How to Implement High-Throughput Screening for Catalyst Discovery (robotics & AI)

AUG 20, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Catalyst Discovery HTS Background and Objectives

High-throughput screening (HTS) for catalyst discovery has emerged as a pivotal approach in accelerating the development of novel catalysts for various chemical processes. This technology combines advanced robotics, automation, and artificial intelligence to rapidly evaluate large numbers of potential catalytic materials. The evolution of HTS in catalyst discovery can be traced back to the early 2000s, when researchers began adapting techniques from pharmaceutical drug discovery to materials science.

The primary objective of implementing HTS for catalyst discovery is to dramatically reduce the time and resources required to identify promising catalytic candidates. Traditional methods of catalyst discovery often rely on intuition, trial-and-error, and time-consuming experimental processes. HTS aims to overcome these limitations by enabling the systematic exploration of vast chemical spaces and complex reaction conditions.

As the field progressed, the integration of robotics became a crucial component in HTS systems. Robotic platforms allow for precise handling of small quantities of materials, parallel synthesis of catalyst libraries, and automated testing of catalytic performance. This automation not only increases throughput but also enhances reproducibility and reduces human error in experimental procedures.

The incorporation of artificial intelligence (AI) and machine learning (ML) algorithms represents the latest frontier in HTS for catalyst discovery. These computational tools can analyze complex datasets generated by high-throughput experiments, identify patterns and trends, and even predict promising catalyst compositions or structures. The synergy between robotics and AI in HTS systems enables a more intelligent and efficient exploration of the catalyst design space.

Current trends in HTS for catalyst discovery focus on developing more sophisticated and integrated platforms that combine synthesis, characterization, and testing capabilities. There is also a growing emphasis on in situ and operando analysis techniques to better understand catalyst behavior under realistic reaction conditions. Additionally, researchers are exploring the use of advanced data analytics and visualization tools to extract meaningful insights from the vast amounts of data generated by HTS experiments.

The ultimate goal of implementing HTS with robotics and AI in catalyst discovery is to accelerate the development of catalysts for critical applications such as renewable energy production, environmental remediation, and sustainable chemical manufacturing. By rapidly identifying and optimizing catalysts with improved activity, selectivity, and stability, this technology has the potential to drive significant advancements in various industrial sectors and contribute to addressing global challenges in energy and sustainability.

The primary objective of implementing HTS for catalyst discovery is to dramatically reduce the time and resources required to identify promising catalytic candidates. Traditional methods of catalyst discovery often rely on intuition, trial-and-error, and time-consuming experimental processes. HTS aims to overcome these limitations by enabling the systematic exploration of vast chemical spaces and complex reaction conditions.

As the field progressed, the integration of robotics became a crucial component in HTS systems. Robotic platforms allow for precise handling of small quantities of materials, parallel synthesis of catalyst libraries, and automated testing of catalytic performance. This automation not only increases throughput but also enhances reproducibility and reduces human error in experimental procedures.

The incorporation of artificial intelligence (AI) and machine learning (ML) algorithms represents the latest frontier in HTS for catalyst discovery. These computational tools can analyze complex datasets generated by high-throughput experiments, identify patterns and trends, and even predict promising catalyst compositions or structures. The synergy between robotics and AI in HTS systems enables a more intelligent and efficient exploration of the catalyst design space.

Current trends in HTS for catalyst discovery focus on developing more sophisticated and integrated platforms that combine synthesis, characterization, and testing capabilities. There is also a growing emphasis on in situ and operando analysis techniques to better understand catalyst behavior under realistic reaction conditions. Additionally, researchers are exploring the use of advanced data analytics and visualization tools to extract meaningful insights from the vast amounts of data generated by HTS experiments.

The ultimate goal of implementing HTS with robotics and AI in catalyst discovery is to accelerate the development of catalysts for critical applications such as renewable energy production, environmental remediation, and sustainable chemical manufacturing. By rapidly identifying and optimizing catalysts with improved activity, selectivity, and stability, this technology has the potential to drive significant advancements in various industrial sectors and contribute to addressing global challenges in energy and sustainability.

Market Analysis for AI-Driven Catalyst Screening

The market for AI-driven catalyst screening is experiencing rapid growth, driven by the increasing demand for efficient and cost-effective catalyst discovery processes in various industries. The global catalyst market, valued at approximately $33.9 billion in 2020, is projected to reach $48.1 billion by 2027, with a compound annual growth rate (CAGR) of 5.1%. Within this broader market, the segment for high-throughput screening technologies is expected to grow at an even faster pace due to the integration of artificial intelligence and robotics.

The pharmaceutical industry remains the largest consumer of catalyst screening technologies, accounting for nearly 40% of the market share. This sector's demand is fueled by the need for faster drug discovery processes and the development of more effective and sustainable catalysts for pharmaceutical synthesis. The petrochemical industry follows closely, representing approximately 30% of the market, as it seeks to optimize refining processes and develop cleaner fuel technologies.

Emerging applications in fine chemicals, agrochemicals, and materials science are also contributing to market expansion. These sectors are increasingly adopting AI-driven catalyst screening to accelerate product development cycles and improve the efficiency of chemical processes. The market is particularly robust in North America and Europe, which together account for over 60% of the global market share, due to the presence of major pharmaceutical and chemical companies, as well as advanced research institutions.

Asia-Pacific is identified as the fastest-growing region for AI-driven catalyst screening, with a projected CAGR of 7.2% from 2021 to 2026. This growth is attributed to increasing investments in R&D by countries like China, Japan, and South Korea, as well as the rapid expansion of their chemical and pharmaceutical industries.

Key market drivers include the growing emphasis on sustainable and green chemistry, which has led to increased demand for catalysts that can reduce energy consumption and minimize waste production. Additionally, the push for process intensification in the chemical industry is creating opportunities for AI-driven screening technologies that can identify catalysts capable of improving reaction yields and selectivity.

The market is also benefiting from advancements in machine learning algorithms and robotics, which are enhancing the speed and accuracy of catalyst discovery. These technological improvements are reducing the time and cost associated with traditional catalyst development methods, making AI-driven screening more attractive to a wider range of industries and research organizations.

The pharmaceutical industry remains the largest consumer of catalyst screening technologies, accounting for nearly 40% of the market share. This sector's demand is fueled by the need for faster drug discovery processes and the development of more effective and sustainable catalysts for pharmaceutical synthesis. The petrochemical industry follows closely, representing approximately 30% of the market, as it seeks to optimize refining processes and develop cleaner fuel technologies.

Emerging applications in fine chemicals, agrochemicals, and materials science are also contributing to market expansion. These sectors are increasingly adopting AI-driven catalyst screening to accelerate product development cycles and improve the efficiency of chemical processes. The market is particularly robust in North America and Europe, which together account for over 60% of the global market share, due to the presence of major pharmaceutical and chemical companies, as well as advanced research institutions.

Asia-Pacific is identified as the fastest-growing region for AI-driven catalyst screening, with a projected CAGR of 7.2% from 2021 to 2026. This growth is attributed to increasing investments in R&D by countries like China, Japan, and South Korea, as well as the rapid expansion of their chemical and pharmaceutical industries.

Key market drivers include the growing emphasis on sustainable and green chemistry, which has led to increased demand for catalysts that can reduce energy consumption and minimize waste production. Additionally, the push for process intensification in the chemical industry is creating opportunities for AI-driven screening technologies that can identify catalysts capable of improving reaction yields and selectivity.

The market is also benefiting from advancements in machine learning algorithms and robotics, which are enhancing the speed and accuracy of catalyst discovery. These technological improvements are reducing the time and cost associated with traditional catalyst development methods, making AI-driven screening more attractive to a wider range of industries and research organizations.

Current Challenges in High-Throughput Catalyst Screening

High-throughput screening (HTS) for catalyst discovery using robotics and AI presents several significant challenges that researchers and industry professionals must address. One of the primary obstacles is the sheer complexity of the chemical space that needs to be explored. The vast number of potential catalyst combinations, including different elements, structures, and compositions, creates an enormous search space that is difficult to navigate efficiently.

Another major challenge lies in the development and optimization of robotic systems capable of handling diverse catalyst synthesis and testing procedures. These systems must be versatile enough to accommodate various reaction conditions, temperatures, pressures, and analytical techniques while maintaining high precision and reproducibility. The integration of multiple robotic components, such as liquid handling, solid dispensing, and reaction monitoring, requires sophisticated engineering and control systems.

Data management and analysis pose significant hurdles in HTS for catalyst discovery. The large volumes of data generated from high-throughput experiments necessitate robust data storage, processing, and analysis pipelines. Developing algorithms and machine learning models capable of extracting meaningful insights from complex, multidimensional datasets remains a considerable challenge. These models must be able to identify trends, predict catalyst performance, and guide the selection of promising candidates for further investigation.

The design of appropriate screening assays and analytical methods presents another set of challenges. Researchers must develop rapid, sensitive, and reliable techniques to evaluate catalyst performance across a wide range of reaction conditions. This often requires the miniaturization and parallelization of analytical instruments, as well as the development of novel sensing technologies capable of providing real-time feedback on reaction progress and product formation.

Ensuring the scalability and transferability of results obtained from high-throughput screening to larger-scale applications is a persistent challenge. Catalysts that perform well in small-scale, high-throughput experiments may not necessarily maintain their efficacy when scaled up to industrial processes. Bridging this gap requires careful consideration of reaction engineering principles and the development of predictive models that can account for scale-dependent phenomena.

The integration of AI and machine learning algorithms into the HTS workflow presents its own set of challenges. Developing accurate predictive models requires high-quality training data, which can be difficult to obtain in the early stages of catalyst discovery. Additionally, balancing the exploration of new chemical space with the exploitation of promising leads remains a complex optimization problem that requires sophisticated AI strategies.

Finally, the cost and resource intensity of implementing and maintaining high-throughput screening platforms for catalyst discovery can be prohibitive for many research institutions and companies. The initial investment in robotics, AI infrastructure, and specialized equipment, coupled with ongoing operational expenses, necessitates careful consideration of the long-term benefits and potential returns on investment.

Another major challenge lies in the development and optimization of robotic systems capable of handling diverse catalyst synthesis and testing procedures. These systems must be versatile enough to accommodate various reaction conditions, temperatures, pressures, and analytical techniques while maintaining high precision and reproducibility. The integration of multiple robotic components, such as liquid handling, solid dispensing, and reaction monitoring, requires sophisticated engineering and control systems.

Data management and analysis pose significant hurdles in HTS for catalyst discovery. The large volumes of data generated from high-throughput experiments necessitate robust data storage, processing, and analysis pipelines. Developing algorithms and machine learning models capable of extracting meaningful insights from complex, multidimensional datasets remains a considerable challenge. These models must be able to identify trends, predict catalyst performance, and guide the selection of promising candidates for further investigation.

The design of appropriate screening assays and analytical methods presents another set of challenges. Researchers must develop rapid, sensitive, and reliable techniques to evaluate catalyst performance across a wide range of reaction conditions. This often requires the miniaturization and parallelization of analytical instruments, as well as the development of novel sensing technologies capable of providing real-time feedback on reaction progress and product formation.

Ensuring the scalability and transferability of results obtained from high-throughput screening to larger-scale applications is a persistent challenge. Catalysts that perform well in small-scale, high-throughput experiments may not necessarily maintain their efficacy when scaled up to industrial processes. Bridging this gap requires careful consideration of reaction engineering principles and the development of predictive models that can account for scale-dependent phenomena.

The integration of AI and machine learning algorithms into the HTS workflow presents its own set of challenges. Developing accurate predictive models requires high-quality training data, which can be difficult to obtain in the early stages of catalyst discovery. Additionally, balancing the exploration of new chemical space with the exploitation of promising leads remains a complex optimization problem that requires sophisticated AI strategies.

Finally, the cost and resource intensity of implementing and maintaining high-throughput screening platforms for catalyst discovery can be prohibitive for many research institutions and companies. The initial investment in robotics, AI infrastructure, and specialized equipment, coupled with ongoing operational expenses, necessitates careful consideration of the long-term benefits and potential returns on investment.

Existing HTS Platforms for Catalyst Discovery

01 Microfluidic systems for high-throughput screening

Microfluidic devices and systems are utilized to enhance the throughput of screening processes. These systems allow for the manipulation of small volumes of liquids, enabling parallel processing and analysis of multiple samples simultaneously. The miniaturization of assays reduces reagent consumption and increases efficiency in drug discovery and other screening applications.- Microfluidic systems for high-throughput screening: Microfluidic devices and systems are utilized to enhance the throughput of screening processes. These systems allow for the manipulation of small volumes of liquids, enabling parallel processing and analysis of multiple samples simultaneously. The miniaturization and integration of various components in microfluidic platforms significantly increase the speed and efficiency of high-throughput screening.

- Automated liquid handling and sample preparation: Automated liquid handling systems and robotic platforms are employed to streamline sample preparation and increase screening throughput. These systems can perform precise and rapid dispensing, mixing, and transfer of reagents and samples, reducing manual intervention and minimizing errors. Integration of automated liquid handling with detection systems further enhances the overall efficiency of high-throughput screening processes.

- Advanced detection and imaging technologies: High-sensitivity detection methods and advanced imaging technologies are implemented to improve the speed and accuracy of data acquisition in high-throughput screening. These may include fluorescence-based detection, label-free detection systems, and high-content imaging platforms. The integration of these technologies with data analysis software enables rapid processing and interpretation of large datasets generated during screening campaigns.

- Miniaturization and parallelization of assays: Miniaturization of assay formats, such as the use of high-density microplates or microarray technologies, allows for increased parallelization and higher throughput. These approaches enable the simultaneous screening of multiple compounds or targets in a single experiment, significantly reducing the time and resources required for large-scale screening campaigns.

- Data management and analysis for high-throughput screening: Advanced data management systems and analysis tools are crucial for handling the large volumes of data generated in high-throughput screening. Machine learning algorithms and artificial intelligence approaches are employed to process and interpret complex datasets, identify patterns, and prioritize hits. These computational methods enhance the efficiency of data analysis and decision-making in screening campaigns.

02 Automated liquid handling and sample preparation

Automated liquid handling systems and robotic platforms are employed to increase the speed and accuracy of sample preparation and reagent dispensing. These systems can handle large numbers of samples and perform complex liquid handling tasks, significantly improving the throughput of screening processes while reducing human error and variability.Expand Specific Solutions03 High-density microplate technologies

Advanced microplate technologies with increased well densities are developed to maximize the number of samples that can be processed simultaneously. These high-density plates, combined with specialized readers and imaging systems, allow for rapid analysis of large sample sets, thereby increasing overall screening throughput.Expand Specific Solutions04 Data analysis and management systems

Sophisticated software and algorithms are implemented to handle the large volumes of data generated by high-throughput screening. These systems automate data analysis, pattern recognition, and result interpretation, enabling rapid identification of hits and lead compounds. Integration of machine learning and artificial intelligence further enhances the speed and accuracy of data processing.Expand Specific Solutions05 Multiplexed assay technologies

Multiplexed assay formats are developed to simultaneously measure multiple parameters or analytes in a single experiment. These technologies, such as bead-based assays or microarray platforms, significantly increase the amount of information obtained from each screening run, thereby improving overall throughput and efficiency of the screening process.Expand Specific Solutions

Key Players in HTS and AI-Driven Catalyst Research

The field of high-throughput screening for catalyst discovery using robotics and AI is in a rapidly evolving phase, with significant market growth potential. The technology's maturity varies across different applications, but it's gaining traction due to its efficiency in accelerating materials discovery. Major players like ExxonMobil, DuPont, and BASF are investing heavily in this area, leveraging their extensive R&D capabilities. Academic institutions such as Harvard, Caltech, and Northwestern University are also contributing to advancements in this field. The market is characterized by a mix of established chemical companies and emerging AI-driven startups like Recursion Pharmaceuticals, indicating a dynamic and competitive landscape with substantial room for innovation and market expansion.

ExxonMobil Technology & Engineering Co.

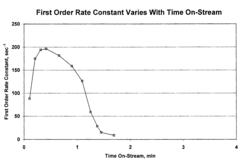

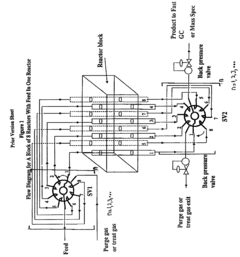

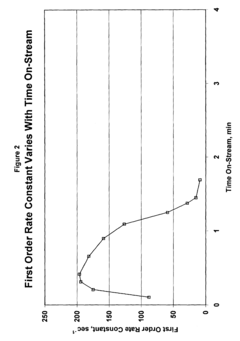

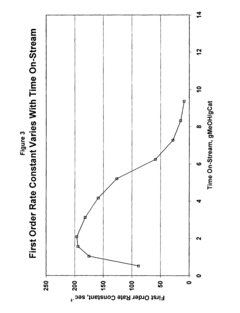

Technical Solution: ExxonMobil has implemented a state-of-the-art high-throughput screening system for catalyst discovery, integrating advanced robotics and AI technologies. Their approach utilizes parallel reactor systems capable of evaluating hundreds of catalysts under industrially relevant conditions simultaneously[13]. The company employs robotic systems for automated catalyst synthesis, sample preparation, and product analysis, ensuring high reproducibility and efficiency. ExxonMobil's AI algorithms analyze the extensive data generated, identifying trends in catalyst performance and guiding the optimization of catalyst formulations[14]. Their platform also incorporates in situ spectroscopic techniques for real-time monitoring of catalytic reactions, providing valuable insights into reaction mechanisms and kinetics[15].

Strengths: High-throughput screening under industrially relevant conditions, AI-driven catalyst optimization, and in situ reaction monitoring. Weaknesses: Potential limitations in exploring highly novel or unconventional catalyst systems outside the company's core focus areas.

DuPont de Nemours, Inc.

Technical Solution: DuPont has implemented an advanced high-throughput screening system for catalyst discovery, combining robotics and AI technologies. Their approach utilizes parallel reactor systems capable of running hundreds of reactions simultaneously under varying conditions[4]. The company employs sophisticated robotics for sample preparation, catalyst synthesis, and product analysis, ensuring high reproducibility and efficiency. DuPont's AI algorithms analyze the extensive data generated, identifying structure-activity relationships and predicting optimal catalyst compositions[5]. The system also incorporates in-line analytics and spectroscopic techniques for rapid characterization of reaction products, enabling real-time optimization of reaction parameters[6].

Strengths: Large-scale parallel testing capabilities, integrated analytics for rapid characterization, and AI-driven optimization. Weaknesses: Potential limitations in handling highly air-sensitive or moisture-sensitive catalysts.

Core AI Algorithms for Catalyst Screening Optimization

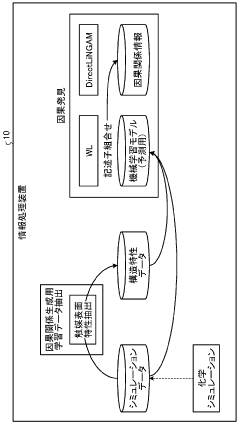

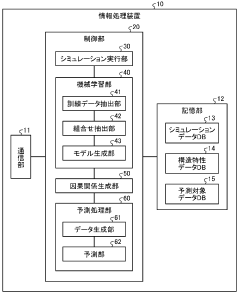

Machine learning program, machine learning method, and information processing device

PatentWO2023199413A1

Innovation

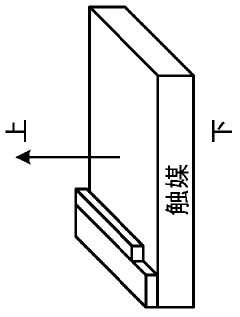

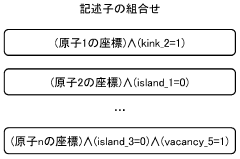

- A machine learning program and device that extracts features related to the surface structure of materials based on atomic arrangement, generates atomic arrangement information, and trains a model to predict chemical reaction outcomes, thereby reducing the search range and accelerating the discovery of promising catalyst compositions.

Method and apparatus for high throughput catalysts screening and optimization

PatentInactiveUS7390664B2

Innovation

- A system with multiple reactors, selection valve systems, and detection devices that allow for simultaneous testing, initialization, regeneration, and reactivation of catalysts while maintaining constant TOS, enabling comparison of catalyst activity and selectivity, and allowing different treatment processes for each reactor.

Regulatory Considerations for AI in Materials Research

The implementation of high-throughput screening for catalyst discovery using robotics and AI presents several regulatory considerations that must be addressed. As this technology combines advanced robotics, artificial intelligence, and materials research, it falls under the purview of multiple regulatory bodies and frameworks.

Firstly, the use of AI in materials research raises concerns about data privacy and security. Regulatory bodies such as the European Union's General Data Protection Regulation (GDPR) and the California Consumer Privacy Act (CCPA) may apply to the collection, processing, and storage of data used in AI-driven catalyst discovery. Researchers and organizations must ensure compliance with these regulations, particularly when handling sensitive or proprietary information related to catalyst formulations and performance data.

Safety regulations are another critical aspect to consider. The use of robotics in high-throughput screening processes may fall under occupational safety and health regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States. These regulations aim to ensure the safety of workers operating alongside robotic systems and may require specific safety protocols, risk assessments, and training programs.

Environmental regulations also play a significant role in this field. The development and testing of catalysts often involve the use of potentially hazardous materials and chemicals. Regulatory bodies such as the Environmental Protection Agency (EPA) in the United States and the European Chemicals Agency (ECHA) have established guidelines for the handling, storage, and disposal of such materials. Compliance with these regulations is essential to minimize environmental impact and ensure responsible research practices.

Intellectual property considerations are paramount in the field of catalyst discovery. The use of AI algorithms and machine learning models in the discovery process may raise questions about patent eligibility and ownership. Regulatory frameworks governing intellectual property rights, such as those established by the World Intellectual Property Organization (WIPO), must be carefully navigated to protect innovations and ensure fair attribution of discoveries.

Additionally, the integration of AI in scientific research may require adherence to ethical guidelines and standards. Organizations such as the IEEE Global Initiative on Ethics of Autonomous and Intelligent Systems have developed frameworks to address ethical considerations in AI research. These guidelines may influence regulatory approaches to AI-driven materials research, particularly in areas such as transparency, accountability, and bias mitigation.

As the field of AI-driven catalyst discovery continues to evolve, researchers and organizations must stay informed about emerging regulations and standards. Collaboration with regulatory bodies and participation in industry-wide initiatives can help shape future regulatory frameworks that balance innovation with safety, ethics, and environmental responsibility.

Firstly, the use of AI in materials research raises concerns about data privacy and security. Regulatory bodies such as the European Union's General Data Protection Regulation (GDPR) and the California Consumer Privacy Act (CCPA) may apply to the collection, processing, and storage of data used in AI-driven catalyst discovery. Researchers and organizations must ensure compliance with these regulations, particularly when handling sensitive or proprietary information related to catalyst formulations and performance data.

Safety regulations are another critical aspect to consider. The use of robotics in high-throughput screening processes may fall under occupational safety and health regulations, such as those enforced by the Occupational Safety and Health Administration (OSHA) in the United States. These regulations aim to ensure the safety of workers operating alongside robotic systems and may require specific safety protocols, risk assessments, and training programs.

Environmental regulations also play a significant role in this field. The development and testing of catalysts often involve the use of potentially hazardous materials and chemicals. Regulatory bodies such as the Environmental Protection Agency (EPA) in the United States and the European Chemicals Agency (ECHA) have established guidelines for the handling, storage, and disposal of such materials. Compliance with these regulations is essential to minimize environmental impact and ensure responsible research practices.

Intellectual property considerations are paramount in the field of catalyst discovery. The use of AI algorithms and machine learning models in the discovery process may raise questions about patent eligibility and ownership. Regulatory frameworks governing intellectual property rights, such as those established by the World Intellectual Property Organization (WIPO), must be carefully navigated to protect innovations and ensure fair attribution of discoveries.

Additionally, the integration of AI in scientific research may require adherence to ethical guidelines and standards. Organizations such as the IEEE Global Initiative on Ethics of Autonomous and Intelligent Systems have developed frameworks to address ethical considerations in AI research. These guidelines may influence regulatory approaches to AI-driven materials research, particularly in areas such as transparency, accountability, and bias mitigation.

As the field of AI-driven catalyst discovery continues to evolve, researchers and organizations must stay informed about emerging regulations and standards. Collaboration with regulatory bodies and participation in industry-wide initiatives can help shape future regulatory frameworks that balance innovation with safety, ethics, and environmental responsibility.

Economic Impact of AI-Driven Catalyst Innovation

The economic impact of AI-driven catalyst innovation is poised to be transformative across multiple industries. As catalysts play a crucial role in numerous chemical processes, advancements in their discovery and optimization can lead to significant cost reductions and efficiency improvements. The integration of artificial intelligence and robotics in high-throughput screening for catalyst discovery is expected to accelerate this innovation process dramatically.

One of the primary economic benefits of AI-driven catalyst innovation is the potential for substantial energy savings in industrial processes. Improved catalysts can lower reaction temperatures and pressures, reducing the energy requirements for chemical production. This not only decreases operational costs for manufacturers but also contributes to reduced carbon emissions, aligning with global sustainability goals.

The pharmaceutical industry stands to gain significantly from AI-driven catalyst discovery. More efficient catalysts can streamline drug synthesis processes, potentially lowering production costs and accelerating the development of new medications. This could lead to more affordable healthcare solutions and faster responses to emerging health challenges.

In the petrochemical sector, enhanced catalysts could optimize fuel production processes, leading to higher yields and improved quality of refined products. This has the potential to impact global energy markets, potentially stabilizing fuel prices and improving energy security for nations dependent on oil imports.

The agricultural industry may also benefit from AI-driven catalyst innovation, particularly in the production of fertilizers. More efficient catalysts could reduce the cost of fertilizer manufacturing, potentially leading to lower food production costs and improved global food security.

Furthermore, the development of novel catalysts through AI-driven methods could open up new markets and industries. For instance, improved catalysts for carbon dioxide conversion could accelerate the growth of the carbon capture and utilization sector, creating new economic opportunities while addressing climate change concerns.

The economic ripple effects of these innovations are likely to extend beyond the immediate industries involved. Reduced production costs and improved efficiencies could lead to lower consumer prices across a wide range of products, from plastics to pharmaceuticals, potentially stimulating economic growth through increased consumer spending.

However, it's important to note that the full economic impact of AI-driven catalyst innovation will depend on the successful integration of these technologies into existing industrial processes. This may require significant initial investments in research, development, and infrastructure, which could present challenges for smaller companies or developing economies.

One of the primary economic benefits of AI-driven catalyst innovation is the potential for substantial energy savings in industrial processes. Improved catalysts can lower reaction temperatures and pressures, reducing the energy requirements for chemical production. This not only decreases operational costs for manufacturers but also contributes to reduced carbon emissions, aligning with global sustainability goals.

The pharmaceutical industry stands to gain significantly from AI-driven catalyst discovery. More efficient catalysts can streamline drug synthesis processes, potentially lowering production costs and accelerating the development of new medications. This could lead to more affordable healthcare solutions and faster responses to emerging health challenges.

In the petrochemical sector, enhanced catalysts could optimize fuel production processes, leading to higher yields and improved quality of refined products. This has the potential to impact global energy markets, potentially stabilizing fuel prices and improving energy security for nations dependent on oil imports.

The agricultural industry may also benefit from AI-driven catalyst innovation, particularly in the production of fertilizers. More efficient catalysts could reduce the cost of fertilizer manufacturing, potentially leading to lower food production costs and improved global food security.

Furthermore, the development of novel catalysts through AI-driven methods could open up new markets and industries. For instance, improved catalysts for carbon dioxide conversion could accelerate the growth of the carbon capture and utilization sector, creating new economic opportunities while addressing climate change concerns.

The economic ripple effects of these innovations are likely to extend beyond the immediate industries involved. Reduced production costs and improved efficiencies could lead to lower consumer prices across a wide range of products, from plastics to pharmaceuticals, potentially stimulating economic growth through increased consumer spending.

However, it's important to note that the full economic impact of AI-driven catalyst innovation will depend on the successful integration of these technologies into existing industrial processes. This may require significant initial investments in research, development, and infrastructure, which could present challenges for smaller companies or developing economies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!