DIW For Catalyst Supports: Surface Area And Mass Transfer Considerations

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DIW Catalyst Support Technology Background and Objectives

Direct Ink Writing (DIW) technology has emerged as a transformative approach in the fabrication of catalyst supports, representing a significant advancement in additive manufacturing techniques applied to catalytic systems. The evolution of DIW for catalyst supports traces back to the early 2000s, when researchers began exploring alternatives to traditional catalyst support manufacturing methods that often lacked precision in structural control and customization capabilities.

The technological trajectory of DIW has been characterized by progressive refinements in ink formulation, extrusion mechanics, and post-processing techniques. Initially limited to simple geometries and basic materials, DIW has evolved to accommodate complex hierarchical structures with tailored porosity—a critical factor for catalyst performance. This evolution has been driven by the increasing demand for catalyst supports that maximize surface area while optimizing mass transfer characteristics.

Current technological objectives for DIW in catalyst support applications center on addressing the fundamental trade-off between high surface area and efficient mass transfer. While high surface area provides more active sites for catalytic reactions, it often comes at the expense of restricted mass transfer due to smaller pore sizes and more tortuous diffusion paths. The primary goal is to develop DIW methodologies that enable precise control over multi-scale porosity, from macro-channels that facilitate bulk flow to micro and mesopores that maximize surface area.

Another critical objective is the enhancement of DIW's capability to produce catalyst supports with improved mechanical integrity and thermal stability, which are essential for industrial applications involving high temperatures and pressures. This includes the development of new ink formulations incorporating ceramic precursors, polymeric binders, and pore-forming agents that can withstand sintering processes without compromising the designed architecture.

The field is also moving toward integrating computational modeling with DIW processes to predict and optimize the relationship between printed structures and their catalytic performance. These models aim to simulate fluid dynamics, reaction kinetics, and heat transfer within the printed structures, enabling rational design of catalyst supports tailored for specific reactions.

Looking forward, the technological roadmap for DIW in catalyst supports is oriented toward achieving unprecedented control over surface chemistry and pore architecture simultaneously, potentially revolutionizing fields such as energy conversion, environmental remediation, and chemical production through more efficient and selective catalytic processes.

The technological trajectory of DIW has been characterized by progressive refinements in ink formulation, extrusion mechanics, and post-processing techniques. Initially limited to simple geometries and basic materials, DIW has evolved to accommodate complex hierarchical structures with tailored porosity—a critical factor for catalyst performance. This evolution has been driven by the increasing demand for catalyst supports that maximize surface area while optimizing mass transfer characteristics.

Current technological objectives for DIW in catalyst support applications center on addressing the fundamental trade-off between high surface area and efficient mass transfer. While high surface area provides more active sites for catalytic reactions, it often comes at the expense of restricted mass transfer due to smaller pore sizes and more tortuous diffusion paths. The primary goal is to develop DIW methodologies that enable precise control over multi-scale porosity, from macro-channels that facilitate bulk flow to micro and mesopores that maximize surface area.

Another critical objective is the enhancement of DIW's capability to produce catalyst supports with improved mechanical integrity and thermal stability, which are essential for industrial applications involving high temperatures and pressures. This includes the development of new ink formulations incorporating ceramic precursors, polymeric binders, and pore-forming agents that can withstand sintering processes without compromising the designed architecture.

The field is also moving toward integrating computational modeling with DIW processes to predict and optimize the relationship between printed structures and their catalytic performance. These models aim to simulate fluid dynamics, reaction kinetics, and heat transfer within the printed structures, enabling rational design of catalyst supports tailored for specific reactions.

Looking forward, the technological roadmap for DIW in catalyst supports is oriented toward achieving unprecedented control over surface chemistry and pore architecture simultaneously, potentially revolutionizing fields such as energy conversion, environmental remediation, and chemical production through more efficient and selective catalytic processes.

Market Analysis for Advanced Catalyst Support Systems

The global market for advanced catalyst support systems is experiencing robust growth, driven primarily by increasing demand in petrochemical, chemical synthesis, and environmental applications. Current market valuation stands at approximately $5.2 billion, with projections indicating a compound annual growth rate of 6.8% through 2028. Direct Ink Writing (DIW) technology for catalyst supports represents an emerging segment within this market, offering significant potential for disruption due to its ability to create precisely engineered structures with optimized surface area and mass transfer properties.

Key market drivers include stringent environmental regulations worldwide that necessitate more efficient catalytic converters and emission control systems. The automotive sector remains the largest consumer of advanced catalyst supports, accounting for roughly 38% of market share, followed by petroleum refining at 27% and chemical manufacturing at 21%. Renewable energy applications, particularly in hydrogen production and fuel cells, represent the fastest-growing segment with 12.3% annual growth.

Regional analysis reveals that Asia-Pacific dominates the market with 42% share, led by China's aggressive investments in chemical manufacturing and environmental technologies. North America and Europe follow with 28% and 24% respectively, with both regions focusing on high-performance specialty applications. The Middle East is emerging as a significant growth region due to diversification efforts beyond traditional petroleum industries.

Customer demand is increasingly focused on catalyst supports that maximize active surface area while minimizing mass transfer limitations. This trend directly aligns with DIW technology's capabilities to create hierarchical porous structures with precisely controlled geometries. Market research indicates that customers are willing to pay premium prices for supports that can demonstrate 15-20% improvements in catalytic efficiency or reductions in precious metal loading.

Competitive landscape analysis shows that traditional catalyst support manufacturers are beginning to invest in additive manufacturing technologies, with several major players establishing R&D programs specifically for DIW applications. However, the market remains fragmented, with specialized materials science companies and academic spin-offs leading innovation in DIW-specific formulations for catalyst supports.

Market barriers include high initial investment costs for DIW equipment, limited scalability of current processes, and regulatory hurdles for novel support materials in sensitive applications like pharmaceuticals and food processing. Nevertheless, the potential for significant performance improvements and material cost savings is driving continued investment and market expansion.

Key market drivers include stringent environmental regulations worldwide that necessitate more efficient catalytic converters and emission control systems. The automotive sector remains the largest consumer of advanced catalyst supports, accounting for roughly 38% of market share, followed by petroleum refining at 27% and chemical manufacturing at 21%. Renewable energy applications, particularly in hydrogen production and fuel cells, represent the fastest-growing segment with 12.3% annual growth.

Regional analysis reveals that Asia-Pacific dominates the market with 42% share, led by China's aggressive investments in chemical manufacturing and environmental technologies. North America and Europe follow with 28% and 24% respectively, with both regions focusing on high-performance specialty applications. The Middle East is emerging as a significant growth region due to diversification efforts beyond traditional petroleum industries.

Customer demand is increasingly focused on catalyst supports that maximize active surface area while minimizing mass transfer limitations. This trend directly aligns with DIW technology's capabilities to create hierarchical porous structures with precisely controlled geometries. Market research indicates that customers are willing to pay premium prices for supports that can demonstrate 15-20% improvements in catalytic efficiency or reductions in precious metal loading.

Competitive landscape analysis shows that traditional catalyst support manufacturers are beginning to invest in additive manufacturing technologies, with several major players establishing R&D programs specifically for DIW applications. However, the market remains fragmented, with specialized materials science companies and academic spin-offs leading innovation in DIW-specific formulations for catalyst supports.

Market barriers include high initial investment costs for DIW equipment, limited scalability of current processes, and regulatory hurdles for novel support materials in sensitive applications like pharmaceuticals and food processing. Nevertheless, the potential for significant performance improvements and material cost savings is driving continued investment and market expansion.

Current Challenges in DIW Catalyst Support Development

Despite significant advancements in Direct Ink Writing (DIW) technology for catalyst support fabrication, several critical challenges persist that impede its widespread industrial adoption. The primary obstacle remains achieving optimal surface area characteristics while maintaining structural integrity. Current DIW processes struggle to create hierarchical porosity that simultaneously provides high specific surface area (>500 m²/g) and efficient mass transfer pathways, which are essential for catalyst performance.

Material formulation presents another significant hurdle. The rheological properties of printable inks must balance contradictory requirements: sufficient viscosity for shape retention during printing versus adequate flowability for extrusion. This balance becomes particularly challenging when incorporating high surface area materials like zeolites or metal-organic frameworks, which tend to agglomerate and disrupt ink homogeneity.

Post-processing treatments, especially calcination and sintering, frequently lead to substantial surface area reduction. Temperature-induced structural collapse can diminish porosity by 30-50%, significantly compromising catalyst efficiency. Current techniques lack precise control over shrinkage and pore evolution during these thermal treatments.

Scalability issues further complicate DIW implementation for catalyst supports. Laboratory-scale successes often fail to translate to industrial production due to inconsistencies in material properties and printing parameters. The absence of standardized quality control metrics specifically tailored for DIW catalyst supports hampers reproducibility across different manufacturing batches and equipment.

Mass transfer limitations represent perhaps the most persistent challenge. While DIW enables precise macrostructure control, optimizing microscale features for enhanced diffusion remains problematic. Current designs struggle to minimize internal concentration gradients that reduce catalyst utilization efficiency, particularly in liquid-phase reactions where diffusion constraints are more pronounced.

Durability concerns also plague DIW-fabricated catalyst supports, especially in harsh reaction environments. Mechanical stability under thermal cycling, chemical resistance to reaction media, and long-term structural integrity all require significant improvement. Current supports often exhibit accelerated degradation compared to conventionally manufactured alternatives.

Integration challenges with existing manufacturing infrastructure present additional barriers. The relatively slow printing speeds of DIW processes (typically 1-10 mm/s) create production bottlenecks that limit industrial viability. Furthermore, quality assurance protocols for DIW-produced catalyst supports remain underdeveloped, complicating regulatory approval and commercial implementation.

Material formulation presents another significant hurdle. The rheological properties of printable inks must balance contradictory requirements: sufficient viscosity for shape retention during printing versus adequate flowability for extrusion. This balance becomes particularly challenging when incorporating high surface area materials like zeolites or metal-organic frameworks, which tend to agglomerate and disrupt ink homogeneity.

Post-processing treatments, especially calcination and sintering, frequently lead to substantial surface area reduction. Temperature-induced structural collapse can diminish porosity by 30-50%, significantly compromising catalyst efficiency. Current techniques lack precise control over shrinkage and pore evolution during these thermal treatments.

Scalability issues further complicate DIW implementation for catalyst supports. Laboratory-scale successes often fail to translate to industrial production due to inconsistencies in material properties and printing parameters. The absence of standardized quality control metrics specifically tailored for DIW catalyst supports hampers reproducibility across different manufacturing batches and equipment.

Mass transfer limitations represent perhaps the most persistent challenge. While DIW enables precise macrostructure control, optimizing microscale features for enhanced diffusion remains problematic. Current designs struggle to minimize internal concentration gradients that reduce catalyst utilization efficiency, particularly in liquid-phase reactions where diffusion constraints are more pronounced.

Durability concerns also plague DIW-fabricated catalyst supports, especially in harsh reaction environments. Mechanical stability under thermal cycling, chemical resistance to reaction media, and long-term structural integrity all require significant improvement. Current supports often exhibit accelerated degradation compared to conventionally manufactured alternatives.

Integration challenges with existing manufacturing infrastructure present additional barriers. The relatively slow printing speeds of DIW processes (typically 1-10 mm/s) create production bottlenecks that limit industrial viability. Furthermore, quality assurance protocols for DIW-produced catalyst supports remain underdeveloped, complicating regulatory approval and commercial implementation.

Current DIW Methods for Optimizing Surface Area

01 3D printing techniques for catalyst supports with controlled porosity

Direct Ink Writing (DIW) enables the fabrication of catalyst supports with precisely controlled porosity and channel structures. This technique allows for the design of hierarchical porous structures that enhance surface area while maintaining optimal mass transfer properties. The controlled architecture facilitates better reactant access to catalytic sites and improves overall catalytic efficiency by balancing surface area with mass transport considerations.- 3D printing techniques for catalyst supports with enhanced surface area: Direct Ink Writing (DIW) enables the fabrication of catalyst supports with controlled architectures that maximize surface area. This additive manufacturing approach allows for precise deposition of catalyst-containing inks to create complex, hierarchical structures with optimized porosity. The resulting 3D-printed supports provide increased surface area for catalyst loading while maintaining structural integrity, leading to improved catalytic performance compared to conventional supports.

- Ink formulations for DIW to enhance mass transfer properties: Specialized ink formulations for Direct Ink Writing can be designed to create catalyst supports with improved mass transfer characteristics. These inks typically contain rheological modifiers, binders, and pore-forming agents that enable the printing of structures with controlled porosity and channel networks. The composition of the ink directly influences the final microstructure of the catalyst support, affecting both surface area and mass transfer efficiency in catalytic reactions.

- Hierarchical porous structures for optimized catalyst performance: DIW technology enables the creation of hierarchical porous structures in catalyst supports that combine macro, meso, and micropores. This multi-scale porosity enhances both surface area and mass transfer properties by providing efficient pathways for reactants and products while maximizing the available surface for catalyst deposition. The controlled architecture allows for optimized flow distribution and reduced pressure drop across the catalyst bed, improving overall reaction efficiency.

- Post-processing treatments to enhance surface properties: Various post-processing treatments can be applied to DIW-printed catalyst supports to further enhance their surface area and mass transfer properties. These treatments include thermal sintering, chemical etching, and surface functionalization techniques that can create additional porosity, remove sacrificial templates, or modify surface chemistry. Such post-processing steps are crucial for optimizing the performance of 3D-printed catalyst supports in specific applications.

- Integration of active catalytic components with DIW supports: Methods for integrating active catalytic components with DIW-printed supports focus on maximizing catalyst utilization while maintaining optimal mass transfer. Techniques include in-situ incorporation of catalytic materials within the printing ink, post-printing impregnation processes, and surface deposition methods. These approaches ensure that catalytic sites are accessible while the engineered support structure facilitates efficient mass transfer, resulting in higher catalytic activity and selectivity.

02 Ink formulation for enhanced surface area in DIW catalyst supports

Specialized ink formulations for DIW incorporate materials that develop high surface area characteristics upon processing. These formulations may include nanoparticles, pore-forming agents, or hierarchical materials that create multi-scale porosity. The rheological properties of these inks are carefully controlled to maintain printability while ensuring the development of high surface area structures after drying, sintering, or other post-processing steps.Expand Specific Solutions03 Mass transfer optimization in 3D printed catalyst structures

DIW enables the creation of catalyst supports with optimized geometries that enhance mass transfer while maintaining high surface area. By designing specific channel dimensions, tortuosity, and interconnectivity, the mass transfer limitations commonly found in traditional catalyst supports can be overcome. These structures facilitate efficient diffusion of reactants to active sites and removal of products, improving overall catalytic performance especially in diffusion-limited reactions.Expand Specific Solutions04 Post-processing techniques to enhance surface properties of DIW catalyst supports

Various post-processing methods can be applied to DIW-fabricated catalyst supports to further enhance their surface area and mass transfer properties. These techniques include chemical etching, thermal treatments, and secondary material deposition. Such processes can create additional micro and mesoporosity within the printed structures, significantly increasing the available surface area while preserving the designed macrostructure that facilitates mass transfer.Expand Specific Solutions05 Integration of functional materials in DIW for catalytic applications

DIW allows for the direct incorporation of catalytically active materials or their precursors into the printing ink. This approach enables the creation of catalyst supports with integrated functionality, where the catalytic material is distributed throughout the structure rather than only on the surface. The technique permits precise control over catalyst loading and distribution, leading to more efficient utilization of expensive catalytic materials while maintaining optimal surface area and mass transfer characteristics.Expand Specific Solutions

Leading Organizations in DIW Catalyst Support Research

The DIW (Direct Ink Writing) for catalyst supports market is currently in a growth phase, with increasing adoption across petrochemical and automotive industries. The market is expanding due to rising demand for high-performance catalysts with optimized surface area and enhanced mass transfer properties. Major petroleum companies like Sinopec, PetroChina, and ConocoPhillips are investing in this technology, while chemical specialists including UOP LLC, Clariant, and LG Chem are developing advanced formulations. Automotive manufacturers Toyota and Honda are exploring DIW for emission control catalysts. The technology is approaching commercial maturity with research institutes like Shanghai Petrochemical Research Institute and Sinopec Research Institute of Petroleum Processing collaborating with industry to overcome remaining challenges in scalability and precision control of porous structures.

China Petroleum & Chemical Corp.

Technical Solution: China Petroleum & Chemical Corp. (Sinopec) has pioneered DIW technology for catalyst supports focusing on optimizing surface area and mass transfer parameters for petroleum refining applications. Their approach combines 3D printing with advanced material science to create structured catalyst supports with controlled hierarchical porosity. Sinopec's technology utilizes specialized ceramic-based inks containing alumina, silica, and proprietary additives that enable precise control of rheological properties during printing and subsequent thermal processing. Their DIW process creates monolithic structures with interconnected macropores (5-50 μm) and mesopores (2-20 nm), achieving surface areas of 150-300 m²/g. The company has developed computational fluid dynamics models to optimize flow patterns within the printed structures, reducing pressure drop by up to 40% while maintaining high catalytic activity. Sinopec's DIW catalyst supports demonstrate enhanced mass transfer efficiency, particularly in diffusion-limited reactions common in hydrocracking and hydrodesulfurization processes[2][5].

Strengths: Extensive experience in petroleum refining applications; integration with existing industrial processes; demonstrated improvements in catalyst efficiency and selectivity. Weaknesses: Technology primarily optimized for petroleum applications rather than broader chemical processes; relatively new to additive manufacturing compared to specialized materials companies; potential challenges in scaling production to meet large industrial demands.

UOP LLC

Technical Solution: UOP LLC has developed advanced Direct Ink Writing (DIW) technology for catalyst supports that addresses critical surface area and mass transfer considerations. Their approach utilizes precisely engineered ceramic inks with controlled rheological properties to create hierarchical porous structures. The company employs multi-material DIW printing to fabricate catalyst supports with tailored macro/microporous architectures that significantly enhance mass transfer efficiency while maintaining high surface area. UOP's proprietary ink formulations incorporate alumina, silica, and zeolite materials with carefully designed binder systems that enable both structural integrity during printing and optimal porosity after thermal processing. Their technology allows for precise control of pore size distribution (typically 1-100 μm for macropores and 2-50 nm for mesopores) and wall thickness (50-500 μm), resulting in catalyst supports with surface areas exceeding 200 m²/g while maintaining excellent mechanical properties and flow characteristics[1][3].

Strengths: Superior control over pore architecture and surface area characteristics; ability to create complex geometries impossible with traditional manufacturing; enhanced mass transfer efficiency leading to improved catalyst performance. Weaknesses: Higher production costs compared to conventional methods; scaling challenges for industrial-scale manufacturing; limited material selection compared to traditional catalyst support fabrication techniques.

Critical Innovations in Mass Transfer Enhancement

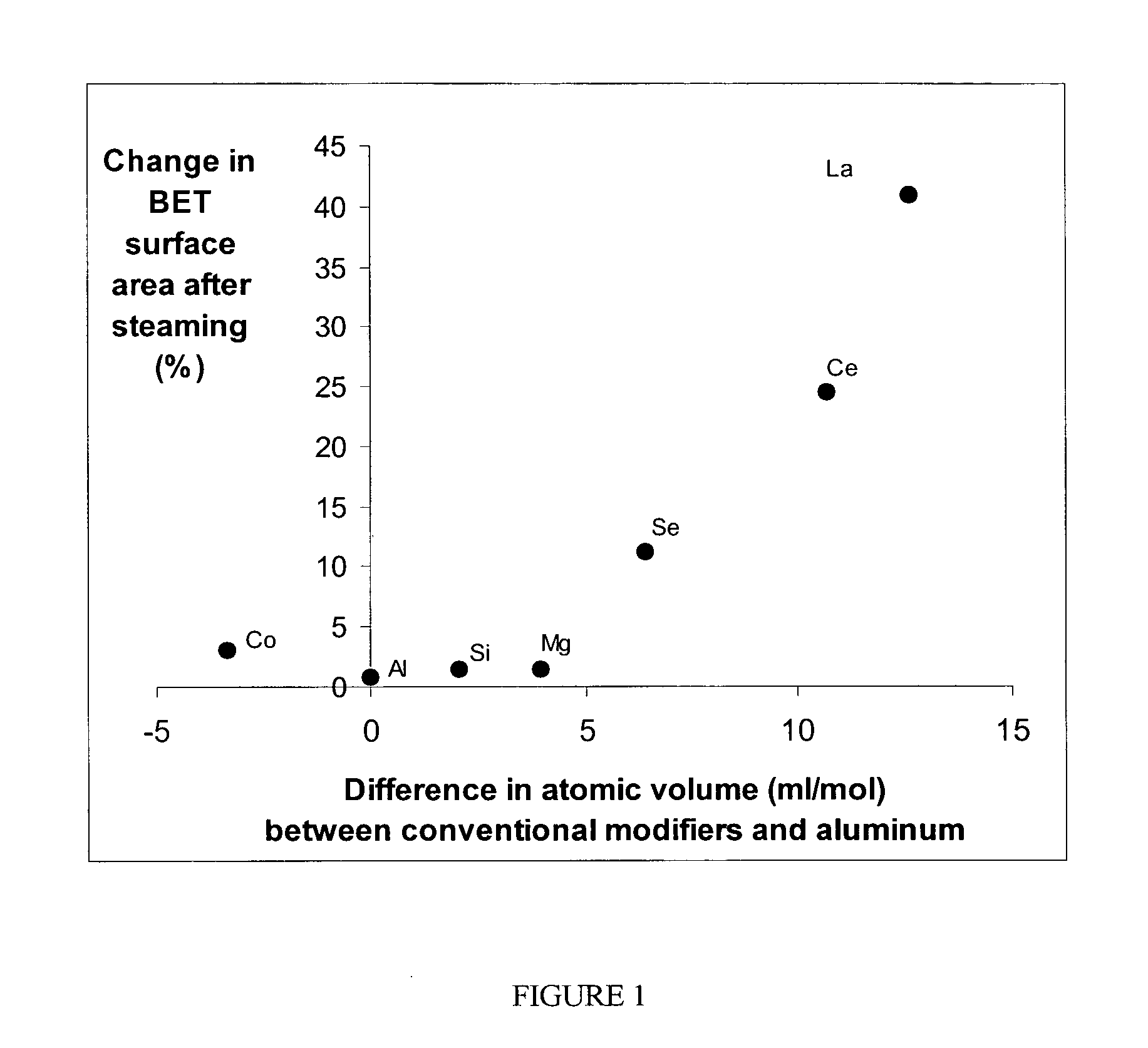

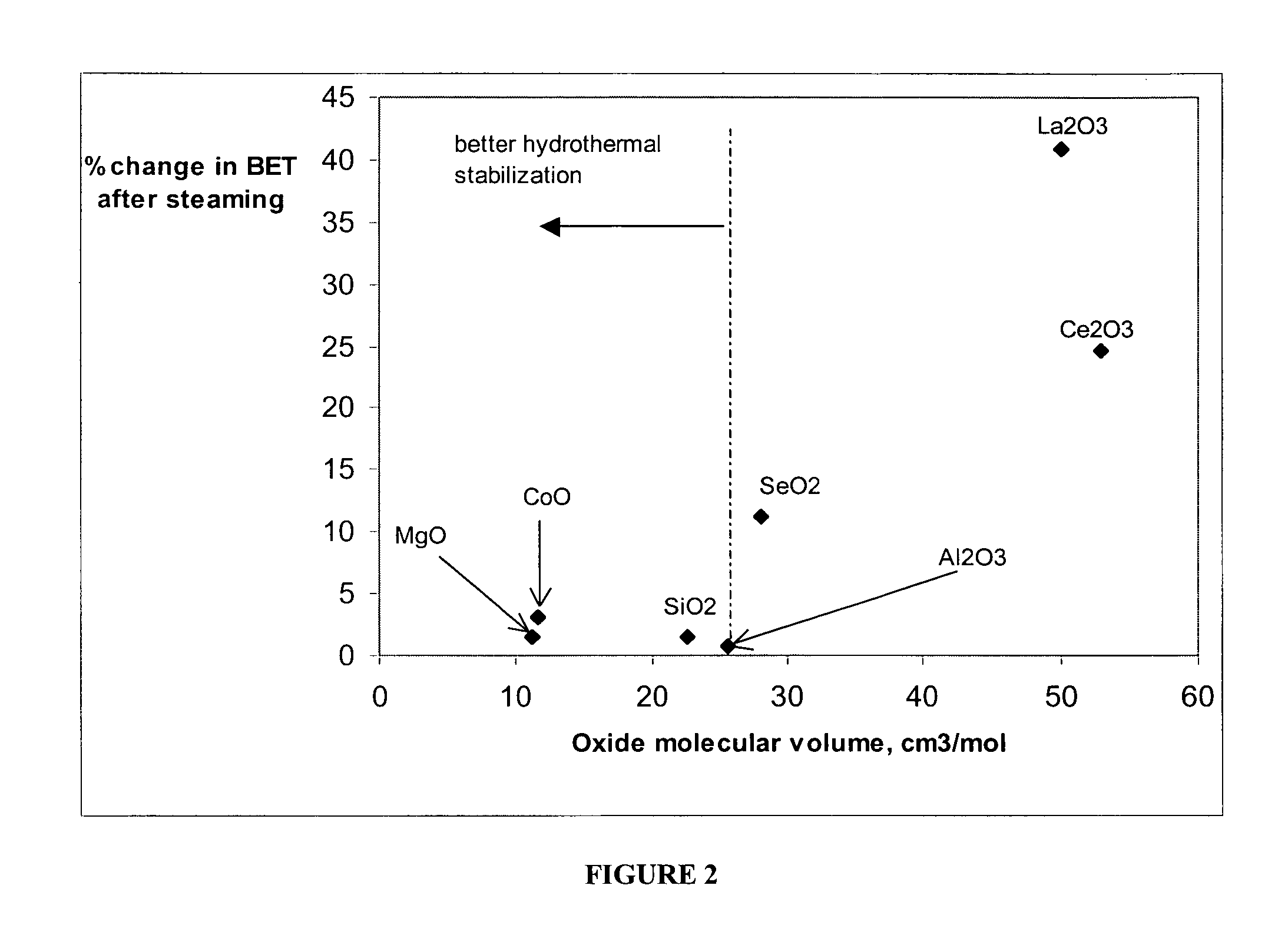

Supports for high surface area catalysts

PatentInactiveUS7276540B2

Innovation

- A thermally stable, high-surface-area alumina support is created by modifying gamma-alumina with aluminum-based agents, such as boehmite or pseudo-boehmite, and calcining at specific temperatures to maintain structural integrity and prevent defect site formation, thereby enhancing hydrothermal stability and catalytic performance.

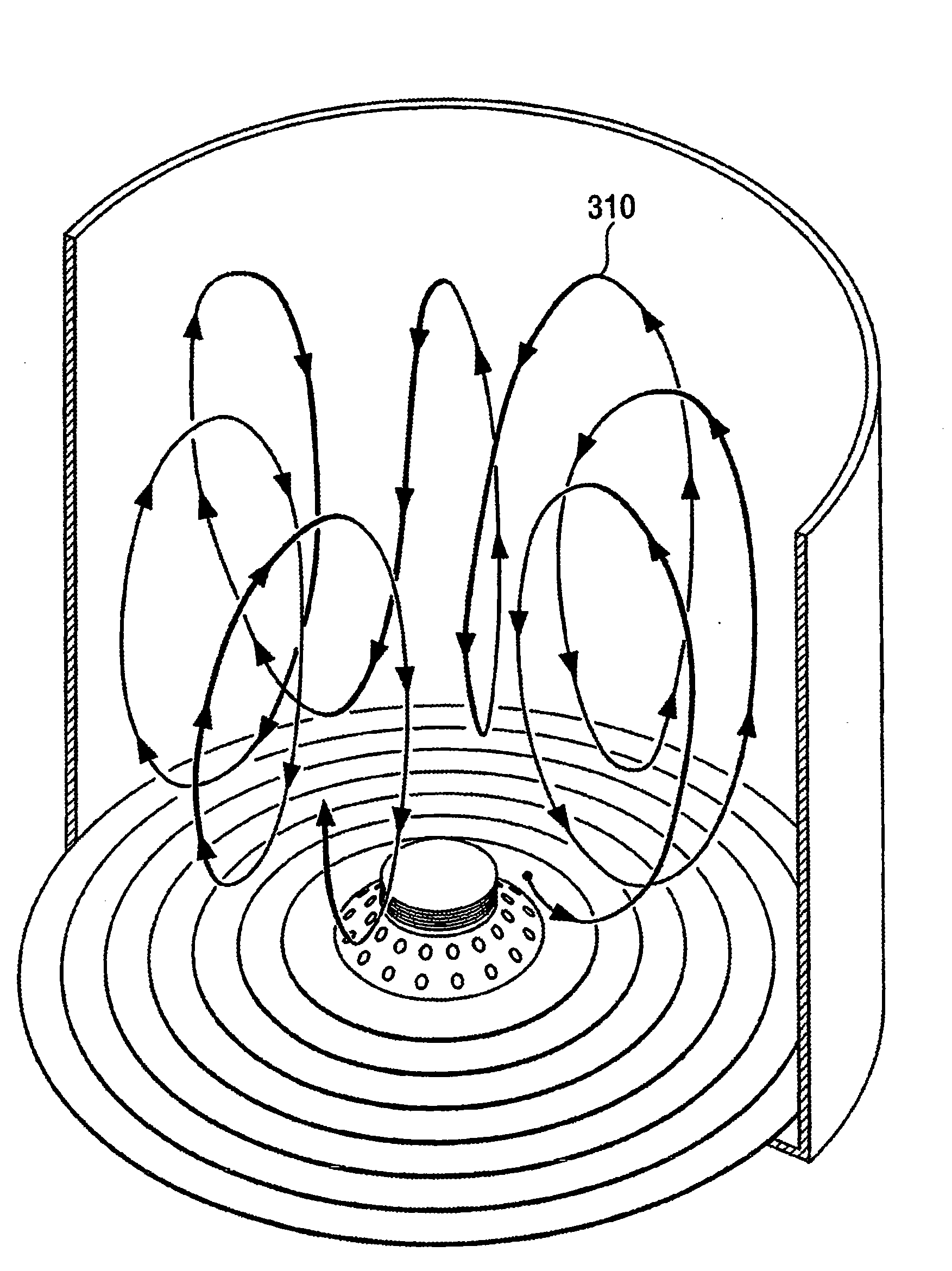

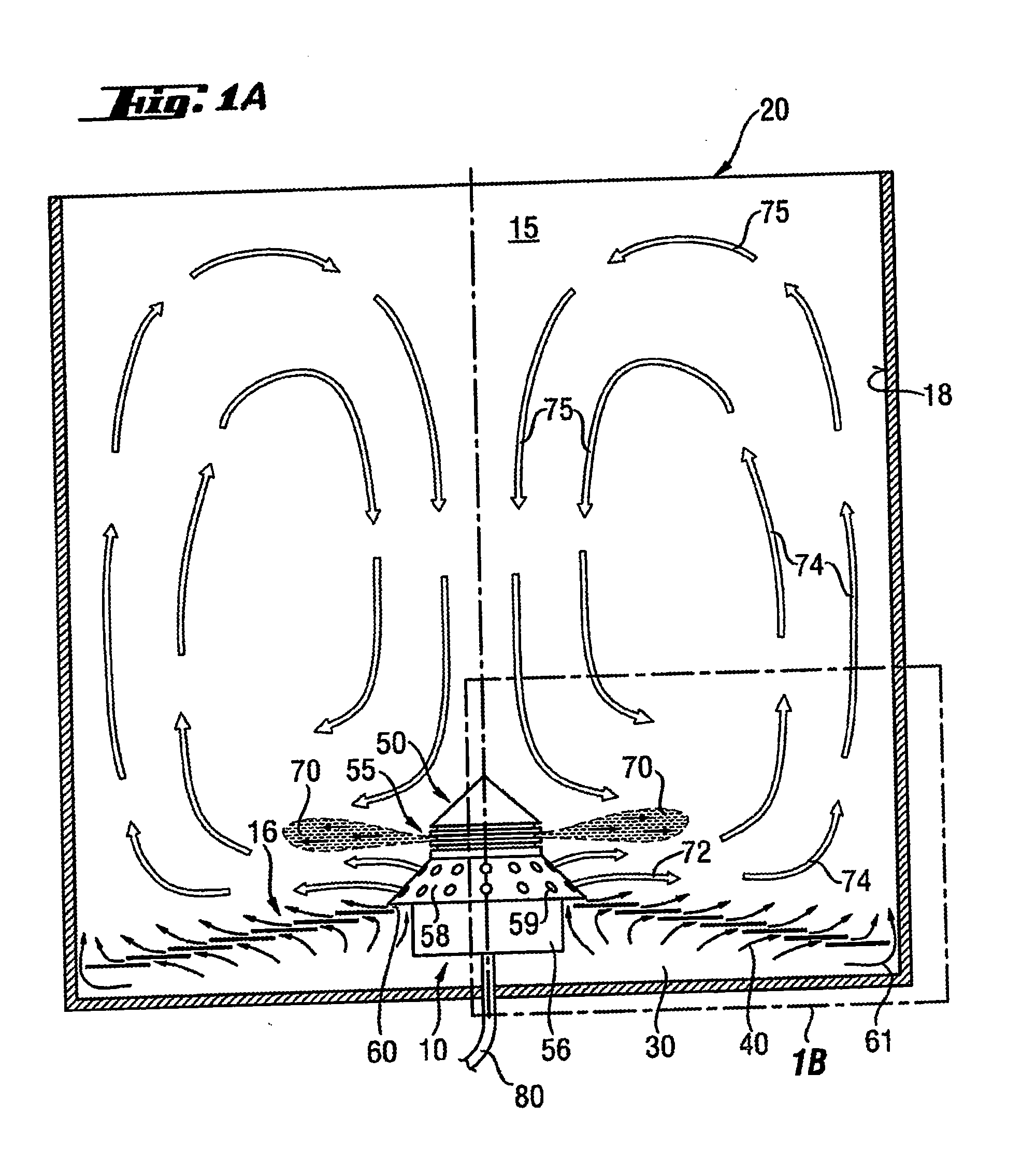

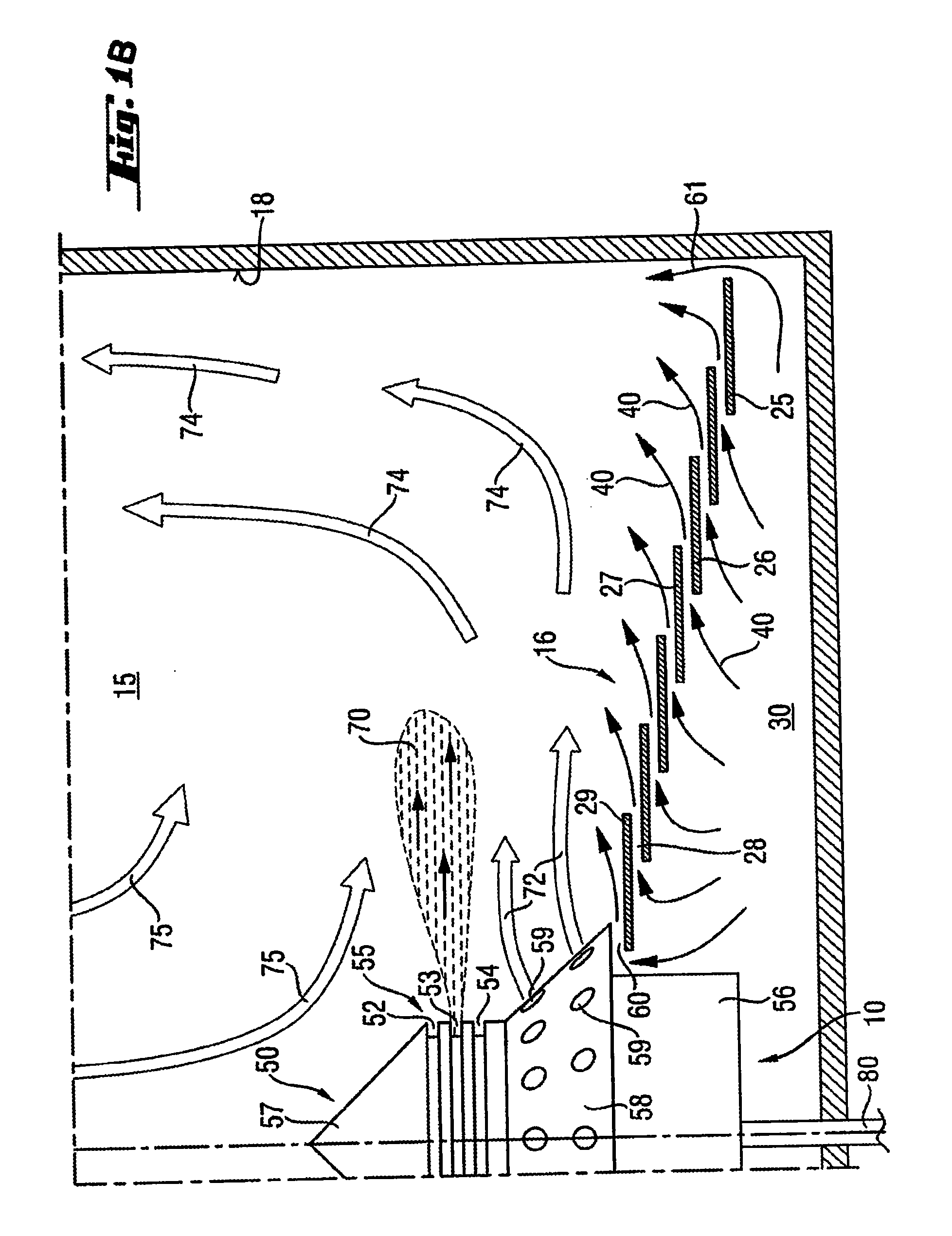

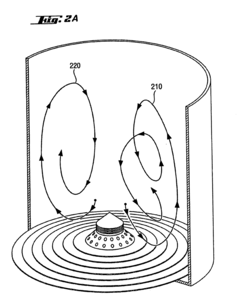

Method for producing a shell catalyst and corresponding shell catalyst

PatentActiveUS20100197488A1

Innovation

- A method involving a fluid bed process where shaped catalyst support bodies circulate elliptically or toroidally, allowing for uniform impregnation of catalytically active species or their precursors across the catalyst support, resulting in shell catalysts with consistent thickness and increased activity.

Sustainability Aspects of DIW Catalyst Technologies

The sustainability of Direct Ink Writing (DIW) catalyst technologies represents a critical dimension in evaluating their long-term viability and environmental impact. When examining DIW for catalyst supports with respect to surface area and mass transfer considerations, several sustainability factors emerge as particularly significant.

The manufacturing process of DIW catalyst supports demonstrates notable sustainability advantages compared to traditional catalyst production methods. The additive manufacturing approach inherently reduces material waste by depositing only the necessary amount of material, contrasting sharply with subtractive manufacturing techniques that can waste up to 90% of raw materials. This precision in material usage translates to reduced environmental footprint and resource consumption.

Energy efficiency constitutes another key sustainability aspect of DIW catalyst technologies. The process typically operates at lower temperatures than conventional catalyst manufacturing methods, resulting in decreased energy requirements. Studies indicate that DIW can achieve energy savings of 30-45% compared to traditional sintering-based approaches, particularly significant when considering the high surface area structures required for effective catalyst supports.

The recyclability and end-of-life considerations for DIW-produced catalyst supports merit careful attention. The monolithic structures created through DIW can be designed for easier recovery of precious metals and other valuable components at the end of the catalyst lifecycle. This design-for-recycling approach enhances the circular economy potential of these materials.

Water usage represents a critical sustainability metric for DIW catalyst technologies. The process typically requires less water than wet chemistry approaches to catalyst preparation, with some DIW formulations achieving water reductions of up to 60%. This aspect becomes particularly relevant when considering the water-intensive nature of many chemical manufacturing processes.

Carbon footprint analysis of DIW catalyst supports reveals potential advantages when optimizing for surface area and mass transfer. The precise control over pore architecture allows for maximizing catalytic efficiency while minimizing material usage, potentially reducing the embedded carbon in the final product by 25-35% compared to conventional catalyst supports with equivalent performance.

Supply chain sustainability also improves through DIW approaches. The ability to manufacture complex catalyst geometries on-demand and on-site reduces transportation requirements and associated emissions. This localized production capability aligns with distributed manufacturing models that enhance supply chain resilience while reducing environmental impact.

The manufacturing process of DIW catalyst supports demonstrates notable sustainability advantages compared to traditional catalyst production methods. The additive manufacturing approach inherently reduces material waste by depositing only the necessary amount of material, contrasting sharply with subtractive manufacturing techniques that can waste up to 90% of raw materials. This precision in material usage translates to reduced environmental footprint and resource consumption.

Energy efficiency constitutes another key sustainability aspect of DIW catalyst technologies. The process typically operates at lower temperatures than conventional catalyst manufacturing methods, resulting in decreased energy requirements. Studies indicate that DIW can achieve energy savings of 30-45% compared to traditional sintering-based approaches, particularly significant when considering the high surface area structures required for effective catalyst supports.

The recyclability and end-of-life considerations for DIW-produced catalyst supports merit careful attention. The monolithic structures created through DIW can be designed for easier recovery of precious metals and other valuable components at the end of the catalyst lifecycle. This design-for-recycling approach enhances the circular economy potential of these materials.

Water usage represents a critical sustainability metric for DIW catalyst technologies. The process typically requires less water than wet chemistry approaches to catalyst preparation, with some DIW formulations achieving water reductions of up to 60%. This aspect becomes particularly relevant when considering the water-intensive nature of many chemical manufacturing processes.

Carbon footprint analysis of DIW catalyst supports reveals potential advantages when optimizing for surface area and mass transfer. The precise control over pore architecture allows for maximizing catalytic efficiency while minimizing material usage, potentially reducing the embedded carbon in the final product by 25-35% compared to conventional catalyst supports with equivalent performance.

Supply chain sustainability also improves through DIW approaches. The ability to manufacture complex catalyst geometries on-demand and on-site reduces transportation requirements and associated emissions. This localized production capability aligns with distributed manufacturing models that enhance supply chain resilience while reducing environmental impact.

Scalability and Industrial Implementation Considerations

The scalability of Direct Ink Writing (DIW) technology for catalyst supports represents a critical consideration for industrial implementation. Current laboratory-scale DIW processes demonstrate promising results in creating high surface area structures with optimized mass transfer properties, but significant challenges emerge when scaling to industrial production volumes.

Manufacturing throughput presents the primary bottleneck in industrial adoption. While laboratory DIW systems typically produce components at rates of 1-10 cm³/hour, industrial applications require production rates 100-1000 times higher. Recent advancements in multi-nozzle printing arrays have shown potential to increase throughput by factors of 10-50, though maintaining consistent rheological properties across multiple extrusion points remains challenging.

Material consistency at scale introduces additional complexity. The specialized inks used in DIW for catalyst supports contain precisely formulated rheological modifiers, porogens, and catalyst precursors. Ensuring batch-to-batch consistency when scaling from laboratory quantities (100-500g) to industrial volumes (100-1000kg) requires sophisticated quality control systems and potentially continuous mixing technologies.

Equipment scaling considerations also impact implementation feasibility. Industrial DIW systems require larger build volumes, more robust motion control systems, and enhanced environmental controls to maintain the precise conditions needed for optimal surface area development. The capital expenditure for such equipment can range from $500,000 to several million dollars, necessitating careful return-on-investment analysis.

Post-processing operations present further scaling challenges. Controlled drying, calcination, and activation steps critical for developing optimal surface area and mass transfer properties must be adapted for larger production volumes. Continuous processing technologies such as conveyor-based calcination systems offer promising alternatives to batch processing but require significant process optimization.

Quality control methodologies must evolve with increased production scale. In-line monitoring of rheological properties, structural integrity, and dimensional accuracy becomes essential. Advanced techniques such as optical coherence tomography and real-time rheological monitoring are being developed specifically for DIW quality assurance at industrial scales.

Economic viability ultimately determines industrial implementation. Current cost analyses indicate DIW-produced catalyst supports command a 3-5x price premium over conventional supports. This premium can be justified in high-value applications where enhanced performance delivers sufficient process improvements, but broader adoption requires continued cost reduction through process optimization and economies of scale.

Manufacturing throughput presents the primary bottleneck in industrial adoption. While laboratory DIW systems typically produce components at rates of 1-10 cm³/hour, industrial applications require production rates 100-1000 times higher. Recent advancements in multi-nozzle printing arrays have shown potential to increase throughput by factors of 10-50, though maintaining consistent rheological properties across multiple extrusion points remains challenging.

Material consistency at scale introduces additional complexity. The specialized inks used in DIW for catalyst supports contain precisely formulated rheological modifiers, porogens, and catalyst precursors. Ensuring batch-to-batch consistency when scaling from laboratory quantities (100-500g) to industrial volumes (100-1000kg) requires sophisticated quality control systems and potentially continuous mixing technologies.

Equipment scaling considerations also impact implementation feasibility. Industrial DIW systems require larger build volumes, more robust motion control systems, and enhanced environmental controls to maintain the precise conditions needed for optimal surface area development. The capital expenditure for such equipment can range from $500,000 to several million dollars, necessitating careful return-on-investment analysis.

Post-processing operations present further scaling challenges. Controlled drying, calcination, and activation steps critical for developing optimal surface area and mass transfer properties must be adapted for larger production volumes. Continuous processing technologies such as conveyor-based calcination systems offer promising alternatives to batch processing but require significant process optimization.

Quality control methodologies must evolve with increased production scale. In-line monitoring of rheological properties, structural integrity, and dimensional accuracy becomes essential. Advanced techniques such as optical coherence tomography and real-time rheological monitoring are being developed specifically for DIW quality assurance at industrial scales.

Economic viability ultimately determines industrial implementation. Current cost analyses indicate DIW-produced catalyst supports command a 3-5x price premium over conventional supports. This premium can be justified in high-value applications where enhanced performance delivers sufficient process improvements, but broader adoption requires continued cost reduction through process optimization and economies of scale.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!