DIW For Metal-Ceramic Composite Structures: Interface Control

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

DIW Metal-Ceramic Composite Technology Background and Objectives

Direct Ink Writing (DIW) technology has evolved significantly over the past two decades as an advanced additive manufacturing technique. Initially developed for polymer-based materials, DIW has progressively expanded to accommodate ceramic, metallic, and more recently, metal-ceramic composite structures. This evolution represents a critical advancement in materials science and manufacturing capabilities, enabling the creation of complex geometries with tailored properties that were previously unattainable through conventional manufacturing methods.

The fundamental principle of DIW involves the extrusion of material-laden inks through fine nozzles to create three-dimensional structures layer by layer. For metal-ceramic composites, this approach offers unprecedented control over composition, microstructure, and ultimately, material properties. The technology's development trajectory has been characterized by continuous improvements in ink formulation, rheological control, and post-processing techniques to enhance the final product's performance characteristics.

Recent technological breakthroughs have focused on addressing the critical challenge of interface control between metal and ceramic phases. Historically, the disparate physical and chemical properties of metals and ceramics have resulted in weak interfacial bonding, compromising the structural integrity and functional performance of composite materials. The evolution of DIW technology has increasingly emphasized strategies to engineer these interfaces at the micro and nanoscale levels.

The primary objective of current DIW research for metal-ceramic composites is to achieve precise control over the metal-ceramic interface to optimize mechanical, thermal, and electrical properties. This includes developing novel ink formulations with tailored rheological properties, implementing in-situ reaction mechanisms during printing, and exploring post-processing techniques that enhance interfacial bonding without compromising the structural integrity of the composite.

Additionally, researchers aim to expand the range of compatible metal-ceramic combinations, increase the resolution and complexity of printable structures, and improve the reproducibility and reliability of the manufacturing process. These advancements are essential for transitioning DIW technology from laboratory demonstrations to industrial applications in aerospace, energy, electronics, and biomedical sectors.

The technology trajectory is now moving toward multi-material printing capabilities, where different material compositions can be strategically deposited within a single structure to create functionally graded materials with position-dependent properties. This represents a paradigm shift in manufacturing, enabling the design and fabrication of components with locally optimized performance characteristics tailored to specific application requirements.

The fundamental principle of DIW involves the extrusion of material-laden inks through fine nozzles to create three-dimensional structures layer by layer. For metal-ceramic composites, this approach offers unprecedented control over composition, microstructure, and ultimately, material properties. The technology's development trajectory has been characterized by continuous improvements in ink formulation, rheological control, and post-processing techniques to enhance the final product's performance characteristics.

Recent technological breakthroughs have focused on addressing the critical challenge of interface control between metal and ceramic phases. Historically, the disparate physical and chemical properties of metals and ceramics have resulted in weak interfacial bonding, compromising the structural integrity and functional performance of composite materials. The evolution of DIW technology has increasingly emphasized strategies to engineer these interfaces at the micro and nanoscale levels.

The primary objective of current DIW research for metal-ceramic composites is to achieve precise control over the metal-ceramic interface to optimize mechanical, thermal, and electrical properties. This includes developing novel ink formulations with tailored rheological properties, implementing in-situ reaction mechanisms during printing, and exploring post-processing techniques that enhance interfacial bonding without compromising the structural integrity of the composite.

Additionally, researchers aim to expand the range of compatible metal-ceramic combinations, increase the resolution and complexity of printable structures, and improve the reproducibility and reliability of the manufacturing process. These advancements are essential for transitioning DIW technology from laboratory demonstrations to industrial applications in aerospace, energy, electronics, and biomedical sectors.

The technology trajectory is now moving toward multi-material printing capabilities, where different material compositions can be strategically deposited within a single structure to create functionally graded materials with position-dependent properties. This represents a paradigm shift in manufacturing, enabling the design and fabrication of components with locally optimized performance characteristics tailored to specific application requirements.

Market Applications and Demand Analysis for Metal-Ceramic Composites

The global market for metal-ceramic composites has been experiencing significant growth, driven by increasing demand across multiple high-value industries. Aerospace and defense sectors represent the largest market segments, with applications in engine components, thermal protection systems, and structural elements that require both high temperature resistance and mechanical strength. These industries value metal-ceramic composites for their ability to withstand extreme operating conditions while maintaining dimensional stability.

The automotive industry presents another substantial market, particularly with the transition toward electric vehicles and more efficient internal combustion engines. Metal-ceramic composites are increasingly utilized in brake systems, engine components, and thermal management systems. Market analysis indicates that this sector's demand is expected to grow at a compound annual rate exceeding the industry average as manufacturers seek materials that can enhance performance while reducing weight.

Electronics and semiconductor manufacturing constitute rapidly expanding application areas, where metal-ceramic composites serve critical roles in thermal management, hermetic packaging, and substrate materials. The miniaturization trend in electronics has intensified the need for materials with superior thermal conductivity and coefficient of thermal expansion matching capabilities.

Energy generation and storage systems represent emerging high-growth markets. Metal-ceramic composites are becoming essential in solid oxide fuel cells, solar energy systems, and advanced battery technologies. The renewable energy transition is accelerating demand for materials that can operate efficiently under variable conditions while maintaining long-term stability.

Medical device manufacturing has also begun adopting metal-ceramic composites, particularly for implantable devices and surgical instruments. The biocompatibility combined with mechanical properties makes these materials uniquely suited for applications where both strength and biological inertness are required.

Market research indicates that the global metal-ceramic composites market is geographically concentrated, with North America, Europe, and East Asia accounting for over 80% of current demand. However, significant growth is anticipated in emerging economies as their manufacturing capabilities advance and industrial applications expand.

A key market driver is the increasing emphasis on sustainability and lifecycle considerations. Metal-ceramic composites often enable longer component lifespans and potential recyclability compared to traditional materials, aligning with growing regulatory and consumer pressures for environmentally responsible manufacturing.

The direct ink writing (DIW) manufacturing approach is positioned to address current market limitations in metal-ceramic composite production, particularly the challenges of interface control that have historically restricted wider adoption. As DIW technology matures, it could potentially unlock new market segments by enabling cost-effective production of geometrically complex components with precisely engineered interfaces.

The automotive industry presents another substantial market, particularly with the transition toward electric vehicles and more efficient internal combustion engines. Metal-ceramic composites are increasingly utilized in brake systems, engine components, and thermal management systems. Market analysis indicates that this sector's demand is expected to grow at a compound annual rate exceeding the industry average as manufacturers seek materials that can enhance performance while reducing weight.

Electronics and semiconductor manufacturing constitute rapidly expanding application areas, where metal-ceramic composites serve critical roles in thermal management, hermetic packaging, and substrate materials. The miniaturization trend in electronics has intensified the need for materials with superior thermal conductivity and coefficient of thermal expansion matching capabilities.

Energy generation and storage systems represent emerging high-growth markets. Metal-ceramic composites are becoming essential in solid oxide fuel cells, solar energy systems, and advanced battery technologies. The renewable energy transition is accelerating demand for materials that can operate efficiently under variable conditions while maintaining long-term stability.

Medical device manufacturing has also begun adopting metal-ceramic composites, particularly for implantable devices and surgical instruments. The biocompatibility combined with mechanical properties makes these materials uniquely suited for applications where both strength and biological inertness are required.

Market research indicates that the global metal-ceramic composites market is geographically concentrated, with North America, Europe, and East Asia accounting for over 80% of current demand. However, significant growth is anticipated in emerging economies as their manufacturing capabilities advance and industrial applications expand.

A key market driver is the increasing emphasis on sustainability and lifecycle considerations. Metal-ceramic composites often enable longer component lifespans and potential recyclability compared to traditional materials, aligning with growing regulatory and consumer pressures for environmentally responsible manufacturing.

The direct ink writing (DIW) manufacturing approach is positioned to address current market limitations in metal-ceramic composite production, particularly the challenges of interface control that have historically restricted wider adoption. As DIW technology matures, it could potentially unlock new market segments by enabling cost-effective production of geometrically complex components with precisely engineered interfaces.

Current Interface Control Challenges in DIW Metal-Ceramic Structures

Direct Ink Writing (DIW) for metal-ceramic composite structures faces significant interface control challenges that impede the full realization of this technology's potential. The interface between metal and ceramic components represents a critical zone where material properties transition, often resulting in mechanical weakness, thermal stress concentration, and chemical incompatibility issues.

The primary challenge lies in achieving strong interfacial bonding while accommodating the inherent differences in thermal expansion coefficients between metals and ceramics. During post-processing thermal treatments, these mismatches generate substantial residual stresses that can lead to delamination, crack formation, and ultimately component failure. Current DIW processes struggle to mitigate these effects, particularly when complex geometries are involved.

Chemical compatibility presents another substantial hurdle. Metal-ceramic interfaces often experience undesired reactions during sintering or high-temperature operation, forming brittle intermetallic compounds or reaction layers that compromise structural integrity. The precise control of these interfacial reactions remains difficult within the constraints of DIW processing parameters.

Rheological challenges further complicate interface control. The distinct flow behaviors of metal and ceramic inks create difficulties in achieving seamless transitions between materials during printing. This often results in porosity, inclusion defects, or weak bonding at interfaces. Current DIW systems lack sophisticated rheological control mechanisms to address these issues effectively.

Microstructural optimization at interfaces represents another significant challenge. The grain structure, orientation, and distribution near interfaces critically influence mechanical properties, yet current DIW approaches provide limited control over these parameters. This results in unpredictable interface properties and performance variability in final components.

Resolution limitations of existing DIW systems also restrict the ability to create functionally graded interfaces that could better distribute stress concentrations. Most commercial systems cannot achieve the microscale precision required for optimal interface engineering in complex metal-ceramic structures.

Post-processing compatibility issues further exacerbate interface control challenges. Sintering protocols optimized for ceramics often prove detrimental to metallic components and vice versa, creating a processing dilemma that frequently results in compromised interface quality.

Finally, real-time monitoring and quality control of interfaces during DIW processing remain underdeveloped. The lack of in-situ characterization techniques specifically designed for metal-ceramic interfaces limits the ability to detect and correct defects during fabrication, resulting in higher rejection rates and inconsistent performance in final components.

The primary challenge lies in achieving strong interfacial bonding while accommodating the inherent differences in thermal expansion coefficients between metals and ceramics. During post-processing thermal treatments, these mismatches generate substantial residual stresses that can lead to delamination, crack formation, and ultimately component failure. Current DIW processes struggle to mitigate these effects, particularly when complex geometries are involved.

Chemical compatibility presents another substantial hurdle. Metal-ceramic interfaces often experience undesired reactions during sintering or high-temperature operation, forming brittle intermetallic compounds or reaction layers that compromise structural integrity. The precise control of these interfacial reactions remains difficult within the constraints of DIW processing parameters.

Rheological challenges further complicate interface control. The distinct flow behaviors of metal and ceramic inks create difficulties in achieving seamless transitions between materials during printing. This often results in porosity, inclusion defects, or weak bonding at interfaces. Current DIW systems lack sophisticated rheological control mechanisms to address these issues effectively.

Microstructural optimization at interfaces represents another significant challenge. The grain structure, orientation, and distribution near interfaces critically influence mechanical properties, yet current DIW approaches provide limited control over these parameters. This results in unpredictable interface properties and performance variability in final components.

Resolution limitations of existing DIW systems also restrict the ability to create functionally graded interfaces that could better distribute stress concentrations. Most commercial systems cannot achieve the microscale precision required for optimal interface engineering in complex metal-ceramic structures.

Post-processing compatibility issues further exacerbate interface control challenges. Sintering protocols optimized for ceramics often prove detrimental to metallic components and vice versa, creating a processing dilemma that frequently results in compromised interface quality.

Finally, real-time monitoring and quality control of interfaces during DIW processing remain underdeveloped. The lack of in-situ characterization techniques specifically designed for metal-ceramic interfaces limits the ability to detect and correct defects during fabrication, resulting in higher rejection rates and inconsistent performance in final components.

Current Interface Control Methods for Metal-Ceramic Bonding

01 DIW techniques for metal-ceramic interface control

Direct Ink Writing (DIW) techniques enable precise control of the interface between metal and ceramic components in composite structures. These methods involve the deposition of specially formulated inks containing metal and ceramic particles in controlled patterns. By manipulating printing parameters such as extrusion pressure, nozzle diameter, and printing speed, the interface characteristics can be optimized for improved mechanical properties and functional performance.- DIW techniques for metal-ceramic interface control: Direct Ink Writing (DIW) enables precise control of metal-ceramic interfaces through tailored ink formulations and deposition parameters. This technique allows for the creation of complex geometries with controlled interfacial properties, enhancing the mechanical and functional performance of the composite structures. The process involves careful rheological control of both metal and ceramic inks to ensure proper flow during extrusion and optimal bonding during sintering.

- Ink formulation strategies for metal-ceramic composites: Specialized ink formulations are critical for successful metal-ceramic composite fabrication via DIW. These formulations typically include metal or ceramic particles, binders, dispersants, and rheology modifiers to achieve printability while maintaining structural integrity. The particle size distribution, solid loading, and viscosity characteristics must be carefully controlled to ensure proper flow during printing and to minimize defects at the interface between dissimilar materials.

- Post-processing techniques for interface optimization: After DIW printing, various post-processing techniques are employed to optimize the metal-ceramic interfaces. These include controlled sintering protocols, heat treatments, and surface modification methods that enhance bonding between the dissimilar materials. The sintering parameters, such as temperature profiles, atmosphere, and pressure, significantly influence the final microstructure and properties of the interface, affecting the overall performance of the composite structure.

- Functional gradient structures via DIW: DIW enables the fabrication of functionally graded metal-ceramic composites with controlled transitions between materials. By gradually changing the composition of the ink during printing, smooth property gradients can be achieved, minimizing thermal stresses and improving mechanical integrity. These gradient structures offer advantages in applications requiring both the thermal resistance of ceramics and the electrical conductivity or toughness of metals.

- Novel applications of DIW metal-ceramic composites: Metal-ceramic composites fabricated via DIW find applications in various high-performance fields including energy storage, electronics, aerospace, and biomedical devices. The ability to precisely control the interface between metals and ceramics enables the development of components with tailored properties such as enhanced thermal management, improved wear resistance, controlled electrical conductivity, and optimized mechanical strength. These composites can be designed with complex architectures that would be difficult or impossible to achieve using conventional manufacturing methods.

02 Ink formulation for metal-ceramic composites

The development of specialized inks is crucial for successful metal-ceramic composite fabrication via DIW. These inks typically contain metal and ceramic particles suspended in a carrier medium with rheological modifiers to ensure printability. The composition, particle size distribution, and solid loading of the inks significantly influence the interface quality between metal and ceramic phases. Additives such as dispersants and binders are incorporated to control viscosity and prevent phase separation during printing and post-processing.Expand Specific Solutions03 Post-processing treatments for interface enhancement

After DIW fabrication, various post-processing treatments are employed to strengthen the metal-ceramic interface. These include thermal sintering under controlled atmospheres, hot isostatic pressing, and infiltration techniques. Such treatments promote diffusion bonding, reduce porosity, and enhance interfacial adhesion between the metal and ceramic phases. The parameters of these treatments, including temperature profiles, holding times, and cooling rates, are optimized to prevent thermal stress-induced cracking while maximizing interfacial strength.Expand Specific Solutions04 Gradient and multilayer interface designs

Advanced metal-ceramic composites often utilize gradient or multilayer interface designs to mitigate thermal expansion mismatches and enhance mechanical properties. These structures feature gradual transitions between metal and ceramic phases, created through programmed variation in material composition during the DIW process. Such gradient interfaces distribute stress more effectively, reducing the likelihood of delamination or cracking under thermal or mechanical loads. Functionally graded materials (FGMs) produced using this approach exhibit superior performance in extreme environments.Expand Specific Solutions05 Characterization and testing of metal-ceramic interfaces

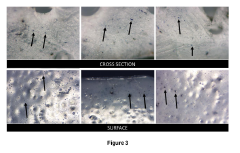

Various analytical techniques are employed to characterize and evaluate the quality of metal-ceramic interfaces produced via DIW. These include scanning electron microscopy (SEM), energy-dispersive X-ray spectroscopy (EDS), X-ray diffraction (XRD), and mechanical testing methods such as shear and tensile testing. Advanced techniques like tomography and in-situ testing provide insights into interface evolution during thermal cycling or mechanical loading. These characterization methods are essential for optimizing DIW processing parameters and validating the performance of metal-ceramic composite structures.Expand Specific Solutions

Leading Research Institutions and Companies in DIW Composites

The DIW (Direct Ink Writing) for metal-ceramic composite structures market is currently in an early growth phase, characterized by increasing research activity but limited commercial deployment. The global market for advanced metal-ceramic composites is projected to reach approximately $5.8 billion by 2026, with interface control technologies representing a critical segment. Leading technology developers include Intel, IBM, and DuPont, who are advancing interface control methodologies to enhance thermal and mechanical properties. Academic institutions like Drexel University and Swiss Federal Institute of Technology are collaborating with industrial partners such as CeramTec and Sumitomo Electric to overcome technical challenges in adhesion and thermal expansion mismatch. The technology is approaching maturity for specialized applications in electronics and aerospace, with Boeing and Microchip Technology implementing early commercial solutions.

Eidgenössische Materialprüfungs & Forschungsanstalt Empa

Technical Solution: Empa has developed a sophisticated DIW approach for metal-ceramic composites focusing on nanoscale interface engineering. Their system employs specially formulated inks containing surface-modified nanoparticles that create controlled transition zones between metal and ceramic phases. The technology utilizes precise rheological control of multi-component inks with tailored viscoelastic properties that maintain structural integrity during printing while enabling strong interfacial bonding during sintering. Empa's process incorporates gradient functional interlayers that mitigate thermal expansion coefficient mismatches and enhance mechanical properties. Their advanced characterization techniques, including in-situ synchrotron X-ray analysis during thermal processing, allow for real-time monitoring of interface evolution. This approach has demonstrated exceptional results in applications requiring thermal cycling resistance, with interfaces maintaining integrity through thousands of thermal cycles between -40°C and 800°C.

Strengths: Exceptional scientific understanding of interface phenomena at the nanoscale; superior characterization capabilities for interface optimization. Weaknesses: Technology requires highly specialized materials and equipment; longer processing times compared to conventional manufacturing methods may limit industrial scalability.

Lawrence Livermore National Security LLC

Technical Solution: Lawrence Livermore National Security has pioneered advanced DIW techniques for metal-ceramic composite structures with precise interface control. Their technology utilizes custom-formulated viscoelastic inks containing metal and ceramic particles suspended in carefully designed polymer matrices. The process employs multi-nozzle extrusion systems with independent temperature control for each material stream, allowing for gradient interfaces between metal and ceramic components. Their proprietary interface modification approach includes in-situ functionalization of particles during printing and post-processing thermal treatments in controlled atmospheres to promote diffusion bonding while minimizing thermal expansion mismatch issues. The system incorporates real-time monitoring with optical and thermal sensors to ensure precise deposition and interface formation, achieving bond strengths up to 85% of theoretical maximum values for various metal-ceramic combinations.

Strengths: Superior interface control through multi-material printing capabilities and in-situ functionalization; extensive experience with national security applications requiring high reliability. Weaknesses: Systems are typically large-scale and expensive, limiting accessibility for smaller manufacturers; proprietary nature of some technologies restricts wider adoption.

Key Patents and Research on Metal-Ceramic Interface Engineering

System and method for direct ink writing

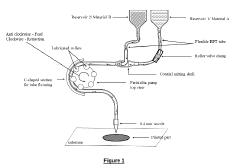

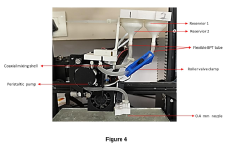

PatentActiveIN202321079655A

Innovation

- A system utilizing a continuous feed mechanism with a peristaltic pump and a specialized coaxial casing for mixing inks from separate supplies, allowing for controlled ink propulsion and in-process composition modulation, enabling precise deposition of composite inks for intricate 3D structures.

Material Compatibility and Selection Criteria

The selection of compatible materials is a critical factor in the success of Direct Ink Writing (DIW) for metal-ceramic composite structures. When designing these composites, the thermal expansion coefficient mismatch between metals and ceramics must be carefully considered to prevent delamination, cracking, or warping during thermal processing. Materials with similar coefficients, such as tungsten-alumina or molybdenum-zirconia pairs, demonstrate superior interface stability during thermal cycling. Additionally, chemical reactivity between metal and ceramic phases must be evaluated to prevent the formation of brittle intermetallic compounds that could compromise structural integrity.

Surface energy compatibility plays a crucial role in determining wetting behavior and adhesion strength at metal-ceramic interfaces. Materials with compatible surface energies promote better interfacial bonding and reduce the likelihood of defect formation during the DIW process. For instance, titanium and its alloys exhibit excellent wetting characteristics with many ceramic materials, making them preferred choices for metal-ceramic composites manufactured via DIW.

Rheological properties of metal and ceramic inks must be carefully matched to ensure uniform flow behavior during co-extrusion processes. Viscosity modifiers and thixotropic agents can be incorporated to achieve comparable flow characteristics between disparate materials. The particle size distribution in both metal and ceramic inks should be optimized to promote homogeneous mixing while maintaining the desired printability and structural properties.

Selection criteria should also account for the intended application environment. For high-temperature applications, refractory metals (tungsten, molybdenum) paired with oxide ceramics (alumina, zirconia) offer superior thermal stability. For corrosive environments, noble metals combined with chemically resistant ceramics provide enhanced durability. Electrical and thermal conductivity requirements further narrow the selection window, particularly for electronic applications where controlled interfacial resistance is desired.

Cost considerations and material availability represent practical constraints in material selection. While precious metals offer excellent compatibility with many ceramics, their high cost may prohibit widespread industrial adoption. Similarly, rare earth element-containing ceramics may provide superior properties but face supply chain challenges. A balanced approach considering performance requirements, processing constraints, and economic factors is essential for successful implementation of DIW for metal-ceramic composites.

Surface energy compatibility plays a crucial role in determining wetting behavior and adhesion strength at metal-ceramic interfaces. Materials with compatible surface energies promote better interfacial bonding and reduce the likelihood of defect formation during the DIW process. For instance, titanium and its alloys exhibit excellent wetting characteristics with many ceramic materials, making them preferred choices for metal-ceramic composites manufactured via DIW.

Rheological properties of metal and ceramic inks must be carefully matched to ensure uniform flow behavior during co-extrusion processes. Viscosity modifiers and thixotropic agents can be incorporated to achieve comparable flow characteristics between disparate materials. The particle size distribution in both metal and ceramic inks should be optimized to promote homogeneous mixing while maintaining the desired printability and structural properties.

Selection criteria should also account for the intended application environment. For high-temperature applications, refractory metals (tungsten, molybdenum) paired with oxide ceramics (alumina, zirconia) offer superior thermal stability. For corrosive environments, noble metals combined with chemically resistant ceramics provide enhanced durability. Electrical and thermal conductivity requirements further narrow the selection window, particularly for electronic applications where controlled interfacial resistance is desired.

Cost considerations and material availability represent practical constraints in material selection. While precious metals offer excellent compatibility with many ceramics, their high cost may prohibit widespread industrial adoption. Similarly, rare earth element-containing ceramics may provide superior properties but face supply chain challenges. A balanced approach considering performance requirements, processing constraints, and economic factors is essential for successful implementation of DIW for metal-ceramic composites.

Sustainability and Environmental Impact Assessment

The sustainability aspects of Direct Ink Writing (DIW) for metal-ceramic composite structures present significant environmental considerations that must be evaluated comprehensively. The manufacturing process itself offers notable advantages over traditional fabrication methods, particularly in terms of material efficiency. DIW technology substantially reduces waste generation through precise deposition of materials, utilizing only the necessary amounts for structure formation, which contrasts sharply with subtractive manufacturing approaches.

Energy consumption analysis reveals that DIW processes typically require less energy compared to conventional sintering or casting methods for metal-ceramic composites. This efficiency stems from the room-temperature processing capabilities of many DIW systems, eliminating the need for energy-intensive high-temperature treatments during the initial forming stage. However, post-processing steps such as sintering or thermal treatments still contribute significantly to the overall energy footprint.

Raw material sourcing for DIW metal-ceramic composites introduces important sustainability considerations. The extraction of rare earth elements and specialized metals often involves environmentally damaging mining practices. Implementation of recycled feedstock materials in DIW inks represents a promising avenue for reducing the environmental impact, though challenges remain in maintaining consistent rheological properties required for precise interface control.

Life cycle assessment (LCA) studies indicate that the environmental benefits of DIW-manufactured metal-ceramic composites extend beyond the production phase. The enhanced interface control enables creation of components with optimized performance characteristics and extended service life, thereby reducing replacement frequency and associated resource consumption. Additionally, the ability to create geometrically complex structures facilitates weight reduction in applications such as aerospace components, contributing to fuel efficiency improvements during operational phases.

Waste management protocols for DIW processes require careful consideration, particularly regarding unused inks containing metal particles and ceramic precursors. These materials may present toxicity concerns if improperly disposed. Developing closed-loop systems for ink recovery and reuse represents an important research direction for improving the sustainability profile of this technology.

Regulatory compliance frameworks are evolving to address the unique environmental considerations of advanced manufacturing techniques like DIW. Manufacturers implementing this technology must navigate varying international standards regarding nanomaterial handling, metal waste disposal, and chemical management. Proactive engagement with regulatory developments can position organizations advantageously as sustainability requirements become increasingly stringent.

Energy consumption analysis reveals that DIW processes typically require less energy compared to conventional sintering or casting methods for metal-ceramic composites. This efficiency stems from the room-temperature processing capabilities of many DIW systems, eliminating the need for energy-intensive high-temperature treatments during the initial forming stage. However, post-processing steps such as sintering or thermal treatments still contribute significantly to the overall energy footprint.

Raw material sourcing for DIW metal-ceramic composites introduces important sustainability considerations. The extraction of rare earth elements and specialized metals often involves environmentally damaging mining practices. Implementation of recycled feedstock materials in DIW inks represents a promising avenue for reducing the environmental impact, though challenges remain in maintaining consistent rheological properties required for precise interface control.

Life cycle assessment (LCA) studies indicate that the environmental benefits of DIW-manufactured metal-ceramic composites extend beyond the production phase. The enhanced interface control enables creation of components with optimized performance characteristics and extended service life, thereby reducing replacement frequency and associated resource consumption. Additionally, the ability to create geometrically complex structures facilitates weight reduction in applications such as aerospace components, contributing to fuel efficiency improvements during operational phases.

Waste management protocols for DIW processes require careful consideration, particularly regarding unused inks containing metal particles and ceramic precursors. These materials may present toxicity concerns if improperly disposed. Developing closed-loop systems for ink recovery and reuse represents an important research direction for improving the sustainability profile of this technology.

Regulatory compliance frameworks are evolving to address the unique environmental considerations of advanced manufacturing techniques like DIW. Manufacturers implementing this technology must navigate varying international standards regarding nanomaterial handling, metal waste disposal, and chemical management. Proactive engagement with regulatory developments can position organizations advantageously as sustainability requirements become increasingly stringent.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!