Post-Processing Automation For High-Volume DIW Operations

DIW Post-Processing Evolution and Objectives

Direct Ink Writing (DIW) post-processing has evolved significantly over the past two decades, transforming from manual, labor-intensive operations to increasingly automated systems capable of handling high-volume production requirements. Initially, DIW post-processing relied heavily on manual intervention for tasks such as curing, sintering, and surface finishing, resulting in inconsistent quality and limited scalability.

The early 2000s marked the beginning of semi-automated post-processing systems, primarily focused on controlled thermal treatment environments. These systems introduced basic programmable temperature profiles for more consistent curing but still required significant operator oversight. By 2010, integration of robotic handling systems began to emerge, enabling more efficient transfer of printed components between processing stations.

A significant technological leap occurred around 2015 with the introduction of in-line monitoring systems capable of real-time quality assessment during post-processing operations. This development represented a crucial step toward closed-loop feedback systems that could make adjustments to processing parameters based on measured outcomes.

Current state-of-the-art post-processing automation incorporates multi-modal processing capabilities, allowing for sequential operations such as UV curing, thermal treatment, and surface finishing within integrated systems. Industry 4.0 principles have been increasingly applied, with digital twins of post-processing operations enabling predictive maintenance and process optimization.

The primary objectives for advancing DIW post-processing automation center around several key areas. First is throughput enhancement, aiming to develop systems capable of handling industrial-scale production volumes without sacrificing quality or precision. Second is process consistency, focusing on eliminating variations between batches through standardized, repeatable procedures with minimal human intervention.

Energy efficiency represents another critical objective, as traditional thermal post-processing methods often consume significant energy. Advanced systems aim to reduce this footprint through optimized heating technologies and recovery systems. Additionally, material-specific optimization seeks to develop tailored post-processing protocols for the expanding range of DIW-compatible materials, including ceramics, polymers, and multi-material composites.

Perhaps most ambitious is the goal of achieving autonomous operation, where AI-driven systems can independently adjust post-processing parameters based on material characteristics, environmental conditions, and desired final properties. This evolution toward fully automated, intelligent post-processing systems represents the frontier of DIW manufacturing technology, promising to unlock new applications and production scales previously unattainable.

Market Analysis for Automated Post-Processing Solutions

The global market for automated post-processing solutions in Direct Ink Writing (DIW) operations is experiencing significant growth, driven by increasing adoption of additive manufacturing across multiple industries. Current market valuation stands at approximately $2.3 billion, with projections indicating a compound annual growth rate of 18.7% through 2028, potentially reaching $5.4 billion by that time.

Manufacturing sectors, particularly aerospace, automotive, and medical device industries, represent the largest market segments for automated post-processing solutions. These industries require high precision, consistency, and throughput that manual post-processing cannot efficiently deliver. The aerospace sector alone accounts for 27% of the current market share, followed by medical devices at 23% and automotive applications at 19%.

Regional analysis reveals North America currently leads the market with 38% share, followed by Europe at 31% and Asia-Pacific at 26%. However, the Asia-Pacific region is demonstrating the fastest growth rate at 22.3% annually, primarily driven by rapid industrialization in China, South Korea, and India, along with significant government investments in advanced manufacturing technologies.

Key market drivers include increasing production volumes requiring scalable solutions, rising labor costs making automation more economically viable, and growing quality control requirements that demand consistent post-processing results. Additionally, sustainability concerns are pushing manufacturers to adopt more efficient post-processing systems that minimize material waste and energy consumption.

Customer demand patterns indicate a strong preference for integrated solutions that can be seamlessly incorporated into existing production lines. End-users are increasingly seeking systems with flexible automation capabilities that can handle various part geometries and material types without significant reconfiguration. Market research shows that 76% of potential buyers prioritize solutions offering quick changeover capabilities for different product types.

Market barriers include high initial investment costs, with comprehensive automated post-processing systems ranging from $150,000 to $750,000 depending on capabilities and throughput requirements. Technical integration challenges with existing manufacturing systems and resistance to workflow changes also represent significant adoption hurdles for many potential customers.

Emerging market opportunities exist in developing specialized post-processing solutions for new materials being used in DIW operations, particularly in composite materials and multi-material printing applications. Additionally, there is growing demand for post-processing systems incorporating real-time quality monitoring and artificial intelligence for adaptive process control.

Current Challenges in High-Volume DIW Post-Processing

Despite significant advancements in Direct Ink Writing (DIW) technology, high-volume manufacturing operations continue to face substantial challenges in the post-processing phase. These challenges represent critical bottlenecks that limit production efficiency, scalability, and ultimately, market adoption of DIW-manufactured components.

The manual handling requirements in current DIW post-processing workflows present a significant obstacle. After printing, components often require careful removal from build platforms, cleaning of support structures, and precise placement into curing equipment. These labor-intensive steps introduce variability in quality and processing time, while also increasing production costs in high-volume scenarios.

Quality consistency remains problematic across large production batches. Post-processing parameters such as curing time, temperature profiles, and post-curing treatments significantly impact final part properties. Without sophisticated automation and monitoring systems, maintaining uniform quality across thousands of components becomes exceedingly difficult, resulting in higher rejection rates and material waste.

The integration gap between printing and post-processing systems represents another major challenge. Most DIW operations utilize disconnected workflows where printed components must be manually transferred between different post-processing stations. This discontinuity creates logistical complexities, increases cycle times, and introduces opportunities for handling damage or contamination.

Energy efficiency concerns are increasingly prominent in high-volume DIW operations. Traditional curing methods often employ energy-intensive thermal or UV processes that scale linearly with production volume. The absence of intelligent energy management systems results in excessive power consumption and environmental impact, particularly problematic as manufacturers face growing sustainability pressures.

Material-specific post-processing requirements further complicate automation efforts. Different ink formulations demand tailored post-processing protocols, including specialized curing profiles, solvent treatments, or thermal conditioning. Developing flexible automation systems capable of handling this diversity without extensive reconfiguration between production runs remains technically challenging.

Regulatory compliance and traceability present additional hurdles, particularly in highly regulated industries such as medical device manufacturing and aerospace. Current post-processing workflows often lack comprehensive digital documentation capabilities, making it difficult to validate process parameters and maintain the detailed processing records required for certification.

State-of-the-Art Automation Techniques

01 Automated post-processing systems for manufacturing

These systems focus on automating post-processing operations in manufacturing environments. They include robotic systems that can perform finishing tasks such as trimming, polishing, and quality inspection after the primary manufacturing process. These automated solutions improve efficiency, reduce manual labor, and ensure consistent quality in the post-production phase.- Automated post-processing systems for manufacturing: These systems focus on automating post-processing operations in manufacturing environments. They include robotic systems that can handle tasks such as trimming, finishing, and quality inspection after the primary manufacturing process. These automated solutions improve efficiency, reduce manual labor, and ensure consistent quality in the final product by eliminating human error and increasing throughput.

- Software-based post-processing automation: This category covers software solutions that automate data or image post-processing workflows. These systems include automated data analysis, report generation, and workflow management tools that streamline post-processing tasks. The software can automatically apply filters, corrections, or transformations to data sets or images without manual intervention, significantly reducing processing time and improving consistency.

- Integrated post-processing control systems: These systems provide comprehensive control over multiple post-processing operations through integrated automation platforms. They feature centralized control interfaces that manage various post-processing equipment and coordinate workflows. The integration allows for seamless operation between different post-processing stages, optimizing resource utilization and enabling real-time monitoring and adjustments to ensure quality standards are maintained.

- Additive manufacturing post-processing automation: This category focuses specifically on automating post-processing tasks for 3D printed or additively manufactured parts. These systems handle operations such as support removal, surface finishing, heat treatment, and dimensional verification that are typically required after the printing process. The automation solutions are designed to address the unique challenges of additive manufacturing post-processing, improving part quality and reducing the labor-intensive aspects of finishing 3D printed components.

- Intelligent post-processing with adaptive capabilities: These advanced systems incorporate artificial intelligence, machine learning, and adaptive algorithms to optimize post-processing operations. They can automatically detect variations in input materials or conditions and adjust processing parameters accordingly. The intelligent systems learn from previous operations to continuously improve performance, reduce waste, and adapt to changing requirements without manual reprogramming, representing the next generation of post-processing automation.

02 Software-based post-processing automation

Software solutions that automate data or image post-processing workflows. These systems include automated data analysis, report generation, and workflow management tools that streamline post-processing tasks. The software can automatically apply filters, corrections, or transformations to data sets or images without human intervention, increasing productivity and reducing processing time.Expand Specific Solutions03 Intelligent control systems for post-processing

Advanced control systems that use artificial intelligence, machine learning, or adaptive algorithms to optimize post-processing operations. These systems can automatically adjust parameters based on feedback, learn from previous operations, and make real-time decisions to improve outcomes. They enable more sophisticated automation by incorporating intelligence into the post-processing workflow.Expand Specific Solutions04 Integrated post-processing automation equipment

Hardware solutions that combine multiple post-processing steps into integrated automated systems. These include conveyor systems, robotic handling equipment, and specialized machinery designed to perform sequential post-processing operations without human intervention. The integration of various post-processing steps into a single automated line increases throughput and reduces handling requirements.Expand Specific Solutions05 Automated quality control in post-processing

Systems specifically designed to automate quality inspection and verification during or after post-processing operations. These include vision systems, sensor arrays, and automated testing equipment that can detect defects, measure dimensions, and verify compliance with specifications. Automating quality control in post-processing ensures consistent standards and reduces the risk of defective products reaching customers.Expand Specific Solutions

Leading Manufacturers and Solution Providers

Post-Processing Automation for High-Volume DIW Operations is currently in an early growth phase, with the market expanding as industries seek efficiency improvements in direct ink writing processes. The global market size is estimated to be approaching $1 billion, driven by semiconductor, electronics, and advanced manufacturing applications. From a technological maturity perspective, the landscape shows varying degrees of development. Industry leaders like QUALCOMM, Intel, and Texas Instruments have made significant advancements in automated post-processing systems, while companies such as IBM, Canon, and Infineon Technologies are developing complementary technologies focusing on quality control and process optimization. KUKA and FUJIFILM Business Innovation are emerging with specialized solutions for industrial automation integration, indicating a technology that is rapidly maturing but still has substantial room for innovation and market expansion.

KUKA Deutschland GmbH

International Business Machines Corp.

Critical Patents and Innovations in Post-Processing

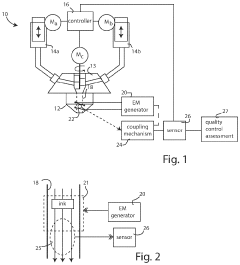

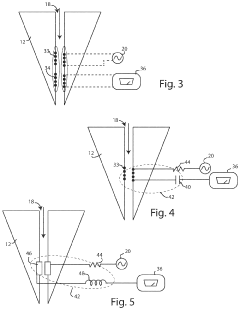

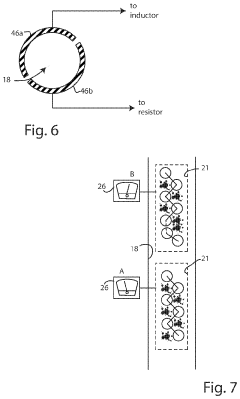

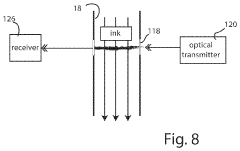

- The integration of an electromagnetic resonant coupling apparatus that introduces electromagnetic energy into the material flow path, allowing for real-time monitoring and control of the feedstock composition by sensing changes in permeability and permittivity properties, using inductive coils or capacitors and RF electronics to provide feedback for adjusting the material composition during the manufacturing process.

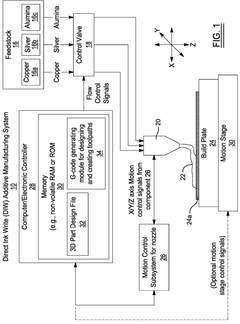

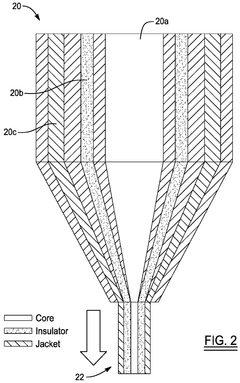

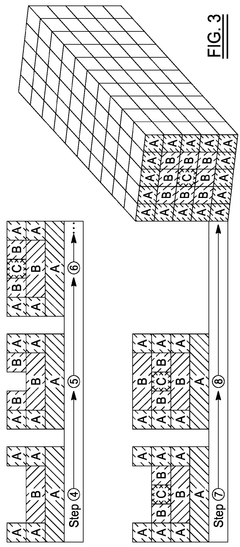

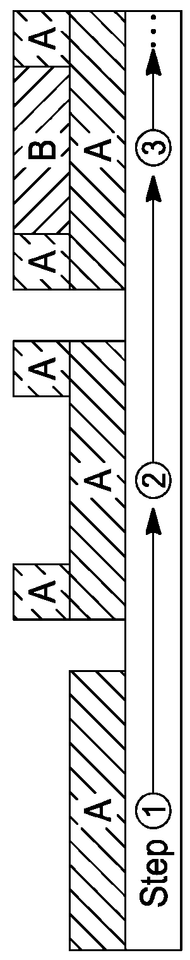

- The development of a direct ink write (DIW) additive manufacturing system capable of extruding and forming three distinct materials - copper, alumina, and silver - into complex geometries, such as helical configurations, to create 3D electromagnets with improved conductivity and structural integrity.

Cost-Benefit Analysis of Automation Implementation

Implementing automation in post-processing operations for high-volume Direct Ink Writing (DIW) requires substantial initial investment. Equipment costs typically range from $150,000 to $500,000 depending on the level of sophistication, with additional expenses for installation, integration with existing systems, and facility modifications. Software licensing and customization can add $50,000-$100,000 to the initial outlay.

Operational cost reductions present the most compelling economic argument for automation. Labor costs in manual post-processing operations often account for 30-40% of total production expenses. Automation can reduce these costs by 60-75%, with a typical manufacturing facility potentially saving $200,000-$350,000 annually in direct labor costs. Additionally, automated systems operate continuously without fatigue, potentially increasing throughput by 40-60% compared to manual operations.

Quality improvements deliver significant but less quantifiable benefits. Automated post-processing reduces defect rates from typical manual levels of 3-5% to below 1%, substantially decreasing rework and scrap costs. For high-value DIW applications in aerospace or medical industries, this quality improvement can represent savings of $75,000-$150,000 annually while enhancing product reliability and customer satisfaction.

Return on investment (ROI) calculations indicate that most DIW post-processing automation systems achieve payback within 18-36 months, depending on production volume and application complexity. Companies operating at higher volumes (>10,000 units monthly) typically experience faster returns, often reaching ROI in under 18 months.

Long-term financial benefits extend beyond direct cost savings. Automated systems offer greater production flexibility, allowing manufacturers to respond more quickly to changing market demands. This agility can increase revenue opportunities by 15-20% through faster time-to-market and improved capacity utilization. Furthermore, automation creates opportunities for data collection and analysis that enable continuous process improvement, potentially yielding an additional 5-10% in efficiency gains annually.

Risk factors must be considered in the cost-benefit equation. Implementation delays can extend ROI timelines, while technology obsolescence may necessitate additional investments. Companies should budget for ongoing maintenance costs (typically 5-8% of initial investment annually) and periodic software updates to maintain system performance and security.

Environmental Impact and Sustainability Considerations

Direct Ink Writing (DIW) operations, while offering significant advantages in additive manufacturing, present substantial environmental challenges that must be addressed as the technology scales to high-volume production. The post-processing phase of DIW operations involves several environmentally impactful activities including cleaning, curing, and waste management. These processes often utilize solvents, energy-intensive curing methods, and generate material waste that can contribute to environmental degradation if not properly managed.

The automation of post-processing presents a unique opportunity to enhance sustainability across the DIW manufacturing lifecycle. By optimizing material usage through precise control systems, automated post-processing can significantly reduce waste generation. Current estimates suggest that automated systems can decrease material waste by 15-30% compared to manual post-processing methods, representing substantial resource conservation in high-volume operations.

Energy consumption remains a critical environmental concern in DIW post-processing. Traditional curing methods, particularly thermal curing, are notoriously energy-intensive. Automated systems incorporating advanced energy management technologies, such as selective curing and energy recovery systems, demonstrate potential energy savings of 20-40%. Furthermore, the integration of renewable energy sources into automated post-processing lines represents an emerging trend that could further reduce the carbon footprint of DIW operations.

Water usage in cleaning processes presents another significant environmental challenge. Automated post-processing systems equipped with closed-loop water recycling capabilities can reduce freshwater consumption by up to 80% compared to conventional methods. Additionally, advanced filtration systems can capture and remove contaminants, allowing for safer water discharge or reuse.

Chemical management in post-processing automation offers substantial sustainability benefits. Precision application systems can reduce solvent usage by 25-50%, while automated chemical recovery systems can reclaim up to 70% of solvents for reuse. The transition toward environmentally benign cleaning agents and bio-based solvents is accelerating, with several promising alternatives currently undergoing industrial validation.

Life cycle assessment (LCA) studies indicate that automated post-processing systems, when properly designed with sustainability considerations, can reduce the overall environmental impact of DIW operations by 30-60% compared to traditional methods. This improvement becomes increasingly significant as production volumes scale, highlighting the importance of sustainable automation in high-volume manufacturing scenarios.