How to Optimize Catalyst Ink Formulations for Membrane Electrode Assembly (MEA)

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Catalyst Ink Optimization Background and Objectives

Catalyst ink optimization for Membrane Electrode Assembly (MEA) has emerged as a critical area of research in the field of fuel cell technology. The development of efficient and cost-effective fuel cells hinges on the ability to create high-performance MEAs, which serve as the heart of these electrochemical devices. The catalyst ink, a complex mixture of catalyst particles, ionomer, and solvent, plays a pivotal role in determining the overall performance and durability of the MEA.

The evolution of catalyst ink formulations can be traced back to the early days of fuel cell research, where simple mixtures of platinum black and polytetrafluoroethylene (PTFE) were used. As the understanding of fuel cell electrochemistry advanced, researchers began to explore more sophisticated ink compositions, incorporating carbon-supported catalysts and perfluorosulfonic acid ionomers. This progression has led to significant improvements in fuel cell performance and durability over the past few decades.

Current research in catalyst ink optimization focuses on several key objectives. Firstly, there is a drive to enhance the utilization of precious metal catalysts, particularly platinum, to reduce costs and improve overall efficiency. This involves developing ink formulations that promote optimal catalyst dispersion and accessibility to reactants. Secondly, researchers aim to improve the ionic and electronic conductivity within the catalyst layer, which is crucial for facilitating efficient electrochemical reactions.

Another important objective is to optimize the porosity and pore size distribution of the catalyst layer. This aspect is critical for managing water transport and gas diffusion within the MEA, which directly impacts fuel cell performance, especially at high current densities. Additionally, there is a growing emphasis on developing ink formulations that enhance the long-term stability and durability of the catalyst layer, addressing issues such as catalyst degradation and ionomer decomposition.

The optimization of catalyst ink formulations also extends to the manufacturing process. Researchers are exploring ways to improve ink rheology and drying characteristics to enable more efficient and scalable MEA production methods. This includes investigating the effects of various solvents, mixing techniques, and deposition methods on the final catalyst layer structure and performance.

As the field progresses, there is an increasing focus on developing catalyst inks for next-generation fuel cell technologies, such as anion exchange membrane fuel cells and high-temperature proton exchange membrane fuel cells. These emerging technologies present new challenges and opportunities in ink formulation, driving innovation in materials selection and processing techniques.

In conclusion, the optimization of catalyst ink formulations for MEAs represents a multifaceted challenge that encompasses materials science, electrochemistry, and manufacturing engineering. The ongoing research in this area is crucial for advancing fuel cell technology towards wider commercial adoption and addressing global energy and environmental challenges.

The evolution of catalyst ink formulations can be traced back to the early days of fuel cell research, where simple mixtures of platinum black and polytetrafluoroethylene (PTFE) were used. As the understanding of fuel cell electrochemistry advanced, researchers began to explore more sophisticated ink compositions, incorporating carbon-supported catalysts and perfluorosulfonic acid ionomers. This progression has led to significant improvements in fuel cell performance and durability over the past few decades.

Current research in catalyst ink optimization focuses on several key objectives. Firstly, there is a drive to enhance the utilization of precious metal catalysts, particularly platinum, to reduce costs and improve overall efficiency. This involves developing ink formulations that promote optimal catalyst dispersion and accessibility to reactants. Secondly, researchers aim to improve the ionic and electronic conductivity within the catalyst layer, which is crucial for facilitating efficient electrochemical reactions.

Another important objective is to optimize the porosity and pore size distribution of the catalyst layer. This aspect is critical for managing water transport and gas diffusion within the MEA, which directly impacts fuel cell performance, especially at high current densities. Additionally, there is a growing emphasis on developing ink formulations that enhance the long-term stability and durability of the catalyst layer, addressing issues such as catalyst degradation and ionomer decomposition.

The optimization of catalyst ink formulations also extends to the manufacturing process. Researchers are exploring ways to improve ink rheology and drying characteristics to enable more efficient and scalable MEA production methods. This includes investigating the effects of various solvents, mixing techniques, and deposition methods on the final catalyst layer structure and performance.

As the field progresses, there is an increasing focus on developing catalyst inks for next-generation fuel cell technologies, such as anion exchange membrane fuel cells and high-temperature proton exchange membrane fuel cells. These emerging technologies present new challenges and opportunities in ink formulation, driving innovation in materials selection and processing techniques.

In conclusion, the optimization of catalyst ink formulations for MEAs represents a multifaceted challenge that encompasses materials science, electrochemistry, and manufacturing engineering. The ongoing research in this area is crucial for advancing fuel cell technology towards wider commercial adoption and addressing global energy and environmental challenges.

MEA Market Demand Analysis

The market demand for Membrane Electrode Assembly (MEA) has been experiencing significant growth, driven by the increasing adoption of fuel cell technologies across various sectors. The automotive industry, in particular, has been a major contributor to this demand surge, as fuel cell electric vehicles (FCEVs) gain traction in the pursuit of cleaner transportation solutions. The global MEA market is expected to expand at a robust rate in the coming years, with projections indicating substantial growth potential.

The demand for MEAs is closely tied to the overall fuel cell market, which has been witnessing a steady rise in applications beyond transportation. Stationary power generation, portable electronics, and aerospace sectors are emerging as key areas driving MEA demand. This diversification of applications is creating new opportunities for MEA manufacturers and catalyst ink formulators to cater to specific requirements across different industries.

In the context of catalyst ink formulations, market demand is increasingly focused on optimizing performance, durability, and cost-effectiveness. End-users are seeking MEAs that can deliver higher power density, improved longevity, and reduced platinum loading without compromising efficiency. This has led to a growing emphasis on advanced catalyst materials and innovative ink formulation techniques that can meet these demanding criteria.

The market is also witnessing a shift towards environmentally friendly and sustainable MEA production processes. There is a rising demand for catalyst inks that utilize eco-friendly solvents and reduce the overall environmental impact of MEA manufacturing. This trend aligns with the broader sustainability goals of industries adopting fuel cell technologies.

Geographically, the demand for MEAs and optimized catalyst ink formulations is particularly strong in regions with well-established fuel cell industries and supportive government policies. North America, Europe, and parts of Asia, especially Japan and South Korea, are at the forefront of MEA market growth. However, emerging economies are also showing increased interest in fuel cell technologies, potentially opening up new markets for MEA products.

The competitive landscape of the MEA market is characterized by a mix of established players and innovative startups. This dynamic is driving continuous improvements in catalyst ink formulations as companies strive to differentiate their offerings and capture market share. Collaborations between MEA manufacturers, catalyst developers, and end-users are becoming more common, fostering an environment of rapid innovation and market-driven product development.

As the fuel cell industry matures, there is a growing emphasis on standardization and quality control in MEA production. This trend is influencing the demand for catalyst ink formulations that can consistently meet stringent performance and durability standards across large-scale manufacturing processes. The ability to scale up production while maintaining quality is becoming a key differentiator in the market.

The demand for MEAs is closely tied to the overall fuel cell market, which has been witnessing a steady rise in applications beyond transportation. Stationary power generation, portable electronics, and aerospace sectors are emerging as key areas driving MEA demand. This diversification of applications is creating new opportunities for MEA manufacturers and catalyst ink formulators to cater to specific requirements across different industries.

In the context of catalyst ink formulations, market demand is increasingly focused on optimizing performance, durability, and cost-effectiveness. End-users are seeking MEAs that can deliver higher power density, improved longevity, and reduced platinum loading without compromising efficiency. This has led to a growing emphasis on advanced catalyst materials and innovative ink formulation techniques that can meet these demanding criteria.

The market is also witnessing a shift towards environmentally friendly and sustainable MEA production processes. There is a rising demand for catalyst inks that utilize eco-friendly solvents and reduce the overall environmental impact of MEA manufacturing. This trend aligns with the broader sustainability goals of industries adopting fuel cell technologies.

Geographically, the demand for MEAs and optimized catalyst ink formulations is particularly strong in regions with well-established fuel cell industries and supportive government policies. North America, Europe, and parts of Asia, especially Japan and South Korea, are at the forefront of MEA market growth. However, emerging economies are also showing increased interest in fuel cell technologies, potentially opening up new markets for MEA products.

The competitive landscape of the MEA market is characterized by a mix of established players and innovative startups. This dynamic is driving continuous improvements in catalyst ink formulations as companies strive to differentiate their offerings and capture market share. Collaborations between MEA manufacturers, catalyst developers, and end-users are becoming more common, fostering an environment of rapid innovation and market-driven product development.

As the fuel cell industry matures, there is a growing emphasis on standardization and quality control in MEA production. This trend is influencing the demand for catalyst ink formulations that can consistently meet stringent performance and durability standards across large-scale manufacturing processes. The ability to scale up production while maintaining quality is becoming a key differentiator in the market.

Current Challenges in Catalyst Ink Formulation

Despite significant advancements in fuel cell technology, optimizing catalyst ink formulations for Membrane Electrode Assembly (MEA) remains a complex challenge. One of the primary hurdles is achieving the ideal balance between catalyst utilization and mass transport properties. The catalyst ink composition directly affects the electrode structure, which in turn influences the overall performance and durability of the fuel cell.

A major challenge lies in the dispersion and stabilization of catalyst nanoparticles within the ink. Agglomeration of these particles can lead to reduced active surface area and poor catalyst utilization. Researchers are grappling with finding the optimal combination of solvents, ionomer content, and additives to ensure uniform dispersion while maintaining the ink's rheological properties suitable for various coating methods.

The selection of an appropriate ionomer and its concentration in the catalyst ink presents another significant challenge. The ionomer plays a crucial role in proton conduction and binding the catalyst particles. However, excessive ionomer can block active sites and hinder gas diffusion, while insufficient amounts may result in poor ionic conductivity and catalyst detachment. Striking the right balance is essential for maximizing MEA performance.

Controlling the ink's rheological properties is vital for achieving uniform electrode layers. The viscosity and surface tension of the ink must be carefully tailored to ensure compatibility with the chosen coating technique, whether it be spray coating, screen printing, or doctor blade methods. Achieving consistent ink properties across different batches and maintaining stability during the coating process remain ongoing challenges.

The interaction between the catalyst ink and the membrane substrate adds another layer of complexity. Ensuring proper adhesion and integration of the catalyst layer with the membrane without compromising the membrane's integrity or causing excessive swelling is a delicate balance that researchers are still trying to perfect.

Environmental and health concerns associated with traditional solvent systems used in catalyst inks have prompted a shift towards more sustainable alternatives. However, transitioning to aqueous-based or low-VOC (Volatile Organic Compound) formulations while maintaining the desired ink properties and MEA performance is proving to be a significant challenge.

Scalability and reproducibility of catalyst ink formulations pose substantial hurdles in translating laboratory-scale successes to industrial production. Maintaining consistent quality and performance across large-scale manufacturing processes requires overcoming issues related to ink stability, homogeneity, and batch-to-batch variations.

A major challenge lies in the dispersion and stabilization of catalyst nanoparticles within the ink. Agglomeration of these particles can lead to reduced active surface area and poor catalyst utilization. Researchers are grappling with finding the optimal combination of solvents, ionomer content, and additives to ensure uniform dispersion while maintaining the ink's rheological properties suitable for various coating methods.

The selection of an appropriate ionomer and its concentration in the catalyst ink presents another significant challenge. The ionomer plays a crucial role in proton conduction and binding the catalyst particles. However, excessive ionomer can block active sites and hinder gas diffusion, while insufficient amounts may result in poor ionic conductivity and catalyst detachment. Striking the right balance is essential for maximizing MEA performance.

Controlling the ink's rheological properties is vital for achieving uniform electrode layers. The viscosity and surface tension of the ink must be carefully tailored to ensure compatibility with the chosen coating technique, whether it be spray coating, screen printing, or doctor blade methods. Achieving consistent ink properties across different batches and maintaining stability during the coating process remain ongoing challenges.

The interaction between the catalyst ink and the membrane substrate adds another layer of complexity. Ensuring proper adhesion and integration of the catalyst layer with the membrane without compromising the membrane's integrity or causing excessive swelling is a delicate balance that researchers are still trying to perfect.

Environmental and health concerns associated with traditional solvent systems used in catalyst inks have prompted a shift towards more sustainable alternatives. However, transitioning to aqueous-based or low-VOC (Volatile Organic Compound) formulations while maintaining the desired ink properties and MEA performance is proving to be a significant challenge.

Scalability and reproducibility of catalyst ink formulations pose substantial hurdles in translating laboratory-scale successes to industrial production. Maintaining consistent quality and performance across large-scale manufacturing processes requires overcoming issues related to ink stability, homogeneity, and batch-to-batch variations.

Existing Catalyst Ink Formulation Strategies

01 Optimization of catalyst ink composition

Improving the formulation of catalyst inks by adjusting the ratio and types of components such as catalysts, ionomers, and solvents. This optimization aims to enhance the performance and durability of the resulting catalyst layers in fuel cells or other electrochemical devices.- Optimization of catalyst ink composition: Improving the formulation of catalyst inks by adjusting the ratio and types of components such as catalysts, ionomers, and solvents. This optimization aims to enhance the performance and durability of the resulting catalyst layers in fuel cells or other electrochemical devices.

- Nanostructured catalyst materials for ink formulations: Incorporating nanostructured catalyst materials into ink formulations to increase the active surface area and improve catalytic activity. This approach can lead to enhanced performance and reduced catalyst loading in electrochemical devices.

- Solvent selection and ink rheology control: Optimizing the selection of solvents and controlling the rheological properties of catalyst inks to improve printability, coating uniformity, and electrode structure. This can lead to better performance and manufacturing efficiency of fuel cells and other electrochemical devices.

- Ionomer integration and distribution in catalyst inks: Improving the integration and distribution of ionomers within catalyst ink formulations to optimize proton conductivity, gas diffusion, and overall electrode performance in fuel cells and related applications.

- Additives for catalyst ink stability and performance: Incorporating additives into catalyst ink formulations to enhance stability, dispersion, and overall performance. These additives can improve ink shelf life, printing characteristics, and the resulting catalyst layer properties in electrochemical devices.

02 Nanostructured catalyst materials for ink formulations

Incorporating nanostructured catalyst materials into ink formulations to increase the active surface area and improve catalytic activity. This approach can lead to enhanced performance and reduced catalyst loading in electrochemical devices.Expand Specific Solutions03 Solvent selection and ink rheology control

Careful selection of solvents and additives to control the rheological properties of catalyst inks. This optimization ensures proper ink dispersion, stability, and printability, leading to improved catalyst layer formation and performance.Expand Specific Solutions04 Ionomer content and distribution optimization

Optimizing the ionomer content and distribution within the catalyst ink to improve proton conductivity and gas diffusion properties of the resulting catalyst layers. This approach aims to enhance the overall performance of fuel cells or other electrochemical devices.Expand Specific Solutions05 Ink deposition and drying techniques

Developing and optimizing ink deposition and drying techniques to achieve uniform catalyst layer formation. This includes methods such as spray coating, screen printing, or inkjet printing, as well as controlled drying processes to ensure optimal catalyst layer structure and performance.Expand Specific Solutions

Key Players in MEA and Catalyst Ink Industry

The catalyst ink formulation optimization for Membrane Electrode Assembly (MEA) is in a mature stage of development, with a competitive landscape dominated by established players. The market size is substantial, driven by the growing demand for fuel cell technologies across various industries. Technologically, the field is well-developed, with companies like Toyota Motor Corp., LG Chem Ltd., and Umicore SA leading the way in innovation. These firms have made significant advancements in catalyst materials, ink composition, and application techniques. However, there's still room for improvement in performance and cost-effectiveness, keeping the competition intense among key players such as BASF Corp., 3M Innovative Properties Co., and emerging companies like Sunrise Power Co., Ltd. and Beijing SinoHytec Co., Ltd.

3M Innovative Properties Co.

Technical Solution: 3M has developed advanced catalyst ink formulations for MEAs using nanostructured thin film (NSTF) catalysts. Their approach involves creating ultra-thin catalyst layers with high surface area and improved mass transport properties. The NSTF catalysts are deposited onto a microstructured substrate, resulting in a highly ordered catalyst layer with enhanced durability and performance[1]. 3M's formulation includes optimized ionomer-to-carbon ratios and carefully controlled solvent mixtures to achieve uniform dispersion and ideal pore structure in the catalyst layer[2]. They have also implemented advanced coating techniques to ensure even distribution of the catalyst ink across the membrane surface[3].

Strengths: High catalyst utilization, improved durability, and enhanced mass transport. Weaknesses: Potentially higher manufacturing costs and complexity compared to traditional catalyst layer formulations.

BASF Corp.

Technical Solution: BASF has developed a comprehensive approach to optimizing catalyst ink formulations for MEAs. Their strategy involves using advanced platinum alloy catalysts with tailored particle sizes and compositions to maximize catalytic activity[4]. BASF's ink formulations incorporate specially designed ionomers that enhance proton conductivity and optimize water management within the catalyst layer[5]. They have also implemented innovative dispersion techniques to ensure uniform distribution of catalyst particles and prevent agglomeration. BASF's formulations often include carefully selected additives to improve ink stability and coating properties, resulting in MEAs with enhanced performance and durability[6].

Strengths: High catalytic activity, improved water management, and enhanced durability. Weaknesses: Potential challenges in scaling up production and higher material costs for specialized components.

Innovative Approaches in Ink Composition

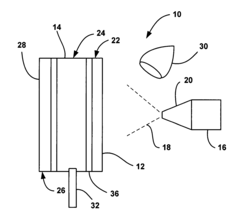

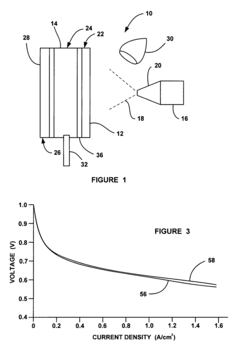

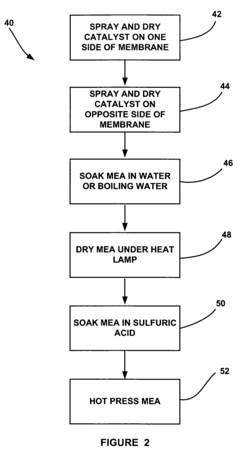

Membrane electrode assembly prepared by direct spray of catalyst to membrane

PatentActiveUS7955758B2

Innovation

- A direct spraying method onto a proton conducting membrane is employed, using a catalyst ink with a controlled ionomer to carbon ratio, where an ionomer layer can be applied first, followed by catalyst layer formation, and subsequent processing steps like soaking and hot-pressing to enhance durability and performance.

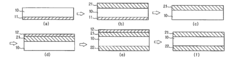

Membrane Electrode Assembly (MEA) Fabrication Procedure on Polymer Electrolyte Membrane Fuel Cell

PatentInactiveUS20110097651A1

Innovation

- A direct coating method is employed where a backing film is used to adhere and fix the catalyst layers on both surfaces of the polymer electrolyte membrane, allowing for the formation of catalyst layers without membrane deformation and increasing the contact area between the electrolyte membrane and catalyst layers, using adhesives like acrylic resin and hot-pressing to secure the layers.

Environmental Impact of Catalyst Ink Production

The environmental impact of catalyst ink production for Membrane Electrode Assembly (MEA) is a critical consideration in the optimization process. The manufacturing of catalyst inks involves various components and processes that can have significant ecological implications. One of the primary concerns is the use of precious metals, particularly platinum, as catalysts. The mining and refining of these metals contribute to habitat destruction, water pollution, and greenhouse gas emissions.

Solvent selection in catalyst ink formulation also plays a crucial role in environmental impact. Traditional organic solvents, such as isopropanol or ethanol, are volatile and can contribute to air pollution and ozone depletion. Furthermore, the disposal of waste solvents poses challenges for proper environmental management. Water-based inks have emerged as a more environmentally friendly alternative, reducing volatile organic compound (VOC) emissions and improving workplace safety.

The production of carbon supports, another key component in catalyst inks, also has environmental implications. The synthesis of carbon nanotubes or graphene, often used as supports, can be energy-intensive and may involve the use of hazardous chemicals. Efforts to develop more sustainable carbon support materials, such as biomass-derived carbons, are ongoing to mitigate these impacts.

Energy consumption during the ink preparation process is another environmental concern. High-energy mixing and dispersion techniques, while effective for creating uniform catalyst distributions, contribute to the overall carbon footprint of MEA production. Optimizing these processes for energy efficiency without compromising ink quality is an important area of research.

The disposal and recycling of MEA components at the end of their lifecycle present additional environmental challenges. Precious metal recovery from used MEAs is crucial for resource conservation and reducing the need for new mining activities. However, the recycling process itself can be energy-intensive and may generate hazardous waste streams if not properly managed.

To address these environmental concerns, researchers and manufacturers are exploring various strategies. These include developing catalyst formulations with reduced precious metal content, investigating alternative catalyst materials, and improving the efficiency of ink preparation processes. Additionally, the implementation of green chemistry principles in ink formulation, such as using bio-based solvents and renewable carbon sources, is gaining traction.

Life cycle assessment (LCA) studies are increasingly being employed to quantify the environmental impacts of different catalyst ink formulations and production methods. These assessments help identify hotspots in the production chain and guide the development of more sustainable MEA technologies. By considering the entire lifecycle of catalyst inks, from raw material extraction to end-of-life management, researchers can make informed decisions to minimize the overall environmental footprint of MEA production.

Solvent selection in catalyst ink formulation also plays a crucial role in environmental impact. Traditional organic solvents, such as isopropanol or ethanol, are volatile and can contribute to air pollution and ozone depletion. Furthermore, the disposal of waste solvents poses challenges for proper environmental management. Water-based inks have emerged as a more environmentally friendly alternative, reducing volatile organic compound (VOC) emissions and improving workplace safety.

The production of carbon supports, another key component in catalyst inks, also has environmental implications. The synthesis of carbon nanotubes or graphene, often used as supports, can be energy-intensive and may involve the use of hazardous chemicals. Efforts to develop more sustainable carbon support materials, such as biomass-derived carbons, are ongoing to mitigate these impacts.

Energy consumption during the ink preparation process is another environmental concern. High-energy mixing and dispersion techniques, while effective for creating uniform catalyst distributions, contribute to the overall carbon footprint of MEA production. Optimizing these processes for energy efficiency without compromising ink quality is an important area of research.

The disposal and recycling of MEA components at the end of their lifecycle present additional environmental challenges. Precious metal recovery from used MEAs is crucial for resource conservation and reducing the need for new mining activities. However, the recycling process itself can be energy-intensive and may generate hazardous waste streams if not properly managed.

To address these environmental concerns, researchers and manufacturers are exploring various strategies. These include developing catalyst formulations with reduced precious metal content, investigating alternative catalyst materials, and improving the efficiency of ink preparation processes. Additionally, the implementation of green chemistry principles in ink formulation, such as using bio-based solvents and renewable carbon sources, is gaining traction.

Life cycle assessment (LCA) studies are increasingly being employed to quantify the environmental impacts of different catalyst ink formulations and production methods. These assessments help identify hotspots in the production chain and guide the development of more sustainable MEA technologies. By considering the entire lifecycle of catalyst inks, from raw material extraction to end-of-life management, researchers can make informed decisions to minimize the overall environmental footprint of MEA production.

Scalability and Cost-effectiveness Analysis

The scalability and cost-effectiveness of catalyst ink formulations for Membrane Electrode Assembly (MEA) are crucial factors in the commercialization of fuel cell technologies. As the demand for fuel cells grows, particularly in automotive and stationary power applications, the ability to scale up production while maintaining or reducing costs becomes paramount.

Scalability in catalyst ink formulations involves the ability to produce large quantities of ink with consistent quality and performance. This requires robust manufacturing processes that can handle increased volumes without compromising the ink's properties. One key aspect is the development of automated mixing and dispersion systems that can maintain uniform particle distribution and prevent agglomeration in larger batches. Additionally, the use of continuous flow reactors for catalyst synthesis can significantly improve scalability compared to batch processes.

Cost-effectiveness is closely tied to scalability but also encompasses material selection and process optimization. The choice of catalyst materials, such as platinum-based alloys or non-precious metal catalysts, greatly impacts the overall cost. Reducing platinum loading while maintaining performance is a primary focus, with researchers exploring novel catalyst structures like core-shell nanoparticles or platinum-group metal-free catalysts. Ionomer selection and optimization also play a crucial role in both performance and cost, with efforts to develop less expensive alternatives to Nafion.

Process optimization for cost reduction includes minimizing waste during ink preparation and application. Advanced coating techniques, such as slot-die coating or inkjet printing, can significantly reduce material waste compared to traditional spray coating methods. These techniques also offer better control over catalyst layer thickness and uniformity, potentially reducing the amount of catalyst required.

The integration of in-line quality control measures is essential for maintaining consistency in large-scale production. Techniques such as real-time viscosity monitoring and particle size analysis can help ensure that ink properties remain within specified ranges throughout the manufacturing process. This not only improves product quality but also reduces the likelihood of costly batch rejections.

Environmental considerations also factor into the scalability and cost-effectiveness analysis. Developing water-based inks instead of solvent-based formulations can reduce environmental impact and associated costs for solvent handling and disposal. Furthermore, the implementation of solvent recovery systems in production facilities can significantly decrease material costs and environmental footprint.

As production scales up, the supply chain for raw materials becomes increasingly important. Establishing reliable sources for catalysts, ionomers, and other components is crucial for maintaining consistent quality and managing costs. Vertical integration or strategic partnerships with suppliers can help secure a stable supply of materials at competitive prices.

Scalability in catalyst ink formulations involves the ability to produce large quantities of ink with consistent quality and performance. This requires robust manufacturing processes that can handle increased volumes without compromising the ink's properties. One key aspect is the development of automated mixing and dispersion systems that can maintain uniform particle distribution and prevent agglomeration in larger batches. Additionally, the use of continuous flow reactors for catalyst synthesis can significantly improve scalability compared to batch processes.

Cost-effectiveness is closely tied to scalability but also encompasses material selection and process optimization. The choice of catalyst materials, such as platinum-based alloys or non-precious metal catalysts, greatly impacts the overall cost. Reducing platinum loading while maintaining performance is a primary focus, with researchers exploring novel catalyst structures like core-shell nanoparticles or platinum-group metal-free catalysts. Ionomer selection and optimization also play a crucial role in both performance and cost, with efforts to develop less expensive alternatives to Nafion.

Process optimization for cost reduction includes minimizing waste during ink preparation and application. Advanced coating techniques, such as slot-die coating or inkjet printing, can significantly reduce material waste compared to traditional spray coating methods. These techniques also offer better control over catalyst layer thickness and uniformity, potentially reducing the amount of catalyst required.

The integration of in-line quality control measures is essential for maintaining consistency in large-scale production. Techniques such as real-time viscosity monitoring and particle size analysis can help ensure that ink properties remain within specified ranges throughout the manufacturing process. This not only improves product quality but also reduces the likelihood of costly batch rejections.

Environmental considerations also factor into the scalability and cost-effectiveness analysis. Developing water-based inks instead of solvent-based formulations can reduce environmental impact and associated costs for solvent handling and disposal. Furthermore, the implementation of solvent recovery systems in production facilities can significantly decrease material costs and environmental footprint.

As production scales up, the supply chain for raw materials becomes increasingly important. Establishing reliable sources for catalysts, ionomers, and other components is crucial for maintaining consistent quality and managing costs. Vertical integration or strategic partnerships with suppliers can help secure a stable supply of materials at competitive prices.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!