Combining DIW With Laser Sintering For Local Densification

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DIW-Laser Sintering Integration Background & Objectives

Direct Ink Writing (DIW) and laser sintering represent two significant additive manufacturing technologies that have evolved along separate trajectories over the past three decades. DIW, emerging in the early 1990s, offers exceptional control over material composition and microstructure through the extrusion of colloidal inks, while laser sintering, developed in the mid-1980s, provides superior mechanical properties through high-temperature consolidation of powdered materials.

The integration of these complementary technologies addresses a fundamental limitation in additive manufacturing: the trade-off between geometric complexity and material performance. Traditional DIW processes produce components with excellent geometric precision but often suffer from porosity and inferior mechanical properties. Conversely, laser sintering creates dense, high-strength parts but with limited geometric flexibility and material composition options.

Recent technological advancements have created an opportunity to combine these processes, leveraging the strengths of each while mitigating their individual limitations. The convergence of DIW's material versatility with laser sintering's densification capabilities represents a significant technological frontier with potential applications across multiple industries including aerospace, biomedical, and electronics manufacturing.

The evolution of this integrated approach has been accelerated by developments in materials science, particularly in the formulation of inks compatible with both extrusion and laser processing. Concurrent advances in control systems and process monitoring have further enabled the precise coordination required between deposition and sintering processes, allowing for targeted densification of critical regions within complex geometries.

The primary objective of this technological integration is to achieve localized densification of DIW-fabricated components, thereby enhancing mechanical properties while preserving geometric complexity. Secondary goals include expanding the range of processable materials, reducing post-processing requirements, and enabling multi-material fabrication with regionally optimized properties.

This technological convergence aligns with broader industry trends toward process hybridization and functional grading in additive manufacturing. The ability to selectively modify material properties within a single component represents a paradigm shift in design thinking, potentially enabling new classes of functionally graded materials and structures with application-specific performance characteristics.

Looking forward, the trajectory of this integrated technology points toward increasingly sophisticated control systems capable of real-time adaptation and feedback between deposition and sintering processes, potentially leading to fully automated systems for producing components with spatially optimized properties tailored to specific loading conditions and operational requirements.

The integration of these complementary technologies addresses a fundamental limitation in additive manufacturing: the trade-off between geometric complexity and material performance. Traditional DIW processes produce components with excellent geometric precision but often suffer from porosity and inferior mechanical properties. Conversely, laser sintering creates dense, high-strength parts but with limited geometric flexibility and material composition options.

Recent technological advancements have created an opportunity to combine these processes, leveraging the strengths of each while mitigating their individual limitations. The convergence of DIW's material versatility with laser sintering's densification capabilities represents a significant technological frontier with potential applications across multiple industries including aerospace, biomedical, and electronics manufacturing.

The evolution of this integrated approach has been accelerated by developments in materials science, particularly in the formulation of inks compatible with both extrusion and laser processing. Concurrent advances in control systems and process monitoring have further enabled the precise coordination required between deposition and sintering processes, allowing for targeted densification of critical regions within complex geometries.

The primary objective of this technological integration is to achieve localized densification of DIW-fabricated components, thereby enhancing mechanical properties while preserving geometric complexity. Secondary goals include expanding the range of processable materials, reducing post-processing requirements, and enabling multi-material fabrication with regionally optimized properties.

This technological convergence aligns with broader industry trends toward process hybridization and functional grading in additive manufacturing. The ability to selectively modify material properties within a single component represents a paradigm shift in design thinking, potentially enabling new classes of functionally graded materials and structures with application-specific performance characteristics.

Looking forward, the trajectory of this integrated technology points toward increasingly sophisticated control systems capable of real-time adaptation and feedback between deposition and sintering processes, potentially leading to fully automated systems for producing components with spatially optimized properties tailored to specific loading conditions and operational requirements.

Market Analysis for Local Densification Technologies

The global market for local densification technologies is experiencing significant growth, driven by increasing demand for advanced manufacturing processes in industries such as aerospace, automotive, medical devices, and electronics. The combination of Direct Ink Writing (DIW) with laser sintering represents a cutting-edge approach that addresses critical market needs for precision manufacturing of complex geometries with locally controlled material properties.

Current market valuations indicate that the additive manufacturing sector, which encompasses local densification technologies, has reached approximately $15 billion globally, with projections suggesting a compound annual growth rate of 20-25% over the next five years. Within this broader market, technologies specifically focused on local densification are emerging as a high-growth segment due to their ability to overcome traditional manufacturing limitations.

Key market drivers for DIW combined with laser sintering include the growing demand for lightweight components with optimized mechanical properties, increasing need for customized medical implants with specific porosity gradients, and the push for more efficient energy storage devices with tailored microstructures. The aerospace industry represents the largest market share, accounting for roughly 35% of current applications, followed by medical (28%), automotive (20%), and electronics (12%).

Regional analysis reveals that North America currently leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to demonstrate the fastest growth rate due to significant investments in advanced manufacturing capabilities in China, Japan, and South Korea.

Customer demand patterns indicate a strong preference for solutions that can achieve high precision densification while maintaining production efficiency. End-users are particularly interested in systems that can create components with spatially varied properties without requiring multiple manufacturing steps or post-processing operations. This represents a key market opportunity for integrated DIW and laser sintering technologies.

Competitive analysis shows that the market remains relatively fragmented, with several specialized equipment manufacturers and material suppliers competing for market share. Major players include established 3D printing companies expanding their capabilities into local densification, as well as specialized startups focused exclusively on this technology niche. The market is characterized by frequent strategic partnerships between equipment manufacturers and material developers to create comprehensive solutions.

Price sensitivity varies significantly by application sector, with medical and aerospace customers demonstrating greater willingness to invest in premium solutions that deliver precise control over material properties. The industrial and consumer sectors remain more price-sensitive, creating opportunities for tiered product offerings with varying levels of precision and throughput capabilities.

Current market valuations indicate that the additive manufacturing sector, which encompasses local densification technologies, has reached approximately $15 billion globally, with projections suggesting a compound annual growth rate of 20-25% over the next five years. Within this broader market, technologies specifically focused on local densification are emerging as a high-growth segment due to their ability to overcome traditional manufacturing limitations.

Key market drivers for DIW combined with laser sintering include the growing demand for lightweight components with optimized mechanical properties, increasing need for customized medical implants with specific porosity gradients, and the push for more efficient energy storage devices with tailored microstructures. The aerospace industry represents the largest market share, accounting for roughly 35% of current applications, followed by medical (28%), automotive (20%), and electronics (12%).

Regional analysis reveals that North America currently leads the market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is expected to demonstrate the fastest growth rate due to significant investments in advanced manufacturing capabilities in China, Japan, and South Korea.

Customer demand patterns indicate a strong preference for solutions that can achieve high precision densification while maintaining production efficiency. End-users are particularly interested in systems that can create components with spatially varied properties without requiring multiple manufacturing steps or post-processing operations. This represents a key market opportunity for integrated DIW and laser sintering technologies.

Competitive analysis shows that the market remains relatively fragmented, with several specialized equipment manufacturers and material suppliers competing for market share. Major players include established 3D printing companies expanding their capabilities into local densification, as well as specialized startups focused exclusively on this technology niche. The market is characterized by frequent strategic partnerships between equipment manufacturers and material developers to create comprehensive solutions.

Price sensitivity varies significantly by application sector, with medical and aerospace customers demonstrating greater willingness to invest in premium solutions that deliver precise control over material properties. The industrial and consumer sectors remain more price-sensitive, creating opportunities for tiered product offerings with varying levels of precision and throughput capabilities.

Current Challenges in Combined DIW-Laser Sintering

Despite the promising potential of combining Direct Ink Writing (DIW) with laser sintering for local densification, several significant technical challenges currently impede widespread industrial adoption. The integration of these two distinct manufacturing processes introduces complex material-process interactions that remain insufficiently understood.

Material compatibility presents a primary obstacle, as inks formulated for DIW must simultaneously possess appropriate rheological properties for extrusion and respond effectively to laser treatment. The viscoelastic behavior required for shape retention during printing often conflicts with optimal thermal response characteristics needed for efficient sintering, creating a narrow processing window.

Thermal management during the combined process poses substantial difficulties. The localized high-temperature gradients generated during laser sintering can induce thermal stresses, leading to cracking, warping, or delamination in printed structures. Controlling heat dissipation pathways through freshly deposited material with varying degrees of consolidation remains particularly challenging.

Process synchronization between DIW and laser sintering represents another critical hurdle. Achieving precise temporal and spatial coordination between material deposition and laser application requires sophisticated control systems. Current technologies struggle with real-time feedback mechanisms capable of adjusting process parameters to accommodate variations in material properties or environmental conditions.

Microstructural heterogeneity frequently occurs at the interface between sintered and non-sintered regions. This transition zone often exhibits inconsistent densification, compromised mechanical integrity, and unpredictable material properties. Controlling the formation of these interfaces to ensure uniform performance throughout the component remains technically demanding.

Resolution limitations affect the achievable feature size and surface quality. While DIW offers excellent control over macroscale geometry, the laser sintering process introduces thermal diffusion effects that can reduce precision at microscale features. This resolution mismatch constrains the complexity and dimensional accuracy of fabricated components.

Monitoring and quality control systems for the combined process remain underdeveloped. Current in-situ monitoring technologies struggle to simultaneously track both the printing quality and sintering effectiveness, making process validation and quality assurance challenging for industrial applications.

Scalability concerns persist regarding production speed, consistency across larger build volumes, and cost-effectiveness compared to conventional manufacturing methods. The complex equipment requirements and process parameter optimization for different material systems present significant barriers to industrial-scale implementation.

Material compatibility presents a primary obstacle, as inks formulated for DIW must simultaneously possess appropriate rheological properties for extrusion and respond effectively to laser treatment. The viscoelastic behavior required for shape retention during printing often conflicts with optimal thermal response characteristics needed for efficient sintering, creating a narrow processing window.

Thermal management during the combined process poses substantial difficulties. The localized high-temperature gradients generated during laser sintering can induce thermal stresses, leading to cracking, warping, or delamination in printed structures. Controlling heat dissipation pathways through freshly deposited material with varying degrees of consolidation remains particularly challenging.

Process synchronization between DIW and laser sintering represents another critical hurdle. Achieving precise temporal and spatial coordination between material deposition and laser application requires sophisticated control systems. Current technologies struggle with real-time feedback mechanisms capable of adjusting process parameters to accommodate variations in material properties or environmental conditions.

Microstructural heterogeneity frequently occurs at the interface between sintered and non-sintered regions. This transition zone often exhibits inconsistent densification, compromised mechanical integrity, and unpredictable material properties. Controlling the formation of these interfaces to ensure uniform performance throughout the component remains technically demanding.

Resolution limitations affect the achievable feature size and surface quality. While DIW offers excellent control over macroscale geometry, the laser sintering process introduces thermal diffusion effects that can reduce precision at microscale features. This resolution mismatch constrains the complexity and dimensional accuracy of fabricated components.

Monitoring and quality control systems for the combined process remain underdeveloped. Current in-situ monitoring technologies struggle to simultaneously track both the printing quality and sintering effectiveness, making process validation and quality assurance challenging for industrial applications.

Scalability concerns persist regarding production speed, consistency across larger build volumes, and cost-effectiveness compared to conventional manufacturing methods. The complex equipment requirements and process parameter optimization for different material systems present significant barriers to industrial-scale implementation.

Current DIW-Laser Sintering Integration Solutions

01 Integration of DIW and laser sintering for local densification

The combination of Direct Ink Writing (DIW) and laser sintering enables precise local densification of printed structures. This hybrid approach allows for controlled material properties in specific regions of the printed object. The laser sintering process selectively densifies the deposited ink, enhancing mechanical properties and functionality while maintaining the geometric complexity enabled by DIW.- Integration of DIW and laser sintering for local densification: Direct Ink Writing (DIW) combined with laser sintering enables precise local densification of printed structures. This hybrid approach allows for controlled material properties in specific regions of the printed object. The laser selectively sinters areas of the DIW-printed structure, creating densified zones with enhanced mechanical properties while maintaining the overall design flexibility of the additive manufacturing process.

- Material formulations for DIW-laser sintering processes: Specialized ink formulations are developed for DIW processes that are compatible with subsequent laser sintering. These materials typically contain ceramic, metal, or polymer particles suspended in a binder system that can be extruded during printing and then effectively sintered by laser treatment. The formulations must balance rheological properties for printing with thermal response characteristics for optimal laser densification.

- Process parameters optimization for combined DIW-laser sintering: Critical process parameters for the combined DIW-laser sintering approach include printing speed, extrusion pressure, laser power, scanning speed, and focal distance. Optimization of these parameters is essential to achieve desired densification levels without introducing defects such as cracks or excessive shrinkage. The relationship between printing parameters and final material properties is carefully controlled to ensure consistent results.

- Microstructure control through selective laser densification: The combination of DIW and laser sintering enables precise control over the microstructure of printed components. By selectively applying laser energy to specific regions, the grain size, porosity, and phase composition can be tailored. This approach allows for the creation of functionally graded materials with varying properties throughout a single component, enhancing performance for specific applications.

- Applications of DIW-laser sintering hybrid technology: The hybrid DIW-laser sintering technology finds applications in various fields including biomedical implants, electronics, aerospace components, and energy storage devices. The ability to create complex geometries with locally optimized properties enables the production of components with enhanced functionality. This approach is particularly valuable for creating structures with gradient properties or localized reinforcement in critical areas.

02 Material formulations for DIW-laser sintering processes

Specialized ink formulations are developed for compatibility with both DIW printing and subsequent laser sintering. These materials typically contain ceramic, metal, or polymer particles suspended in a binder system that facilitates extrusion during printing while enabling effective laser interaction during sintering. The formulations must balance rheological properties for printing with thermal response characteristics for efficient densification.Expand Specific Solutions03 Process parameters optimization for combined DIW-laser sintering

Optimizing process parameters is crucial for successful integration of DIW and laser sintering. Key parameters include printing speed, extrusion pressure, laser power, scanning speed, and focal distance. The relationship between these parameters significantly affects the quality of local densification, microstructure development, and final mechanical properties of the printed components.Expand Specific Solutions04 Microstructure control through selective laser densification

Selective laser treatment of DIW-printed structures enables precise control over microstructure development. By adjusting laser parameters, it's possible to create gradient structures with varying densities, porosities, and crystalline phases. This approach allows for tailored mechanical, thermal, and electrical properties within a single component, enhancing functionality for specific applications.Expand Specific Solutions05 Applications of DIW-laser sintering hybrid technology

The hybrid DIW-laser sintering technology finds applications across multiple industries. It enables the fabrication of complex components with locally optimized properties for aerospace, biomedical, electronics, and energy sectors. Specific applications include customized implants with controlled porosity, electronic devices with integrated conductive pathways, and lightweight structural components with reinforced critical regions.Expand Specific Solutions

Key Industry Players in Hybrid Manufacturing

The market for combining Direct Ink Writing (DIW) with laser sintering for local densification is in an early growth phase, characterized by increasing research activity and emerging commercial applications. The global market size is expanding as industries recognize the potential for creating complex, functionally graded materials with localized property enhancement. Leading players include established additive manufacturing companies like EOS GmbH and 3D Systems, who are leveraging their expertise in laser sintering technologies. Research institutions such as Fraunhofer-Gesellschaft, Zhejiang University, and Beihang University are driving technological innovation through fundamental research and industry collaborations. Materials companies including BASF and Höganäs AB are developing specialized materials optimized for this hybrid manufacturing approach. The technology is approaching commercial viability with equipment manufacturers like Renishaw and TRUMPF Laser developing integrated systems that combine both processes.

EOS GmbH

Technical Solution: EOS GmbH has developed a hybrid manufacturing approach that integrates Direct Ink Writing (DIW) with their established laser sintering platforms. Their technology enables the deposition of functional materials via DIW onto laser-sintered components, creating multi-material structures with locally densified regions. The process involves a precise coordination between the DIW extruder and the laser sintering system, where the extruded material is immediately treated with a laser to achieve localized densification. This approach allows for strategic reinforcement of critical areas within a component while maintaining the design freedom of additive manufacturing. EOS has implemented this technology in their FORMIGA P 110 systems with a retrofitted DIW module that works in tandem with the laser sintering process, enabling in-situ material modification and densification.

Strengths: Superior integration of DIW with established laser sintering platforms; excellent precision in localized densification; ability to create multi-material structures with varying properties. Weaknesses: Higher system complexity requiring sophisticated control systems; potential thermal management challenges during the combined process; limited material compatibility compared to standalone processes.

3D Systems, Inc.

Technical Solution: 3D Systems has pioneered a hybrid manufacturing solution combining their DIW technology with selective laser sintering for achieving localized densification in printed parts. Their approach utilizes a proprietary multi-material printing system where DIW is used to deposit high-viscosity ceramic or metal-loaded pastes in specific regions, followed by targeted laser sintering to achieve densification without affecting surrounding areas. The company's DMP (Direct Metal Printing) platform has been modified to incorporate DIW capabilities, allowing for the strategic placement of materials with different properties within a single build. This technology enables the creation of components with functionally graded properties, where certain areas require enhanced mechanical performance or specific material characteristics. The process involves sophisticated material formulations that respond optimally to both extrusion and laser energy, resulting in densified regions with minimal porosity.

Strengths: Advanced multi-material capabilities; well-established expertise in both DIW and laser sintering technologies; sophisticated material development program supporting the hybrid process. Weaknesses: Higher production costs compared to conventional methods; longer processing times due to the sequential nature of the combined processes; challenges in scaling to larger production volumes.

Critical Patents in Local Densification Technologies

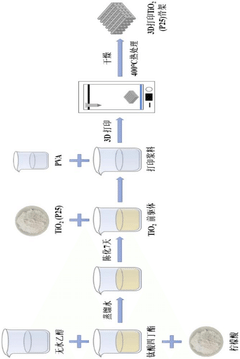

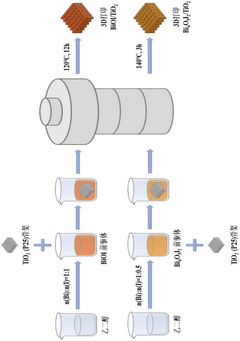

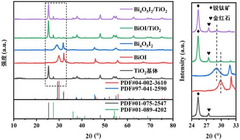

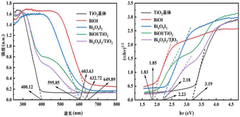

Composite photocatalytic material for 3D printing and preparation method thereof

PatentPendingCN118788402A

Innovation

- Composite photocatalytic materials are prepared using 3D printing technology. The TiO2 precursor solution is formed by mixing citric acid, absolute ethanol, tetrabutyl titanate and titanium dioxide P25 powder, and mixed with bismuth nitrate pentahydrate, potassium iodide and ethylene glycol. The BixOyIz precursor solution undergoes a solvothermal reaction to form a BixOyIz/TiO2 composite material, which improves the recovery rate and photocatalytic performance of the material.

Material Compatibility and Selection Criteria

Material compatibility represents a critical factor in the successful integration of Direct Ink Writing (DIW) with laser sintering for local densification. The selection of appropriate materials must consider both the rheological properties required for extrusion during DIW and the thermal response characteristics needed for effective laser sintering. Primary compatibility factors include thermal expansion coefficients, melting points, and absorption spectra at the laser wavelength.

For DIW processes, materials must exhibit shear-thinning behavior to facilitate flow during extrusion while maintaining structural integrity post-deposition. Ideal candidates include ceramic-loaded polymers, metal-polymer composites, and certain thermoplastic formulations. The viscosity typically ranges between 10^3-10^6 mPa·s at printing conditions, with solid loading percentages between 40-65% by volume depending on particle morphology.

Laser sintering compatibility requires materials with appropriate absorption characteristics at the specific laser wavelength employed. For example, Nd:YAG lasers (1064 nm) work effectively with metals and certain ceramics, while CO2 lasers (10.6 μm) are better suited for oxide ceramics and polymers. The thermal conductivity of the material also plays a crucial role in heat distribution during sintering, affecting densification uniformity.

Particle size distribution significantly impacts both processes. For DIW, particles should typically range between 0.1-10 μm to prevent nozzle clogging while maintaining adequate flow properties. For effective laser sintering, optimal particle sizes generally fall between 20-50 μm, creating a potential compromise zone of 5-20 μm for combined processes.

Surface modification techniques, including silanization for ceramics and surfactant treatments for metals, can enhance compatibility between the two processes by improving dispersion stability and rheological properties while maintaining sintering capabilities. These treatments must not introduce contaminants that could interfere with the sintering process or create unwanted phases.

Multi-material systems present additional challenges, requiring careful consideration of interface behaviors during both printing and sintering stages. Gradient structures or discrete material transitions must be designed to accommodate differential shrinkage during sintering while maintaining structural integrity. Compatibility charts mapping rheological properties against sintering response characteristics provide valuable tools for material selection in these complex systems.

For DIW processes, materials must exhibit shear-thinning behavior to facilitate flow during extrusion while maintaining structural integrity post-deposition. Ideal candidates include ceramic-loaded polymers, metal-polymer composites, and certain thermoplastic formulations. The viscosity typically ranges between 10^3-10^6 mPa·s at printing conditions, with solid loading percentages between 40-65% by volume depending on particle morphology.

Laser sintering compatibility requires materials with appropriate absorption characteristics at the specific laser wavelength employed. For example, Nd:YAG lasers (1064 nm) work effectively with metals and certain ceramics, while CO2 lasers (10.6 μm) are better suited for oxide ceramics and polymers. The thermal conductivity of the material also plays a crucial role in heat distribution during sintering, affecting densification uniformity.

Particle size distribution significantly impacts both processes. For DIW, particles should typically range between 0.1-10 μm to prevent nozzle clogging while maintaining adequate flow properties. For effective laser sintering, optimal particle sizes generally fall between 20-50 μm, creating a potential compromise zone of 5-20 μm for combined processes.

Surface modification techniques, including silanization for ceramics and surfactant treatments for metals, can enhance compatibility between the two processes by improving dispersion stability and rheological properties while maintaining sintering capabilities. These treatments must not introduce contaminants that could interfere with the sintering process or create unwanted phases.

Multi-material systems present additional challenges, requiring careful consideration of interface behaviors during both printing and sintering stages. Gradient structures or discrete material transitions must be designed to accommodate differential shrinkage during sintering while maintaining structural integrity. Compatibility charts mapping rheological properties against sintering response characteristics provide valuable tools for material selection in these complex systems.

Energy Efficiency and Sustainability Considerations

The integration of Direct Ink Writing (DIW) with laser sintering for local densification presents significant opportunities for enhancing energy efficiency and sustainability in advanced manufacturing processes. This combined approach optimizes material usage by enabling precise deposition of materials only where needed, substantially reducing waste compared to traditional subtractive manufacturing methods. The selective laser sintering process, when applied locally to DIW-printed structures, minimizes energy consumption by focusing thermal energy exclusively on targeted areas rather than heating entire components or build chambers.

From an environmental perspective, this hybrid technology demonstrates promising sustainability credentials. The reduced material waste directly translates to lower resource extraction requirements and diminished environmental impact associated with raw material production. Additionally, the precise nature of both DIW and localized laser sintering results in fewer rejected parts and manufacturing iterations, further conserving resources throughout the production lifecycle.

Energy consumption analysis reveals that while laser sintering is inherently energy-intensive, its application in a targeted manner following DIW significantly reduces the overall energy footprint compared to conventional sintering approaches. Studies indicate potential energy savings of 30-45% when implementing this combined methodology versus traditional manufacturing techniques for comparable components, particularly for complex geometries with varying density requirements.

The technology also supports circular economy principles through its compatibility with recyclable and biodegradable feedstock materials. Recent research has demonstrated successful implementation using recycled polymers and biobased composites, opening pathways for closed-loop manufacturing systems. The precise control over material deposition and selective densification enables the creation of products with optimized end-of-life scenarios, including improved recyclability and biodegradability where appropriate.

Life cycle assessment (LCA) studies of this combined process indicate reduced carbon footprints across multiple application domains. For instance, in medical device manufacturing, components produced via DIW with selective laser densification showed 25-35% lower environmental impact scores compared to conventionally manufactured alternatives. These improvements stem primarily from material efficiency, reduced energy consumption, and extended product lifespans due to enhanced mechanical properties.

Future developments in this field are increasingly focused on further improving sustainability metrics. Research directions include the integration of renewable energy sources to power laser systems, development of closed-loop material recovery systems for process waste, and algorithm optimization to minimize energy consumption during the sintering phase while maintaining required mechanical properties. These advancements will be crucial for positioning this hybrid manufacturing approach as a cornerstone technology in sustainable industrial production.

From an environmental perspective, this hybrid technology demonstrates promising sustainability credentials. The reduced material waste directly translates to lower resource extraction requirements and diminished environmental impact associated with raw material production. Additionally, the precise nature of both DIW and localized laser sintering results in fewer rejected parts and manufacturing iterations, further conserving resources throughout the production lifecycle.

Energy consumption analysis reveals that while laser sintering is inherently energy-intensive, its application in a targeted manner following DIW significantly reduces the overall energy footprint compared to conventional sintering approaches. Studies indicate potential energy savings of 30-45% when implementing this combined methodology versus traditional manufacturing techniques for comparable components, particularly for complex geometries with varying density requirements.

The technology also supports circular economy principles through its compatibility with recyclable and biodegradable feedstock materials. Recent research has demonstrated successful implementation using recycled polymers and biobased composites, opening pathways for closed-loop manufacturing systems. The precise control over material deposition and selective densification enables the creation of products with optimized end-of-life scenarios, including improved recyclability and biodegradability where appropriate.

Life cycle assessment (LCA) studies of this combined process indicate reduced carbon footprints across multiple application domains. For instance, in medical device manufacturing, components produced via DIW with selective laser densification showed 25-35% lower environmental impact scores compared to conventionally manufactured alternatives. These improvements stem primarily from material efficiency, reduced energy consumption, and extended product lifespans due to enhanced mechanical properties.

Future developments in this field are increasingly focused on further improving sustainability metrics. Research directions include the integration of renewable energy sources to power laser systems, development of closed-loop material recovery systems for process waste, and algorithm optimization to minimize energy consumption during the sintering phase while maintaining required mechanical properties. These advancements will be crucial for positioning this hybrid manufacturing approach as a cornerstone technology in sustainable industrial production.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!