How to Scale Catalyst Synthesis from Gram to Kilogram Scale (process controls)

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Catalyst Upscaling Background and Objectives

Catalyst synthesis upscaling from gram to kilogram scale represents a critical transition in the development of industrial catalytic processes. This evolution from laboratory-scale production to industrial-scale manufacturing is essential for the commercialization of catalytic technologies across various sectors, including petrochemicals, fine chemicals, and environmental applications.

The historical trajectory of catalyst upscaling has been marked by significant challenges and innovations. Initially, the focus was primarily on maintaining catalyst performance during scale-up, with less emphasis on process controls. However, as industrial demands grew, the need for more sophisticated and reliable upscaling methodologies became apparent. This shift led to the integration of advanced process control techniques and the development of specialized equipment for large-scale catalyst synthesis.

The primary objective of catalyst upscaling is to achieve consistent and reproducible catalyst properties at larger scales while optimizing resource utilization and minimizing waste. This involves addressing several key aspects, including maintaining uniform particle size distribution, ensuring homogeneous composition, and preserving the desired surface area and porosity characteristics. Additionally, the upscaling process aims to enhance the economic viability of catalyst production by improving yield, reducing energy consumption, and streamlining manufacturing processes.

Recent technological advancements have significantly contributed to the field of catalyst upscaling. The introduction of continuous flow reactors, for instance, has revolutionized the approach to large-scale synthesis by offering better control over reaction parameters and improved scalability. Similarly, the application of in-situ characterization techniques has enabled real-time monitoring of catalyst properties during synthesis, facilitating more precise process control.

The evolution of catalyst upscaling techniques is closely tied to the broader trends in process intensification and green chemistry. There is a growing emphasis on developing sustainable upscaling methods that minimize environmental impact while maximizing efficiency. This includes exploring alternative solvents, implementing energy-efficient heating and mixing technologies, and optimizing reactor designs to reduce waste generation.

Looking ahead, the field of catalyst upscaling is poised for further innovation. Emerging technologies such as artificial intelligence and machine learning are expected to play a crucial role in optimizing upscaling processes, predicting scale-up challenges, and designing more efficient synthesis routes. Moreover, the integration of modular and flexible manufacturing concepts is likely to reshape the approach to catalyst production, enabling more adaptable and cost-effective scaling strategies.

The historical trajectory of catalyst upscaling has been marked by significant challenges and innovations. Initially, the focus was primarily on maintaining catalyst performance during scale-up, with less emphasis on process controls. However, as industrial demands grew, the need for more sophisticated and reliable upscaling methodologies became apparent. This shift led to the integration of advanced process control techniques and the development of specialized equipment for large-scale catalyst synthesis.

The primary objective of catalyst upscaling is to achieve consistent and reproducible catalyst properties at larger scales while optimizing resource utilization and minimizing waste. This involves addressing several key aspects, including maintaining uniform particle size distribution, ensuring homogeneous composition, and preserving the desired surface area and porosity characteristics. Additionally, the upscaling process aims to enhance the economic viability of catalyst production by improving yield, reducing energy consumption, and streamlining manufacturing processes.

Recent technological advancements have significantly contributed to the field of catalyst upscaling. The introduction of continuous flow reactors, for instance, has revolutionized the approach to large-scale synthesis by offering better control over reaction parameters and improved scalability. Similarly, the application of in-situ characterization techniques has enabled real-time monitoring of catalyst properties during synthesis, facilitating more precise process control.

The evolution of catalyst upscaling techniques is closely tied to the broader trends in process intensification and green chemistry. There is a growing emphasis on developing sustainable upscaling methods that minimize environmental impact while maximizing efficiency. This includes exploring alternative solvents, implementing energy-efficient heating and mixing technologies, and optimizing reactor designs to reduce waste generation.

Looking ahead, the field of catalyst upscaling is poised for further innovation. Emerging technologies such as artificial intelligence and machine learning are expected to play a crucial role in optimizing upscaling processes, predicting scale-up challenges, and designing more efficient synthesis routes. Moreover, the integration of modular and flexible manufacturing concepts is likely to reshape the approach to catalyst production, enabling more adaptable and cost-effective scaling strategies.

Industrial Demand for Large-Scale Catalyst Production

The industrial demand for large-scale catalyst production has been steadily increasing across various sectors, driven by the growing need for efficient and sustainable chemical processes. Catalysts play a crucial role in numerous industrial applications, including petroleum refining, petrochemical production, environmental remediation, and fine chemical synthesis. As these industries expand and face stricter environmental regulations, the demand for high-performance catalysts in larger quantities has become more pronounced.

In the petroleum refining sector, the push for cleaner fuels and the processing of heavier crude oils have led to an increased demand for advanced hydroprocessing catalysts. These catalysts are required in substantial quantities to remove impurities such as sulfur and nitrogen from fuel streams, meeting stringent environmental standards. The petrochemical industry, on the other hand, relies heavily on catalysts for the production of plastics, fibers, and other essential materials. As global consumption of these products continues to rise, so does the need for large-scale catalyst production to support manufacturing processes.

Environmental applications represent another significant driver for industrial-scale catalyst production. Catalytic converters in automobiles, for instance, require substantial amounts of precious metal catalysts to reduce harmful emissions. With the global automotive industry expanding and emission standards becoming more stringent, the demand for these catalysts has surged. Similarly, industrial air and water treatment processes increasingly utilize catalysts to remove pollutants, further contributing to the need for large-scale production.

The fine chemicals and pharmaceutical industries also contribute to the growing demand for catalysts at industrial scales. As these sectors focus on developing more complex molecules and improving process efficiencies, the reliance on specialized catalysts has intensified. The production of active pharmaceutical ingredients (APIs) often involves multiple catalytic steps, each requiring specific catalysts in significant quantities to meet production targets.

Emerging technologies and industries are creating new avenues for catalyst applications, further fueling the demand for large-scale production. For example, the renewable energy sector, particularly in the production of biofuels and the development of fuel cells, relies heavily on catalytic processes. As these technologies mature and scale up, the demand for associated catalysts is expected to grow substantially.

The transition from laboratory-scale synthesis to industrial-scale production presents numerous challenges, including maintaining catalyst performance, ensuring consistency, and optimizing cost-effectiveness. As a result, there is a pressing need for innovative approaches to scale up catalyst synthesis while maintaining or improving catalytic activity, selectivity, and stability. This demand drives research and development efforts focused on process controls, reactor design, and novel synthesis methods capable of producing high-quality catalysts at kilogram scales and beyond.

In the petroleum refining sector, the push for cleaner fuels and the processing of heavier crude oils have led to an increased demand for advanced hydroprocessing catalysts. These catalysts are required in substantial quantities to remove impurities such as sulfur and nitrogen from fuel streams, meeting stringent environmental standards. The petrochemical industry, on the other hand, relies heavily on catalysts for the production of plastics, fibers, and other essential materials. As global consumption of these products continues to rise, so does the need for large-scale catalyst production to support manufacturing processes.

Environmental applications represent another significant driver for industrial-scale catalyst production. Catalytic converters in automobiles, for instance, require substantial amounts of precious metal catalysts to reduce harmful emissions. With the global automotive industry expanding and emission standards becoming more stringent, the demand for these catalysts has surged. Similarly, industrial air and water treatment processes increasingly utilize catalysts to remove pollutants, further contributing to the need for large-scale production.

The fine chemicals and pharmaceutical industries also contribute to the growing demand for catalysts at industrial scales. As these sectors focus on developing more complex molecules and improving process efficiencies, the reliance on specialized catalysts has intensified. The production of active pharmaceutical ingredients (APIs) often involves multiple catalytic steps, each requiring specific catalysts in significant quantities to meet production targets.

Emerging technologies and industries are creating new avenues for catalyst applications, further fueling the demand for large-scale production. For example, the renewable energy sector, particularly in the production of biofuels and the development of fuel cells, relies heavily on catalytic processes. As these technologies mature and scale up, the demand for associated catalysts is expected to grow substantially.

The transition from laboratory-scale synthesis to industrial-scale production presents numerous challenges, including maintaining catalyst performance, ensuring consistency, and optimizing cost-effectiveness. As a result, there is a pressing need for innovative approaches to scale up catalyst synthesis while maintaining or improving catalytic activity, selectivity, and stability. This demand drives research and development efforts focused on process controls, reactor design, and novel synthesis methods capable of producing high-quality catalysts at kilogram scales and beyond.

Current Challenges in Catalyst Synthesis Scaling

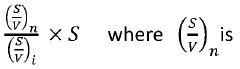

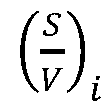

The scaling of catalyst synthesis from gram to kilogram scale presents several significant challenges that researchers and manufacturers must address. One of the primary obstacles is maintaining consistent product quality across different batch sizes. As the reaction volume increases, heat and mass transfer become more complex, potentially leading to non-uniform temperature distribution and concentration gradients. These factors can significantly impact the catalyst's particle size, morphology, and overall performance.

Process control becomes increasingly critical at larger scales. Precise temperature regulation, which is relatively straightforward in small-scale laboratory settings, becomes more challenging in industrial reactors. Even minor fluctuations can lead to substantial variations in catalyst properties. Similarly, mixing efficiency often decreases with scale-up, potentially resulting in inhomogeneous reaction conditions and inconsistent product characteristics.

Another major challenge lies in the handling and processing of larger quantities of materials. Safety considerations become more pronounced, particularly when dealing with air-sensitive or pyrophoric precursors commonly used in catalyst synthesis. Ensuring proper containment, inert atmospheres, and safe handling procedures at kilogram scale requires significant engineering and safety protocols.

The economic aspects of scaling also present hurdles. While larger batches can potentially reduce per-unit costs, they also increase the financial risk associated with failed batches. The cost of raw materials and specialized equipment for large-scale synthesis can be substantial, necessitating careful cost-benefit analysis and process optimization to ensure economic viability.

Reproducibility and batch-to-batch consistency pose additional challenges. Slight variations in raw material quality, environmental conditions, or process parameters can have magnified effects at larger scales. Developing robust quality control measures and establishing reliable analytical methods for characterizing kilogram-scale batches are essential but often complex tasks.

Environmental and sustainability concerns also become more prominent with increased production scale. Managing waste streams, reducing solvent usage, and minimizing energy consumption require innovative approaches and often necessitate re-evaluation of synthesis routes that may have been acceptable at smaller scales.

Lastly, regulatory compliance and documentation requirements typically increase with scale. Ensuring that scaled-up processes meet Good Manufacturing Practice (GMP) standards and other relevant regulations can be a time-consuming and resource-intensive process, particularly for catalysts intended for use in regulated industries such as pharmaceuticals or food production.

Process control becomes increasingly critical at larger scales. Precise temperature regulation, which is relatively straightforward in small-scale laboratory settings, becomes more challenging in industrial reactors. Even minor fluctuations can lead to substantial variations in catalyst properties. Similarly, mixing efficiency often decreases with scale-up, potentially resulting in inhomogeneous reaction conditions and inconsistent product characteristics.

Another major challenge lies in the handling and processing of larger quantities of materials. Safety considerations become more pronounced, particularly when dealing with air-sensitive or pyrophoric precursors commonly used in catalyst synthesis. Ensuring proper containment, inert atmospheres, and safe handling procedures at kilogram scale requires significant engineering and safety protocols.

The economic aspects of scaling also present hurdles. While larger batches can potentially reduce per-unit costs, they also increase the financial risk associated with failed batches. The cost of raw materials and specialized equipment for large-scale synthesis can be substantial, necessitating careful cost-benefit analysis and process optimization to ensure economic viability.

Reproducibility and batch-to-batch consistency pose additional challenges. Slight variations in raw material quality, environmental conditions, or process parameters can have magnified effects at larger scales. Developing robust quality control measures and establishing reliable analytical methods for characterizing kilogram-scale batches are essential but often complex tasks.

Environmental and sustainability concerns also become more prominent with increased production scale. Managing waste streams, reducing solvent usage, and minimizing energy consumption require innovative approaches and often necessitate re-evaluation of synthesis routes that may have been acceptable at smaller scales.

Lastly, regulatory compliance and documentation requirements typically increase with scale. Ensuring that scaled-up processes meet Good Manufacturing Practice (GMP) standards and other relevant regulations can be a time-consuming and resource-intensive process, particularly for catalysts intended for use in regulated industries such as pharmaceuticals or food production.

Existing Strategies for Gram-to-Kilogram Upscaling

01 Large-scale catalyst synthesis methods

Various techniques for scaling up catalyst production, including continuous flow processes, reactor design optimization, and automated synthesis systems. These methods aim to increase production efficiency while maintaining catalyst quality and performance.- Large-scale catalyst synthesis methods: Various techniques for scaling up catalyst production, including continuous flow processes, reactor design optimization, and automated synthesis systems. These methods aim to increase production efficiency while maintaining catalyst quality and performance.

- Nanoparticle catalyst synthesis: Approaches for synthesizing nanoparticle catalysts at scale, focusing on controlling particle size, shape, and composition. These methods often involve specialized reactors and precise control of reaction conditions to achieve uniform nanoparticle production.

- Supported catalyst preparation: Techniques for preparing supported catalysts on an industrial scale, including impregnation methods, co-precipitation, and sol-gel processes. These approaches focus on achieving uniform catalyst distribution on support materials and optimizing catalyst-support interactions.

- Catalyst synthesis process intensification: Methods for intensifying catalyst synthesis processes to increase productivity and reduce costs. This includes the use of microwave-assisted synthesis, ultrasound-enhanced reactions, and high-pressure synthesis techniques to accelerate catalyst production and improve yields.

- Green and sustainable catalyst synthesis: Environmentally friendly approaches to large-scale catalyst synthesis, focusing on reducing waste, using renewable resources, and minimizing energy consumption. These methods often involve bio-inspired synthesis routes and the use of non-toxic precursors.

02 Nanoparticle catalyst synthesis

Approaches for synthesizing nanoparticle catalysts at scale, focusing on controlling particle size, shape, and composition. These methods often involve precise control of reaction conditions and the use of specialized equipment to ensure uniformity in large-scale production.Expand Specific Solutions03 Supported catalyst preparation techniques

Methods for preparing supported catalysts on an industrial scale, including impregnation, precipitation, and sol-gel techniques. These approaches focus on achieving uniform distribution of active components on support materials and optimizing catalyst loading for large-scale applications.Expand Specific Solutions04 Catalyst synthesis process intensification

Strategies for intensifying catalyst synthesis processes to improve efficiency and reduce costs at scale. This includes the use of microreactors, ultrasonic irradiation, and other advanced technologies to enhance mixing, heat transfer, and reaction kinetics in large-scale production.Expand Specific Solutions05 Green and sustainable catalyst synthesis

Environmentally friendly approaches to large-scale catalyst synthesis, focusing on reducing waste, using renewable resources, and minimizing energy consumption. These methods often involve the use of bio-based precursors, solvent-free synthesis, and recycling of reaction media.Expand Specific Solutions

Key Players in Industrial Catalyst Production

The catalyst synthesis scaling process from gram to kilogram is in a transitional phase, with the market showing significant growth potential. The technology is advancing rapidly, driven by increasing demand in various industries. While not fully mature, the process is progressing towards commercial viability. Key players like BASF, Evonik, and Chevron Phillips Chemical are leading innovation, with emerging competition from companies such as PetroChina and Sinopec. The involvement of diverse firms, including ExxonMobil and Shell, indicates a competitive landscape with opportunities for technological breakthroughs. As the market expands, we can expect further advancements in process controls and scalability, potentially revolutionizing catalyst production efficiency.

ExxonMobil Chemical Patents, Inc.

Technical Solution: ExxonMobil has developed a scalable process for catalyst synthesis that involves precise control of reaction parameters. Their approach utilizes a continuous flow reactor system with in-line monitoring and automated feedback loops[1]. This allows for real-time adjustments of temperature, pressure, and reactant ratios to maintain optimal conditions as production scales up. The company has also implemented advanced computational modeling to predict and optimize catalyst performance at different scales[3]. Their process incorporates specialized mixing technologies to ensure uniform distribution of precursors and consistent particle size distribution from gram to kilogram quantities[5].

Strengths: Advanced process control systems, computational modeling capabilities, and specialized mixing technologies. Weaknesses: High capital investment required for sophisticated equipment and potential challenges in maintaining precise control at very large scales.

Evonik Operations GmbH

Technical Solution: Evonik has developed a scalable catalyst synthesis process based on microemulsion technology. Their approach allows for precise control of particle size and composition by manipulating the microemulsion structure[8]. The company has implemented advanced process analytical technology (PAT) for continuous monitoring and control of reaction parameters. Evonik's method includes innovative stabilization techniques to prevent agglomeration and maintain catalyst dispersion during scale-up[10]. They have also developed specialized drying and activation processes to preserve catalyst surface area and activity at larger production volumes[12].

Strengths: Precise control of particle properties, advanced process analytical technology, and innovative stabilization techniques. Weaknesses: Potential challenges in handling large volumes of microemulsions and ensuring consistent emulsion stability at industrial scales.

Critical Process Control Innovations

Process for scale-up of electrochemically mediated atom transfer radical polymerization without deoxygenation

PatentWO2023170646A1

Innovation

- The implementation of electrochemically mediated ATRP (eATRP) with an embedded O2 scavenging cycle using α-ketoacid salts or esters, such as sodium pyruvate, to self-degass the reaction mixture, allowing polymerization to proceed without oxygen removal, and using renewable electricity for scalable polymer production.

Environmental Impact of Large-Scale Catalyst Production

The environmental impact of large-scale catalyst production is a critical consideration as the synthesis process scales up from gram to kilogram quantities. As production volumes increase, the potential for environmental harm grows proportionally, necessitating careful assessment and mitigation strategies.

One of the primary concerns is the increased energy consumption associated with larger-scale operations. Heating, cooling, and mixing processes require significantly more power when scaled up, potentially leading to higher greenhouse gas emissions if not managed properly. Implementing energy-efficient technologies and exploring renewable energy sources can help mitigate this impact.

Chemical waste generation is another major environmental issue. Larger batches produce more by-products and unreacted materials, which must be properly treated and disposed of. Developing more selective catalysts and optimizing reaction conditions can reduce waste generation. Additionally, implementing closed-loop systems and recycling processes can minimize the amount of waste released into the environment.

Water usage and contamination are also significant concerns. Many catalyst synthesis processes require large volumes of water for reactions, purification, and cleaning. As production scales up, water consumption increases dramatically. Implementing water recycling systems and developing water-efficient synthesis methods can help reduce the strain on local water resources.

Air pollution is another potential consequence of large-scale catalyst production. Volatile organic compounds (VOCs) and particulate matter emissions may increase with production volume. Installing proper ventilation systems, using scrubbers, and implementing stringent emission control measures are essential to minimize air quality impacts.

The sourcing of raw materials for catalyst production can have far-reaching environmental implications. Mining and processing of precious metals and rare earth elements often involve significant environmental disruption. As production scales up, the demand for these materials increases, potentially exacerbating associated environmental issues. Developing catalysts that use more abundant and environmentally friendly materials can help address this concern.

Lastly, the transportation and storage of larger quantities of catalysts and raw materials can increase the risk of accidental releases and spills. Implementing robust safety protocols, using appropriate containment systems, and developing emergency response plans are crucial to preventing and mitigating potential environmental contamination.

To address these environmental challenges, adopting green chemistry principles and life cycle assessment approaches is essential. By considering the entire production process from raw material extraction to final product disposal, manufacturers can identify and minimize environmental impacts at each stage. This holistic approach ensures that the benefits of large-scale catalyst production do not come at an unacceptable environmental cost.

One of the primary concerns is the increased energy consumption associated with larger-scale operations. Heating, cooling, and mixing processes require significantly more power when scaled up, potentially leading to higher greenhouse gas emissions if not managed properly. Implementing energy-efficient technologies and exploring renewable energy sources can help mitigate this impact.

Chemical waste generation is another major environmental issue. Larger batches produce more by-products and unreacted materials, which must be properly treated and disposed of. Developing more selective catalysts and optimizing reaction conditions can reduce waste generation. Additionally, implementing closed-loop systems and recycling processes can minimize the amount of waste released into the environment.

Water usage and contamination are also significant concerns. Many catalyst synthesis processes require large volumes of water for reactions, purification, and cleaning. As production scales up, water consumption increases dramatically. Implementing water recycling systems and developing water-efficient synthesis methods can help reduce the strain on local water resources.

Air pollution is another potential consequence of large-scale catalyst production. Volatile organic compounds (VOCs) and particulate matter emissions may increase with production volume. Installing proper ventilation systems, using scrubbers, and implementing stringent emission control measures are essential to minimize air quality impacts.

The sourcing of raw materials for catalyst production can have far-reaching environmental implications. Mining and processing of precious metals and rare earth elements often involve significant environmental disruption. As production scales up, the demand for these materials increases, potentially exacerbating associated environmental issues. Developing catalysts that use more abundant and environmentally friendly materials can help address this concern.

Lastly, the transportation and storage of larger quantities of catalysts and raw materials can increase the risk of accidental releases and spills. Implementing robust safety protocols, using appropriate containment systems, and developing emergency response plans are crucial to preventing and mitigating potential environmental contamination.

To address these environmental challenges, adopting green chemistry principles and life cycle assessment approaches is essential. By considering the entire production process from raw material extraction to final product disposal, manufacturers can identify and minimize environmental impacts at each stage. This holistic approach ensures that the benefits of large-scale catalyst production do not come at an unacceptable environmental cost.

Quality Assurance in Scaled Catalyst Manufacturing

Quality assurance plays a crucial role in scaling catalyst synthesis from gram to kilogram scale. As production volumes increase, maintaining consistent product quality becomes increasingly challenging. Implementing robust quality control measures is essential to ensure the scaled-up catalyst meets specifications and performs reliably in industrial applications.

A comprehensive quality assurance program for scaled catalyst manufacturing should encompass several key elements. First, raw material testing and supplier qualification are critical. Incoming ingredients must be rigorously analyzed to verify purity, composition, and physical properties. Establishing strong relationships with reliable suppliers helps maintain consistency in raw material quality over time.

In-process controls are vital during scaled production. Key process parameters such as temperature, pressure, pH, and mixing speed must be continuously monitored and tightly controlled. Statistical process control techniques can be employed to detect deviations early and make real-time adjustments. Regular sampling and testing throughout the synthesis process allows for rapid identification and correction of any quality issues.

Analytical testing of the final catalyst product is essential to verify it meets all specifications. This typically includes assessing chemical composition, surface area, particle size distribution, and catalytic activity. Developing robust analytical methods that can handle larger sample sizes is important when scaling up. Automated testing systems can help increase throughput for high-volume production.

Batch record documentation becomes even more critical at larger scales. Detailed records of raw materials, process parameters, in-process test results, and final product data must be maintained for each production batch. This allows for traceability and troubleshooting of any quality deviations. Electronic batch record systems can improve data integrity and accessibility compared to paper-based methods.

Implementing a formal change control process is crucial when scaling up catalyst synthesis. Any modifications to raw materials, equipment, or procedures must be carefully evaluated for potential impacts on product quality. Validation studies may be required to demonstrate equivalency after significant changes. A cross-functional team should review and approve all proposed changes.

Finally, ongoing stability testing of catalyst batches is important to verify shelf life and performance over time. Accelerated aging studies can provide early indications of potential stability issues. Retaining and periodically re-testing retained samples allows for long-term quality monitoring. This data can inform continuous improvement efforts in the scaled manufacturing process.

A comprehensive quality assurance program for scaled catalyst manufacturing should encompass several key elements. First, raw material testing and supplier qualification are critical. Incoming ingredients must be rigorously analyzed to verify purity, composition, and physical properties. Establishing strong relationships with reliable suppliers helps maintain consistency in raw material quality over time.

In-process controls are vital during scaled production. Key process parameters such as temperature, pressure, pH, and mixing speed must be continuously monitored and tightly controlled. Statistical process control techniques can be employed to detect deviations early and make real-time adjustments. Regular sampling and testing throughout the synthesis process allows for rapid identification and correction of any quality issues.

Analytical testing of the final catalyst product is essential to verify it meets all specifications. This typically includes assessing chemical composition, surface area, particle size distribution, and catalytic activity. Developing robust analytical methods that can handle larger sample sizes is important when scaling up. Automated testing systems can help increase throughput for high-volume production.

Batch record documentation becomes even more critical at larger scales. Detailed records of raw materials, process parameters, in-process test results, and final product data must be maintained for each production batch. This allows for traceability and troubleshooting of any quality deviations. Electronic batch record systems can improve data integrity and accessibility compared to paper-based methods.

Implementing a formal change control process is crucial when scaling up catalyst synthesis. Any modifications to raw materials, equipment, or procedures must be carefully evaluated for potential impacts on product quality. Validation studies may be required to demonstrate equivalency after significant changes. A cross-functional team should review and approve all proposed changes.

Finally, ongoing stability testing of catalyst batches is important to verify shelf life and performance over time. Accelerated aging studies can provide early indications of potential stability issues. Retaining and periodically re-testing retained samples allows for long-term quality monitoring. This data can inform continuous improvement efforts in the scaled manufacturing process.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!