Metrology Methods For Dimensional Accuracy In DIW Parts

DIW Metrology Background and Objectives

Direct Ink Writing (DIW) has emerged as a prominent additive manufacturing technique over the past two decades, evolving from early extrusion-based systems to sophisticated multi-material fabrication platforms. This evolution has been driven by the increasing demand for complex geometries and customized structures across industries including aerospace, biomedical, and electronics. The fundamental principle of DIW involves the controlled deposition of viscous materials through a nozzle to create three-dimensional structures layer by layer, offering advantages in material versatility and resolution compared to other additive manufacturing methods.

The dimensional accuracy of DIW-fabricated parts represents a critical quality parameter that directly impacts functionality, reliability, and reproducibility. As DIW applications expand into high-precision fields such as microfluidics, tissue engineering scaffolds, and electronic components, the tolerance requirements have become increasingly stringent, often demanding accuracies in the micrometer range. This heightened precision requirement necessitates advanced metrology methods capable of comprehensive dimensional assessment.

Traditional metrology approaches have proven insufficient for the unique challenges presented by DIW parts, including complex internal features, multi-material interfaces, and non-linear geometries. The viscoelastic nature of DIW materials introduces additional complexities, as parts may undergo dimensional changes during curing or post-processing stages. These challenges have catalyzed research into specialized metrology solutions tailored to the specific characteristics of DIW manufacturing.

The primary objective of this technical research is to comprehensively evaluate existing and emerging metrology methods for dimensional accuracy assessment in DIW parts. This includes investigating both contact and non-contact measurement techniques, in-process monitoring systems, and post-fabrication verification approaches. The research aims to identify methodologies that can effectively characterize critical dimensional parameters including feature size, layer height consistency, surface roughness, and internal geometry fidelity.

Furthermore, this investigation seeks to establish correlations between process parameters, material properties, and dimensional outcomes to develop predictive models for accuracy control. By understanding these relationships, manufacturers can implement proactive quality control strategies rather than relying solely on post-production inspection. The ultimate goal is to establish standardized metrology protocols that enable consistent dimensional accuracy across different DIW systems, materials, and application domains.

This research also aims to identify technological gaps in current metrology approaches and propose innovative solutions that leverage advances in fields such as machine vision, artificial intelligence, and sensor technology. By addressing these challenges, the industry can accelerate the adoption of DIW for high-precision applications where dimensional accuracy serves as a critical performance determinant.

Market Analysis for Precision DIW Manufacturing

The global market for Direct Ink Writing (DIW) manufacturing is experiencing significant growth, driven by increasing demand for customized, high-precision components across multiple industries. Current market valuations indicate that the precision additive manufacturing sector, which includes DIW technologies, has reached approximately 3.5 billion USD in 2023, with a projected compound annual growth rate of 18% through 2028.

The healthcare and biomedical sectors represent the largest market segment for precision DIW manufacturing, accounting for nearly 35% of the total market share. This dominance stems from the technology's ability to produce patient-specific implants, tissue scaffolds, and drug delivery systems with exceptional dimensional accuracy. The aerospace industry follows closely behind at 22% market share, where lightweight yet structurally complex components with tight tolerances are increasingly manufactured using DIW techniques.

Consumer electronics manufacturers have also begun adopting precision DIW technologies, particularly for producing miniaturized components and embedded electronics. This sector currently represents approximately 15% of the market but is expected to grow at an above-average rate of 23% annually as electronics continue to decrease in size while increasing in complexity.

Regionally, North America leads the precision DIW manufacturing market with approximately 40% share, followed by Europe (30%) and Asia-Pacific (25%). However, the Asia-Pacific region is projected to witness the fastest growth rate over the next five years, primarily driven by rapid industrialization in China, South Korea, and Singapore, along with substantial government investments in advanced manufacturing technologies.

The demand for metrology methods specifically designed for DIW parts is being fueled by increasingly stringent quality control requirements across industries. End-users are demanding dimensional accuracies in the range of 5-10 micrometers for critical applications, creating a specialized sub-market for advanced measurement systems tailored to DIW manufacturing processes.

Key market drivers include the growing adoption of Industry 4.0 principles, which emphasize in-line quality control and real-time process monitoring. Additionally, regulatory requirements in medical and aerospace applications are becoming more stringent, necessitating improved metrology solutions that can verify dimensional accuracy with greater precision and reliability.

Market barriers include the high cost of advanced metrology equipment, which can represent up to 15% of the total investment in a precision DIW manufacturing setup. Additionally, the lack of standardized measurement protocols specifically for DIW processes creates challenges for quality certification and cross-compatibility between different manufacturing facilities.

Current Metrology Challenges in DIW Technology

Direct Ink Writing (DIW) technology faces significant metrology challenges that impede its widespread industrial adoption. The dimensional accuracy verification of DIW-manufactured parts remains problematic due to the complex geometries and material properties inherent to this additive manufacturing process. Traditional contact measurement methods often prove inadequate as they risk deforming the sometimes delicate structures of freshly printed parts, particularly when dealing with soft materials or green bodies prior to sintering.

Non-contact optical methods such as laser scanning and structured light systems offer alternatives but struggle with the varied surface reflectivity of DIW materials. Highly reflective or transparent materials can cause data loss or inaccurate measurements, while dark or matte surfaces may absorb too much light for effective scanning. Additionally, deep recesses and internal features common in complex DIW parts often remain inaccessible to optical systems.

X-ray computed tomography (CT) provides comprehensive volumetric data but remains prohibitively expensive for routine quality control and typically requires significant time for data acquisition and processing. This creates a bottleneck in production environments where rapid feedback on dimensional accuracy is essential for process optimization.

Real-time monitoring during the DIW process presents another significant challenge. Current in-situ measurement technologies lack the resolution necessary to detect minor deviations that can accumulate throughout the build process. The viscoelastic behavior of many DIW materials further complicates matters, as parts may experience dimensional changes during curing or post-processing stages that are difficult to predict and measure accurately.

Standardization represents another critical hurdle. Unlike more established manufacturing methods, DIW lacks comprehensive measurement standards and protocols. This absence creates inconsistencies in how dimensional accuracy is reported across different research groups and manufacturers, hampering meaningful comparisons and technology advancement.

The multi-material capabilities of DIW introduce additional complexity to metrology efforts. Different materials within the same part may exhibit varying shrinkage rates, thermal behaviors, and mechanical properties, necessitating sophisticated measurement approaches that can account for these material-specific characteristics.

Finally, the correlation between process parameters and final dimensional accuracy remains poorly understood. Current metrology methods struggle to provide the comprehensive data needed to establish robust process-structure-property relationships that would enable more predictable outcomes in DIW manufacturing.

State-of-the-Art Dimensional Accuracy Methods

01 Optical metrology systems for dimensional accuracy

Optical metrology systems utilize light-based measurement techniques to assess dimensional accuracy with high precision. These systems include interferometry, optical scanning, and imaging technologies that can measure surface features, contours, and dimensions without physical contact. The non-contact nature of optical metrology makes it ideal for delicate components or when physical probing might alter the measurement. These systems can achieve sub-micron accuracy and are widely used in semiconductor manufacturing, precision engineering, and quality control applications.- Optical metrology systems for dimensional accuracy: Optical metrology systems utilize light-based measurement techniques to achieve high dimensional accuracy in manufacturing and inspection processes. These systems include interferometry, structured light projection, and optical scanning technologies that can measure surface features, contours, and dimensions with high precision. The non-contact nature of optical metrology makes it suitable for delicate components and allows for rapid inspection without risking damage to the measured object.

- Machine learning and AI in dimensional metrology: Advanced computational methods including machine learning and artificial intelligence are being integrated into dimensional metrology systems to enhance measurement accuracy and efficiency. These technologies enable automated feature recognition, defect classification, and predictive analytics for quality control. AI algorithms can process complex measurement data, identify patterns, and optimize measurement strategies, resulting in improved dimensional accuracy and reduced inspection time.

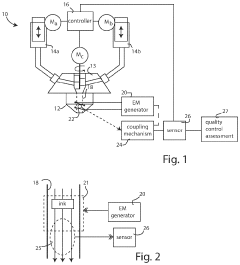

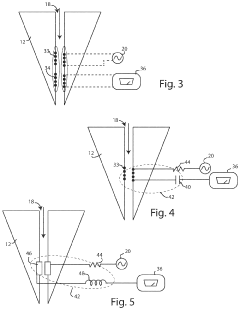

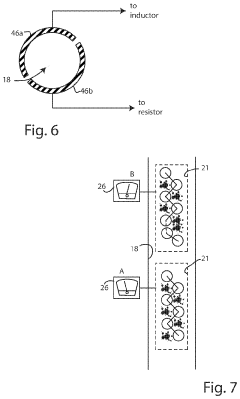

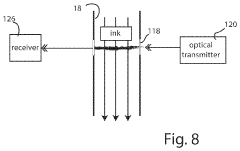

- In-process measurement and real-time monitoring: In-process measurement techniques allow for dimensional accuracy verification during manufacturing rather than only after completion. These methods incorporate sensors and monitoring systems directly into production equipment to provide real-time feedback on dimensional parameters. By continuously monitoring critical dimensions during fabrication, manufacturers can make immediate adjustments to process parameters, reducing scrap rates and ensuring consistent dimensional accuracy across production runs.

- Multi-sensor coordinate measuring systems: Multi-sensor coordinate measuring systems combine different measurement technologies such as tactile probes, laser scanners, and vision systems into a single platform. This integration allows for comprehensive dimensional accuracy assessment by leveraging the strengths of each technology. These systems can automatically select the optimal measurement method based on the feature being measured, providing enhanced accuracy for complex geometries and improving measurement efficiency for parts with diverse dimensional requirements.

- Image processing techniques for dimensional measurement: Advanced image processing techniques enable high-precision dimensional measurements from digital images. These methods include edge detection algorithms, pattern recognition, and photogrammetry that can extract accurate dimensional information from visual data. By analyzing multiple images from different angles or using calibrated reference objects, these systems can achieve sub-micron measurement accuracy. Image processing approaches are particularly valuable for measuring features that are difficult to access with conventional contact measurement tools.

02 Machine learning and AI in dimensional metrology

Advanced computational methods including machine learning and artificial intelligence are being integrated into metrology systems to enhance dimensional accuracy assessment. These technologies enable automated feature recognition, defect classification, and measurement optimization. AI algorithms can analyze complex measurement data, identify patterns, and make predictions about dimensional variations. Machine learning models can be trained to improve measurement accuracy over time by learning from historical data and reducing systematic errors, ultimately providing more reliable dimensional measurements in manufacturing environments.Expand Specific Solutions03 In-process metrology for manufacturing dimensional control

In-process metrology systems enable real-time monitoring and control of dimensional accuracy during manufacturing operations. These systems integrate measurement capabilities directly into production equipment, allowing for immediate detection of dimensional deviations. By continuously monitoring critical dimensions during fabrication, manufacturers can make adjustments before defects occur, reducing waste and improving overall quality. This approach is particularly valuable in advanced manufacturing processes where tight tolerances must be maintained consistently across large production volumes.Expand Specific Solutions04 3D scanning and imaging techniques for dimensional verification

Three-dimensional scanning and imaging technologies provide comprehensive dimensional verification by capturing complete geometric data of objects. These methods include structured light scanning, laser triangulation, photogrammetry, and computed tomography, which generate detailed 3D models for dimensional analysis. The resulting point clouds or mesh models can be compared against reference designs to identify dimensional deviations across the entire object surface. These techniques are particularly valuable for complex geometries where traditional measurement methods would be insufficient or time-consuming.Expand Specific Solutions05 Statistical methods for dimensional accuracy assessment

Statistical approaches to dimensional metrology involve sampling strategies, uncertainty analysis, and statistical process control to ensure measurement reliability. These methods include gauge repeatability and reproducibility studies, measurement system analysis, and statistical tolerance analysis. By applying statistical principles to measurement data, manufacturers can quantify measurement uncertainty, establish confidence intervals, and make informed decisions about process capability. Statistical methods help distinguish between actual dimensional variations in products and variations introduced by the measurement system itself.Expand Specific Solutions

Leading Companies in DIW Metrology Solutions

The dimensional accuracy metrology landscape for Direct Ink Writing (DIW) parts is evolving rapidly, currently transitioning from early development to commercial application phase. The market is expanding as additive manufacturing adoption grows, with projected significant growth in precision measurement solutions. Leading semiconductor equipment manufacturers like ASML, KLA, and Applied Materials are leveraging their advanced metrology expertise in this space. Academic institutions including MIT and UNC are contributing fundamental research, while specialized metrology companies such as Zygo and Mitutoyo are developing tailored solutions. The ecosystem also includes manufacturing technology providers like FANUC and Tornos, indicating a maturing technology landscape with increasing industrial applications requiring high-precision measurement capabilities.

ASML Netherlands BV

KLA Corp.

Key Metrology Patents and Technical Literature

- The integration of an electromagnetic resonant coupling apparatus that introduces electromagnetic energy into the material flow path, allowing for real-time monitoring and control of the feedstock composition by sensing changes in permeability and permittivity properties, using inductive coils or capacitors and RF electronics to provide feedback for adjusting the material composition during the manufacturing process.

Standards and Calibration Protocols

Standardization in Direct Ink Writing (DIW) metrology represents a critical foundation for ensuring dimensional accuracy across the additive manufacturing industry. Currently, ISO/ASTM 52900 provides the overarching framework for additive manufacturing terminology, while ISO/ASTM 52901 establishes requirements for purchased parts. However, DIW-specific dimensional metrology standards remain underdeveloped compared to other AM technologies, creating challenges for consistent quality assurance.

Calibration protocols for DIW systems must address the unique rheological properties of extruded materials. The NIST Additive Manufacturing Metrology Testbed (AMMT) offers valuable calibration methodologies that can be adapted for DIW processes, particularly focusing on nozzle positioning accuracy and material flow rate calibration. These protocols typically require calibration at multiple points throughout the build volume using certified reference artifacts with known dimensions.

Reference artifacts for DIW calibration should ideally incorporate features that challenge the process capabilities, including thin walls, overhangs, and fine details. The NIST-developed Standard Reference Material 2088 serves as an example, though specialized artifacts for DIW systems are still emerging. Calibration frequency recommendations suggest daily verification of critical parameters and comprehensive calibration monthly or after significant system modifications.

Traceability chains in DIW metrology must be established from the measurement instrument to national or international standards. This typically involves using calibrated optical or contact measurement systems that have been verified against certified reference standards. Documentation of this traceability chain is essential for regulatory compliance in industries such as medical device manufacturing and aerospace.

Measurement uncertainty quantification presents particular challenges in DIW processes due to material shrinkage, environmental factors, and process variability. The GUM (Guide to the Expression of Uncertainty in Measurement) methodology provides a framework for uncertainty analysis, requiring identification of all error sources, determination of standard uncertainties, calculation of combined uncertainties, and expression of expanded uncertainty with a defined confidence level.

Round-robin testing among different laboratories has revealed significant variability in dimensional measurements of DIW parts, highlighting the need for standardized measurement protocols. Recent initiatives by ASTM Committee F42 on Additive Manufacturing Technologies are working to develop consensus standards specifically addressing DIW dimensional metrology, with draft standards expected within the next two years.

Cost-Benefit Analysis of Metrology Systems

When evaluating metrology systems for Direct Ink Writing (DIW) additive manufacturing, a comprehensive cost-benefit analysis is essential for making informed investment decisions. Initial acquisition costs vary significantly across different metrology technologies, with optical systems typically ranging from $50,000 to $200,000, while advanced CT scanning equipment may exceed $500,000. However, acquisition cost represents only one component of the total cost of ownership.

Operational expenses must be carefully considered, including calibration requirements, maintenance contracts, specialized operator training, and software licensing fees. These recurring costs can accumulate to 15-20% of the initial investment annually. Energy consumption also varies substantially between systems, with CT scanners consuming up to ten times more power than optical measurement systems.

Throughput capacity directly impacts return on investment. High-speed optical scanning systems can process multiple parts per hour, while CT scanning may require 30-60 minutes per part. This throughput differential significantly affects cost per measurement and overall production efficiency. Additionally, the physical footprint of metrology equipment affects facility costs, with large CT systems requiring dedicated rooms versus compact optical systems that can be integrated into production lines.

The benefits side of the equation must quantify both tangible and intangible returns. Improved dimensional accuracy verification leads to measurable reductions in scrap rates, typically 5-15% for DIW manufacturing processes. Enhanced quality control capabilities enable faster process optimization, reducing development cycles by up to 40% when implementing in-line metrology systems.

Advanced metrology systems provide valuable data analytics capabilities, enabling predictive maintenance and process drift detection that can prevent costly production interruptions. The ability to document compliance with industry standards and customer specifications also carries significant value, particularly in regulated industries like aerospace and medical device manufacturing.

Return on investment timelines vary by application, with high-volume production environments typically achieving ROI within 12-24 months, while low-volume, high-complexity applications may require 36-48 months. Organizations must also consider scalability and future-proofing, as metrology needs may evolve with production volumes and complexity.

The optimal metrology solution balances initial investment against long-term operational benefits. For many DIW applications, a hybrid approach combining affordable in-line optical measurement for routine verification with periodic high-resolution CT scanning for critical features offers the most favorable cost-benefit ratio.