzer performance and increased energy consumption to maintain desired hydrogen production rates.

Another significant challenge is catalyst degradation due to repeated oxidation and reduction cycles. This is particularly problematic in proton exchange membrane (PEM) electrolyzers, where catalysts are subjected to high potentials and acidic environments. The cycling can lead to dissolution of catalyst particles, agglomeration, and detachment from support materials, all of which contribute to a loss of active surface area and reduced catalytic activity.

Catalyst stability in alkaline environments poses a unique set of challenges. While alkaline electrolyzers offer the advantage of using non-noble metal catalysts, these materials are often susceptible to corrosion and structural changes in highly basic conditions. The dissolution and reprecipitation of catalyst materials can lead to changes in morphology and composition, affecting long-term stability and performance.

The development of catalyst supports that maintain high surface area and conductivity over extended periods is another ongoing challenge. Carbon-based supports, commonly used in PEM electrolyzers, are prone to corrosion at high potentials, leading to catalyst detachment and loss. Alternative support materials must balance stability, conductivity, and surface area to ensure optimal catalyst dispersion and longevity.

Addressing these challenges requires a multifaceted approach, combining advances in materials science, electrochemistry, and engineering. Strategies such as developing poison-resistant catalyst formulations, implementing more effective purification systems for feedwater, and designing novel catalyst structures that mitigate degradation mechanisms are all active areas of research. The ultimate goal is to create catalysts that maintain high activity and selectivity over thousands of hours of operation, significantly reducing the operational costs and improving the economic viability of hydrogen production through electrolysis.

Existing Catalyst Poisoning Mitigation Strategies

01 Catalyst protection and regeneration methods

Various methods are employed to protect catalysts from poisoning and regenerate poisoned catalysts in electrolyzers. These include using protective coatings, implementing purification systems to remove contaminants, and developing regeneration processes to restore catalyst activity. Such techniques help extend catalyst life and maintain electrolyzer efficiency.- Catalyst protection and regeneration methods: Various methods are employed to protect catalysts from poisoning and regenerate them after exposure to contaminants. These include using protective coatings, implementing purification systems to remove impurities, and developing regeneration processes to restore catalyst activity. Such techniques help extend the lifespan of catalysts in electrolyzers and maintain their efficiency.

- Novel catalyst materials resistant to poisoning: Research focuses on developing new catalyst materials that are inherently resistant to poisoning. These materials may include alloys, composites, or nanostructured catalysts designed to withstand common contaminants in electrolyzer systems. The goal is to create more durable and efficient catalysts that can operate in challenging environments without significant performance degradation.

- Impurity detection and removal systems: Advanced impurity detection and removal systems are integrated into electrolyzer designs to prevent catalyst poisoning. These systems may include sensors for real-time monitoring of contaminant levels, filtration mechanisms, and purification processes to maintain the purity of reactants and electrolytes. By minimizing exposure to harmful substances, these systems help preserve catalyst performance and longevity.

- Operational strategies to mitigate poisoning: Specific operational strategies are developed to mitigate the risk of catalyst poisoning in electrolyzers. These may include optimized start-up and shut-down procedures, controlled operating conditions, and periodic maintenance routines. By implementing these strategies, operators can minimize the accumulation of contaminants on catalyst surfaces and maintain optimal performance over extended periods.

- In-situ catalyst regeneration techniques: In-situ regeneration techniques are developed to restore catalyst activity without the need for system disassembly. These methods may involve electrochemical treatments, chemical flushing, or thermal processes that can be applied while the electrolyzer remains in place. Such techniques aim to extend operational periods between major maintenance events and reduce downtime associated with catalyst poisoning.

02 Novel catalyst materials resistant to poisoning

Research focuses on developing new catalyst materials that are inherently resistant to poisoning. These materials may include alloys, nanostructured catalysts, or composite materials designed to withstand common contaminants in electrolyzer systems. The goal is to create more durable and efficient catalysts for long-term operation.Expand Specific Solutions03 Contaminant detection and removal systems

Advanced systems are being developed to detect and remove contaminants before they reach the catalyst. These may include inline sensors, filtration systems, and chemical traps designed to capture specific poisoning agents. By preventing contaminants from reaching the catalyst, these systems help maintain electrolyzer performance and extend catalyst life.Expand Specific Solutions04 Operational strategies to minimize catalyst poisoning

Implementing specific operational strategies can help minimize catalyst poisoning in electrolyzers. These may include optimizing operating conditions, implementing regular maintenance schedules, and using pulsed or cyclic operation to reduce contaminant buildup. Such strategies aim to prolong catalyst life and maintain electrolyzer efficiency.Expand Specific Solutions05 Catalyst poisoning mitigation in specific electrolyzer types

Different types of electrolyzers (e.g., PEM, alkaline, solid oxide) face unique challenges in catalyst poisoning. Research is ongoing to develop tailored solutions for each electrolyzer type, considering their specific operating conditions, electrolyte compositions, and common contaminants. This approach aims to provide more effective and targeted solutions for catalyst poisoning mitigation.Expand Specific Solutions

Key Players in Electrolyzer Industry

The catalyst poisoning mechanisms in electrolyzers represent a critical challenge in the evolving field of clean energy technologies. The industry is currently in a growth phase, with increasing market size driven by the global push for sustainable energy solutions. The technology's maturity is advancing rapidly, with key players like Johnson Matthey, Industrie De Nora, and Haldor Topsøe leading research and development efforts. These companies are focusing on innovative catalyst designs and protective measures to mitigate poisoning effects, thereby improving electrolyzer efficiency and longevity. As the market expands, collaboration between academic institutions like Xiamen University and industry leaders is accelerating progress in understanding and addressing catalyst degradation mechanisms.

Haldor Topsøe A/S

Technical Solution: Haldor Topsøe has focused on developing poison-resistant catalysts for electrolyzers. Their approach involves creating multi-metallic catalysts with specific atomic arrangements that minimize binding of poisoning species. They've implemented a novel synthesis method that results in highly dispersed nanoparticles with increased active sites and improved poison tolerance[4]. Additionally, they've developed a proprietary catalyst support material that helps in trapping potential poisons before they reach the active sites[5]. Haldor Topsøe has also introduced an in-situ purification system that continuously removes contaminants from the electrolyte, reducing the overall poisoning effect[6].

Strengths: Innovative multi-metallic catalyst designs, proprietary support materials, and integrated purification systems. Weaknesses: Complex synthesis processes may lead to higher production costs.

BASF Corp.

Technical Solution: BASF has developed a comprehensive approach to mitigate catalyst poisoning in electrolyzers. Their strategy includes the use of hierarchical porous catalysts that provide improved mass transport and reduced accumulation of poisoning species[7]. They've also implemented a novel coating technology that creates a selective membrane on the catalyst surface, allowing reactants to pass while blocking common poisons[8]. BASF has further developed an intelligent control system that monitors catalyst performance in real-time and adjusts operating conditions to minimize poisoning effects[9]. Additionally, they've introduced a modular catalyst design that allows for easy replacement of poisoned components without full system shutdown.

Strengths: Holistic approach combining material science and system engineering, innovative coating technology, and intelligent control systems. Weaknesses: High initial implementation costs for the comprehensive solution.

Innovative Anti-Poisoning Catalyst Designs

Catalyst for oxygen reduction

PatentActiveUS20070219086A1

Innovation

- A chemically stable form of supported ruthenium sulfide catalyst is developed through gas-solid reactions, incorporating a conductive inert support like carbon black and treated with hydrogen sulfide, which is incorporated into gas diffusion electrodes with a hydrophobic binder, offering enhanced stability and activity in hydrochloric acid environments.

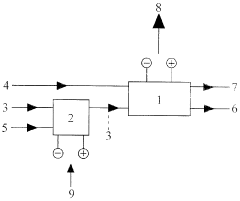

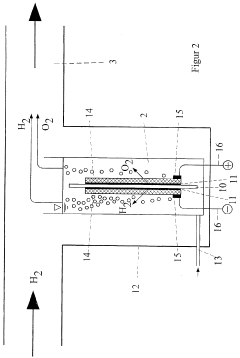

Fuel cell with an oxygen supply into the fuel

PatentWO1998021775A1

Innovation

- A fuel cell system incorporating an electrolyzer to produce nitrogen-free oxygen, which is fed into the fuel supply line, allowing for simple control and integration with the fuel cell's power output, using product water for electrolysis and minimizing energy consumption.

Environmental Impact of Catalyst Materials

The environmental impact of catalyst materials used in electrolyzers is a critical consideration in the development and implementation of sustainable hydrogen production technologies. Catalysts play a crucial role in enhancing the efficiency of electrolysis processes, but their production, use, and disposal can have significant environmental implications.

The most commonly used catalysts in electrolyzers are noble metals such as platinum, iridium, and ruthenium. These materials are rare and their extraction often involves energy-intensive mining processes that can lead to habitat destruction, soil erosion, and water pollution. The scarcity of these metals also raises concerns about the long-term sustainability of their use in large-scale electrolyzer deployments.

During the operation of electrolyzers, catalyst materials may gradually degrade or leach into the electrolyte solution. This can result in the release of potentially harmful metal ions into the environment if proper treatment and disposal methods are not employed. The presence of these metal ions in water systems can have detrimental effects on aquatic ecosystems and potentially enter the food chain.

The production of catalyst materials often involves the use of hazardous chemicals and energy-intensive processes. These manufacturing steps can contribute to air and water pollution, as well as greenhouse gas emissions. Additionally, the transportation of raw materials and finished catalysts adds to the overall carbon footprint of electrolyzer systems.

End-of-life management of electrolyzers presents another environmental challenge. The recovery and recycling of catalyst materials from decommissioned electrolyzers are essential to minimize waste and reduce the demand for new raw materials. However, current recycling processes for these materials are often complex and energy-intensive, potentially offsetting some of the environmental benefits.

To mitigate these environmental impacts, researchers are exploring alternative catalyst materials and designs. This includes the development of non-noble metal catalysts, such as nickel-based alloys or metal oxides, which are more abundant and potentially less environmentally harmful. Additionally, efforts are being made to improve catalyst efficiency and durability, reducing the overall material requirements and extending the lifespan of electrolyzer systems.

Advancements in green chemistry and sustainable manufacturing processes are also being pursued to minimize the environmental footprint of catalyst production. This includes the use of bio-inspired synthesis methods, recycled materials, and cleaner production techniques that reduce waste and energy consumption.

The most commonly used catalysts in electrolyzers are noble metals such as platinum, iridium, and ruthenium. These materials are rare and their extraction often involves energy-intensive mining processes that can lead to habitat destruction, soil erosion, and water pollution. The scarcity of these metals also raises concerns about the long-term sustainability of their use in large-scale electrolyzer deployments.

During the operation of electrolyzers, catalyst materials may gradually degrade or leach into the electrolyte solution. This can result in the release of potentially harmful metal ions into the environment if proper treatment and disposal methods are not employed. The presence of these metal ions in water systems can have detrimental effects on aquatic ecosystems and potentially enter the food chain.

The production of catalyst materials often involves the use of hazardous chemicals and energy-intensive processes. These manufacturing steps can contribute to air and water pollution, as well as greenhouse gas emissions. Additionally, the transportation of raw materials and finished catalysts adds to the overall carbon footprint of electrolyzer systems.

End-of-life management of electrolyzers presents another environmental challenge. The recovery and recycling of catalyst materials from decommissioned electrolyzers are essential to minimize waste and reduce the demand for new raw materials. However, current recycling processes for these materials are often complex and energy-intensive, potentially offsetting some of the environmental benefits.

To mitigate these environmental impacts, researchers are exploring alternative catalyst materials and designs. This includes the development of non-noble metal catalysts, such as nickel-based alloys or metal oxides, which are more abundant and potentially less environmentally harmful. Additionally, efforts are being made to improve catalyst efficiency and durability, reducing the overall material requirements and extending the lifespan of electrolyzer systems.

Advancements in green chemistry and sustainable manufacturing processes are also being pursued to minimize the environmental footprint of catalyst production. This includes the use of bio-inspired synthesis methods, recycled materials, and cleaner production techniques that reduce waste and energy consumption.

Economic Viability of Advanced Catalysts

The economic viability of advanced catalysts in electrolyzers is a critical factor in the widespread adoption of hydrogen production technologies. As catalyst poisoning remains a significant challenge, the development of more resilient and efficient catalysts becomes paramount. The cost-benefit analysis of implementing advanced catalysts must consider both the initial investment and long-term operational savings.

Advanced catalysts, designed to mitigate poisoning mechanisms, often come with higher upfront costs due to the use of precious metals or complex manufacturing processes. However, their increased durability and resistance to degradation can lead to substantial savings over time. These catalysts typically exhibit longer lifespans, reducing the frequency of replacement and associated downtime costs.

The economic impact of catalyst poisoning in electrolyzers is multifaceted. It not only affects the direct costs of catalyst replacement but also influences energy efficiency, production rates, and overall system performance. Advanced catalysts that can maintain high activity levels in the presence of contaminants contribute to sustained hydrogen production rates, thereby improving the return on investment for electrolyzer operators.

Market analysis indicates a growing demand for high-performance electrolyzers in various sectors, including renewable energy storage, industrial processes, and transportation. This demand drives innovation in catalyst technology, potentially leading to economies of scale that could reduce the costs of advanced catalysts in the future. As production volumes increase, the price gap between conventional and advanced catalysts is expected to narrow.

The economic viability of advanced catalysts also depends on the specific application and operating conditions. In environments with high levels of contaminants, the benefits of poison-resistant catalysts become more pronounced, justifying the higher initial investment. Conversely, in cleaner operating conditions, the cost-benefit ratio may favor more conventional catalyst options.

Regulatory factors play a crucial role in the economic landscape of advanced catalysts. As environmental regulations become more stringent, the value proposition of catalysts that enable cleaner and more efficient hydrogen production strengthens. Government incentives and carbon pricing mechanisms can further enhance the economic attractiveness of advanced catalyst technologies.

In conclusion, while advanced catalysts designed to mitigate poisoning mechanisms may present higher upfront costs, their potential for long-term operational savings and improved system performance makes them economically viable in many scenarios. The evolving market dynamics and regulatory environment are likely to further improve their cost-effectiveness, solidifying their role in the future of hydrogen production technologies.

Advanced catalysts, designed to mitigate poisoning mechanisms, often come with higher upfront costs due to the use of precious metals or complex manufacturing processes. However, their increased durability and resistance to degradation can lead to substantial savings over time. These catalysts typically exhibit longer lifespans, reducing the frequency of replacement and associated downtime costs.

The economic impact of catalyst poisoning in electrolyzers is multifaceted. It not only affects the direct costs of catalyst replacement but also influences energy efficiency, production rates, and overall system performance. Advanced catalysts that can maintain high activity levels in the presence of contaminants contribute to sustained hydrogen production rates, thereby improving the return on investment for electrolyzer operators.

Market analysis indicates a growing demand for high-performance electrolyzers in various sectors, including renewable energy storage, industrial processes, and transportation. This demand drives innovation in catalyst technology, potentially leading to economies of scale that could reduce the costs of advanced catalysts in the future. As production volumes increase, the price gap between conventional and advanced catalysts is expected to narrow.

The economic viability of advanced catalysts also depends on the specific application and operating conditions. In environments with high levels of contaminants, the benefits of poison-resistant catalysts become more pronounced, justifying the higher initial investment. Conversely, in cleaner operating conditions, the cost-benefit ratio may favor more conventional catalyst options.

Regulatory factors play a crucial role in the economic landscape of advanced catalysts. As environmental regulations become more stringent, the value proposition of catalysts that enable cleaner and more efficient hydrogen production strengthens. Government incentives and carbon pricing mechanisms can further enhance the economic attractiveness of advanced catalyst technologies.

In conclusion, while advanced catalysts designed to mitigate poisoning mechanisms may present higher upfront costs, their potential for long-term operational savings and improved system performance makes them economically viable in many scenarios. The evolving market dynamics and regulatory environment are likely to further improve their cost-effectiveness, solidifying their role in the future of hydrogen production technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!