Photoelectrocatalysts for Solar-Driven Green Hydrogen: Materials and Stability

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Photoelectrocatalysis Background and Objectives

Photoelectrocatalysis has emerged as a promising technology for sustainable hydrogen production, addressing the global need for clean energy solutions. This field combines the principles of photocatalysis and electrocatalysis to harness solar energy for water splitting, offering a potential pathway to green hydrogen generation. The development of photoelectrocatalysts has been driven by the increasing demand for renewable energy sources and the urgent need to reduce carbon emissions.

The evolution of photoelectrocatalysis can be traced back to the discovery of the Honda-Fujishima effect in 1972, which demonstrated the possibility of water splitting using titanium dioxide electrodes under ultraviolet light. Since then, significant advancements have been made in materials science, nanotechnology, and surface engineering, leading to the development of more efficient and stable photoelectrocatalysts.

The primary objective of research in this field is to design and synthesize photoelectrocatalysts that can efficiently convert solar energy into chemical energy in the form of hydrogen. This involves optimizing light absorption, charge separation, and catalytic activity while ensuring long-term stability under operating conditions. The ultimate goal is to achieve a solar-to-hydrogen conversion efficiency that surpasses the threshold for commercial viability, typically considered to be around 10%.

Current research trends focus on exploring novel materials and nanostructures to enhance the performance of photoelectrocatalysts. This includes the development of heterojunction systems, plasmonic materials, and quantum dot-sensitized electrodes. Additionally, there is a growing emphasis on understanding and mitigating degradation mechanisms to improve the stability and longevity of these catalysts.

The technological trajectory in photoelectrocatalysis is moving towards the integration of multiple functionalities within a single material or device. This includes the development of tandem systems that can utilize a broader spectrum of solar radiation and the incorporation of co-catalysts to facilitate charge transfer and surface reactions. Furthermore, there is an increasing focus on scalable fabrication methods and the use of earth-abundant materials to ensure the economic viability of large-scale hydrogen production.

As the field progresses, interdisciplinary collaboration between materials scientists, chemists, physicists, and engineers is becoming increasingly important. The convergence of expertise from various domains is essential for addressing the complex challenges associated with photoelectrocatalyst design and optimization. This collaborative approach is expected to accelerate the development of next-generation materials and systems for solar-driven hydrogen production.

The evolution of photoelectrocatalysis can be traced back to the discovery of the Honda-Fujishima effect in 1972, which demonstrated the possibility of water splitting using titanium dioxide electrodes under ultraviolet light. Since then, significant advancements have been made in materials science, nanotechnology, and surface engineering, leading to the development of more efficient and stable photoelectrocatalysts.

The primary objective of research in this field is to design and synthesize photoelectrocatalysts that can efficiently convert solar energy into chemical energy in the form of hydrogen. This involves optimizing light absorption, charge separation, and catalytic activity while ensuring long-term stability under operating conditions. The ultimate goal is to achieve a solar-to-hydrogen conversion efficiency that surpasses the threshold for commercial viability, typically considered to be around 10%.

Current research trends focus on exploring novel materials and nanostructures to enhance the performance of photoelectrocatalysts. This includes the development of heterojunction systems, plasmonic materials, and quantum dot-sensitized electrodes. Additionally, there is a growing emphasis on understanding and mitigating degradation mechanisms to improve the stability and longevity of these catalysts.

The technological trajectory in photoelectrocatalysis is moving towards the integration of multiple functionalities within a single material or device. This includes the development of tandem systems that can utilize a broader spectrum of solar radiation and the incorporation of co-catalysts to facilitate charge transfer and surface reactions. Furthermore, there is an increasing focus on scalable fabrication methods and the use of earth-abundant materials to ensure the economic viability of large-scale hydrogen production.

As the field progresses, interdisciplinary collaboration between materials scientists, chemists, physicists, and engineers is becoming increasingly important. The convergence of expertise from various domains is essential for addressing the complex challenges associated with photoelectrocatalyst design and optimization. This collaborative approach is expected to accelerate the development of next-generation materials and systems for solar-driven hydrogen production.

Green Hydrogen Market Analysis

The green hydrogen market is experiencing rapid growth and transformation, driven by increasing global focus on decarbonization and sustainable energy solutions. As countries and industries seek to reduce their carbon footprint, green hydrogen has emerged as a promising alternative to fossil fuels, particularly in hard-to-abate sectors such as heavy industry, long-distance transportation, and energy storage.

The market for green hydrogen is expected to expand significantly in the coming years, with projections indicating substantial growth across various regions. Europe, in particular, has taken a leading role in promoting green hydrogen adoption, with ambitious targets set by the European Union to increase production capacity. Other major markets, including North America, Asia-Pacific, and the Middle East, are also showing increased interest and investment in green hydrogen technologies.

Key drivers of market growth include government support through policies and incentives, declining costs of renewable energy sources, and technological advancements in electrolysis and fuel cell technologies. The transportation sector, especially in heavy-duty vehicles and maritime applications, is anticipated to be a major consumer of green hydrogen, as it offers a viable solution for long-range, zero-emission mobility.

Industrial applications represent another significant market segment for green hydrogen. Sectors such as steel production, chemical manufacturing, and refining are exploring green hydrogen as a means to reduce their carbon emissions and meet increasingly stringent environmental regulations. The potential for green hydrogen in these industries is substantial, as it can replace fossil fuels in high-temperature processes and serve as a feedstock for various chemical products.

Energy storage and grid balancing applications are also driving demand for green hydrogen. As the share of variable renewable energy sources in the power mix increases, green hydrogen can play a crucial role in long-term energy storage and grid stability. This application is particularly relevant for regions with high renewable energy potential but limited grid infrastructure.

Despite the promising outlook, challenges remain in scaling up the green hydrogen market. These include the need for significant infrastructure investments, high production costs compared to conventional hydrogen, and the requirement for supportive regulatory frameworks. However, ongoing research and development efforts, particularly in photoelectrocatalysts for solar-driven hydrogen production, are addressing these challenges and paving the way for more efficient and cost-effective green hydrogen solutions.

As the market evolves, collaborations between industry players, research institutions, and governments will be crucial in overcoming barriers and accelerating the adoption of green hydrogen technologies. The development of international standards and certification schemes for green hydrogen production and trade is also expected to facilitate market growth and ensure sustainability across the value chain.

The market for green hydrogen is expected to expand significantly in the coming years, with projections indicating substantial growth across various regions. Europe, in particular, has taken a leading role in promoting green hydrogen adoption, with ambitious targets set by the European Union to increase production capacity. Other major markets, including North America, Asia-Pacific, and the Middle East, are also showing increased interest and investment in green hydrogen technologies.

Key drivers of market growth include government support through policies and incentives, declining costs of renewable energy sources, and technological advancements in electrolysis and fuel cell technologies. The transportation sector, especially in heavy-duty vehicles and maritime applications, is anticipated to be a major consumer of green hydrogen, as it offers a viable solution for long-range, zero-emission mobility.

Industrial applications represent another significant market segment for green hydrogen. Sectors such as steel production, chemical manufacturing, and refining are exploring green hydrogen as a means to reduce their carbon emissions and meet increasingly stringent environmental regulations. The potential for green hydrogen in these industries is substantial, as it can replace fossil fuels in high-temperature processes and serve as a feedstock for various chemical products.

Energy storage and grid balancing applications are also driving demand for green hydrogen. As the share of variable renewable energy sources in the power mix increases, green hydrogen can play a crucial role in long-term energy storage and grid stability. This application is particularly relevant for regions with high renewable energy potential but limited grid infrastructure.

Despite the promising outlook, challenges remain in scaling up the green hydrogen market. These include the need for significant infrastructure investments, high production costs compared to conventional hydrogen, and the requirement for supportive regulatory frameworks. However, ongoing research and development efforts, particularly in photoelectrocatalysts for solar-driven hydrogen production, are addressing these challenges and paving the way for more efficient and cost-effective green hydrogen solutions.

As the market evolves, collaborations between industry players, research institutions, and governments will be crucial in overcoming barriers and accelerating the adoption of green hydrogen technologies. The development of international standards and certification schemes for green hydrogen production and trade is also expected to facilitate market growth and ensure sustainability across the value chain.

Photoelectrocatalyst Materials: State and Challenges

Photoelectrocatalyst materials for solar-driven green hydrogen production have made significant strides in recent years, yet they still face considerable challenges. The current state of these materials is characterized by a diverse range of semiconductors, including metal oxides, nitrides, and sulfides. Among these, titanium dioxide (TiO2) remains a benchmark material due to its stability and low cost, although its wide bandgap limits its solar spectrum utilization.

Transition metal oxides, such as hematite (α-Fe2O3) and tungsten trioxide (WO3), have gained attention for their narrow bandgaps and abundance. However, they struggle with poor charge carrier mobility and short hole diffusion lengths. Innovative strategies like nanostructuring and doping have been employed to mitigate these issues, resulting in improved photoelectrochemical performance.

Emerging materials like bismuth vanadate (BiVO4) and tantalum nitride (Ta3N5) show promise due to their suitable band positions and visible light absorption. Nevertheless, they face stability concerns in aqueous electrolytes, particularly under prolonged operation.

One of the primary challenges in photoelectrocatalyst development is achieving a balance between light absorption, charge separation, and surface catalysis. Many materials that exhibit excellent light absorption properties often suffer from poor charge transport or inadequate catalytic activity at the surface.

Stability remains a critical issue for most photoelectrocatalyst materials. Photocorrosion and degradation under operating conditions significantly hinder long-term performance and practical application. Protective layers and co-catalysts have been explored to enhance stability, but further improvements are necessary for commercial viability.

The scalability of high-performance photoelectrocatalyst materials presents another significant challenge. Many promising materials rely on complex synthesis methods or rare elements, limiting their potential for large-scale deployment. Developing earth-abundant, easily processable materials without compromising efficiency is crucial for the widespread adoption of solar-driven hydrogen production.

Efficiency is still a major hurdle in the field. While theoretical solar-to-hydrogen conversion efficiencies can reach up to 30%, practical systems typically achieve much lower values. Improving charge separation, reducing recombination losses, and enhancing catalytic activity are key areas of focus for increasing overall system efficiency.

In conclusion, while photoelectrocatalyst materials have progressed substantially, overcoming the challenges of stability, efficiency, and scalability remains crucial for realizing the potential of solar-driven green hydrogen production. Future research directions should focus on novel material design, advanced characterization techniques, and innovative strategies to address these persistent challenges.

Transition metal oxides, such as hematite (α-Fe2O3) and tungsten trioxide (WO3), have gained attention for their narrow bandgaps and abundance. However, they struggle with poor charge carrier mobility and short hole diffusion lengths. Innovative strategies like nanostructuring and doping have been employed to mitigate these issues, resulting in improved photoelectrochemical performance.

Emerging materials like bismuth vanadate (BiVO4) and tantalum nitride (Ta3N5) show promise due to their suitable band positions and visible light absorption. Nevertheless, they face stability concerns in aqueous electrolytes, particularly under prolonged operation.

One of the primary challenges in photoelectrocatalyst development is achieving a balance between light absorption, charge separation, and surface catalysis. Many materials that exhibit excellent light absorption properties often suffer from poor charge transport or inadequate catalytic activity at the surface.

Stability remains a critical issue for most photoelectrocatalyst materials. Photocorrosion and degradation under operating conditions significantly hinder long-term performance and practical application. Protective layers and co-catalysts have been explored to enhance stability, but further improvements are necessary for commercial viability.

The scalability of high-performance photoelectrocatalyst materials presents another significant challenge. Many promising materials rely on complex synthesis methods or rare elements, limiting their potential for large-scale deployment. Developing earth-abundant, easily processable materials without compromising efficiency is crucial for the widespread adoption of solar-driven hydrogen production.

Efficiency is still a major hurdle in the field. While theoretical solar-to-hydrogen conversion efficiencies can reach up to 30%, practical systems typically achieve much lower values. Improving charge separation, reducing recombination losses, and enhancing catalytic activity are key areas of focus for increasing overall system efficiency.

In conclusion, while photoelectrocatalyst materials have progressed substantially, overcoming the challenges of stability, efficiency, and scalability remains crucial for realizing the potential of solar-driven green hydrogen production. Future research directions should focus on novel material design, advanced characterization techniques, and innovative strategies to address these persistent challenges.

Current Photoelectrocatalyst Material Solutions

01 Improving stability through material selection

Enhancing the stability of photoelectrocatalysts can be achieved by carefully selecting materials with inherent stability under operating conditions. This includes choosing robust semiconductor materials, protective coatings, and co-catalysts that resist degradation during the photoelectrocatalytic process.- Improving stability through material selection: Enhancing the stability of photoelectrocatalysts can be achieved by carefully selecting materials with inherent stability under operating conditions. This includes choosing robust semiconductor materials, protective coatings, and co-catalysts that resist degradation during the photoelectrocatalytic process.

- Structural modifications for enhanced stability: Modifying the structure of photoelectrocatalysts can significantly improve their stability. This may involve creating core-shell structures, nanostructured surfaces, or hierarchical architectures that protect the active sites from degradation while maintaining high catalytic activity.

- Surface passivation techniques: Applying surface passivation techniques can enhance the stability of photoelectrocatalysts by reducing surface defects and preventing undesired reactions. This may include atomic layer deposition of protective layers or chemical treatments to neutralize reactive surface sites.

- Optimization of operating conditions: Stability of photoelectrocatalysts can be improved by optimizing operating conditions such as pH, temperature, and applied potential. This involves identifying and maintaining the optimal range of conditions that minimize degradation while maximizing catalytic performance.

- In-situ regeneration and self-healing mechanisms: Developing photoelectrocatalysts with in-situ regeneration or self-healing capabilities can significantly enhance long-term stability. This may involve incorporating sacrificial agents or designing systems that can repair damage during operation, thus extending the catalyst's lifetime.

02 Structural modifications for enhanced stability

Modifying the structure of photoelectrocatalysts can significantly improve their stability. This may involve creating core-shell structures, nanostructured surfaces, or hierarchical architectures that protect the active sites while maintaining high catalytic activity.Expand Specific Solutions03 Surface passivation techniques

Applying surface passivation techniques can protect photoelectrocatalysts from degradation. This includes the deposition of thin protective layers, surface functionalization, or the introduction of passivating agents that prevent corrosion and maintain long-term stability.Expand Specific Solutions04 Optimization of operating conditions

Tailoring the operating conditions can significantly enhance the stability of photoelectrocatalysts. This involves optimizing parameters such as pH, temperature, electrolyte composition, and light intensity to minimize degradation and maintain consistent performance over time.Expand Specific Solutions05 In-situ regeneration and self-healing mechanisms

Developing photoelectrocatalysts with in-situ regeneration or self-healing capabilities can greatly improve their long-term stability. This may involve incorporating materials that can repair damage during operation or designing systems that allow for periodic regeneration of the catalytic surface.Expand Specific Solutions

Key Players in Photoelectrocatalysis Research

The research on photoelectrocatalysts for solar-driven green hydrogen production is in a rapidly evolving phase, with significant market potential due to the global push for clean energy solutions. The technology is progressing but still faces challenges in material efficiency and stability. Key players like Massachusetts Institute of Technology, King Abdullah University of Science & Technology, and Imperial College London are at the forefront of academic research, while companies such as SABIC Global Technologies BV and Saudi Arabian Oil Co. are investing in commercial applications. The involvement of diverse institutions across academia and industry indicates a competitive landscape with opportunities for breakthrough innovations in materials science and catalysis.

Massachusetts Institute of Technology

Technical Solution: MIT has developed advanced photoelectrocatalysts for solar-driven green hydrogen production. Their research focuses on novel materials such as metal oxides and perovskites with enhanced light absorption and charge separation properties. They have engineered nanostructured electrodes to increase the active surface area and improve catalytic efficiency[1]. MIT's approach also includes the development of tandem photoelectrochemical cells that can utilize a broader spectrum of sunlight, potentially achieving solar-to-hydrogen efficiencies of over 10%[2]. Additionally, they are working on protective coatings to enhance the stability of photoelectrodes in harsh electrolyte environments, addressing one of the key challenges in long-term operation of these systems[3].

Strengths: Cutting-edge materials science, high-efficiency designs, and innovative nanostructuring techniques. Weaknesses: Potential high costs of advanced materials and fabrication processes, which may limit large-scale implementation.

King Abdullah University of Science & Technology

Technical Solution: KAUST has made significant strides in photoelectrocatalyst research for solar hydrogen production. They have developed novel earth-abundant materials, such as bismuth vanadate and iron oxide, modified with co-catalysts to enhance their performance[4]. Their approach includes band gap engineering and surface modification to improve light absorption and charge carrier dynamics. KAUST researchers have also explored the use of plasmonic nanoparticles to enhance light trapping and local electric field intensities, boosting the overall efficiency of water splitting[5]. Furthermore, they have made progress in developing scalable fabrication methods for large-area photoelectrodes, which is crucial for industrial applications[6].

Strengths: Focus on earth-abundant materials, scalable fabrication techniques, and innovative light management strategies. Weaknesses: Potential challenges in achieving long-term stability of earth-abundant materials in aqueous environments.

Innovative Photoelectrocatalyst Designs

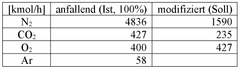

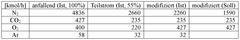

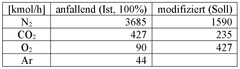

Green hydrogen, synthesis gas with a reduced nitrogen content, and flue gas for the synthesis of ammonia and urea

PatentWO2025125181A1

Innovation

- The process involves using flue gas as a source of additional CO2, combining CO2 substreams from steam reforming and flue gas combustion, and modifying the flue gas by adding electrolytically produced O2 to reduce excess nitrogen, allowing for efficient separation using existing CO2 scrubbing technology.

Patent

Innovation

- Novel photoelectrocatalyst material with enhanced light absorption and charge separation properties for efficient solar-driven hydrogen production.

- Innovative electrode design incorporating nanostructured features to increase active surface area and facilitate charge transport.

- Development of a hybrid photoelectrocatalytic system combining multiple materials to achieve broader spectrum utilization and improved efficiency.

Environmental Impact Assessment

The environmental impact assessment of photoelectrocatalysts for solar-driven green hydrogen production is a critical aspect of evaluating the sustainability and long-term viability of this technology. While the primary goal of these catalysts is to produce clean energy in the form of hydrogen, it is essential to consider their entire lifecycle and potential environmental consequences.

One of the key environmental benefits of photoelectrocatalysts is their ability to harness solar energy for hydrogen production, potentially reducing reliance on fossil fuels and decreasing greenhouse gas emissions. This aligns with global efforts to combat climate change and transition towards renewable energy sources. However, the manufacturing process of these catalysts must be scrutinized for its environmental footprint.

The production of photoelectrocatalysts often involves the use of rare earth elements and precious metals, which can have significant environmental impacts during mining and extraction processes. These activities may lead to habitat destruction, soil erosion, and water pollution if not properly managed. Additionally, the energy-intensive nature of catalyst synthesis and fabrication processes could potentially offset some of the environmental gains if not powered by renewable energy sources.

Water consumption is another critical factor to consider in the environmental assessment of photoelectrocatalysts. While the hydrogen production process itself uses water as a feedstock, the amount required is relatively small compared to other industrial processes. However, the water used in the manufacturing and cooling processes of catalyst production facilities should be carefully monitored and managed to minimize impact on local water resources.

The stability and longevity of photoelectrocatalysts play a crucial role in their overall environmental impact. More stable catalysts that maintain their efficiency over extended periods reduce the need for frequent replacement, thereby minimizing waste generation and resource consumption associated with manufacturing new catalysts. Research into improving catalyst stability is thus not only economically beneficial but also environmentally crucial.

End-of-life considerations for photoelectrocatalysts are equally important. Developing efficient recycling and recovery processes for the valuable materials used in these catalysts can significantly reduce their environmental footprint. This includes establishing proper disposal protocols and investing in technologies that can effectively separate and reuse catalyst components.

Lastly, the potential for unintended environmental consequences must be evaluated. For instance, the large-scale deployment of photoelectrocatalyst systems may impact local ecosystems through land use changes or alterations in local temperature and humidity patterns. Comprehensive environmental impact studies should be conducted to assess and mitigate these potential effects.

One of the key environmental benefits of photoelectrocatalysts is their ability to harness solar energy for hydrogen production, potentially reducing reliance on fossil fuels and decreasing greenhouse gas emissions. This aligns with global efforts to combat climate change and transition towards renewable energy sources. However, the manufacturing process of these catalysts must be scrutinized for its environmental footprint.

The production of photoelectrocatalysts often involves the use of rare earth elements and precious metals, which can have significant environmental impacts during mining and extraction processes. These activities may lead to habitat destruction, soil erosion, and water pollution if not properly managed. Additionally, the energy-intensive nature of catalyst synthesis and fabrication processes could potentially offset some of the environmental gains if not powered by renewable energy sources.

Water consumption is another critical factor to consider in the environmental assessment of photoelectrocatalysts. While the hydrogen production process itself uses water as a feedstock, the amount required is relatively small compared to other industrial processes. However, the water used in the manufacturing and cooling processes of catalyst production facilities should be carefully monitored and managed to minimize impact on local water resources.

The stability and longevity of photoelectrocatalysts play a crucial role in their overall environmental impact. More stable catalysts that maintain their efficiency over extended periods reduce the need for frequent replacement, thereby minimizing waste generation and resource consumption associated with manufacturing new catalysts. Research into improving catalyst stability is thus not only economically beneficial but also environmentally crucial.

End-of-life considerations for photoelectrocatalysts are equally important. Developing efficient recycling and recovery processes for the valuable materials used in these catalysts can significantly reduce their environmental footprint. This includes establishing proper disposal protocols and investing in technologies that can effectively separate and reuse catalyst components.

Lastly, the potential for unintended environmental consequences must be evaluated. For instance, the large-scale deployment of photoelectrocatalyst systems may impact local ecosystems through land use changes or alterations in local temperature and humidity patterns. Comprehensive environmental impact studies should be conducted to assess and mitigate these potential effects.

Techno-Economic Analysis of Green Hydrogen Production

The techno-economic analysis of green hydrogen production via solar-driven photoelectrocatalysis is crucial for assessing the viability and potential of this emerging technology. This analysis considers various factors, including capital costs, operational expenses, and overall system efficiency.

Capital costs for photoelectrocatalytic systems primarily encompass the expenses associated with photocatalyst materials, electrodes, membranes, and auxiliary components such as tanks and pumps. The choice of photoelectrocatalyst materials significantly impacts both performance and cost. Noble metal-based catalysts, while highly efficient, are expensive and may hinder large-scale implementation. Alternatively, earth-abundant materials like metal oxides and sulfides offer a more cost-effective solution but often struggle with stability and efficiency issues.

Operational costs are primarily driven by maintenance requirements, replacement of degraded components, and energy inputs for auxiliary processes. The stability of photoelectrocatalysts plays a critical role in determining long-term operational expenses. Materials with higher stability reduce the frequency of replacement and maintenance, thereby lowering overall costs. However, achieving both high efficiency and long-term stability remains a significant challenge in the field.

System efficiency is a key factor in the economic viability of solar-driven green hydrogen production. Current photoelectrocatalytic systems typically achieve solar-to-hydrogen conversion efficiencies in the range of 1-10%. Improving this efficiency is crucial for reducing the required solar collection area and associated costs. Advancements in materials science and nanotechnology offer promising avenues for enhancing system performance without significantly increasing costs.

The scalability of photoelectrocatalytic hydrogen production systems is another important consideration. While laboratory-scale demonstrations have shown promise, scaling up to industrial levels presents numerous engineering and economic challenges. These include maintaining uniform illumination over large areas, managing heat dissipation, and ensuring even distribution of reactants across the catalyst surface.

When comparing photoelectrocatalytic hydrogen production to other green hydrogen technologies, such as electrolysis powered by photovoltaics, several trade-offs emerge. Photoelectrocatalysis offers the potential for a more integrated and compact system, potentially reducing balance-of-plant costs. However, the technology's lower maturity level compared to established electrolysis methods introduces higher risk and uncertainty in economic projections.

In conclusion, the techno-economic analysis of solar-driven green hydrogen production via photoelectrocatalysis reveals a technology with significant potential but also substantial challenges. Continued research and development efforts focused on improving catalyst efficiency, stability, and cost-effectiveness are essential for enhancing the economic viability of this promising approach to sustainable hydrogen production.

Capital costs for photoelectrocatalytic systems primarily encompass the expenses associated with photocatalyst materials, electrodes, membranes, and auxiliary components such as tanks and pumps. The choice of photoelectrocatalyst materials significantly impacts both performance and cost. Noble metal-based catalysts, while highly efficient, are expensive and may hinder large-scale implementation. Alternatively, earth-abundant materials like metal oxides and sulfides offer a more cost-effective solution but often struggle with stability and efficiency issues.

Operational costs are primarily driven by maintenance requirements, replacement of degraded components, and energy inputs for auxiliary processes. The stability of photoelectrocatalysts plays a critical role in determining long-term operational expenses. Materials with higher stability reduce the frequency of replacement and maintenance, thereby lowering overall costs. However, achieving both high efficiency and long-term stability remains a significant challenge in the field.

System efficiency is a key factor in the economic viability of solar-driven green hydrogen production. Current photoelectrocatalytic systems typically achieve solar-to-hydrogen conversion efficiencies in the range of 1-10%. Improving this efficiency is crucial for reducing the required solar collection area and associated costs. Advancements in materials science and nanotechnology offer promising avenues for enhancing system performance without significantly increasing costs.

The scalability of photoelectrocatalytic hydrogen production systems is another important consideration. While laboratory-scale demonstrations have shown promise, scaling up to industrial levels presents numerous engineering and economic challenges. These include maintaining uniform illumination over large areas, managing heat dissipation, and ensuring even distribution of reactants across the catalyst surface.

When comparing photoelectrocatalytic hydrogen production to other green hydrogen technologies, such as electrolysis powered by photovoltaics, several trade-offs emerge. Photoelectrocatalysis offers the potential for a more integrated and compact system, potentially reducing balance-of-plant costs. However, the technology's lower maturity level compared to established electrolysis methods introduces higher risk and uncertainty in economic projections.

In conclusion, the techno-economic analysis of solar-driven green hydrogen production via photoelectrocatalysis reveals a technology with significant potential but also substantial challenges. Continued research and development efforts focused on improving catalyst efficiency, stability, and cost-effectiveness are essential for enhancing the economic viability of this promising approach to sustainable hydrogen production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!