How to Translate Catalyst Lab Metrics to Stack-Level Performance Predictions

AUG 20, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Catalyst Metrics Background

Catalyst metrics play a crucial role in understanding and predicting the performance of fuel cell systems. These metrics, derived from laboratory-scale experiments, provide valuable insights into the electrochemical behavior of catalysts under controlled conditions. The primary focus of catalyst metrics is to evaluate the activity, selectivity, and stability of catalytic materials, which are essential for optimizing fuel cell performance.

Historically, catalyst metrics have evolved from simple measures of catalytic activity to more sophisticated parameters that account for various aspects of catalyst behavior. Early metrics primarily focused on turnover frequency and reaction rates. However, as the field progressed, researchers recognized the need for more comprehensive metrics that could capture the complexities of catalyst performance in real-world applications.

In the context of fuel cells, particularly proton exchange membrane fuel cells (PEMFCs), catalyst metrics typically include measurements such as electrochemically active surface area (ECSA), mass activity, and specific activity. These metrics provide quantitative data on the catalyst's ability to facilitate the oxygen reduction reaction (ORR) at the cathode and the hydrogen oxidation reaction (HOR) at the anode.

The development of advanced characterization techniques has significantly enhanced the accuracy and reliability of catalyst metrics. Techniques such as cyclic voltammetry, rotating disk electrode (RDE) measurements, and in-situ spectroscopic methods have become standard tools for assessing catalyst performance at the laboratory scale. These methods allow researchers to probe the fundamental properties of catalysts under various operating conditions, providing a wealth of data for analysis and optimization.

However, translating these laboratory-scale metrics to stack-level performance predictions presents significant challenges. The controlled environment of laboratory tests often fails to capture the complex interactions and operating conditions present in full-scale fuel cell stacks. Factors such as mass transport limitations, temperature gradients, and water management issues can significantly impact the overall performance of a fuel cell system.

Furthermore, the scaling effects from single-cell laboratory tests to multi-cell stacks introduce additional complexities. The uniformity of catalyst distribution, the impact of cell-to-cell variations, and the effects of stack design on overall performance are factors that are not fully captured by traditional catalyst metrics. This gap between laboratory measurements and real-world performance has led to ongoing research efforts aimed at developing more robust predictive models and scaling methodologies.

As the field of fuel cell technology continues to advance, there is a growing emphasis on developing catalyst metrics that can more accurately predict stack-level performance. This includes the integration of multi-scale modeling approaches, the development of accelerated stress tests that better simulate real-world conditions, and the use of advanced data analytics to correlate laboratory metrics with full-scale system performance.

Historically, catalyst metrics have evolved from simple measures of catalytic activity to more sophisticated parameters that account for various aspects of catalyst behavior. Early metrics primarily focused on turnover frequency and reaction rates. However, as the field progressed, researchers recognized the need for more comprehensive metrics that could capture the complexities of catalyst performance in real-world applications.

In the context of fuel cells, particularly proton exchange membrane fuel cells (PEMFCs), catalyst metrics typically include measurements such as electrochemically active surface area (ECSA), mass activity, and specific activity. These metrics provide quantitative data on the catalyst's ability to facilitate the oxygen reduction reaction (ORR) at the cathode and the hydrogen oxidation reaction (HOR) at the anode.

The development of advanced characterization techniques has significantly enhanced the accuracy and reliability of catalyst metrics. Techniques such as cyclic voltammetry, rotating disk electrode (RDE) measurements, and in-situ spectroscopic methods have become standard tools for assessing catalyst performance at the laboratory scale. These methods allow researchers to probe the fundamental properties of catalysts under various operating conditions, providing a wealth of data for analysis and optimization.

However, translating these laboratory-scale metrics to stack-level performance predictions presents significant challenges. The controlled environment of laboratory tests often fails to capture the complex interactions and operating conditions present in full-scale fuel cell stacks. Factors such as mass transport limitations, temperature gradients, and water management issues can significantly impact the overall performance of a fuel cell system.

Furthermore, the scaling effects from single-cell laboratory tests to multi-cell stacks introduce additional complexities. The uniformity of catalyst distribution, the impact of cell-to-cell variations, and the effects of stack design on overall performance are factors that are not fully captured by traditional catalyst metrics. This gap between laboratory measurements and real-world performance has led to ongoing research efforts aimed at developing more robust predictive models and scaling methodologies.

As the field of fuel cell technology continues to advance, there is a growing emphasis on developing catalyst metrics that can more accurately predict stack-level performance. This includes the integration of multi-scale modeling approaches, the development of accelerated stress tests that better simulate real-world conditions, and the use of advanced data analytics to correlate laboratory metrics with full-scale system performance.

Market Demand Analysis

The market demand for translating catalyst lab metrics to stack-level performance predictions is driven by the growing need for efficient and cost-effective fuel cell technologies. As the global push for clean energy solutions intensifies, fuel cell manufacturers and researchers are increasingly seeking ways to optimize their products and accelerate development cycles.

The automotive industry represents a significant portion of this demand, with major car manufacturers investing heavily in hydrogen fuel cell vehicles. These companies require accurate performance predictions to design and produce competitive fuel cell stacks that meet stringent efficiency, durability, and cost targets. The ability to translate lab-scale catalyst metrics to full-stack performance can significantly reduce development time and costs, making it a crucial capability in this fast-paced market.

In the stationary power sector, there is a rising interest in fuel cell systems for backup power and distributed generation. Operators of data centers, telecommunications networks, and critical infrastructure are looking for reliable, clean energy solutions. Accurate performance predictions based on catalyst metrics can help manufacturers tailor their products to specific applications and operating conditions, enhancing market competitiveness.

The portable electronics market also shows potential for micro fuel cells, where precise performance predictions are essential for miniaturization and integration. Manufacturers in this space need tools to quickly assess and optimize catalyst performance for their compact designs.

Government and academic research institutions contribute to the demand as well, seeking better tools for fundamental research and technology transfer. Improved methods for translating lab results to real-world performance can accelerate the commercialization of new catalyst technologies and support policy decisions on clean energy initiatives.

Geographically, the demand is strongest in regions with established fuel cell industries and supportive policies, such as Japan, South Korea, Germany, and parts of the United States. However, emerging markets in China and India are showing rapid growth as these countries invest in clean energy technologies to address air quality concerns and energy security.

The market size for tools and services related to catalyst performance prediction is difficult to quantify precisely but is expected to grow in tandem with the overall fuel cell market. Industry reports suggest that the global fuel cell market is expanding at a compound annual growth rate of over 20%, indicating a robust demand for advanced development tools and methodologies.

As environmental regulations become stricter and the pressure to commercialize clean energy technologies intensifies, the ability to accurately translate catalyst lab metrics to stack-level performance will become increasingly valuable. This capability not only supports product development but also aids in quality control, supply chain management, and strategic decision-making for companies in the fuel cell industry.

The automotive industry represents a significant portion of this demand, with major car manufacturers investing heavily in hydrogen fuel cell vehicles. These companies require accurate performance predictions to design and produce competitive fuel cell stacks that meet stringent efficiency, durability, and cost targets. The ability to translate lab-scale catalyst metrics to full-stack performance can significantly reduce development time and costs, making it a crucial capability in this fast-paced market.

In the stationary power sector, there is a rising interest in fuel cell systems for backup power and distributed generation. Operators of data centers, telecommunications networks, and critical infrastructure are looking for reliable, clean energy solutions. Accurate performance predictions based on catalyst metrics can help manufacturers tailor their products to specific applications and operating conditions, enhancing market competitiveness.

The portable electronics market also shows potential for micro fuel cells, where precise performance predictions are essential for miniaturization and integration. Manufacturers in this space need tools to quickly assess and optimize catalyst performance for their compact designs.

Government and academic research institutions contribute to the demand as well, seeking better tools for fundamental research and technology transfer. Improved methods for translating lab results to real-world performance can accelerate the commercialization of new catalyst technologies and support policy decisions on clean energy initiatives.

Geographically, the demand is strongest in regions with established fuel cell industries and supportive policies, such as Japan, South Korea, Germany, and parts of the United States. However, emerging markets in China and India are showing rapid growth as these countries invest in clean energy technologies to address air quality concerns and energy security.

The market size for tools and services related to catalyst performance prediction is difficult to quantify precisely but is expected to grow in tandem with the overall fuel cell market. Industry reports suggest that the global fuel cell market is expanding at a compound annual growth rate of over 20%, indicating a robust demand for advanced development tools and methodologies.

As environmental regulations become stricter and the pressure to commercialize clean energy technologies intensifies, the ability to accurately translate catalyst lab metrics to stack-level performance will become increasingly valuable. This capability not only supports product development but also aids in quality control, supply chain management, and strategic decision-making for companies in the fuel cell industry.

Current Challenges

Translating catalyst lab metrics to stack-level performance predictions presents several significant challenges in the field of fuel cell technology. One of the primary obstacles is the complexity of scaling up from laboratory-scale experiments to full-size fuel cell stacks. The controlled environment of a lab often fails to accurately represent the dynamic conditions present in a real-world fuel cell system, leading to discrepancies between predicted and actual performance.

Another major challenge lies in the multitude of variables that influence stack-level performance. While catalyst metrics provide valuable insights into electrochemical activity, they do not account for factors such as mass transport limitations, thermal management, and water balance within the stack. These additional parameters can significantly impact overall system efficiency and durability, making direct translation of lab results problematic.

The heterogeneity of catalyst distribution and activity across a full-scale membrane electrode assembly (MEA) further complicates the translation process. Lab-scale measurements typically focus on idealized, uniform catalyst layers, whereas real-world MEAs may exhibit variations in catalyst loading, particle size distribution, and local reaction conditions. This non-uniformity can lead to localized performance hotspots or degradation zones that are not captured by simplified lab metrics.

Moreover, the dynamic nature of fuel cell operation poses a substantial challenge. Catalyst performance in a laboratory setting is often measured under steady-state conditions, while actual fuel cell stacks experience frequent load changes, start-stop cycles, and varying environmental conditions. These transient effects can significantly alter catalyst behavior and overall stack performance, making it difficult to extrapolate lab results to real-world scenarios.

The issue of catalyst durability and degradation mechanisms also presents a significant hurdle. Long-term performance predictions based on short-term lab tests may not accurately capture the complex degradation processes that occur over thousands of hours of operation. Factors such as catalyst sintering, carbon support corrosion, and membrane degradation can dramatically affect stack-level performance over time, yet these effects are challenging to simulate or predict from initial lab metrics.

Additionally, the interaction between different components within the fuel cell stack introduces another layer of complexity. The performance of the catalyst layer is intimately linked with the properties of the gas diffusion layer, membrane, and bipolar plates. Lab-scale metrics often fail to account for these synergistic effects, leading to potential overestimation or underestimation of stack-level performance.

Lastly, the challenge of data interpretation and model development cannot be overlooked. Translating lab metrics to stack-level predictions requires sophisticated modeling techniques that can bridge the gap between microscale catalyst behavior and macroscale stack performance. Developing accurate, robust models that can account for the myriad of variables and their complex interactions remains an ongoing challenge in the field.

Another major challenge lies in the multitude of variables that influence stack-level performance. While catalyst metrics provide valuable insights into electrochemical activity, they do not account for factors such as mass transport limitations, thermal management, and water balance within the stack. These additional parameters can significantly impact overall system efficiency and durability, making direct translation of lab results problematic.

The heterogeneity of catalyst distribution and activity across a full-scale membrane electrode assembly (MEA) further complicates the translation process. Lab-scale measurements typically focus on idealized, uniform catalyst layers, whereas real-world MEAs may exhibit variations in catalyst loading, particle size distribution, and local reaction conditions. This non-uniformity can lead to localized performance hotspots or degradation zones that are not captured by simplified lab metrics.

Moreover, the dynamic nature of fuel cell operation poses a substantial challenge. Catalyst performance in a laboratory setting is often measured under steady-state conditions, while actual fuel cell stacks experience frequent load changes, start-stop cycles, and varying environmental conditions. These transient effects can significantly alter catalyst behavior and overall stack performance, making it difficult to extrapolate lab results to real-world scenarios.

The issue of catalyst durability and degradation mechanisms also presents a significant hurdle. Long-term performance predictions based on short-term lab tests may not accurately capture the complex degradation processes that occur over thousands of hours of operation. Factors such as catalyst sintering, carbon support corrosion, and membrane degradation can dramatically affect stack-level performance over time, yet these effects are challenging to simulate or predict from initial lab metrics.

Additionally, the interaction between different components within the fuel cell stack introduces another layer of complexity. The performance of the catalyst layer is intimately linked with the properties of the gas diffusion layer, membrane, and bipolar plates. Lab-scale metrics often fail to account for these synergistic effects, leading to potential overestimation or underestimation of stack-level performance.

Lastly, the challenge of data interpretation and model development cannot be overlooked. Translating lab metrics to stack-level predictions requires sophisticated modeling techniques that can bridge the gap between microscale catalyst behavior and macroscale stack performance. Developing accurate, robust models that can account for the myriad of variables and their complex interactions remains an ongoing challenge in the field.

Existing Translation Methods

01 Performance monitoring and analysis in catalyst labs

Systems and methods for monitoring and analyzing performance metrics in catalyst laboratories. This includes real-time data collection, analysis of experimental results, and evaluation of catalyst efficiency. The approach enables researchers to track key performance indicators, optimize processes, and make data-driven decisions to improve catalyst development.- Performance monitoring and analysis of catalyst labs: Systems and methods for monitoring and analyzing the performance of catalyst labs, including tracking various metrics such as reaction rates, yields, and efficiency. These tools help researchers and lab managers to assess the effectiveness of different catalysts and optimize experimental processes.

- Automated data collection and reporting for catalyst experiments: Implementation of automated systems for collecting, processing, and reporting data from catalyst experiments. These systems streamline the process of gathering performance metrics, reducing manual errors and improving the efficiency of lab operations.

- Machine learning and AI for catalyst performance prediction: Utilization of machine learning and artificial intelligence algorithms to analyze catalyst lab metrics and predict performance outcomes. These advanced techniques enable researchers to optimize catalyst formulations and reaction conditions more efficiently.

- Real-time monitoring and optimization of catalyst processes: Development of real-time monitoring systems that allow for immediate adjustments to catalyst processes based on performance metrics. These systems enable continuous optimization of reaction conditions and rapid response to any deviations from expected performance.

- Integration of catalyst lab metrics with business performance indicators: Systems for integrating catalyst lab performance metrics with broader business performance indicators. This approach allows organizations to assess the impact of catalyst research on overall business objectives and make data-driven decisions for resource allocation and research priorities.

02 Automated catalyst testing and evaluation

Automated systems for testing and evaluating catalysts in laboratory settings. These systems incorporate high-throughput screening techniques, robotic handling, and advanced analytics to rapidly assess catalyst performance. The automation allows for increased efficiency, reproducibility, and the ability to test a large number of catalyst formulations in a shorter time frame.Expand Specific Solutions03 Data management and visualization for catalyst research

Specialized software and tools for managing, analyzing, and visualizing large datasets generated in catalyst research. These solutions provide researchers with intuitive interfaces to explore complex data, identify trends, and generate insights. Features may include interactive dashboards, statistical analysis tools, and machine learning algorithms to aid in the interpretation of experimental results.Expand Specific Solutions04 Integration of catalyst lab metrics with business intelligence

Systems that integrate catalyst lab performance metrics with broader business intelligence platforms. This approach allows organizations to align research outcomes with strategic goals, assess the economic impact of catalyst innovations, and make informed decisions about resource allocation and project prioritization. It enables a holistic view of the catalyst development process within the context of overall business performance.Expand Specific Solutions05 Machine learning and AI for catalyst performance prediction

Application of machine learning and artificial intelligence techniques to predict and optimize catalyst performance. These advanced algorithms analyze historical data, experimental results, and molecular structures to identify patterns and make predictions about catalyst behavior. This approach can accelerate the discovery of new catalysts and improve the efficiency of existing ones by reducing the need for extensive experimental testing.Expand Specific Solutions

Key Industry Players

The catalyst lab metrics to stack-level performance prediction landscape is in a transitional phase, with growing market potential as energy efficiency and emissions reduction become increasingly critical. The technology is maturing but still evolving, with varying levels of sophistication across players. Key companies like BASF, Chevron Phillips, and Total Petrochemicals are investing heavily in R&D to bridge the gap between lab-scale and industrial-scale performance. Academic institutions such as Xi'an Jiaotong University and Central South University are also contributing significantly to advancing predictive modeling techniques. The competitive field is diverse, with both established chemical giants and specialized technology firms vying for market share in this niche but strategically important area.

Total Petrochemicals & Refining USA, Inc.

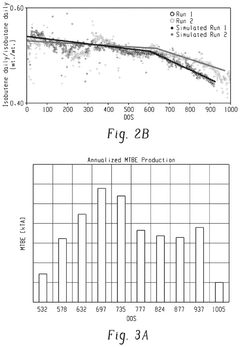

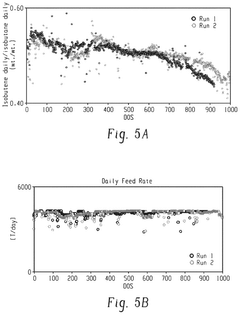

Technical Solution: Total Petrochemicals & Refining USA, Inc. has developed a data-driven approach to translate catalyst lab metrics to stack-level performance predictions. Their method leverages historical data from both laboratory experiments and industrial-scale operations to build predictive models. The company employs advanced statistical techniques, such as principal component analysis and partial least squares regression, to identify key correlations between lab-scale metrics and stack performance indicators[5]. Total's approach also incorporates real-time monitoring and adaptive modeling to continuously refine predictions based on operational data from active fuel cell stacks[6].

Strengths: Robust statistical foundation, ability to leverage large-scale industrial data. Weaknesses: Heavily reliant on historical data, which may limit predictive accuracy for novel catalyst formulations.

Chevron Phillips Chemical Co. LP

Technical Solution: Chevron Phillips Chemical Co. LP has developed a hybrid approach that combines physics-based modeling with data-driven techniques to translate catalyst lab metrics to stack-level performance predictions. Their methodology incorporates detailed kinetic models of catalyst behavior, which are then integrated with machine learning algorithms to capture complex, non-linear relationships between lab-scale metrics and stack performance[7]. The company utilizes advanced imaging techniques, such as 3D tomography, to characterize catalyst structure and distribution within fuel cell electrodes, providing crucial inputs for their predictive models[8].

Strengths: Integration of fundamental physical models with data-driven approaches, strong focus on catalyst structure-performance relationships. Weaknesses: May require extensive characterization efforts to fully leverage the hybrid modeling approach.

Core Predictive Models

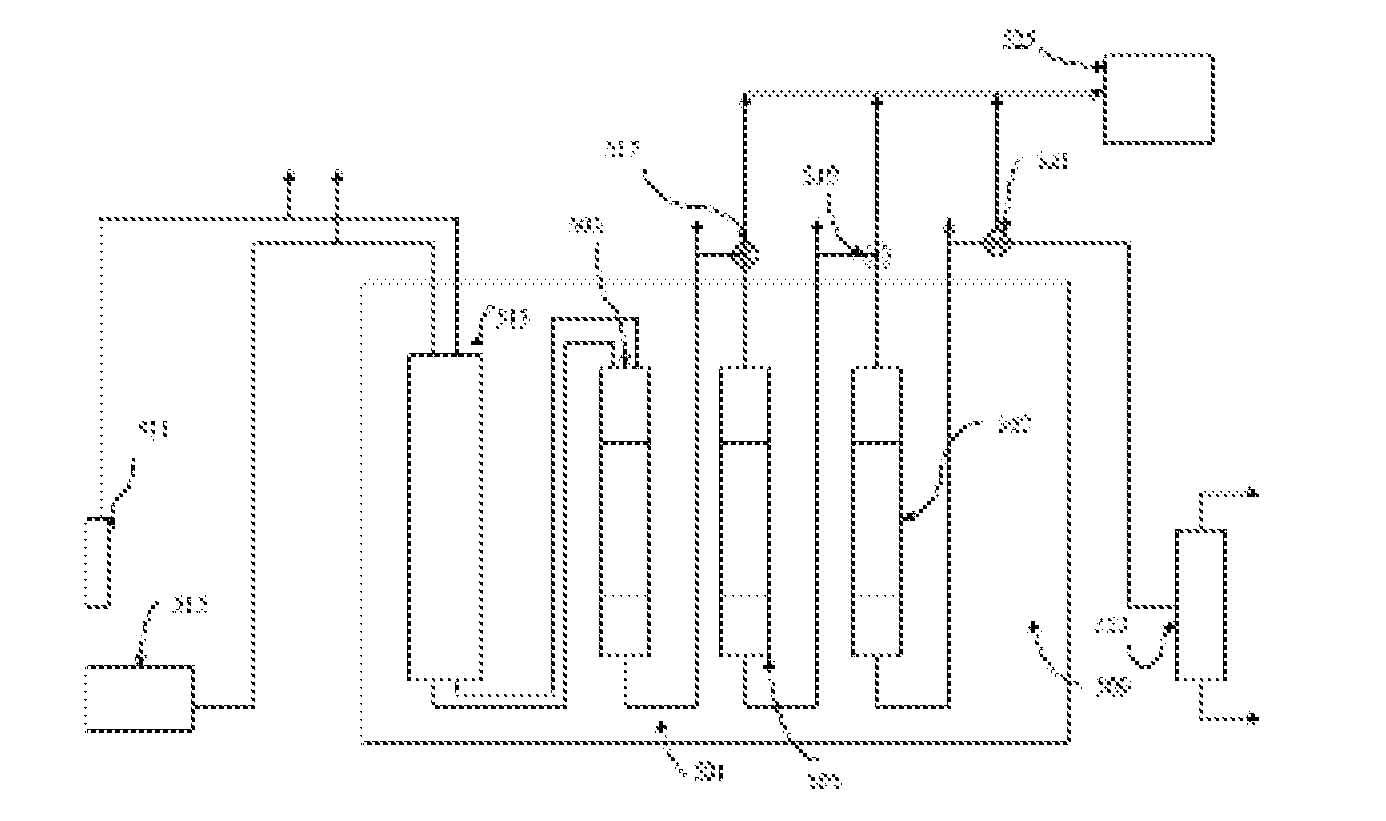

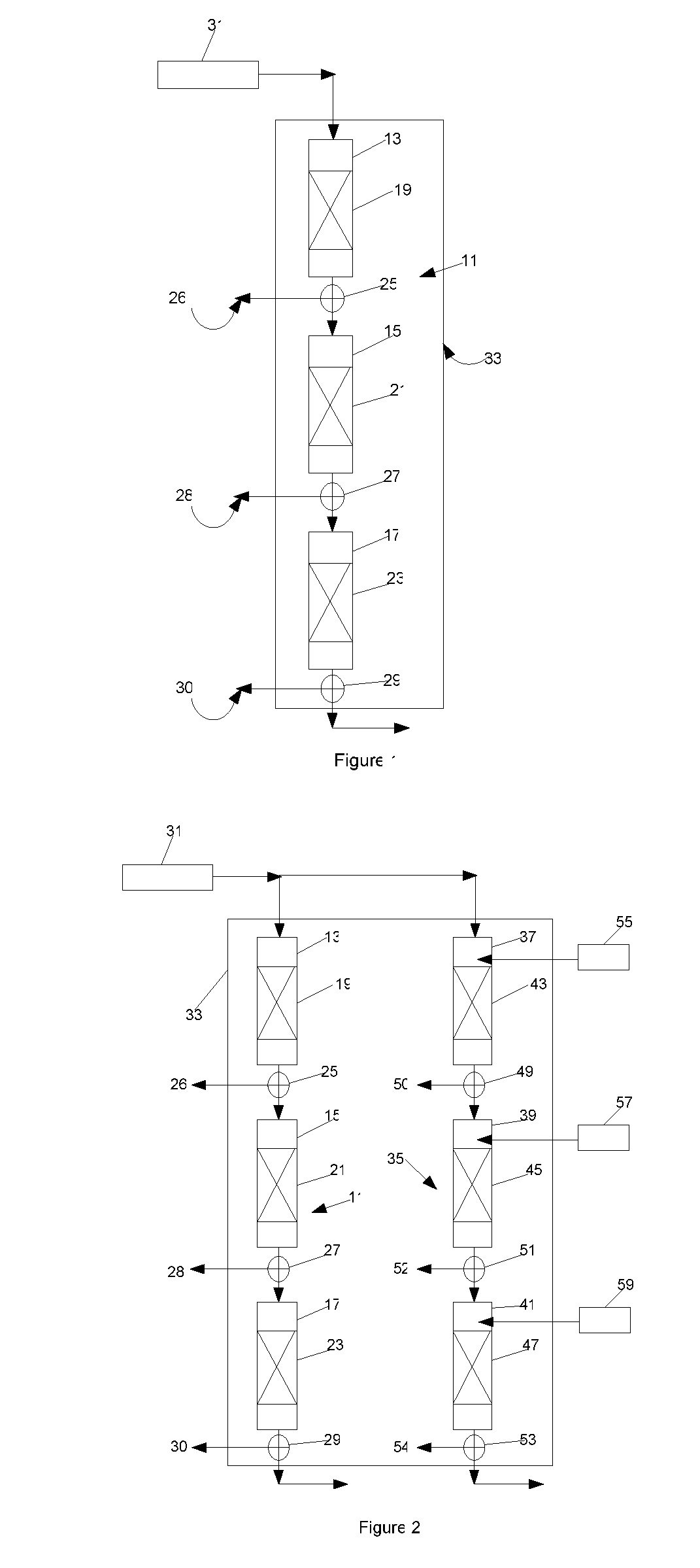

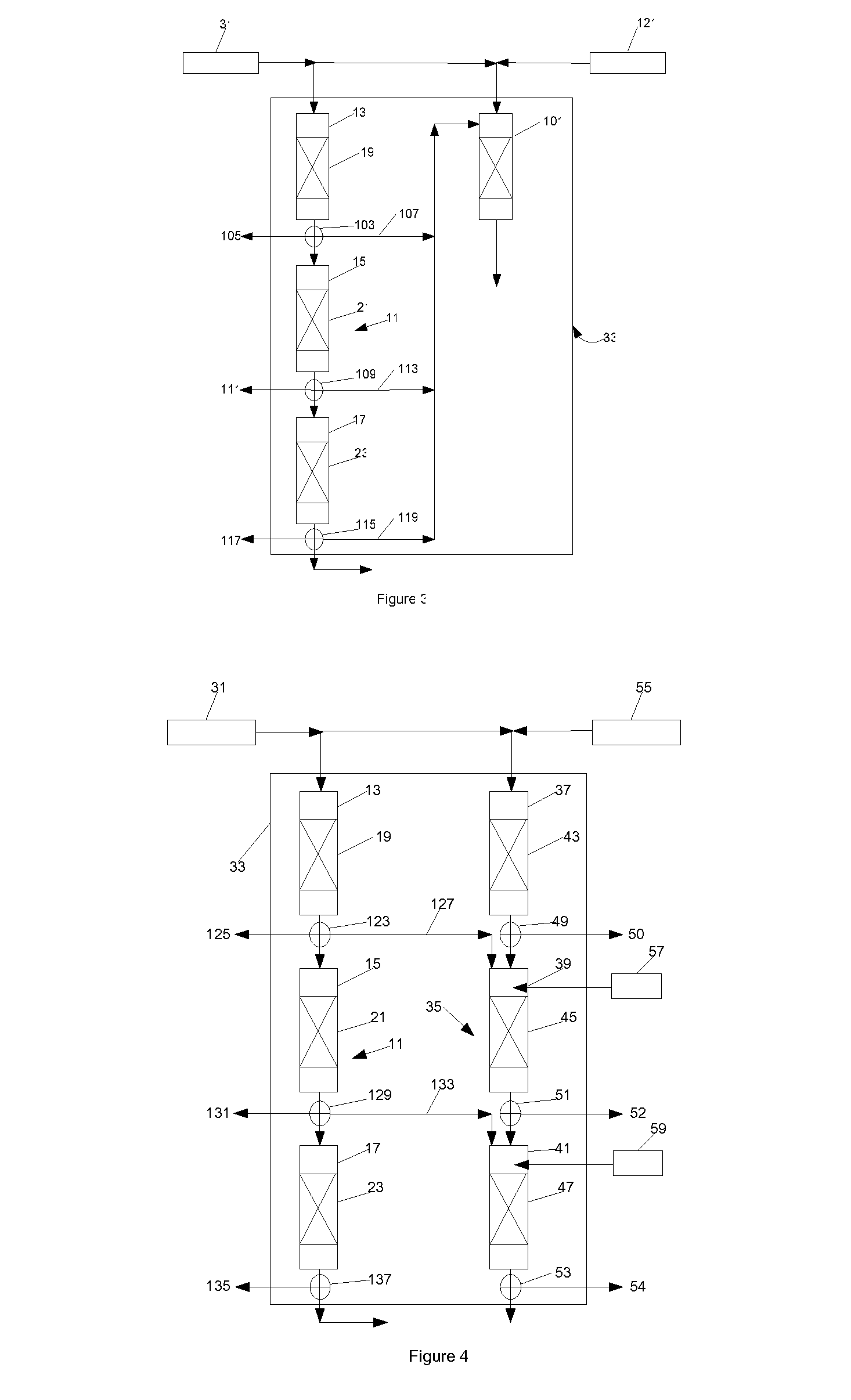

High throughput development method for catalytic hydroprocessing of dirty feedstocks

PatentInactiveUS20100320121A1

Innovation

- The use of high throughput laboratory scale catalytic process development apparatus with multistage series-connected plug-flow reactors to iteratively investigate hydroprocessing steps, sampling effluents, and optimizing catalyst bed characteristics and process conditions for improved productivity and selectivity.

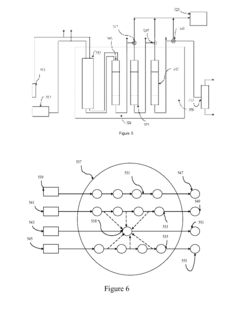

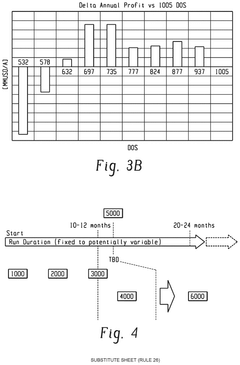

Method for predicting performance drop of a commercial alkane dehydrogenation unit and optimizing run duration

PatentPendingUS20250050299A1

Innovation

- A process for operating a chemical process that involves deriving coefficients for a process performance model from historical feed and production data, formulating the model, predicting changes in production, and adjusting processing parameters based on economic data and predicted changes.

Regulatory Considerations

The translation of catalyst lab metrics to stack-level performance predictions in fuel cell technology is subject to various regulatory considerations that must be carefully addressed. These regulations are designed to ensure the safety, reliability, and environmental compliance of fuel cell systems across different applications and industries.

One of the primary regulatory bodies overseeing fuel cell technology is the U.S. Department of Energy (DOE), which has established specific performance targets and testing protocols for fuel cell systems. These guidelines influence how lab-scale catalyst metrics are interpreted and applied to larger stack-level predictions. Researchers and manufacturers must adhere to these standards when developing and validating their performance models.

Environmental regulations also play a crucial role in the development and implementation of fuel cell technology. The Environmental Protection Agency (EPA) sets emissions standards that fuel cell systems must meet, particularly for mobile applications such as vehicles. This necessitates accurate translation of catalyst performance metrics to ensure that stack-level predictions align with these regulatory requirements.

In the automotive sector, the California Air Resources Board (CARB) has implemented stringent regulations for zero-emission vehicles, which include fuel cell electric vehicles. These regulations impact how catalyst lab metrics are interpreted and applied to predict stack-level performance in real-world driving conditions. Manufacturers must demonstrate compliance with these standards through rigorous testing and validation procedures.

International standards, such as those set by the International Organization for Standardization (ISO), also influence the translation of catalyst metrics to stack-level predictions. ISO 14687, for instance, specifies the quality requirements for hydrogen fuel used in proton exchange membrane (PEM) fuel cells. Adherence to these standards is essential when extrapolating lab-scale catalyst performance to full-scale stack operations.

Safety regulations, including those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, impact the design and operation of fuel cell systems. These regulations must be considered when translating catalyst metrics to stack-level performance predictions, ensuring that the predicted performance aligns with safety requirements for various applications.

The regulatory landscape for fuel cell technology is dynamic, with new standards and guidelines emerging as the technology advances. Researchers and manufacturers must stay informed about these regulatory changes and adapt their methods for translating catalyst lab metrics to stack-level performance predictions accordingly. This ongoing process ensures that fuel cell systems remain compliant with evolving regulatory frameworks while pushing the boundaries of performance and efficiency.

One of the primary regulatory bodies overseeing fuel cell technology is the U.S. Department of Energy (DOE), which has established specific performance targets and testing protocols for fuel cell systems. These guidelines influence how lab-scale catalyst metrics are interpreted and applied to larger stack-level predictions. Researchers and manufacturers must adhere to these standards when developing and validating their performance models.

Environmental regulations also play a crucial role in the development and implementation of fuel cell technology. The Environmental Protection Agency (EPA) sets emissions standards that fuel cell systems must meet, particularly for mobile applications such as vehicles. This necessitates accurate translation of catalyst performance metrics to ensure that stack-level predictions align with these regulatory requirements.

In the automotive sector, the California Air Resources Board (CARB) has implemented stringent regulations for zero-emission vehicles, which include fuel cell electric vehicles. These regulations impact how catalyst lab metrics are interpreted and applied to predict stack-level performance in real-world driving conditions. Manufacturers must demonstrate compliance with these standards through rigorous testing and validation procedures.

International standards, such as those set by the International Organization for Standardization (ISO), also influence the translation of catalyst metrics to stack-level predictions. ISO 14687, for instance, specifies the quality requirements for hydrogen fuel used in proton exchange membrane (PEM) fuel cells. Adherence to these standards is essential when extrapolating lab-scale catalyst performance to full-scale stack operations.

Safety regulations, including those enforced by the Occupational Safety and Health Administration (OSHA) in the United States, impact the design and operation of fuel cell systems. These regulations must be considered when translating catalyst metrics to stack-level performance predictions, ensuring that the predicted performance aligns with safety requirements for various applications.

The regulatory landscape for fuel cell technology is dynamic, with new standards and guidelines emerging as the technology advances. Researchers and manufacturers must stay informed about these regulatory changes and adapt their methods for translating catalyst lab metrics to stack-level performance predictions accordingly. This ongoing process ensures that fuel cell systems remain compliant with evolving regulatory frameworks while pushing the boundaries of performance and efficiency.

Economic Impact Assessment

The economic impact of translating catalyst lab metrics to stack-level performance predictions is significant and far-reaching. This translation capability has the potential to revolutionize the fuel cell industry, particularly in the development and optimization of proton exchange membrane fuel cells (PEMFCs). By accurately predicting stack-level performance based on laboratory-scale catalyst metrics, companies can substantially reduce development time and costs associated with scaling up new catalyst materials.

The ability to make reliable stack-level predictions from lab-scale data can lead to more efficient resource allocation in research and development efforts. Companies can prioritize the most promising catalyst candidates earlier in the development process, potentially saving millions of dollars in unnecessary large-scale testing. This improved efficiency could accelerate the pace of innovation in the fuel cell industry, leading to more rapid advancements in performance and durability.

Furthermore, this translation capability could have a profound impact on the commercialization of fuel cell technologies. More accurate performance predictions at the stack level can help manufacturers better estimate production costs and set competitive pricing strategies. This, in turn, could lead to increased market penetration of fuel cell technologies in various applications, from automotive to stationary power generation.

The economic benefits extend beyond the fuel cell industry itself. As fuel cell technology becomes more cost-effective and reliable, it could play a larger role in the transition to clean energy systems. This could contribute to job creation in the renewable energy sector and stimulate economic growth in related industries, such as hydrogen production and distribution.

Additionally, improved fuel cell performance and cost-effectiveness could accelerate the adoption of hydrogen-powered vehicles. This shift could have significant implications for the automotive industry, potentially disrupting traditional supply chains and creating new economic opportunities in vehicle manufacturing and infrastructure development.

From a global perspective, the ability to translate catalyst metrics to stack-level performance could enhance international competitiveness in the fuel cell market. Countries and companies that master this capability may gain a significant advantage in the race to develop and commercialize next-generation fuel cell technologies, potentially leading to increased exports and economic growth.

In conclusion, the economic impact of this translation capability is multifaceted, affecting not only the fuel cell industry but also broader sectors of the economy. By enabling more efficient development processes, accelerating innovation, and potentially reducing costs, it could play a crucial role in shaping the future of clean energy technologies and their economic implications.

The ability to make reliable stack-level predictions from lab-scale data can lead to more efficient resource allocation in research and development efforts. Companies can prioritize the most promising catalyst candidates earlier in the development process, potentially saving millions of dollars in unnecessary large-scale testing. This improved efficiency could accelerate the pace of innovation in the fuel cell industry, leading to more rapid advancements in performance and durability.

Furthermore, this translation capability could have a profound impact on the commercialization of fuel cell technologies. More accurate performance predictions at the stack level can help manufacturers better estimate production costs and set competitive pricing strategies. This, in turn, could lead to increased market penetration of fuel cell technologies in various applications, from automotive to stationary power generation.

The economic benefits extend beyond the fuel cell industry itself. As fuel cell technology becomes more cost-effective and reliable, it could play a larger role in the transition to clean energy systems. This could contribute to job creation in the renewable energy sector and stimulate economic growth in related industries, such as hydrogen production and distribution.

Additionally, improved fuel cell performance and cost-effectiveness could accelerate the adoption of hydrogen-powered vehicles. This shift could have significant implications for the automotive industry, potentially disrupting traditional supply chains and creating new economic opportunities in vehicle manufacturing and infrastructure development.

From a global perspective, the ability to translate catalyst metrics to stack-level performance could enhance international competitiveness in the fuel cell market. Countries and companies that master this capability may gain a significant advantage in the race to develop and commercialize next-generation fuel cell technologies, potentially leading to increased exports and economic growth.

In conclusion, the economic impact of this translation capability is multifaceted, affecting not only the fuel cell industry but also broader sectors of the economy. By enabling more efficient development processes, accelerating innovation, and potentially reducing costs, it could play a crucial role in shaping the future of clean energy technologies and their economic implications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!